A treatment method for high-concentration organic wastewater

A technology of organic wastewater and treatment methods, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of no obvious improvement in treatment efficiency, high dosage of chemicals, and low treatment Cost and other issues, to achieve the effects of less loss of micro-electrolytic filler, high utilization efficiency, and cost-saving treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

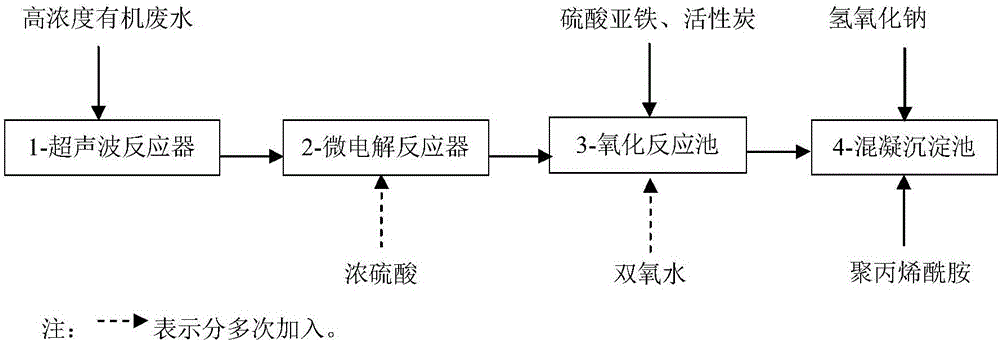

Method used

Image

Examples

Embodiment 1

[0024] See Table 1 for the water quality indicators of the mother liquor of antibiotic pharmaceutical wastewater from a pharmaceutical factory. Put 2L of the waste water into the ultrasonic reactor through the water inlet pipe, turn on the power for ultrasonic cracking, the ultrasonic wave is set to 20KHz, and the intensity is 10W / cm 2 , Ultrasonic reaction for 30 minutes, turn off the power after the reaction is completed, the waste water is discharged into the micro-electrolysis reactor through the outlet pipe, the inner volume of the reactor is 4L, the mass of iron and carbon is 1K, the aeration device is turned on, the dissolved oxygen is 2mg / L, Add concentrated sulfuric acid once at the beginning of the reaction, adjust the pH value of the wastewater to 1.0, add concentrated sulfuric acid once after reacting for 30 minutes, adjust the pH value of the wastewater to 1.0, and turn off the aeration device after reacting for 60 minutes, and the wastewater is discharged into the...

Embodiment 2

[0029] For a pesticide wastewater, the water quality indicators are shown in Table 2. Put 5L of the waste water into the ultrasonic reactor through the water inlet pipe, turn on the power for ultrasonic cracking, set the ultrasonic frequency to 50KHz, and the intensity to 5W / cm 2 , Ultrasonic reaction for 5 minutes, turn off the power after the reaction is completed, the waste water is discharged into the micro-electrolysis reactor through the outlet pipe, the volume of the reactor is 10L, the mass of iron and carbon is 3Kg, the aeration device is turned on, the dissolved oxygen is 4mg / L, Add concentrated sulfuric acid once at the beginning of the reaction, adjust the pH value of the wastewater to 5.0, add concentrated sulfuric acid once after reacting for 30 minutes, adjust the pH value of the wastewater to 3.0, and turn off the aeration device after reacting for 60 minutes, and the wastewater is discharged into the oxidation reaction pool through the outlet pipe. Start stirr...

Embodiment 3

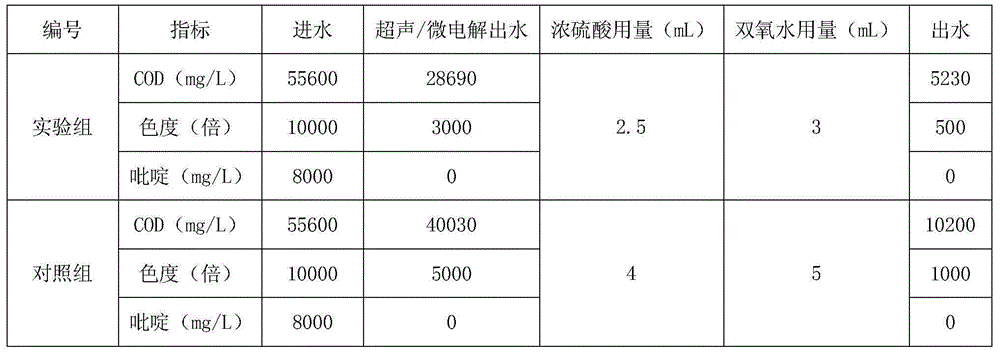

[0033] The mother liquor of antibiotic pharmaceutical wastewater from a pharmaceutical factory, the water quality index is shown in Table 3. The water quality of the following experimental group and control group was the same. Experimental group: 1L of the waste water is introduced into the ultrasonic reactor through the water inlet pipe, and the power is turned on for ultrasonic cracking. The ultrasonic frequency is 40KHz and the intensity is 20W / cm2 ,Ultrasonic reaction for 10 minutes, turn off the power after the reaction is completed, the waste water is discharged into the micro-electrolysis reactor through the outlet pipe, the volume of the reactor is 2L, the mass of iron and carbon is 0.5Kg, the aeration device is turned on, the dissolved oxygen is 3mg / L, Add concentrated sulfuric acid once at the beginning of the reaction, adjust the pH value of the wastewater to 2.0, add concentrated sulfuric acid once after reacting for 30 minutes, adjust the pH value of the wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com