Treatment method for sewage produced in caprolactam ammoximation process

A technology for caprolactam amidoxime and sewage production, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high equipment investment and complicated operation, and reduce investment and operating costs. , No secondary pollution, low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

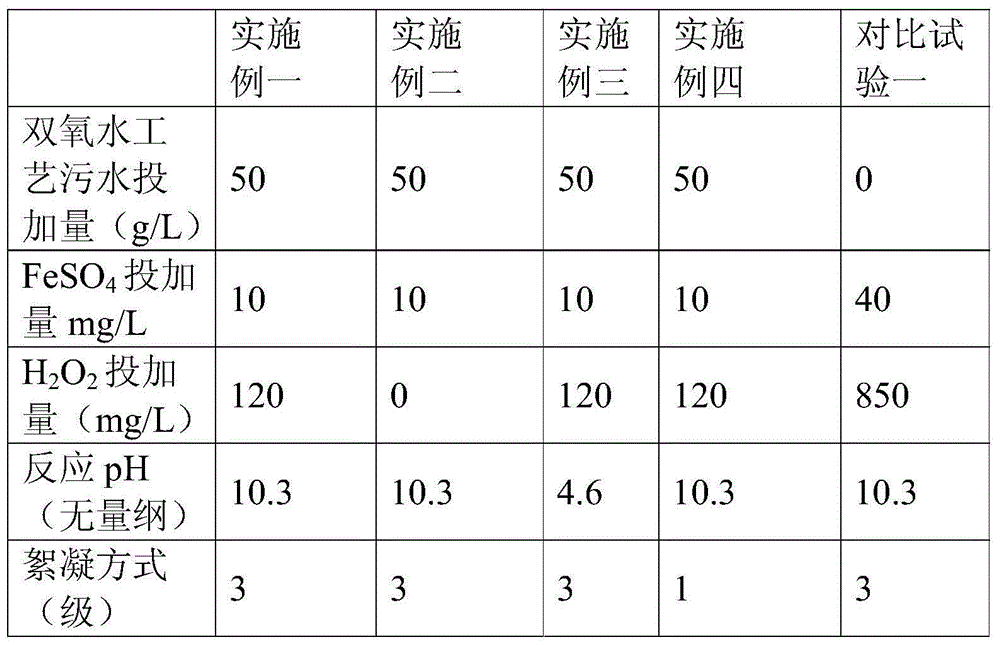

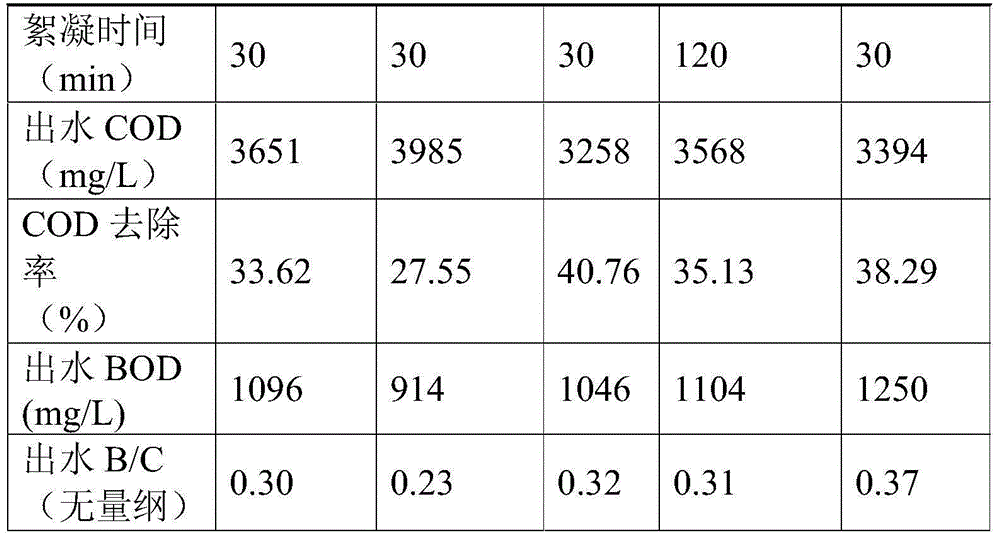

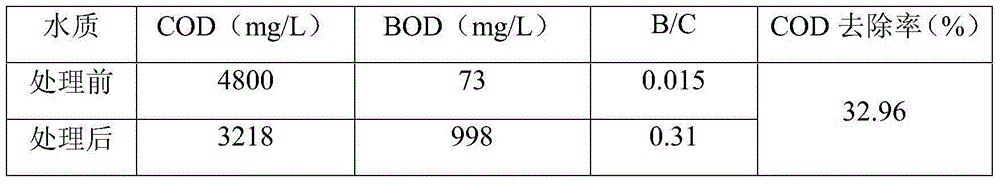

Embodiment 1

[0022] Under alkaline reaction conditions, the main oxidant is the sewage produced in the anthraquinone hydrogen peroxide production process, and the auxiliary oxidant is H 2 o 2 , the catalyst is Fe 2+ .

[0023] The caprolactam ammoximation production process sewage of a chemical enterprise has a COD of 5500mg / L, a B / C of 0.010, and a pH of 10.3.

[0024] The caprolactam ammoximation production process sewage is processed according to the following steps,

[0025] 1) Introduce the sewage generated by the ammoximation in the caprolactam plant and the hydrogen peroxide production process into the regulating tank respectively. The residence time of sewage in the regulating tank is 10 hours to ensure the stability of water quality and water quantity;

[0026] 2) The sewage in the adjustment tank is pumped to the advanced oxidation reaction tank, the reaction environment is alkaline (pH=10.3), and a certain amount of FeSO is added at the same time 4 solution and H 2 o 2 , ...

Embodiment 2

[0029] Under alkaline reaction conditions, the main oxidant is the sewage produced in the anthraquinone hydrogen peroxide production process, and the catalyst is Fe 2+ , without the use of co-oxidants.

[0030] The water quality of the caprolactam ammoximation production process sewage is the same as that of Example 1, that is, its COD is 5500 mg / L, B / C is 0.010, and pH=10.3.

[0031] The caprolactam ammoximation production process sewage is processed according to the following steps,

[0032] 1) Introduce the sewage generated by the ammoximation in the caprolactam plant and the hydrogen peroxide production process into the regulating tank respectively. The residence time of sewage in the regulating tank is 10 hours to ensure the stability of water quality and water quantity;

[0033] 2) The sewage in the adjustment tank is pumped to the advanced oxidation reaction tank, the reaction environment is alkaline (pH=10.3), and a certain amount of FeSO is added at the same time 4...

Embodiment 3

[0036] Under acidic reaction conditions, the main oxidant is the sewage produced in the anthraquinone hydrogen peroxide production process, and the auxiliary oxidant is H 2 o 2 , the catalyst is Fe 2+ .

[0037]The water quality of caprolactam ammoximation production process wastewater is the same as that of Example 1 except for pH, that is, its COD is 5500 mg / L, B / C is 0.010, and pH=4.6.

[0038] The caprolactam ammoximation production process sewage is processed according to the following steps,

[0039] 1) Introduce the sewage generated by the ammoximation in the caprolactam plant and the hydrogen peroxide production process into the regulating tank respectively. The residence time of sewage in the regulating tank is 10 hours to ensure the stability of water quality and water quantity;

[0040] 2) The sewage in the adjustment tank is pumped to the advanced oxidation reaction tank, the reaction environment is acidic (pH=4.6), and a certain amount of FeSO is added at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com