Method for treating wastewater of methyl methacrylate device

A methyl methacrylate and wastewater treatment technology, which is applied in the directions of heating water/sewage treatment, extraction water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as difficult to meet the requirements of biochemical treatment, and meet the requirements of biochemical treatment required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

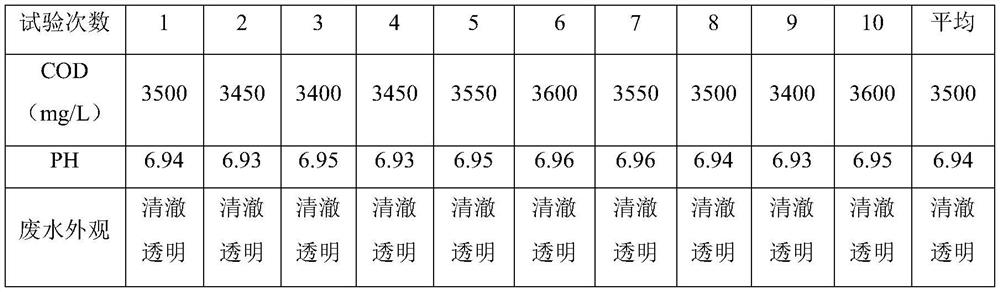

Embodiment 1

[0036] Take the wastewater from a methyl methacrylate plant in a domestic factory.

[0037] Extractant preparation: its components include: n-hexane, cyclohexane, octanol. The mass ratio of each component is: n-hexane:cyclohexane:octanol=96:2.5:1.5. Mix n-hexane, cyclohexane and octanol according to the proportion and stir evenly to prepare the extractant.

[0038] The extraction process is as follows: the extraction quality of extractant and waste water is 1:10, the extraction temperature is 298K, the stirring speed is 40r / min, the stirring time is 15min, and the standing time is 30min, and then the methyl methacrylate is extracted and separated to obtain the extracted Yu phase.

[0039] Add alkali (sodium hydroxide) to the raffinate phase to adjust the pH to 7.0.

[0040] The rectification process is: the total height of the rectification column packing is 40cm (20 trays), the height of the rectification section is 12cm (6 trays), the height of the stripping section is 28...

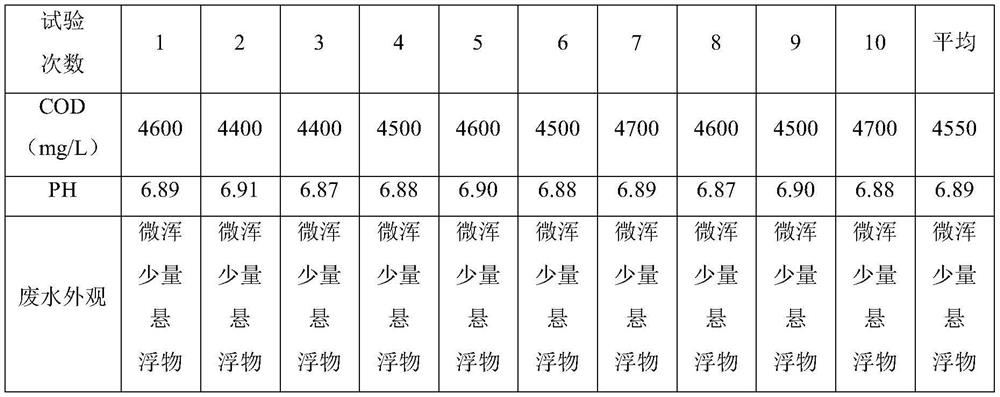

Embodiment 2

[0045] Take the wastewater from a methyl methacrylate plant in a domestic factory.

[0046] Extractant preparation: its components include: n-hexane, cyclohexane, octanol. The mass ratio of each component is: n-hexane:cyclohexane:octanol=95:3:2. Mix n-hexane, cyclohexane and octanol according to the proportion and stir evenly to prepare the extractant.

[0047] The extraction process is as follows: the extraction quality of extractant and wastewater is 1:10, the extraction temperature is 298K, the stirring speed is 40r / min, the stirring time is 15min, and the standing time is 30min.

[0048] Add alkali (sodium hydroxide) to the raffinate to adjust the pH to 7.0.

[0049] The rectification process is that the total height of the rectification column packing is 40cm (20 trays), the height of the rectification section is 12cm (6 trays), the height of the stripping section is 28cm (14 trays), and the temperature of the tower still 100°C, the temperature at the top of the tower is...

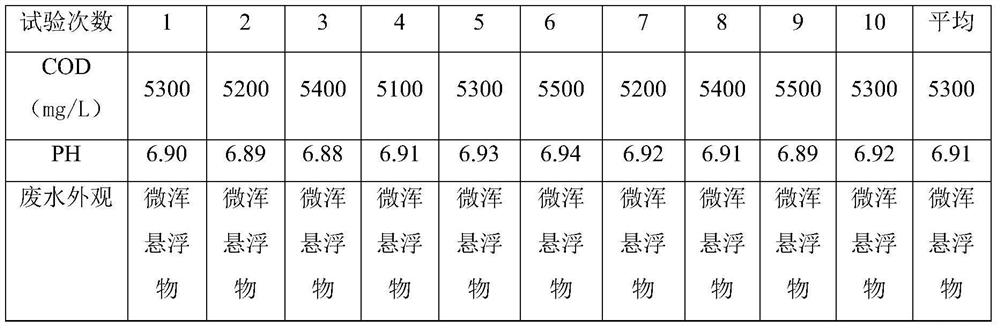

Embodiment 3

[0054] Take the wastewater from a methyl methacrylate plant in a domestic factory.

[0055] Extractant preparation: its components include: n-hexane, cyclohexane, octanol. The mass ratio of each component is: n-hexane:cyclohexane:octanol=97:2:1. Mix n-hexane, cyclohexane and octanol according to the proportion and stir evenly to prepare the extractant.

[0056] The extraction process is as follows: the extraction quality of extractant and wastewater is 1:10, the extraction temperature is 298K, the stirring speed is 40r / min, the stirring time is 15min, and the standing time is 30min.

[0057] Add alkali (sodium hydroxide) to the raffinate to adjust the pH to 7.0.

[0058] The rectification process is that the total height of the rectification column packing is 40cm (20 trays), the height of the rectification section is 12cm (6 trays), the height of the stripping section is 28cm (14 trays), and the temperature of the tower still 100°C, the temperature at the top of the tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com