Method for treating wastewater in process for synthesizing N-phenylmaleimide by one-step method

A technology of maleimide and treatment method is applied in the field of treatment of wastewater from one-step synthesis of N-phenylmaleimide process, and can solve the problems of large amount of production, limited COD removal rate and high treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

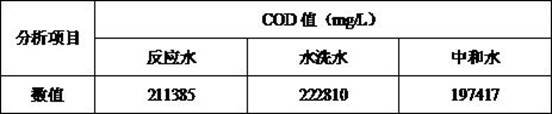

Image

Examples

Embodiment 1

[0034] N-PMI wastewater (COD value 210115 mg / L) was neutralized to pH = 4 by adding lye, stirred evenly and suction filtered to obtain a clarified filtrate. Fill the catalytic oxidation reactor with activated carbon catalyst, the filling volume is 1 / 2 of the volume of the reactor, and add water until the liquid level is flush with the catalyst level. The filtrate and air were passed through the top and bottom of the catalytic oxidation reactor respectively, and the volume flow rate of the catalyst was 20 h -1 , The ratio of filtrate to air flow rate is 1:150. Under the action of the catalyst, the gas-liquid contacts in countercurrent, and an oxidation reaction occurs at room temperature to generate catalytic oxidation wastewater with a COD value of 14560 mg / L. Add the catalytic oxidation wastewater to the Fenton reactor, add acid to pH = 4, and then add Fenton’s reagent (30% H 2 o 2 solution) and catalyst (FeSO 4 ), H in the reaction system 2 O, H 2 o 2 , FeSO 4 The ma...

Embodiment 2

[0036] N-PMI wastewater (COD value 210115 mg / L) was neutralized to pH = 4 by adding lye, stirred evenly and suction filtered to obtain a clarified filtrate. Fill the catalytic oxidation reactor with activated carbon catalyst, the filling volume is 1 / 2 of the volume of the reactor, and add water until the liquid level is flush with the catalyst level. The filtrate and air were passed through the top and bottom of the catalytic oxidation reactor respectively, and the volume flow rate of the catalyst was 30 h -1 , The ratio of filtrate to air flow rate is 1:180. Under the action of the catalyst, the gas-liquid contacts in countercurrent, and an oxidation reaction occurs at room temperature to generate catalytic oxidation wastewater with a COD value of 13970 mg / L. Add the catalytic oxidation wastewater to the Fenton reactor, add acid to pH = 4, and then add Fenton’s reagent (30% H 2 o 2 solution) and catalyst (FeSO 4 ), H in the reaction system 2 O, H 2 o 2 , FeSO4 The mass...

Embodiment 3

[0038] N-PMI wastewater (COD value 210115 mg / L) was neutralized to pH = 4 by adding lye, stirred evenly and suction filtered to obtain a clarified filtrate. Fill the catalytic oxidation reactor with activated carbon catalyst, the filling volume is 1 / 2 of the volume of the reactor, and add water until the liquid level is flush with the catalyst level. The filtrate and air were passed through the top and bottom of the catalytic oxidation reactor respectively, and the volume flow rate of the catalyst was 25 h -1 , The ratio of filtrate to air flow rate is 1:200. Under the action of the catalyst, the gas-liquid contacts in countercurrent, and an oxidation reaction occurs at room temperature to generate catalytic oxidation wastewater with a COD value of 11430 mg / L. Add the catalytic oxidation wastewater to the Fenton reactor, add acid to pH = 4, and then add Fenton’s reagent (30% H 2 o 2 solution) and catalyst (FeSO 4 ), H in the reaction system 2 O, H 2 o 2 , FeSO 4 The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com