Comprehensive treatment technique for recycling glyphosate mother liquor

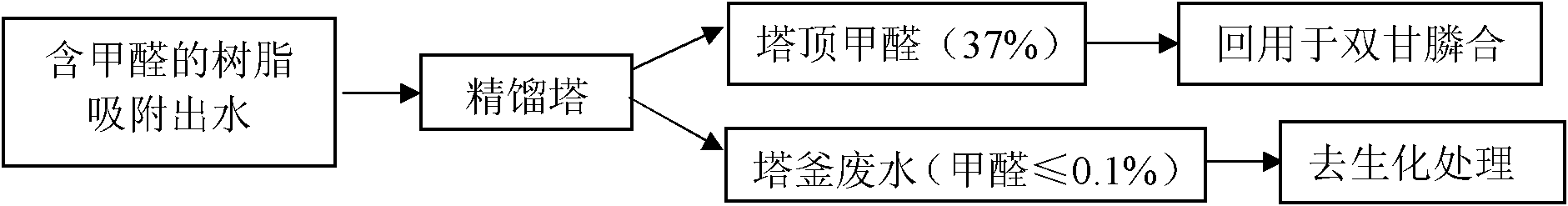

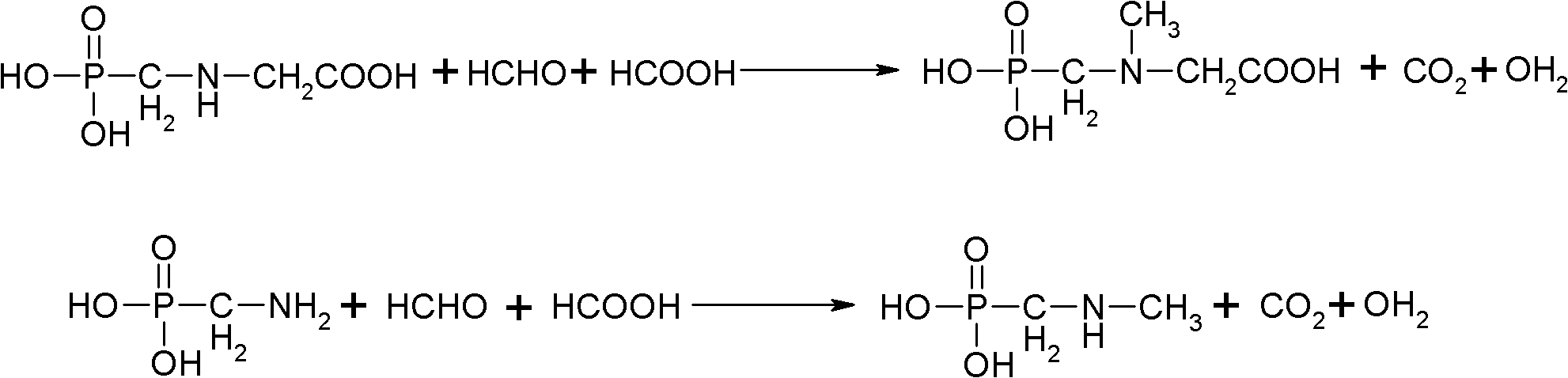

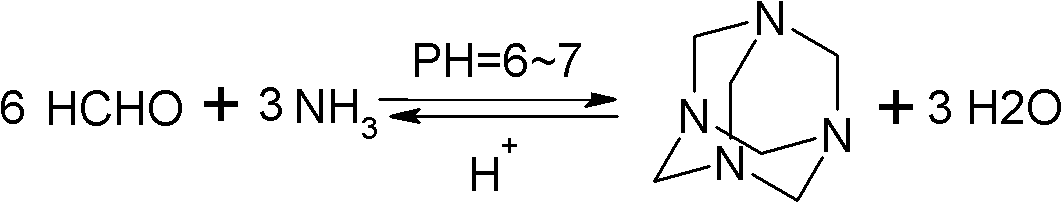

A technology of glyphosate mother liquor and glyphosate, which is applied in the fields of compounds of group 5/15 elements of the periodic table, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the problem of high incineration cost and treatment Insufficient technical integration and other issues, to achieve high resource recovery rate and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the preparation I of modified resin

[0039] Put 200ml of D318 macroporous weakly basic acrylic anion exchange resin into the ion exchange column. The ion exchange column is kept warm with jacketed hot water, controlled at 30-40°C, and washed with ethanol. The flow rate of ethanol washing is 100ml / hr, and the washing time is 4hr; when the ethanol washing is finished, the residual ethanol in the resin is blown dry with air pressure; adjust and stably control the temperature of the hot water jacket to 60-65°C Pour 100ml of 20% ammonia water into the resin exchange column to soak the resin for 30 minutes; after soaking, keep at 60-65 degrees, continuously and stably add 300ml of 20% ammonia water, and extract at the same speed at the same time, control the feeding and discharging speed of 100ml / hr. After the alkali feeding is completed, the extraction is continued until it is dry, and the resin is washed with deionized water until the pH value of the effluent...

Embodiment 2

[0040] Embodiment 2: Preparation II of modified resin

[0041] Put 200ml of D311 macroporous weakly basic acrylic anion exchange resin into the ion exchange column. The ion exchange column is kept warm with jacketed hot water, controlled at 30-40°C, and washed with methanol. Methanol washing is controlled at a flow rate of 100ml / hr, and the washing time is 5hr; after the methanol washing is completed, the residual methanol in the resin is blown dry with air pressure; the temperature of the hot water jacket is adjusted and stably controlled to 55-60°C, and the pre-configured Pour 100ml of triethylamine into the resin exchange column to soak the resin for 30min; after soaking, keep 60-65℃, add 300ml of triethylamine continuously and stably, and extract at the same speed at the same time, control the feeding and discharging speed of 100ml / hr. After the alkali feeding is completed, the extraction is continued until it is dry, and the resin is washed with deionized water until the ...

Embodiment 3

[0042] Embodiment 3: the preparation III of modified resin

[0043] Put 200ml of D301 macroporous weakly basic styrene-based type I anion exchange resin into the ion exchange column. The ion exchange column is kept warm with jacketed hot water, controlled at 30-40°C, and washed with ethanol. The flow rate of ethanol washing is 80ml / hr, and the washing time is 6hr; when the ethanol washing is finished, the residual ethanol in the resin is blown dry with air pressure; Pour 100ml of 20% sodium hydroxide aqueous solution into the resin exchange column to soak the resin for 30min; after soaking, keep at 60-65 degrees, continuously and stably add 300ml of 20% sodium hydroxide aqueous solution, and extract at the same speed, control the feeding and discharging speed of 100ml / hr. After the alkali feeding is completed, the extraction is continued until it is dry, and the resin is washed with deionized water until the PH value of the effluent reaches neutral, that is, the modified wea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com