Patents

Literature

116results about How to "Increased chance of reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

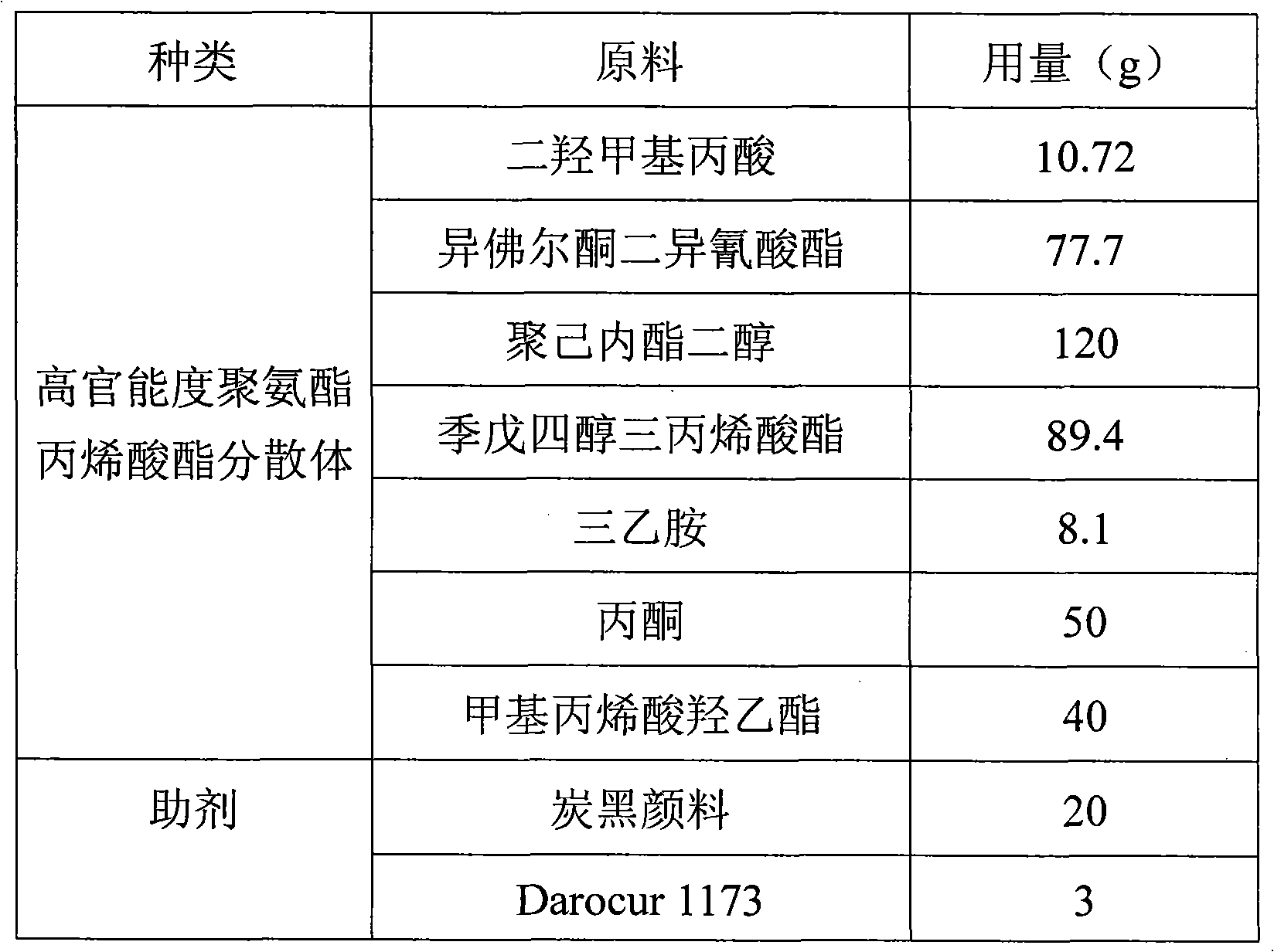

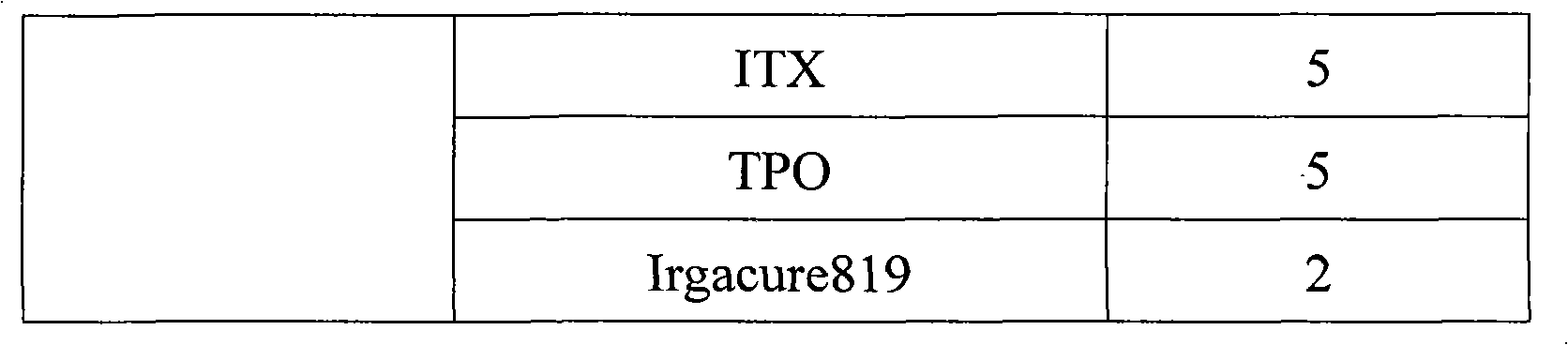

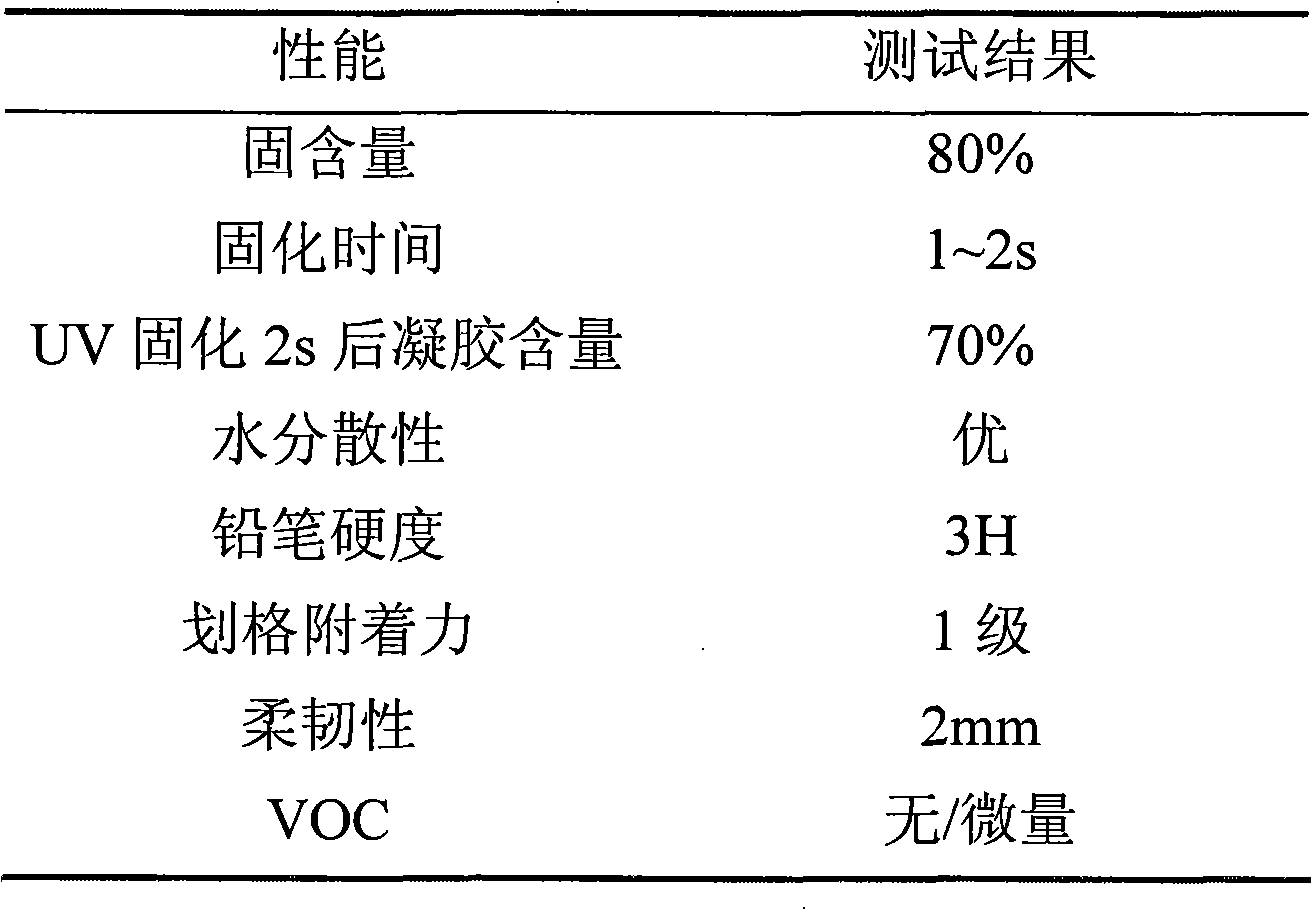

Water-based UV black ink with super-high solid content and preparation method thereof

InactiveCN101659809AEmissions are environmentally friendly and non-toxicHealthy littleInksWater basedPliability

The invention discloses water-based UV black ink with super-high solid content and a preparation method thereof. The black ink comprises the following components in percentage by weight: 20%-60% of high-functionality water-based polyurethane acrylate, 5%-8% of compound photoinitiator, 15%-35% of hydrophilic acrylate diluted body or prepolymer, 10%-25% of solvent and 5%-15% of nano-carbon black pigment. The light curing time of the water-based UV black colored paint of the invention is shorter than 5 seconds, the bottom layer can be completely cured, the comprehensive properties of adhesive force, hardness, toughness and the like are excellent, and the water-based UV black colored paint can be widely applied to the fields of ink, wood paint and the like; the solid content is as high as 80%;and the water-based UV black ink has short drying and curing time, simple construction technology and high production efficiency, can be diluted by water or ethanol or other nontoxic solvents for regulating the viscosity, is suitable for various production modes and production requirements, and is environment-friendly and nontoxic.

Owner:FOSHAN CITY SHUNDE DISTRICT DEMEI CHEM

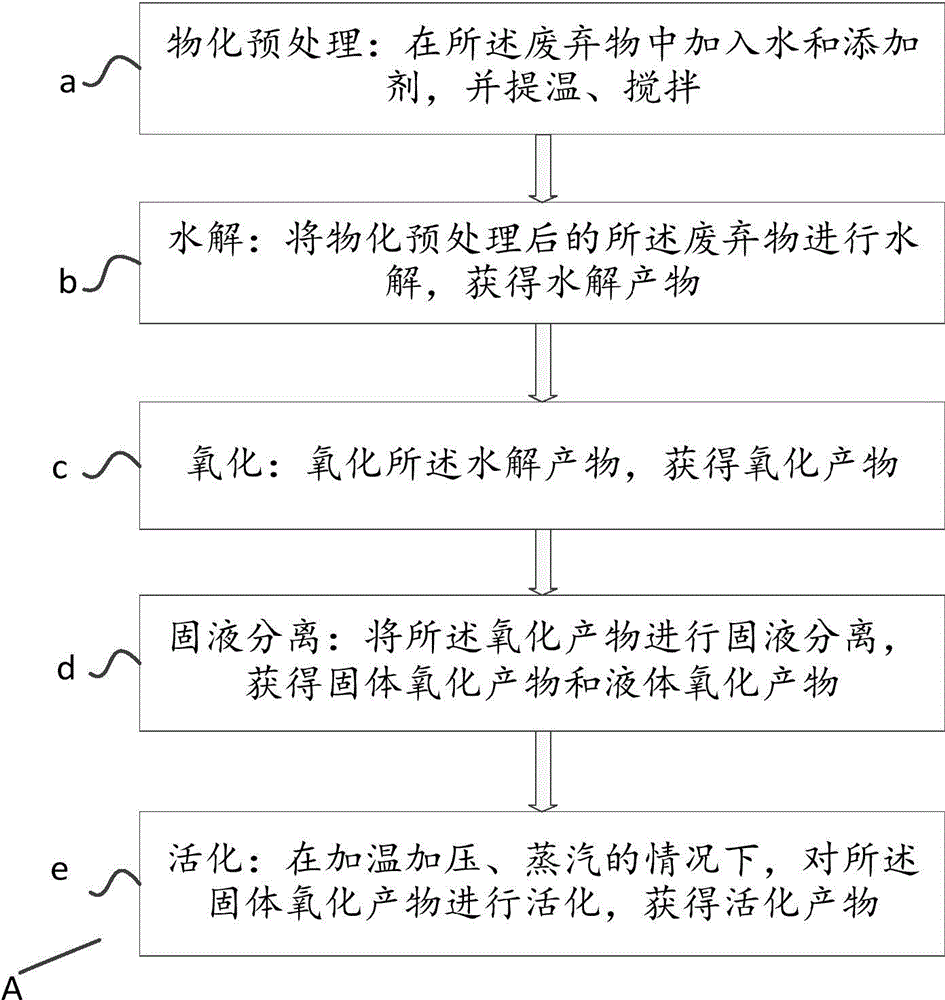

Method and device for treating organic solid waste

ActiveCN104148358AComplete oxidationAvoid lostSolid waste disposalClimate change adaptationCompound (substance)Biological activation

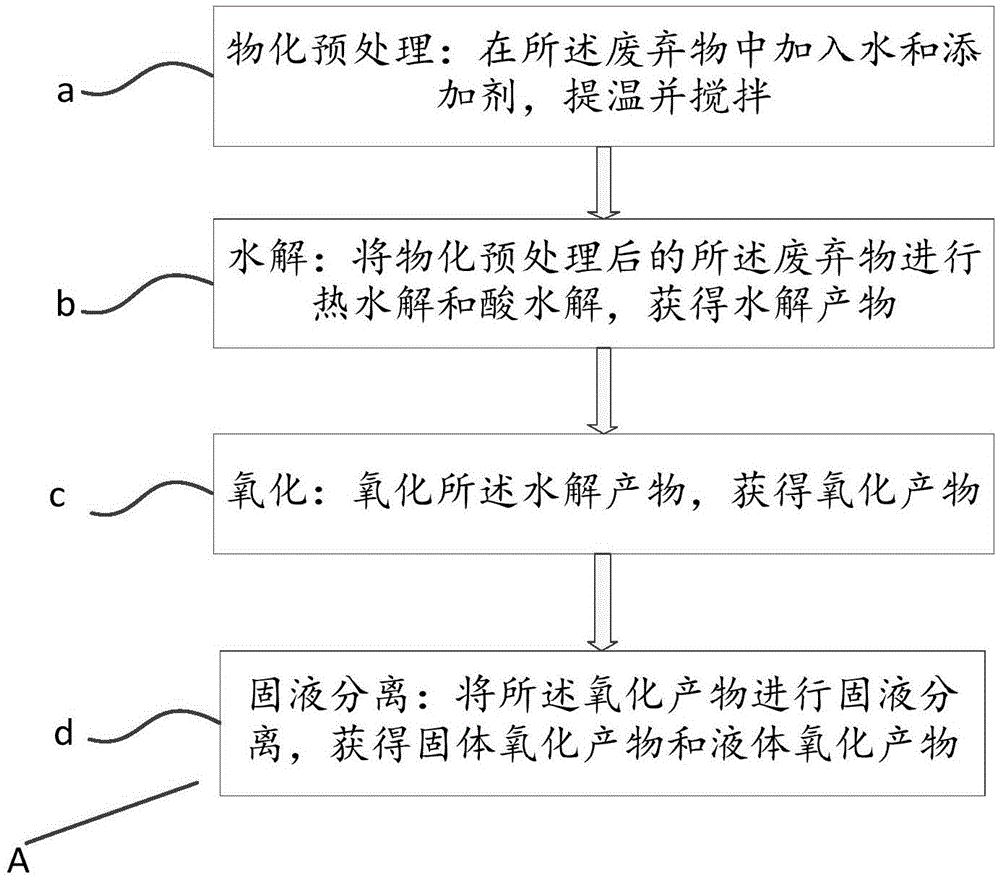

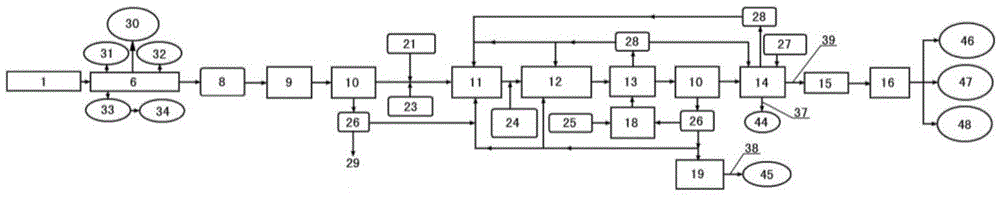

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely hydrolyzing the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; (d) carrying out solid-liquid separation, namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product; and (e) carrying out activation, namely activating the solid oxidization product in the case of heating, pressurizing, steaming and additive adding, thereby obtaining an activated product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

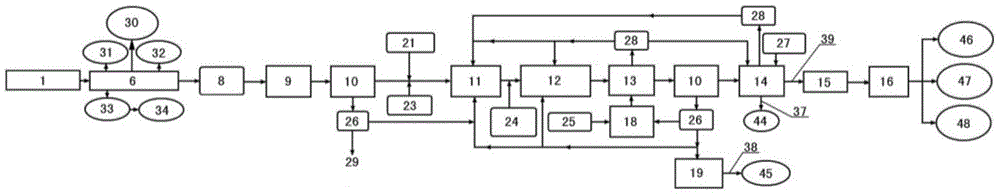

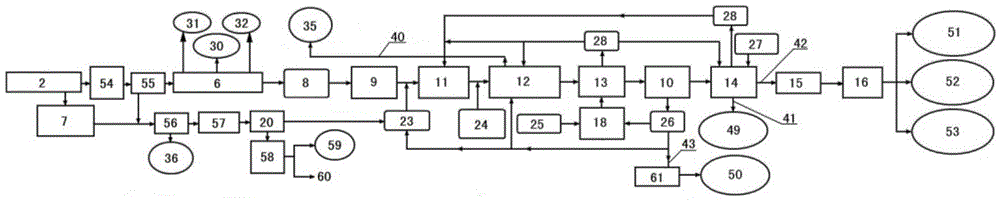

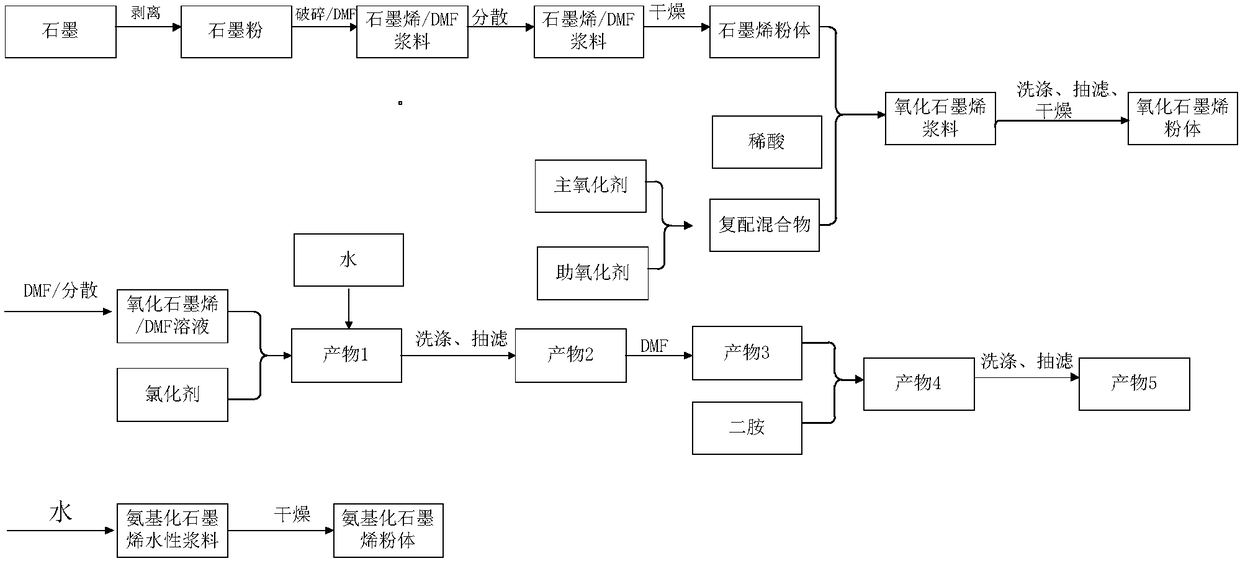

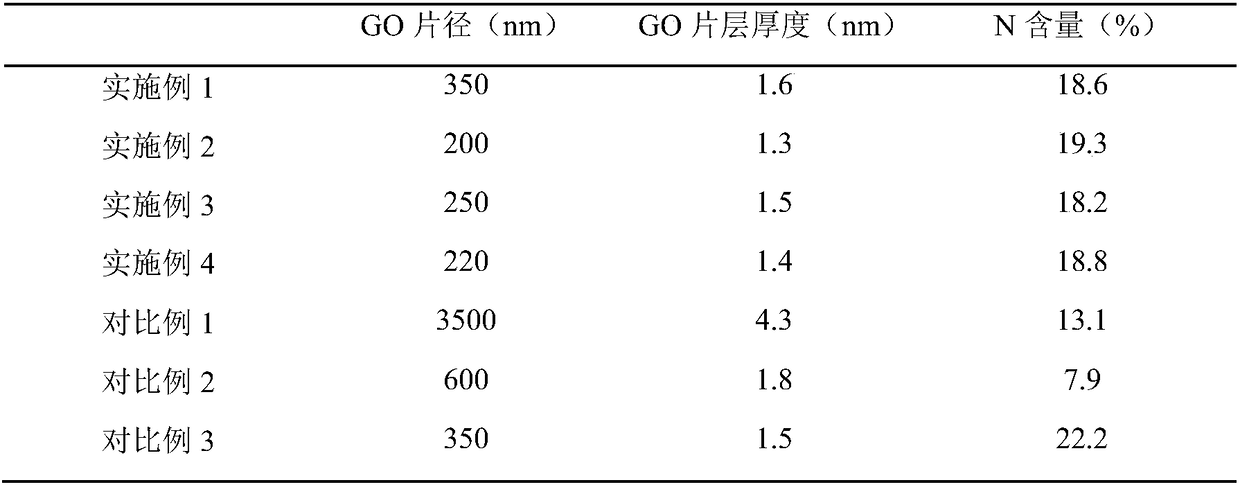

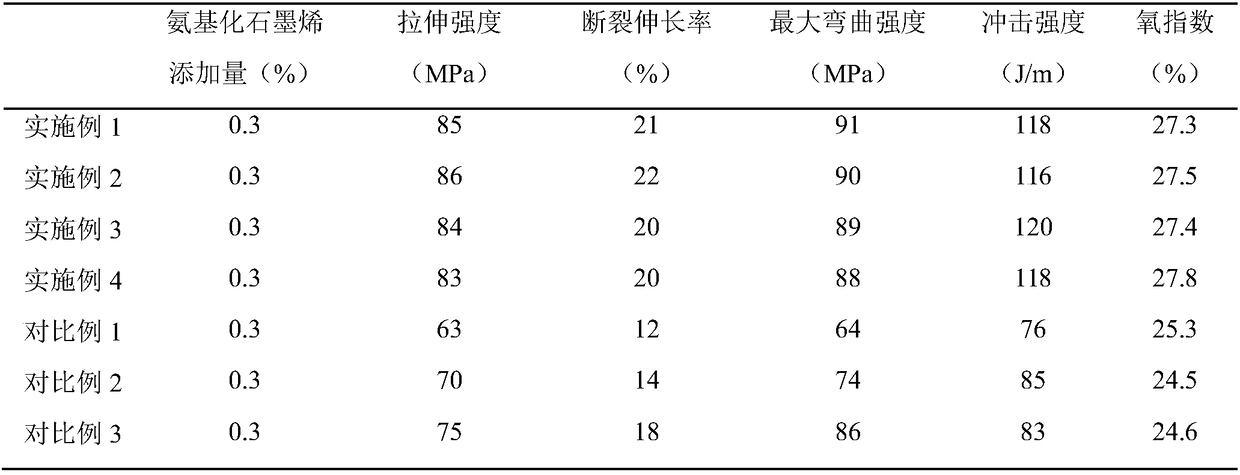

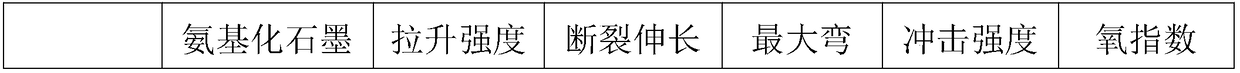

Preparation method of industrial aminated graphene

ActiveCN108373149AReduce dosageLittle damage to the lamellar structureGrapheneBulk chemical productionCvd grapheneDiamine

The invention discloses a preparation method of industrial aminated graphene. The preparation method of the industrial aminated graphene belongs to the technical field of graphene preparation, and comprises the steps of firstly stripping graphite through a mechanical stripping method, oxidizing through adjusting the matching ratio of a main oxidizing agent and an auxiliary oxidizing agent, then activating hydroxyl and carboxyl on the surface of graphene oxide through a chlorinating agent, and finally selecting appropriate diamine for carrying out amination reaction. According to the preparation method of the industrial aminated graphene provided by the invention, through adopting a stripping manner at first, the dosage of the oxidizing agents can be reduced, an ideal effect is achieved atthe same time, and the problem of poor modification effect caused by high oxygen content and severe destructiveness on a graphene slice layer due to large dosage of the oxidizing agents is solved.

Owner:CHANGZHOU HIGHBERY NEW NANO MATERIALS TECH CO LTD +1

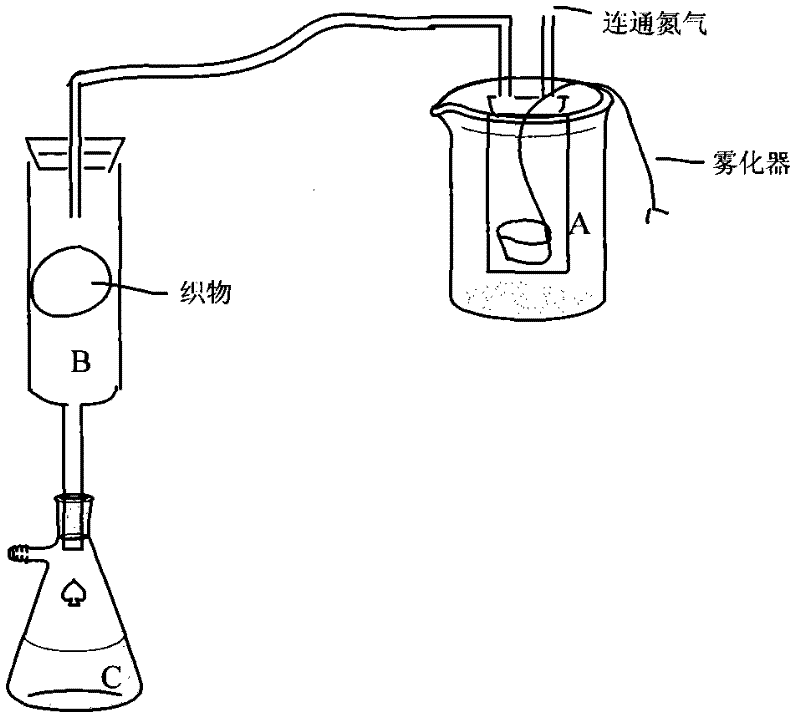

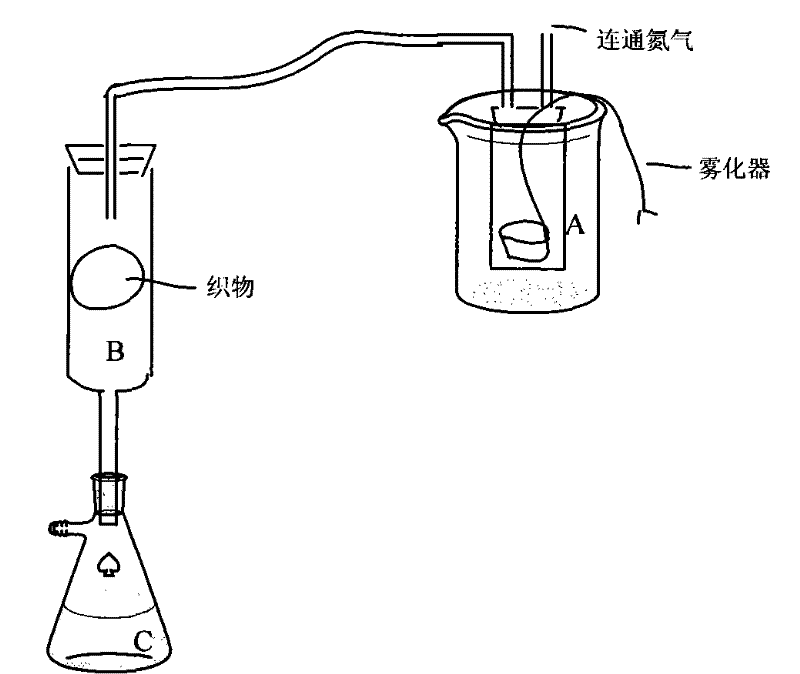

Preparation method of composite conductive fabric with spray polymerization

InactiveCN102312376AImprove conductivityStable conductivityVegetal fibresAnimal fibresSolventChemistry

The invention which relates to a preparation method of a composite conductive fabric with spray polymerization belongs to the technical field of textiles. An atomization mode is adopted in the invention to atomize a monomer solution into particles, and an in situ polymerization reaction is initiated on a monomer under the effect of an oxidant deposited in the fabric to prepare the composite conductive fabric. The preparation method of the invention which has the advantages of easy controlled condition, simple operation, low raw material cost, and less energy consumption is suitable for the large scale and industrial production. Compared with routine products prepared with a liquid-phase oxidation method, the adhesion between a conducting layer and a fabric matrix of the composite conductive fabric prepared in the invention is substantially improved, the conducting layer is more compacted, and protrude wear resistances and solvent resistances are possessed; the surface resistor of the preparative composite conductive fabric is 10-10<5>omega / cm<2>, the conductivity is good, the electromagnetic shielding property and the flexibility of a product (the composite conductive fabric) are good, and the surface resistor of the product in the invention is sensitive to the change of pressure, elasticity and the like, so the product can be widely applied to the sensor field, the antistaticfield, the anti-electromagnetic shielding field and the like.

Owner:WUHAN TEXTILE UNIV

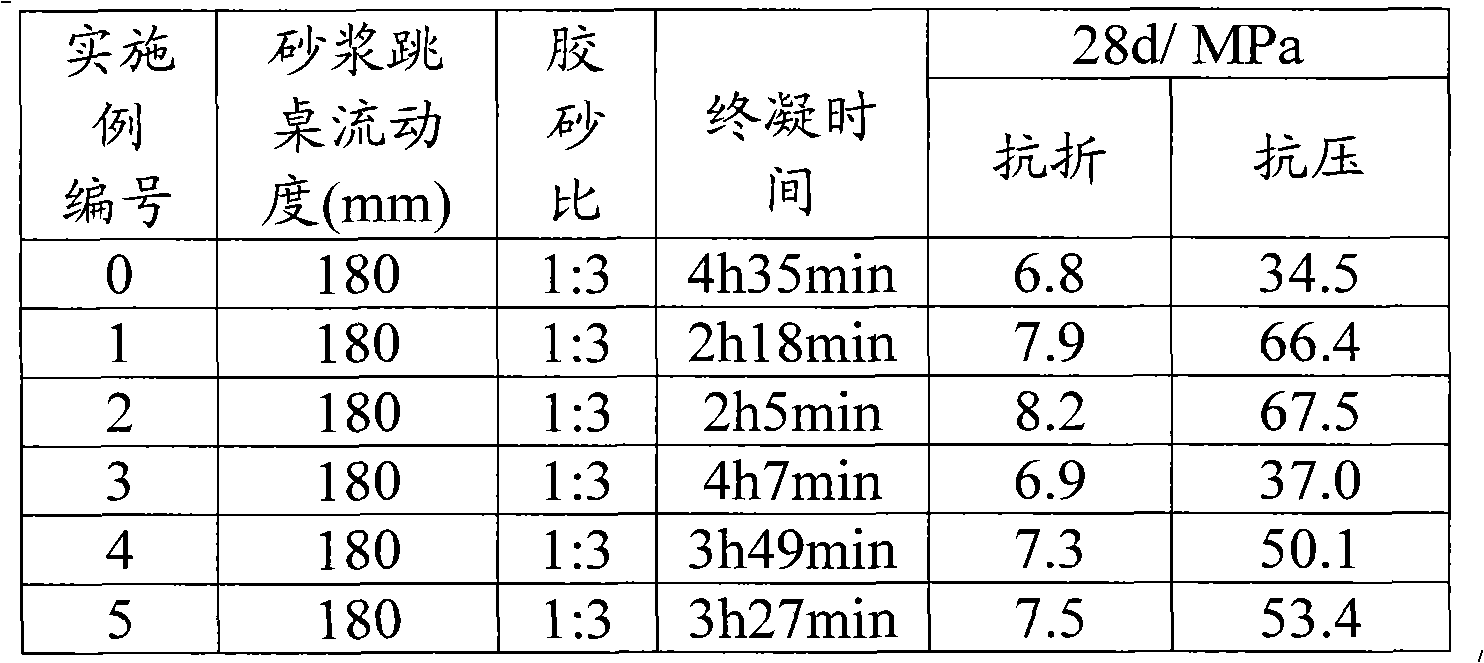

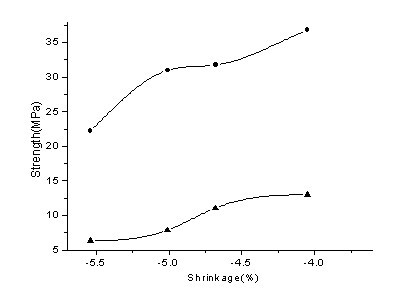

Wet fly ash gelled material and preparation method thereof

InactiveCN101786821AHigh value-added utilizationImprove governance efficiencySolid waste managementSlagMetakaolin

The invention aims to provide a wet fly ash gelled material with high intensity and low cost and a preparation method thereof. According to the method, wet fly ash is used as a main raw material and the preparation method solves the problem of recovering an industrial solid waste of the wet fly ash. The wet fly ash gelled material is prepared from the following raw materials in percentage by mass: 45 to 66 percent of dried wet fly ash, 28 to 49 percent of active mineral material and 1.5 to 8 percent of chemical curing agent, wherein the active mineral material is prepared from the following raw materials in percentage by mass: 10 to 60 percent of blast furnace slag, 10 to 50 percent of cement clinker, 10 to 40 percent of metakaolin and 5 to 10 percent of gypsum; and the chemical curing agent is prepared from the following raw materials in percentage by mass: 3 to 30 percent of aluminum sulphate, 5 to 30 percent of potassium carbonate, 5 to 30 percent of sodium silicate, 5 to 40 percent of sodium carbonate, 5 to 30 percent of sodium sulphate and 10 to 60 percent of water reducing agent.

Owner:重庆市建筑科学研究院有限公司

Method and device for treating organic solid waste

ActiveCN104148357AAvoid unfit problemsImprove efficiencySolid waste disposalAcid hydrolysisCompound (substance)

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely carrying out thermal hydrolysis and acid hydrolysis on the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; and (d) carrying out solid-liquid separation namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

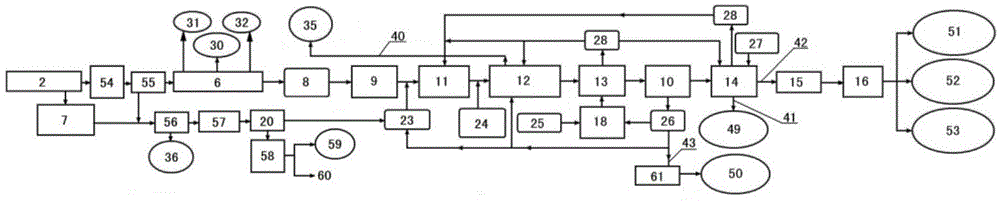

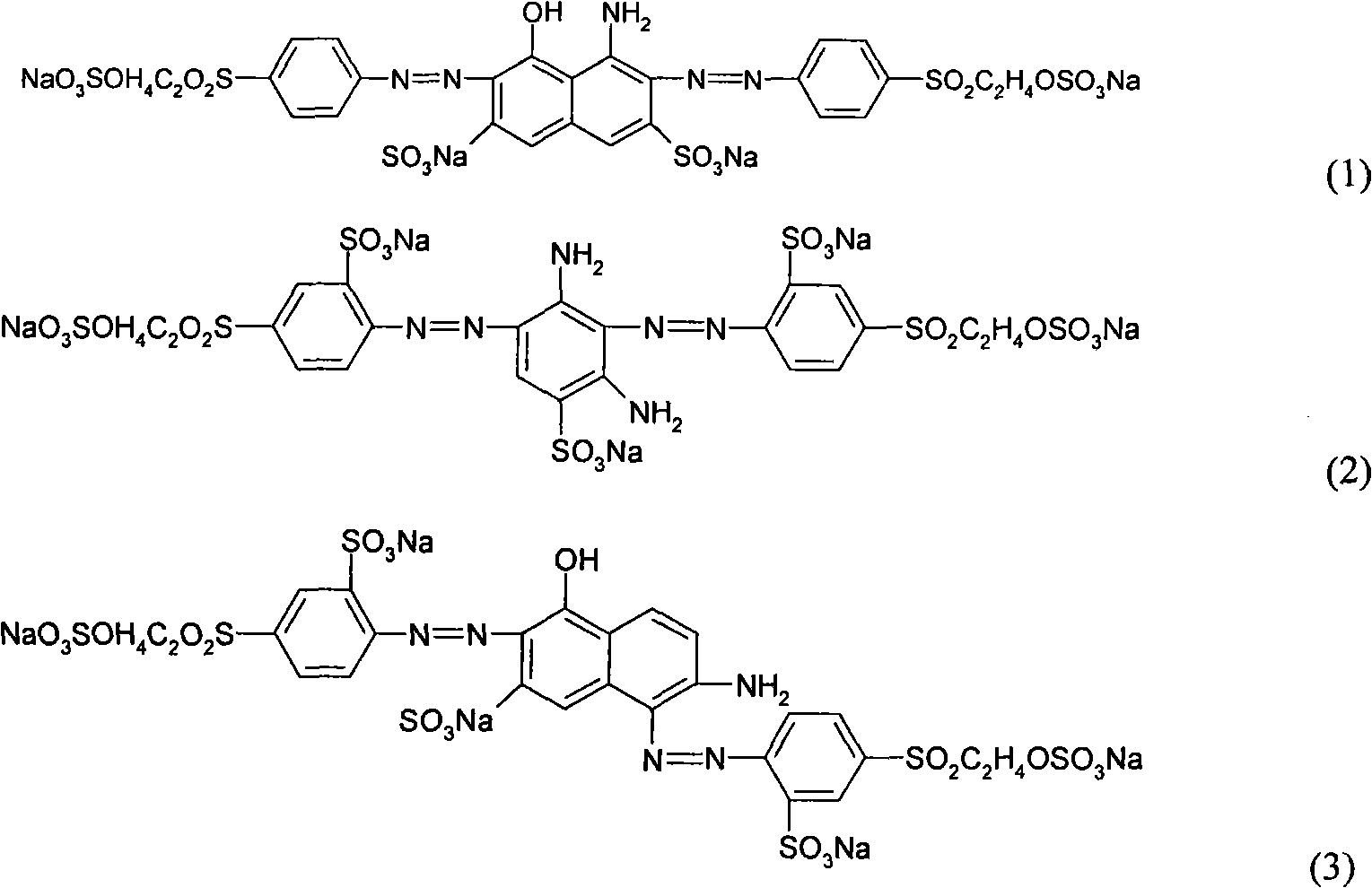

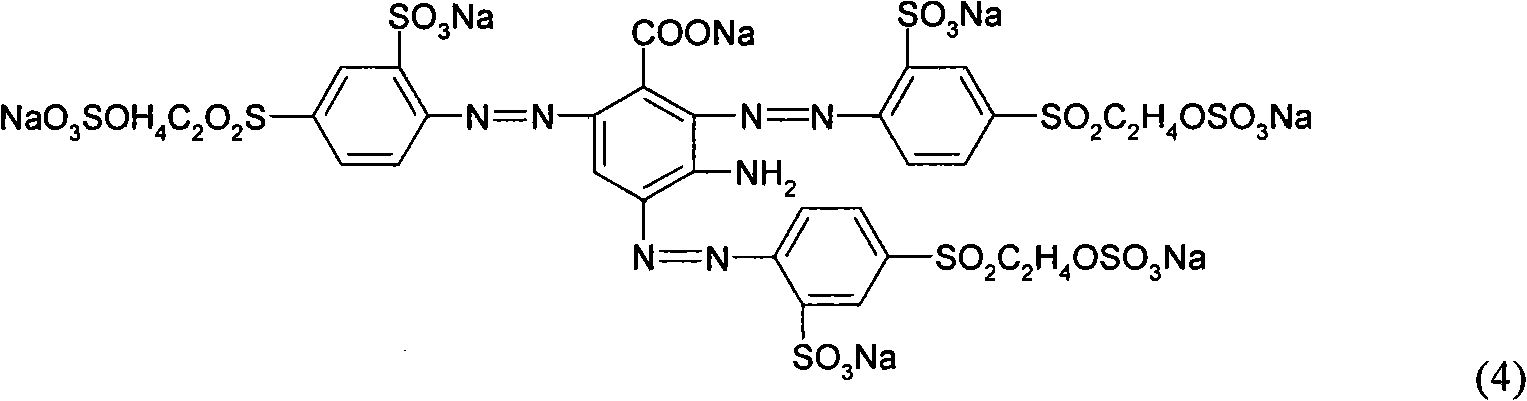

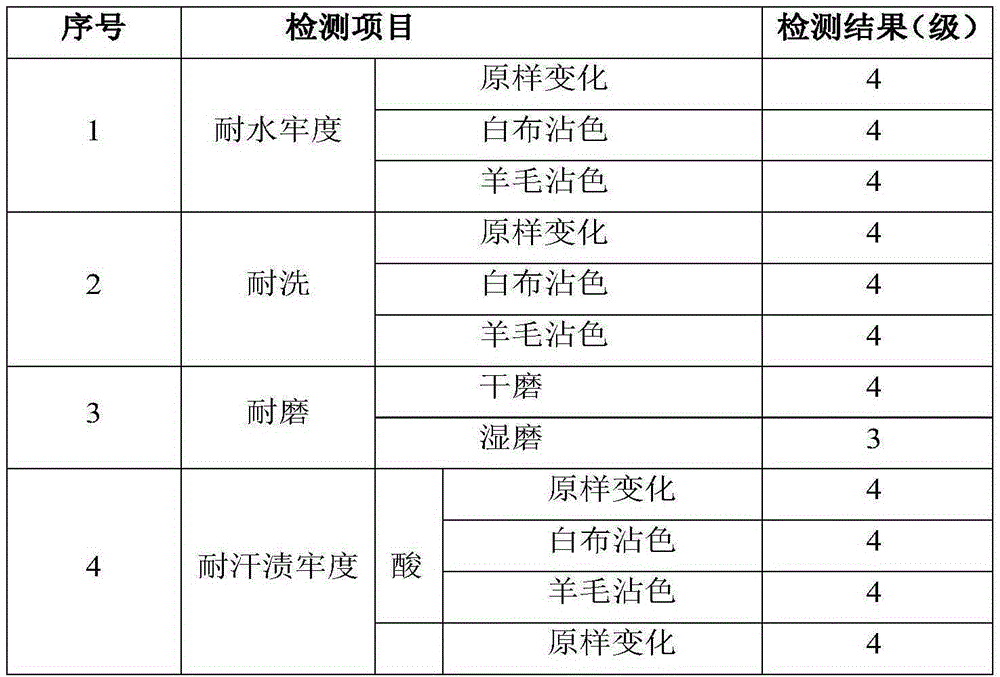

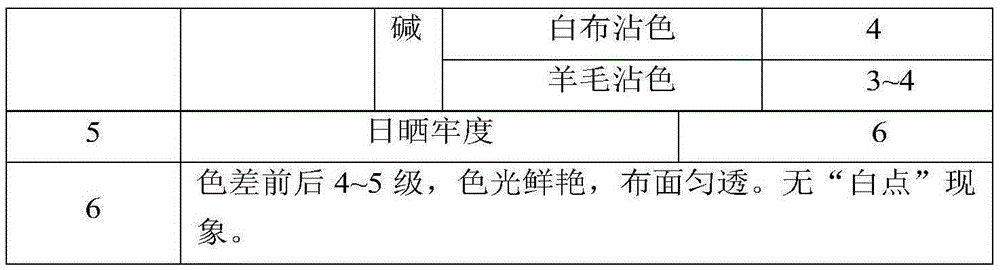

Composite active black dye

ActiveCN101580649AStrong color fixing abilityExcellent color depthOrganic dyesDyeing processDyeingFiber

The invention relates to a composite active black dye, which is characterized in that the dye is compounded by four dyes shown in formula (1), formula (2), formula (3) and formula (4) according to parts by weight of 80-84, 6-10, 1-3 and 6-10, has high responsiveness, good color fixing capability and excellent deep dyeing property, and is suitable for dyeing cotton fiber.

Owner:HUBEI HUALI DYESTUFF INDAL

Single-component moisture-curing polyurethane adhesive for car roof and preparation method thereof

ActiveCN104017533AReduce the use temperatureFast curingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolyurethane adhesiveAdhesive cement

The invention relates to a single-component moisture-curing polyurethane adhesive for a car roof and a preparation method thereof. The obtained adhesive has the advantages of low application temperature, rapid curing speed and convenience in application. By introducing an ethylene oxide chain link in the adhesive molecular structure, the probability of reaction of the NCO groups with water in the later stage is increased, and then by combination with a composite catalyst, the latter curing speed is greatly improved; by adding No. 6 solvent oil, the anti-freezing performance of the adhesive is improved, and the storage is also more stable; and by adding a certain amount of a water removal agent, the effect of water in raw materials and the environment on the stability of the adhesive is eliminated.

Owner:重庆中科力泰高分子材料有限公司

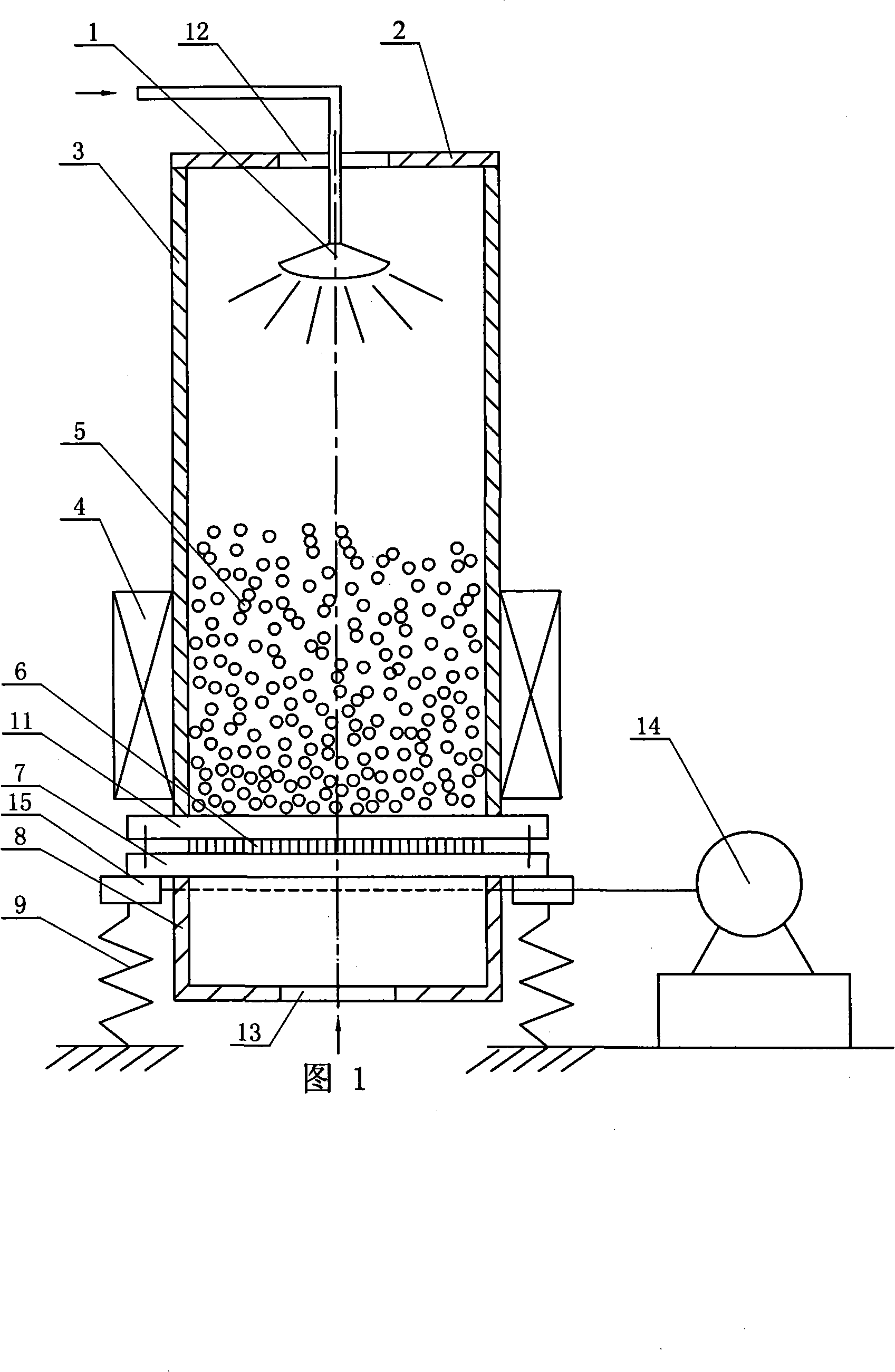

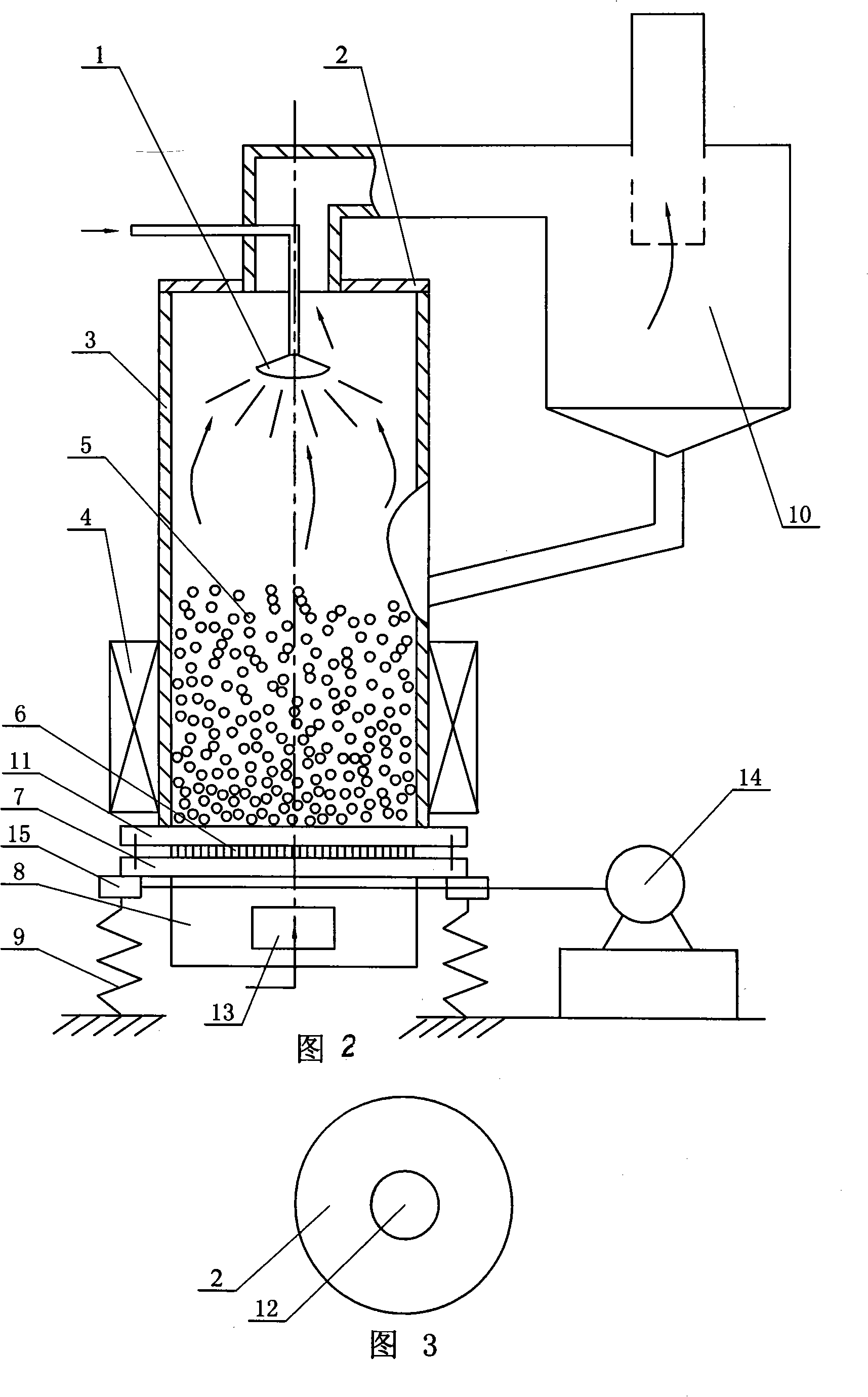

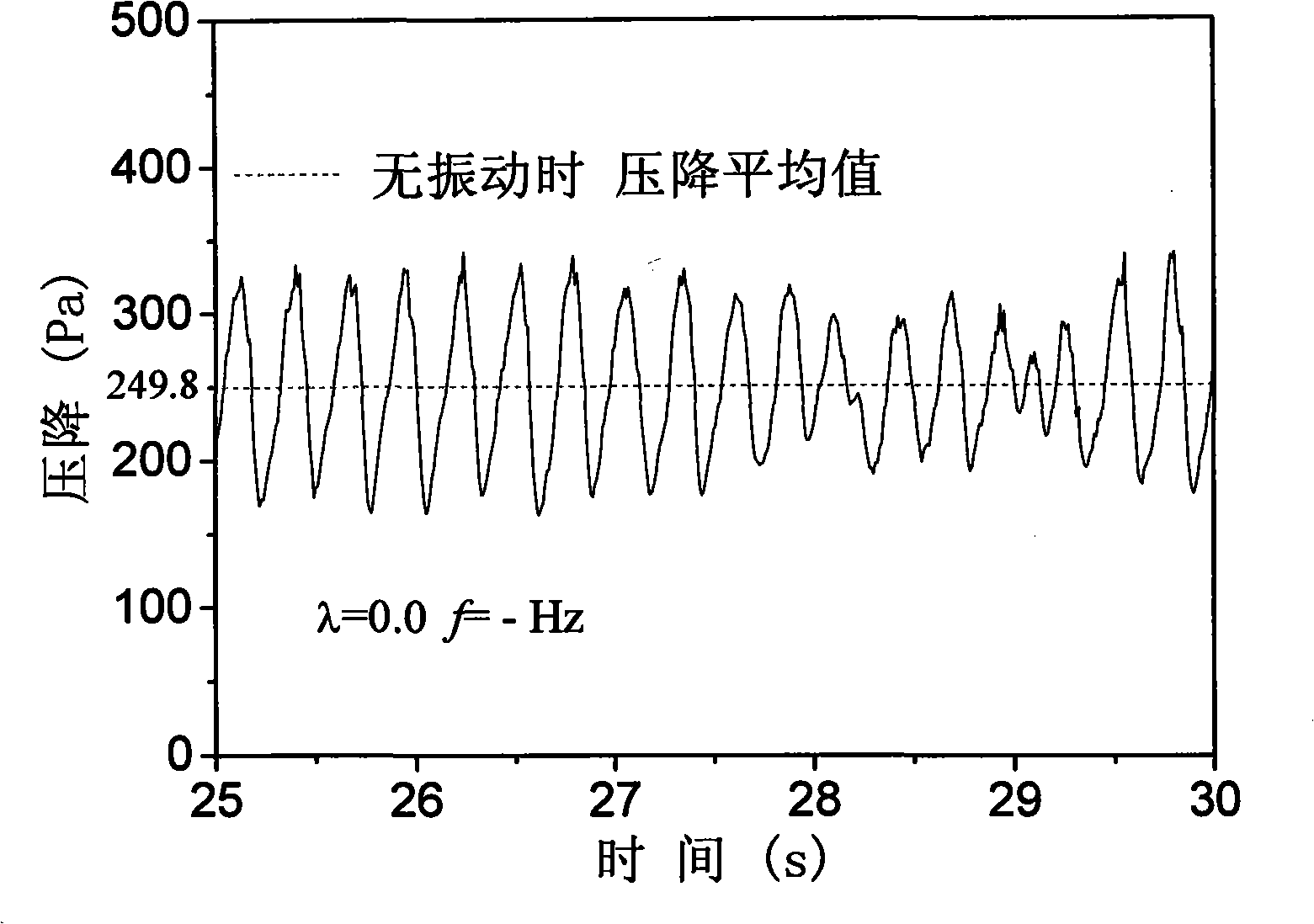

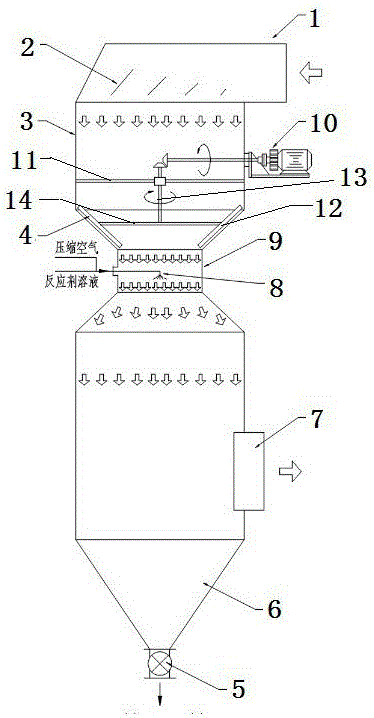

Vibrating magnetic coupling fluid bed flue gas desulfurization reactor

InactiveCN101259374AExtended reaction timeIncrease exerciseDispersed particle separationFixed frameFlue gas

A magnetic vibration coupling fluidized bed flue gas desulfurization reactor relates to a fluidized bed flue gas desulfurization reactor which aims at the problems of slow speed, short time and low efficiency of desulfurization reaction of a magnetic fluidized bed flue gas desulfurization device. An annular upper cover (2) is fixedly connected with the upper end surface of a cylinder (3); the central hole of the annular upper cover (2) is a flue gas outlet (12); an upper fixing frame board and a lower fixing frame board are fixedly arranged between the cylinder (3) and a bellows (8); a magnetic bed material (5) is arranged in the cylinder (3); a grid plate (6) is fixedly arranged between the upper and the lower fixing frame boards; an atomizer (1) is hung in the cylinder (3); a magnetic spiral loop (4) is sheathed on the cylinder (3); the two ends of three to four excitation springs (9) are respectively and fixedly connected with bases (15) and the ground; the bases (15)are fixedly connected with the lower fixing frame board (7); three or four bases are all connected with an excitation motor (14). The reactor of the invention has the advantages of fast speed, long time, high efficiency of desulfurization reaction and little scale formed on the inner wall of the reactor.

Owner:HARBIN INST OF TECH

Production method of active carbon of direct carbon conversion fuel cell

InactiveCN101777652ALarge specific surface areaGood electrical conductivityCell electrodesDirect carbon fuel cellBiomass

The invention discloses a production method of active carbon of a direct carbon conversion fuel cell, which mainly comprises the steps of: producing carbonization material by taking biomass such as oak scobs or bamboo chip, and the like as raw material; taking K2CO3 or and the mixture of K2CO3 and KOH as a activating agent; activating the carbonization material under the carbonization temperature of 750-1000 DEG C and the atmosphere of nitrogen to obtain the active carbon; loading active carbon by means of Ni with additive to improve the electric conduction performance of the active carbon; and leaching with acid solution to increase the type and the content of the oxygen-containing functional group on the surface of the active carbon and reduce the ash content of the active carbon. The specific surface area of the treated active carbon can be reach 1967 m<2> / g; the volume resistivity can be reduced at 1654 mu omega.m; the type and the content of the oxygen-containing functional group are increased; the ash content is greatly reduced; and the specific surface area, the electric conduction performance, the ash content and the combination property of the surface oxygen-containing functional group are better adapted to the requirement of direct carbon fuel cell to fuel, compared with the raw materials of the existing direct carbon fuel cell such as black lead, active carbon, petroleum coke and the like.

Owner:SOUTHEAST UNIV

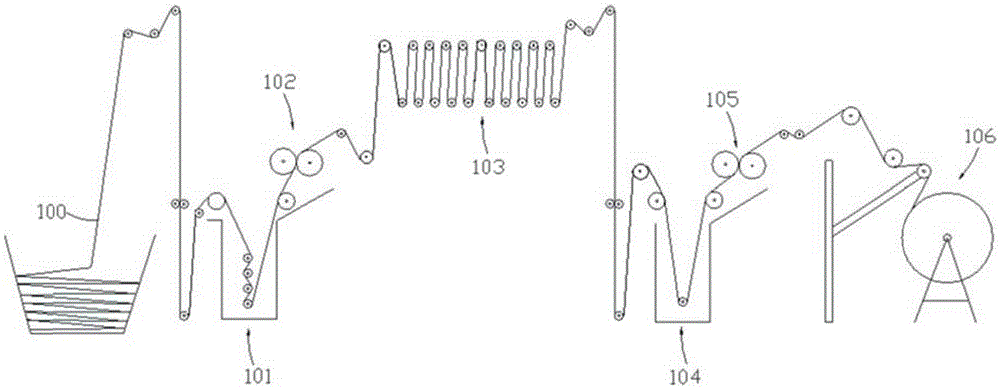

Reactive dye cold pad-batch dyeing equipment and dyeing method

ActiveCN105256485AImprove solubilityIncrease dosageSucessive textile treatmentsTextile treatment machine arrangementsBiochemical engineeringDeoxygenation

The invention relates to the technical field of dyeing and provides reactive dye cold pad-batch dyeing equipment and a dyeing method. The dyeing equipment comprises a first dipping tank, a first padder, a ventilating device, a second dipping tank, a second padder and a rolling and piling device. The dyeing method comprises the following steps of primary padding, wherein fabric sequentially passes through the first dipping tank and the first padder, and the first dipping tank contains reactive dye and deoxygenation enzyme; ventilating treatment for 1-4 minutes; secondary padding, wherein the fabric sequentially passes through the second dipping tank and the second padder, and the second dipping tank contains alkaline agents; aftertreatment. According to the reactive dye cold pad-batch dyeing method, the reactive dye and the alkaline agents are padded in a separated mode, and the problems that because the reactive dye and the alkaline agents react before padding, diffusivity of the reactive dye is decreased, and dyeing is unstable are solved; the selection range of the reactive dye and the color fixing alkaline agents is enlarged, the requirement for the equipment is lowered, a proportioning pump is omitted, and operation is convenient.

Owner:新乡橄榄枝纺织化工有限公司

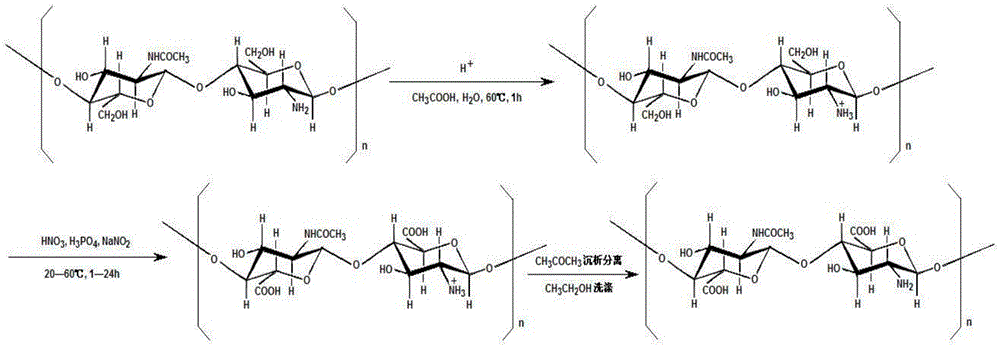

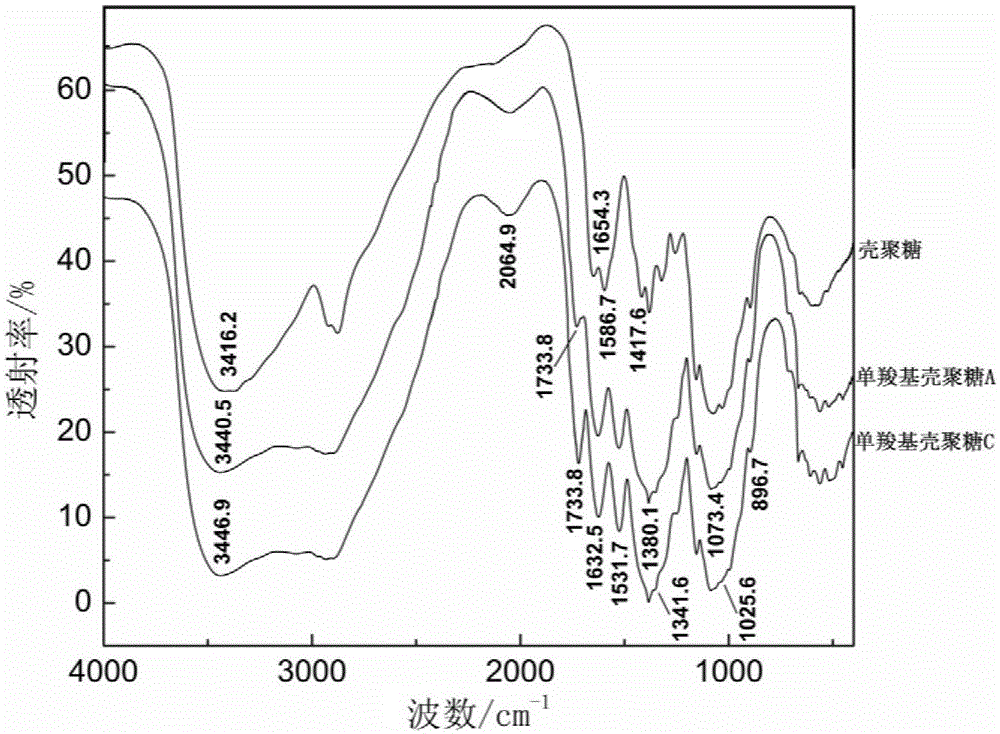

Water-soluble antibacterial monocarboxylic chitosan as well as preparation method and application thereof

ActiveCN105061637AHigh oxidation selectivityQuick responseAnimal fibresPhosphoric acidAntibacterial activity

The invention discloses a water-soluble antibacterial monocarboxylic chitosan as well as a preparation method and application thereof. The preparation method of the monocarboxylic chitosan is characterized by comprising the following steps: dissolving macromolecular chitosan in a diluted acetic acid solution, and then selectively oxidizing part or all of hydroxyl groups at the C6 site of the chitosan into carboxyl groups by utilizing a concentrated nitric acid-concentrated phosphoric acid-sodium nitrite system, thereby obtaining the monocarboxylic chitosan. The water-soluble antibacterial monocarboxylic chitosan disclosed by the invention can be used for carrying out amide modification on real silk fabrics so as to obtain monocarboxylic chitosan amide modified real silk fabrics. The method disclosed by the invention is simple in operation, high in reaction speed and easy to control, the prepared monocarboxylic chitosan amide modified real silk fabrics have lasting and efficient antibacterial activity and good wearability and are environment-friendly, and the negative effects on good real silk characteristics and human health caused by using chemical crosslinking agents in conventional chitosan modification are overcome.

Owner:ANHUI AGRICULTURAL UNIVERSITY

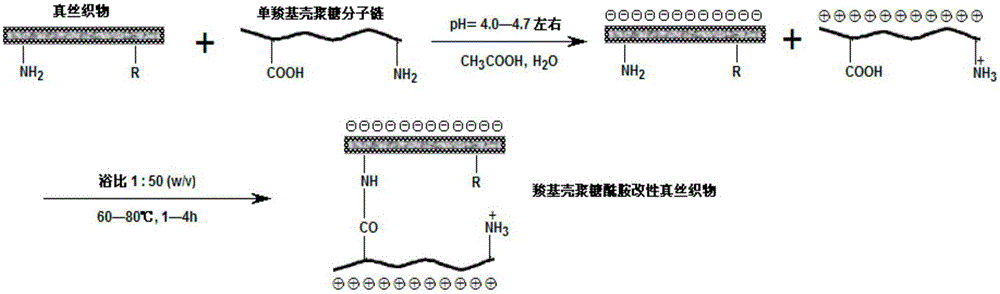

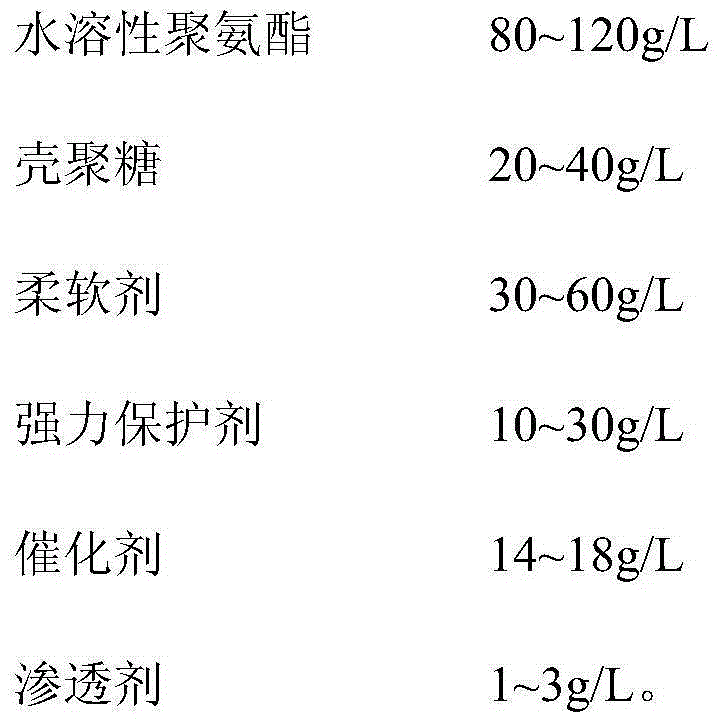

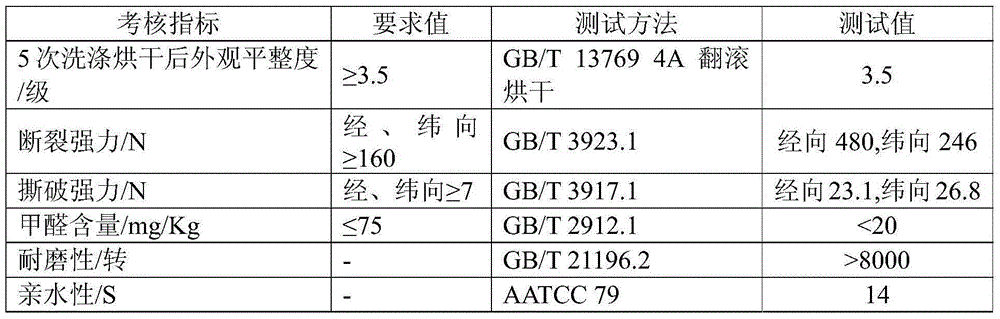

Anti-crease finishing liquid and anti-crease finishing method for real silk shell fabric

InactiveCN105155278AIncrease the degree of cross-linkingImprove wrinkle resistanceAnimal fibresWater solubleEngineering

The invention discloses anti-crease finishing liquid. The anti-crease finishing liquid is prepared from 80-120 g / L of water soluble polyurethane, 20-40 g / L of chitosan, 30-60 g / L of softening agent, 10-30 g / L of powerful protective agent, 14-18 g / L of catalyst and 1-3 g / L of penetrant with the total volume of the anti-crease finishing liquid as the benchmark. Real silk shell fabric finished through the anti-crease finishing liquid and method continues to keep good breathability, moisture permeability, smoothness and draping performance and has excellent appearance flatness and comfort.

Owner:LUOLAI LIFESTYLE TECH CO LTD +1

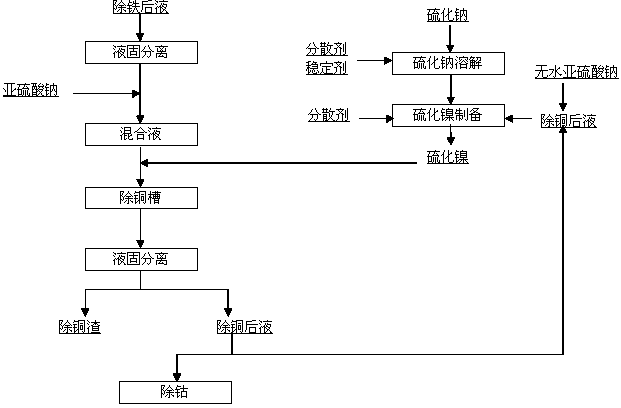

Copper removal method

ActiveCN103820809AIncreased chance of reactionShort processElectrolysis componentsPhotography auxillary processesAutomatic controlElectrolysis

The invention relates to a chemical purification method, especially to a copper removal method which is suitable for a nickel electrolysis anolyte purification process. The copper removal method provided by the invention is obviously different from a copper removal method by adding anode mud in nickel ore concentrate as follows: a sodium hydrosulphite solution is added in an iron-removed liquid to activate copper ions and increase reaction probability between copper ions and amorphous nickel sulfide; as amorphous nickel sulfide is added into a copper removal tank in a slurry form, labor intensity is reduced, it is convenient to realize automatic control, and stabilization and continuity of the copper removal process are guaranteed; and as copper slag can directly enter a copper melting system, the technology is optimized, flow of copper impurity in the system is shortened, copper slag is processed not by the use of chlorine, and the environment is improved. Through detection, a copper-removed liquid contains 0.4-2.5ppm of copper. Thus, purification requirements are met. The mass ratio of copper to nickel in the copper slag is 15-17. The copper slag can be directly melted to produce anode plates.

Owner:JINCHUAN GROUP LIMITED +1

Auric potassium cyanide and method for preparing same

InactiveCN101289746AReduce capacityIncreased chance of reactionElectrolysis componentsMetal cyanidesElectrolysisPotassium cyanide

The invention discloses a method for making potassium auric cyanide, which uses potassuim cyanide and metallic gold as raw materials and matches the gold per kilogram with 1020-1030 grams of the potassuim cyanide. The method comprises the following: 1) a step of pressing gold, which is to roll the gold into a thin gold sheet as an electrode; 2) a step of electrolyzing, which is to carry out electrolysis reaction in a diaphragm electrolyzer with the thin gold sheet as an anode, a stainless steel sheet as a cathode and a potassuim cyanide solution as electrolyte, so as to gradually dissolve the thin gold sheet as the anode into Au(CN)2<->; 3) a step of purifying, which is to purify potassium auric cyanide generated in electrolysis through a low-temperature cooling crystallization method after the thin gold sheet is completely dissolved; 4) a step of condensing; 5) a step of purifying repeatedly; 6) a step of condensing; 7) a step of drying, which is to bake potassium auric cyanide crystals in vacuum so as to get a finished product. The adoption of the method shortens electrolysis time, reduces purifying times, and improves the quality and yield of potassium auric cyanide.

Owner:吴朝勤

Flax fibre modifying method

InactiveCN1584183AImprove dyeing effectLoose arrangementPhysical treatmentFlax fibreMaterials science

This invention publishes the method of color flax fibre. A kind of character-change flax fibre: (1.) Put the flax fibre into 50-300g per L carbamide liquid. After endosmosis, put it out. (2) Heat the flax fibre in 300-400w micro-wave oven for 1-4 minutes. (3) Heat the flax fibre in the 600-hange the flax fibre. The color deepness can rise by 6%. (4) The flax fibre after character-change, the face will become coarse, it shows the face of some fibre molecule is cloven, and the face of other fibre molecule appears floss. So the fibre is a little loose, and it is dasy to be 800w imcro-wave oven for 0.5-3 minutes. The availability of the invention is: After character-c colored and character-change, the mechanics capability is not changed.

Owner:HEILONGJIANG UNIV

Development and application method of bismuth oxyhalide system material for processing organic pollutant efficiently

InactiveCN103055901AReduce manufacturing costSimple processPhysical/chemical process catalystsWater/sewage treatment by irradiationSemiconductor materialsFixed bed

The invention discloses a development and application method of a bismuth oxyhalide system material for processing organic pollutant efficiently. A novel semiconducting material which is low in synthesis cost, pollution-free and high in efficiency, and can use visible light to degrade organic pollutants can efficiently degrade pollutants in waste water, and fully mineralizes the pollutants into carbon dioxide and water, and accordingly no secondary pollutant is produced. Two aspects of synthesis technology and a material system are improved, wherein a low temperature precipitation method is adopted to synthesize a series of visible light catalysis degradation materials, and the system is mainly semiconducting materials doped with bismuth chloride oxide-I of a nanometer nuclear shell structure and compounded semiconducting materials of bismuth oxyiodide and bismuthyl bromide which are both of a slice sphere structure. The material system can be recycled and repeatedly used, and is still remarkable in degradation effect. The development and application method can be applied to printing and dyeing wastewater treatment, places materials on a fluidized bed or a fixed bed for lighting, and removes the organic pollutants with trace chemical oxygen demand and biochemical oxygen demand by deeply disposing. The bismuth oxyhalide system material can be widely applied to aspects of producing electron function materials, fire retardant, optical materials, medical composite materials, radiation proof materials and the like.

Owner:XINCHANG GUANYANG TECH DEV

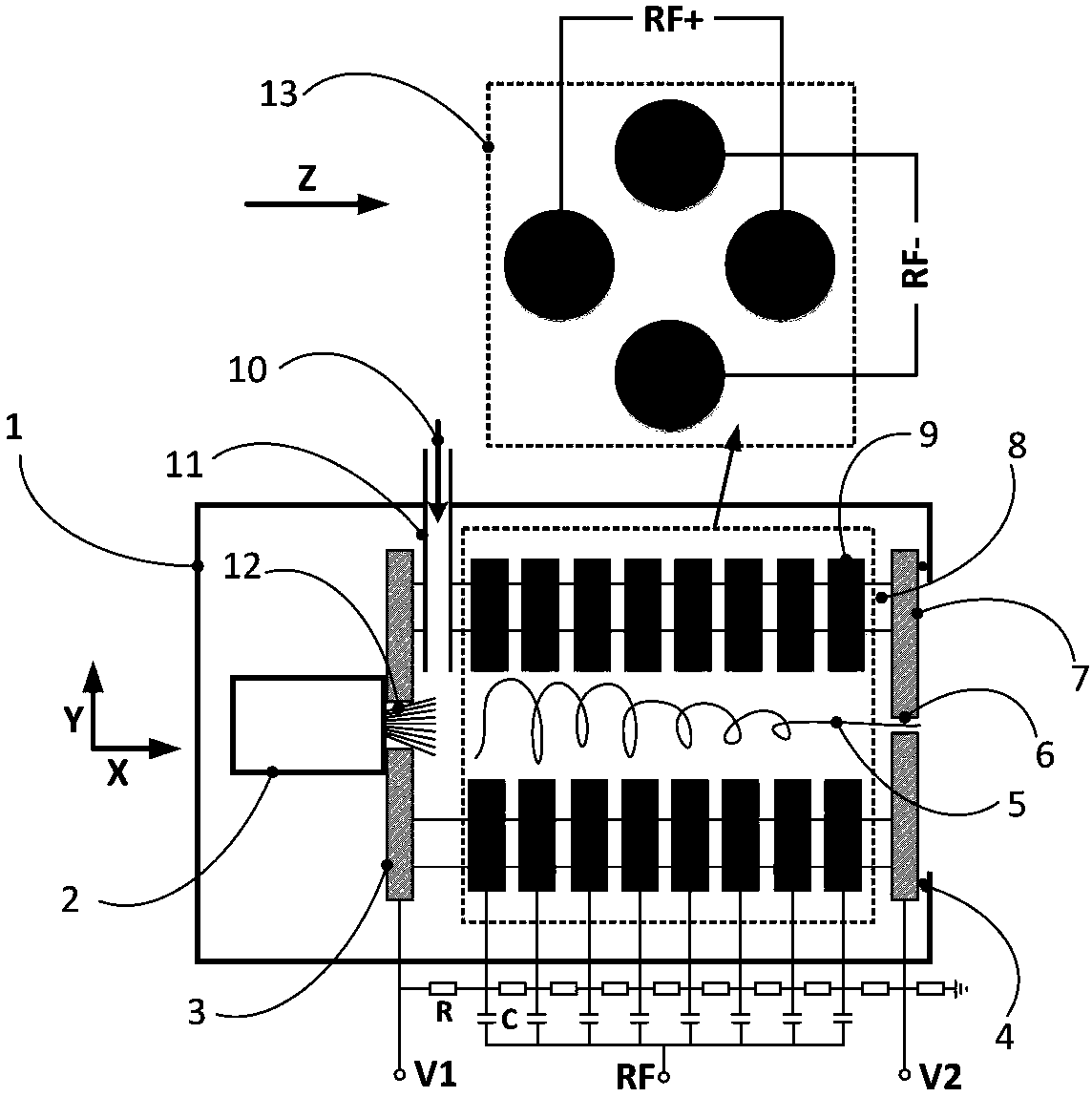

Radio frequency focusing enhanced vacuum ultraviolet mass spectrometry ionization source

ActiveCN108091540AImprove transmission efficiencyIncreased chance of reactionStability-of-path spectrometersElectron/ion optical arrangementsReaction rateUltraviolet

The invention relates to a mass spectrometry instrument, in particular to a focusing enhanced ultraviolet ionization source based on a radio frequency segmented quadrupole rod for mass spectrometry. The ultraviolet ionization source specifically comprises an ionization source cavity, a vacuum ultraviolet lamp, a repulsion electrode, a gas injection tube, a segmented quadrupole rod and a differential electrode. The ionization source uses the quadrupole rod to improve the ion collision frequency at medium pressure. Therefore, the focusing and other properties are enhanced, the transmission efficiency of ions and the probability of molecular-ion reaction are improved, the ionization efficiency of the vacuum ultraviolet ionization source is enhanced, and the sensitivity of the instrument is greatly improved. Meanwhile, by introducing a segmented structure, a suitable axial electric field can be controlled, the reaction rate and dissociation can be controlled, and the selectivity of the ionization source can be improved.

Owner:SHENZHEN BREATHA BIOTECHNOLOGY CO LTD

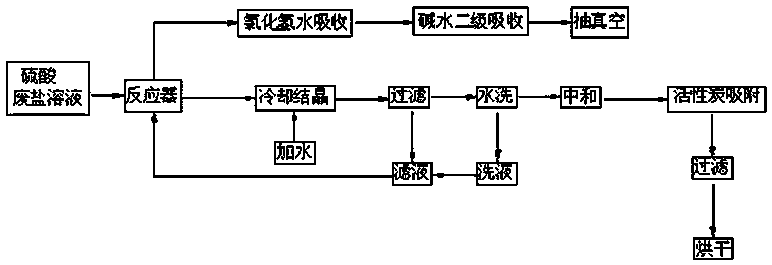

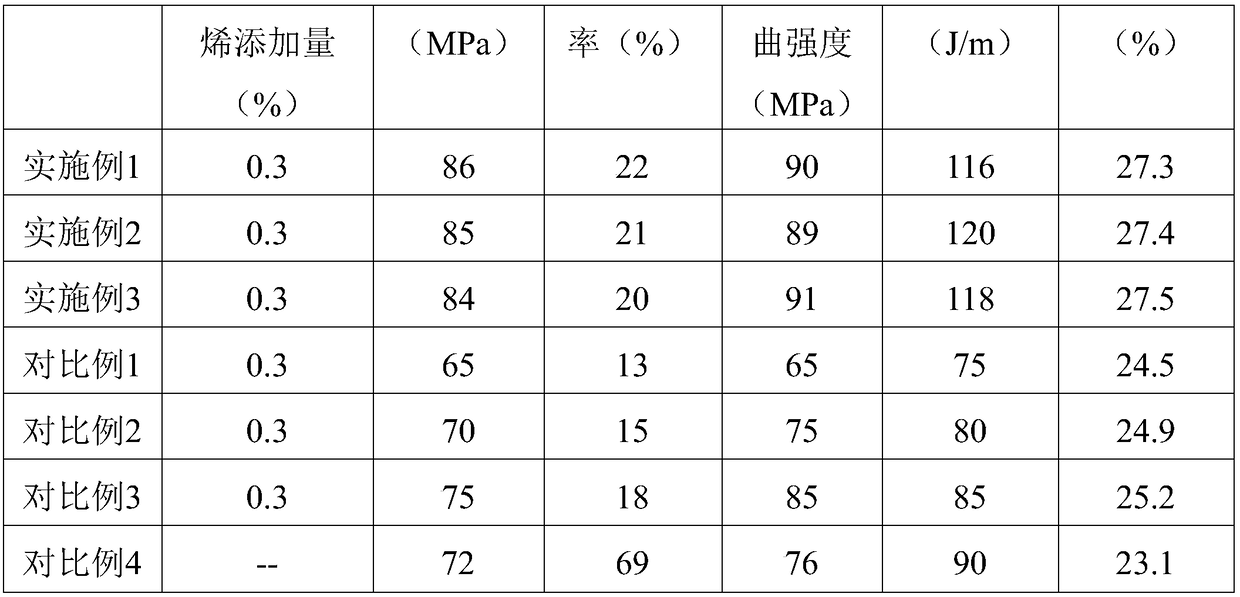

Industrial organic waste salt treatment process

ActiveCN110695059AIncrease concentrationHigh removal rateSolid waste disposalTransportation and packagingEnvironmental engineeringOrganic matter

The invention discloses an industrial organic waste salt treatment process which comprises the following steps: adding a certain amount of waste salt solution into a reactor; then adding sulfuric acidto stir for a warming reaction, and after the reaction, continuously adding a certain amount of waste salt solution; sucking hydrogen chloride gas in a resultant of reaction in a negative pressure condition into an absorption tower to be absorbed by water to be finally converted into a by-product hydrochloric acid; and carrying out cooling, crystallizing, filtering, filter cake washing, neutralizing, adsorbing, filtering and drying on another resultant sodium sulfate to finally prepare a product sodium sulfate. According to the process, waste salt is recycled, and organic matters can be removed in a normal temperature condition without high temperature incineration, so that the energy source is saved, the investment and operating cost are reduced, and the produced sodium sulfate is recycled, so that a purpose of turning waste into wealth is achieved.

Owner:SHANGYU ZHONGLIAN ENVIRONMENTAL PROTECTION CO LTD

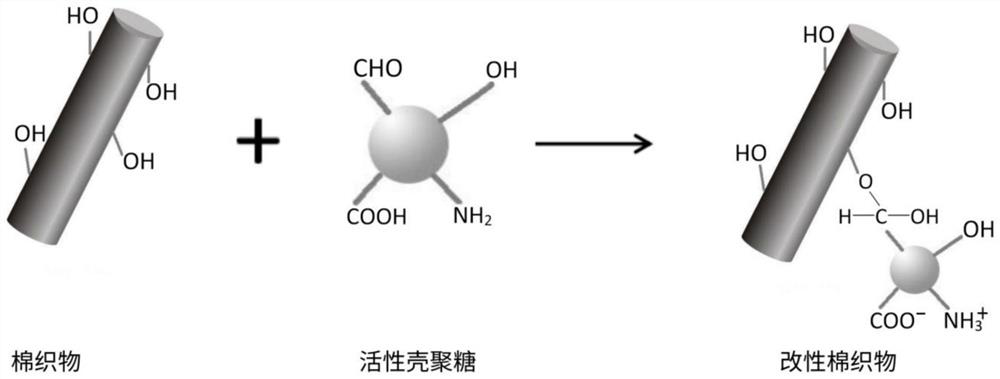

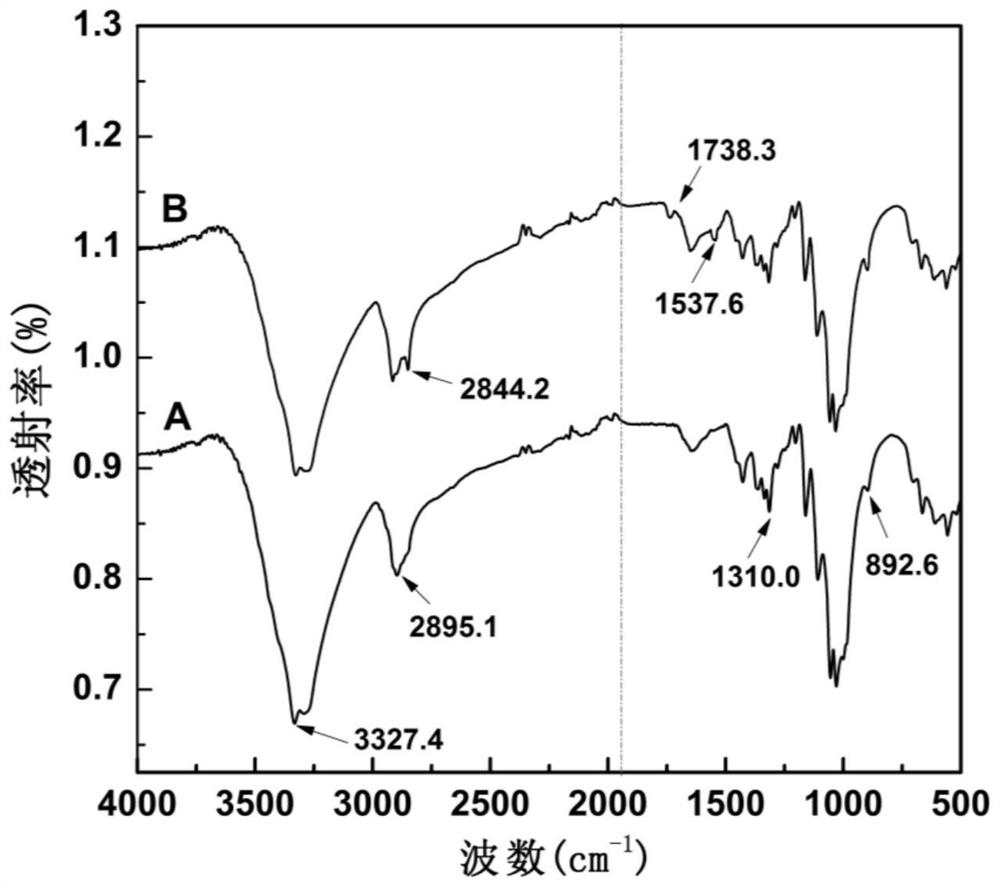

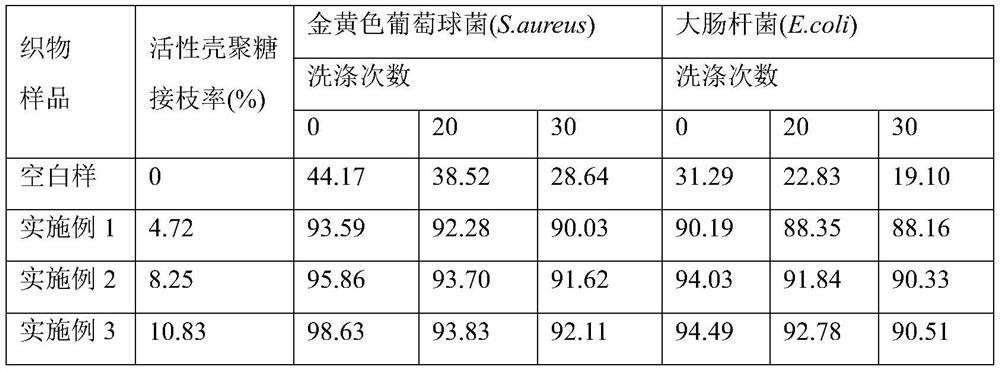

Preparation method of active chitosan modified cotton fabric

PendingCN112160161AAntibacterial lasting and efficientHuman-friendlyBiochemical fibre treatmentGrip property fibresHemiacetalPolymer science

The invention discloses a preparation method of an active chitosan modified cotton fabric. The preparation method comprises the following steps of wetting and swelling a cotton fabric in a mixed medium of 1-ethyl-3-methylimidazolium bisulfate ionic liquid and deionized water, taking out the fabric, and adding active chitosan to dissolve; and forming hemiacetal chemical bonds through reacting between hydroxyl in the cotton fabric with aldehyde groups of the active chitosan. The preparation method is simple and easy to implement, high in grafting rate, free of chemical cross-linking agents and environment-friendly, the prepared active chitosan modified cotton fabric is efficient and durable in antibiosis, good in washing resistance, high in wearing comfort and friendly to the human body, andtherefore the actual application prospect is wide.

Owner:ANHUI AGRICULTURAL UNIVERSITY

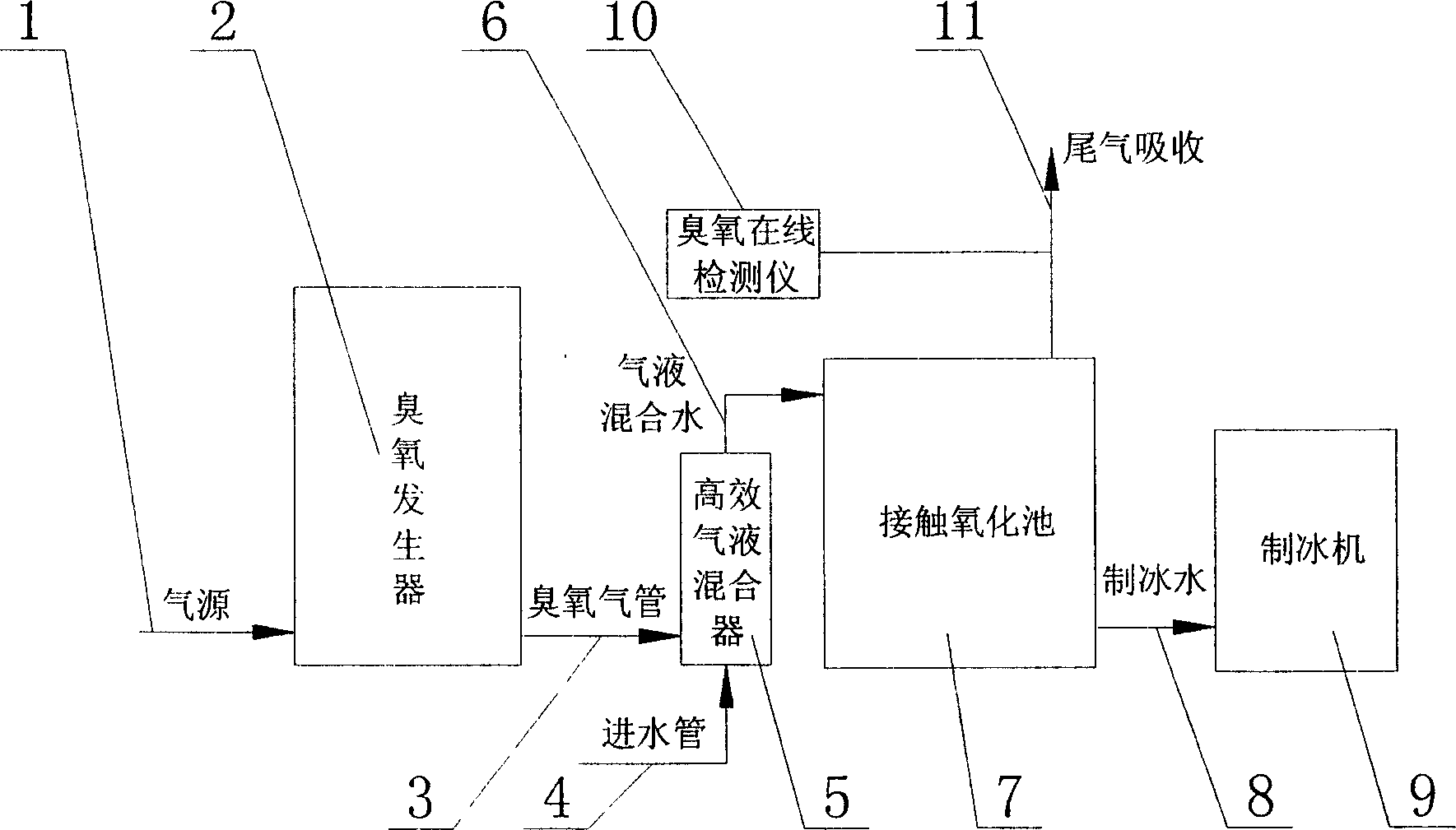

Disinfecting and sterilization method of water for making ice

InactiveCN1948174ASpread evenlyImprove toleranceWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationIce waterProduct gas

The present invention relates to a method for sterilizing ice-making water. Said method includes the following steps: making air source of air be passed through an ozonator to produce ozone mixed gas, then making the ozone mixed gas be passed through an ozone gas pipe and fed into a high-effective gas-liquid mixer simultaneously together with the water feeding into water intake pipe, and making the gas-liquid mixed water discharged from the high-effective gas-liquid mixer be flowed into a contact oxidation tank, and the ice-making water be fed into an ice-making machine to produce ice block.

Owner:SHENYANG JIANZHU UNIVERSITY

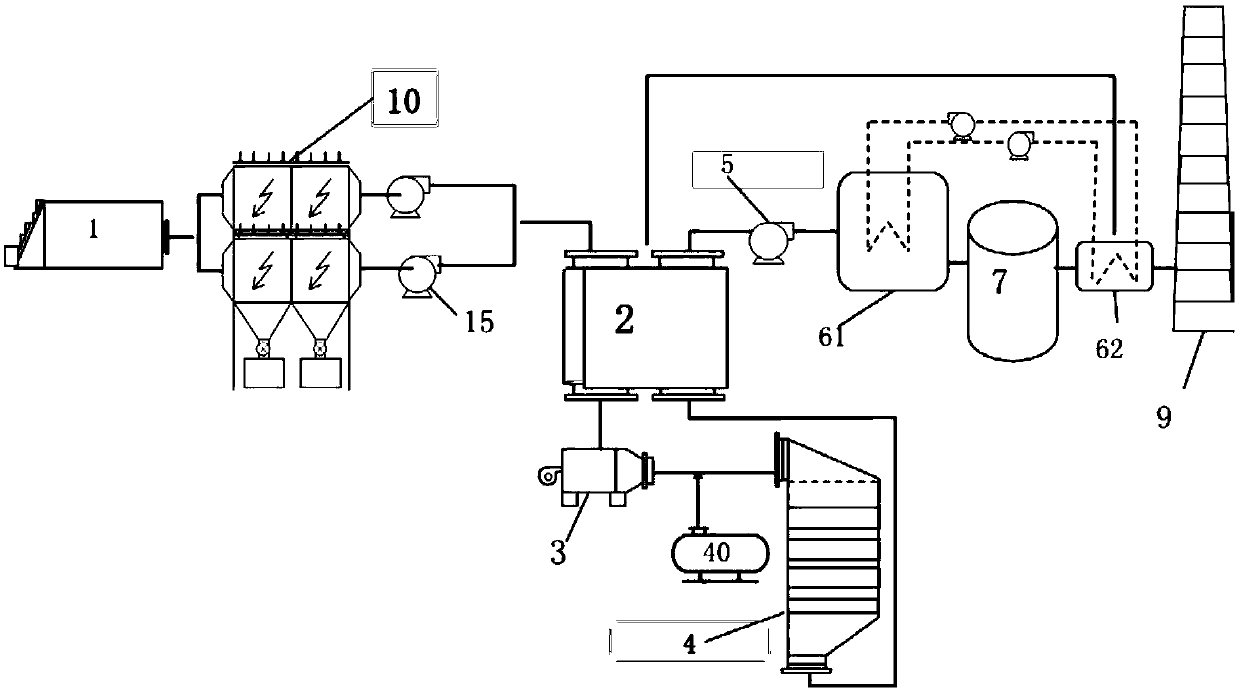

Technological method of desulfurization, denitrification, dust removal, white elimination and purification for sintering flue gas

InactiveCN109603546AReduce consumptionReduce the temperature of sintering flue gasDispersed particle separationFlue gasHeat exchanger temperature

The invention provides a technological method of desulfurization, denitrification, dust removal, white elimination and purification for sintering flue gas. The technological method includes the stepsthat sintering raw flue gas is introduced into a rotary type flue gas heat exchanger and has heat exchange with high-temperature sintering flue gas which enters the rotary type flue gas heat exchangerafter denitrification, heated sintering raw flue gas is heated to 320 DEG C through an after-burning device, then ammonia gas is uniformly sprayed into the heated sintering raw flue gas, then the mixture enters a denitrification reactor for flue gas denitrification, after denitrification, high-temperature sintering raw flue gas returns heat to the sintering raw flue gas through the rotary type flue gas heat exchanger and then enters an ammonia process desulfurization system for cooling, dust removing and desulfurizing, and finally deep dust removal and mist removal are conducted on the flue gas after densulfurization so that desulfurized pure flue gas after desulfurization and mist removal can enter a flue gas water-medium type heat exchanger temperature-increase segment. Energy consumption needed by denitrification of sintering flue gas is lowered, after desulfurization, the temperature and the water content of the saturated flue gas are decreased, the temperature of the desulfurizedflue gas is increased through the rotary type flue gas heat exchanger to realize white elimination of the flue gas, the technological route is simple, and operation is easy.

Owner:LIUZHOU IRON & STEEL

High-stability nonionic N-vinyl butyrate lactam iodine and preparation method thereof

The invention provides a preparation method of high-stability nonionic N-vinyl butyrate lactam iodine, which is to prepare high-stability nonionic N-vinyl butyrate lactam iodine by stirring nonionic N-vinyl butyrate lactam, iodine and a grinding aid at 50 to 90 DEG C and a rotation speed of 50 to 800r / min for 1 to 12 hours, wherein the K value of the nonionic N-vinyl butyrate lactam is 32+-1, the main peak PD value is less than or equal to 1.6, and the water content is less than or equal to 2.5 percent; preferably, the grinding aid is one or several of sodium chloride, sodium citrate, sodium carbonate and sodium phosphate, the added amount of the grinding aid is 0.02 to 2 percent based on the total amount of the nonionic N-vinyl butyrate lactam and the iodine; and the N-vinyl butyrate lactam is polyvinylpyrrolidone (PVP)-K32. The invention also provides high-stability nonionic N-vinyl butyrate lactam iodine prepared by the method. With high stability, the high-stability nonionic N-vinyl butyrate lactam iodine can be stored and used for a long term and is suitable for large-scale promotion and use.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

Method for separating silicon dioxide in wollastonite raw ore

The invention discloses a method for separating silicon dioxide in wollastonite raw ore. The method comprises the steps that the wollastonite raw ore is subjected to smashing, ball milling and magnetic separation to obtain a material A; water is added into the material A, the pH is adjusted, oxidized paraffinum sodium salt and stearic acid are added for flotation, and a material B is obtained; the material B is added into an oxalic acid solution with the pH being 1-3 after being calcined, and filtering, washing and drying are carried out to obtain a material C; the material C is added into water, ammonium chloride is added, ammonium chloride is added after microwave heating, the pH is adjusted to range from 0.6 to 1.2, and sol is obtained; a surface active agent is added into the sol, the pH is adjusted to range from 3 to 4, hydrochloric acid is added, the pH is adjusted to range from 0.6 to 1.2, and a material D is obtained; the material D, sodium fluoride, sodium hydroxide, hydrochloric acid and nitrilotrimethylene triphosphonic acid are added into water for a hydrothermal reaction. According to the method for separating silicon dioxide in the wollastonite raw ore, the steps are simple, and obtained silicon dioxide is high in yield and purity, good in stability and capable of being applied to multiple fields.

Owner:望江县金峰矿产品科技有限公司

Venturi type desulfurizing device adopting spray drying method and desulfurizing method of desulfurizing device

ActiveCN105944539AAvoid dust accumulationEvenly distributedGas treatmentDispersed particle separationChemical reactionFlue gas

The invention relates to a venturi type desulfurizing device adopting a spray drying method and a desulfurizing method of the desulfurizing device. A vertical cylindrical tower-shaped structure is adopted, a venturi throat is arranged in the middle of a tower body, and flue gas enters a shell through an upper air inlet and passes through a desulfurizing tower from top to bottom. SO2 in the high-temperature flue gas and a reactant sprayed in through a nozzle are subjected to a chemical reaction, a reaction side product is solid Na2SO3 powder, most of the solid Na2SO3 powder falls into a lower ash bucket, and the rest of the solid Na2SO3 powder is discharged out of the tower body from a lower air outlet of the tower body along with the desulfurized flue gas, enters a subsequent dust removing process and is collected. The PH value of the solid desulfurizing side product is neutral or alkaline, no wastewater is generated in the whole desulfurizing process, and the temperature of the flue gas at an outlet of the desulfurizing tower is higher than the dew point temperature by 15 DEG C or above all the time. The problems that in a traditional desulfurizing technology, flue gas is not distributed uniformly in a flow field of a desulfurizing tower, full mixing of a desulfurizing agent and the flue gas is not uniform, mushroom heads and hair hanging are likely to be formed at a nozzle by a reactant and a reaction side product, and consequently running stability is influenced are solved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

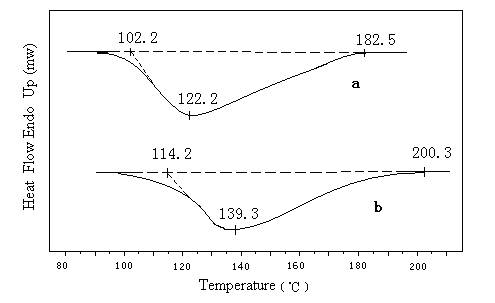

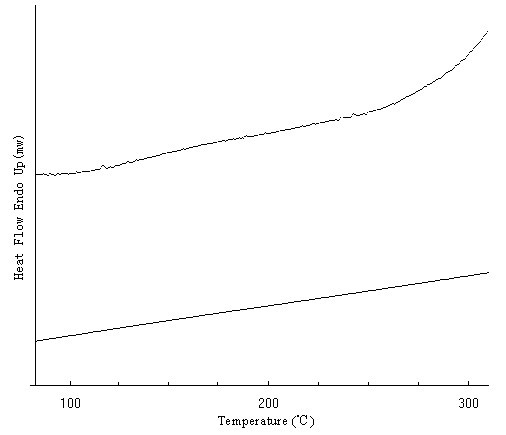

Method for preparing high-strength epoxy resin adhesive

InactiveCN102153730AIncrease the lengthIncreased shear strengthEpoxy resin adhesivesEpoxyBoron trifluoride

The invention relates to a method for preparing cured modified epoxy resin. The method comprises the following steps: mixing prepolymers at different weight ratios and synthesizing at molar ratios of 2:1, 3:2 and 4:3 with epoxy resin in a container at room temperature, adding boron trifluoride ethylamine curing agent which is 3% of the weight of the mixed resin, stirring uniformly, mixing the mixture in the container for 1 hour in an ultrasonic cleaner; and putting the mixture in a vacuum baking oven to remove air bubbles for 2 hours. The polymerization activity of an epoxy group is greater than that of a spiral ring group, and the epoxy group can be subjected to the ring opening reaction at lower temperature. The starting temperature of curing reaction is 102 DEG C, and modified epoxy resin containing 20% of prepolymer is cured for 4 hours at the constant temperature of 102 DEG C and then cooled. The invention avoids the defects of the matrix, which are probably resulted from the aggregation of spiral ring monomers and ensures that the resin is more stable and practical.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

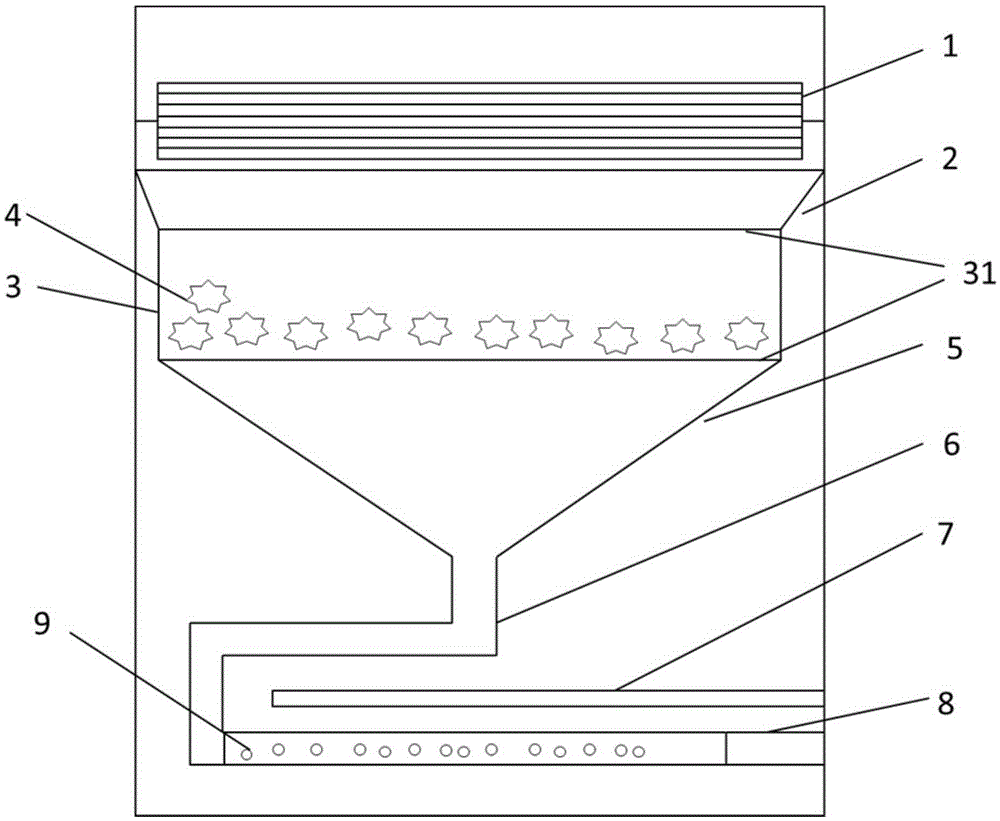

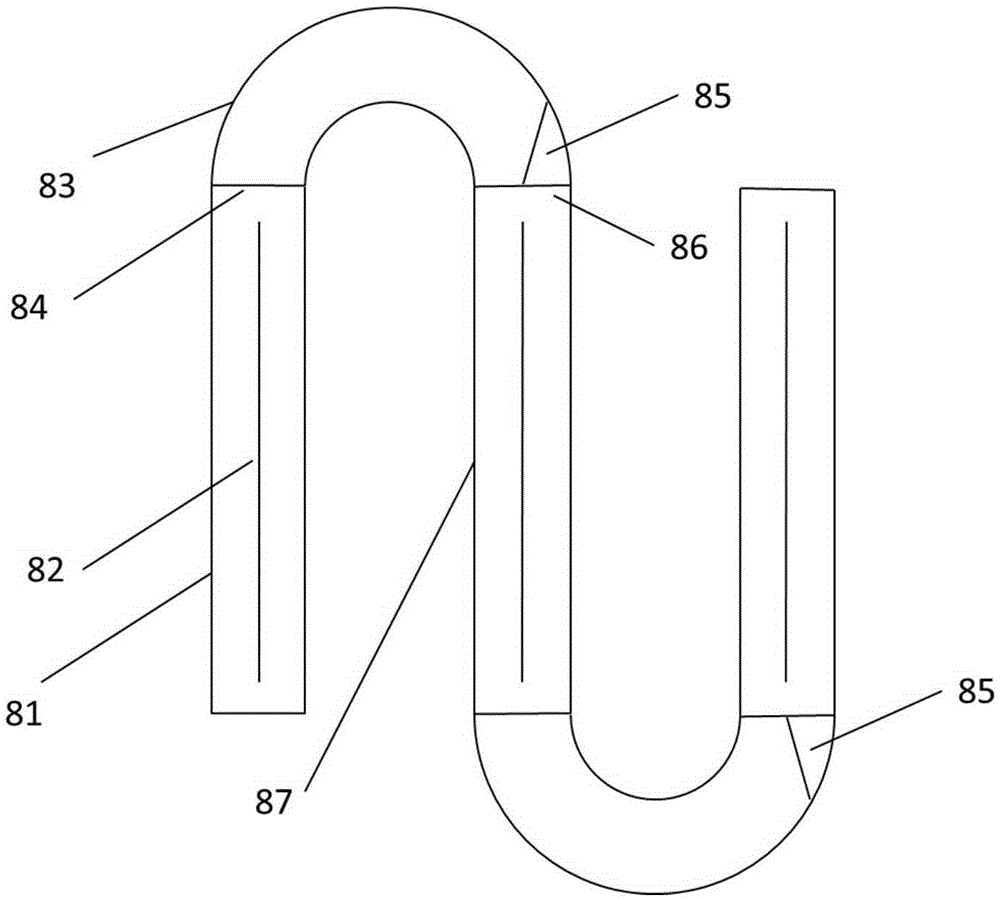

Air purification device

InactiveCN105413455AImprove purification rateIncreased chance of reactionDispersed particle separationEngineeringAir purification

The invention discloses an air purification device which comprises active titanium dioxide powder (9), wherein the active titanium dioxide powder (9) is loaded in a transparent straight pipe (81) of a photocatalytic pipe (8); two ends of the transparent straight pipe (81) are closed by breathable films (84), so that air is allowed to pass through the films, but the active titanium dioxide powder (9) cannot pass through the films; a flow guide plate (82) is fixed in the transparent straight pipe (81); clearances are reserved between two ends of the flow guide plate (82) and two ends of the transparent straight pipe (81); one end of the transparent straight pipe (81) is connected with one end of an elbow (83); the other end of the elbow (83) is a half-blowing connection end (86); an inclined guide plate (85) is fixed in the elbow (83) at this end; one end of the inclined guide plate (85) is fixed on the elbow (83), and the other end of the inclined guide plate (85) points to the middle part of the half-blowing connection end (86); the air purification device further comprises an ultraviolet lamp (7); the ultraviolet lamp (7) is arranged at the upper end of the transparent straight pipe. Air is fully mixed with the active titanium dioxide powder in the transparent straight pipe, so that the reaction efficiency is improved.

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

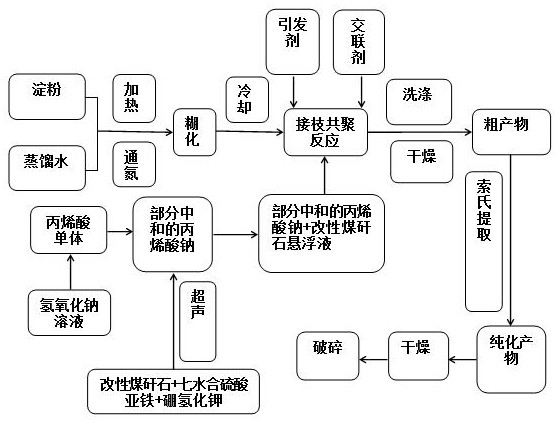

Starch grafted coal gangue coated nano zero-valent iron composite material and preparation method thereof

PendingCN112263996AIncrease valueIncrease added valueOther chemical processesWater contaminantsPotassium borohydrideActive agent

The invention relates to the field of composite material preparation, in particular to a starch grafted coal gangue coated nano zero-valent iron composite material and a preparation method thereof. Inthe reversed-phase suspension polymerization, a reversed-phase suspension polymerization system consists of a water phase and an oil phase; the water phase is composed of water, starch, an initiator,a cross-linking agent, a polymeric monomer, ferrous sulfate heptahydrate, potassium borohydride and a surfactant, and the oil phase is composed of a dispersing agent; the volume ratio of the water phase to the oil phase is 1-5. The composite material obtained by the invention not only has good adsorption capacity of coal gangue, but also fully utilizes a complex three-dimensional network structure and various active functional groups of starch to stabilize and disperse nano zero-valent iron, can effectively prevent the oxidation of the nano zero-valent iron, and has a good treatment effect onCr (VI) containing water.

Owner:YULIN UNIV

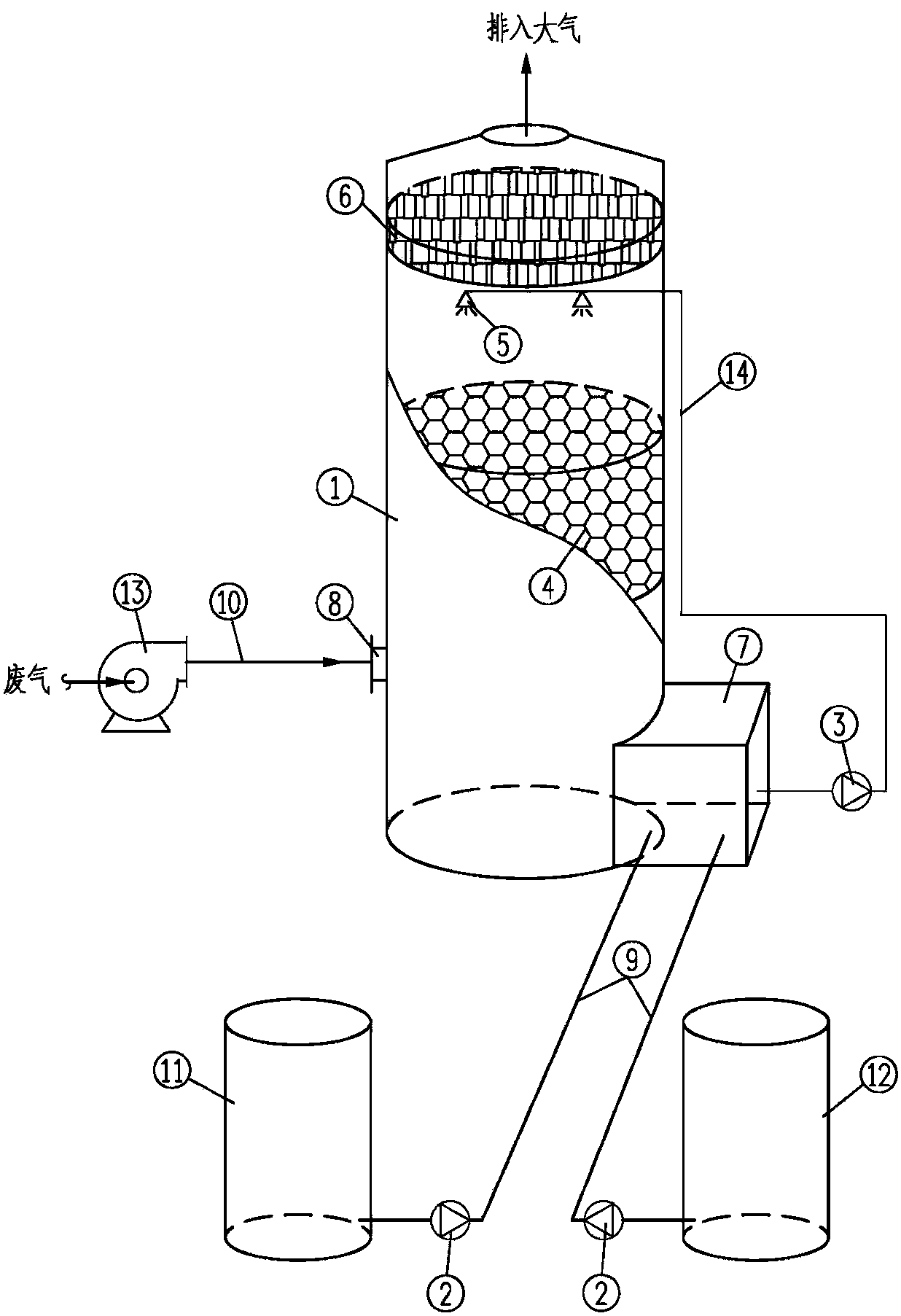

Treatment method and device suitable for treatment of medium and high temperature organic waste gas

InactiveCN110420542AReduce mass transfer resistance at the gas-liquid interfaceImprove removal efficiencyGas treatmentDispersed particle separationPersulfateGas phase

The invention provides a treatment method and device suitable for treatment of medium and high temperature organic waste gas. The process utilizes a sulfate free radical (SO4<->.) generated by contactactivation of a persulfate (S2O8<2->) and a high-temperature gas as a strong oxidant, and utilizes the characteristic that a solubilizing agent has a hydrophilic exterior and a hydrophobic interior or one hydrophilic end and one hydrophobic end to capture the insoluble organic waste gas in the gas phase by the solubilizing agent interface, so that the waste gas more easily breaks through gas-liquid mass transfer resistance, and the waste gas is dissolved and enters a spray liquid to be oxidatively decomposed. The treatment device for the waste gas mainly comprises a waste-gas reaction tower,medicine storage tanks, medicine adding pumps, a circulation pump, a high-temperature-resistant filler, atomizing spray nozzles, a demister and the like. Compared with a common Fenton method, the method provided by the invention does not need to cool the high-temperature waste gas; and transition metal modified cyclodextrin helps the waste gas to break through the gas-liquid mass transfer resistance, and transition metal groups have a promoting effect on generation of the SO4<->. by activation of the persulfate.

Owner:广州中洲环保科技有限公司 +1

Preparation method of graphene

ActiveCN108793134AReduce dosageImprove performanceGrapheneBulk chemical productionFiltrationReaction temperature

The invention discloses a preparation method of graphene. The preparation method of the graphene comprises the following steps: 1, stripping graphite by a supercritical carbon dioxide stripping method, dispersing the obtained graphite powder into deionized water, crushing by a homogenizer, controlling the pressure to 90 to 150 MPa, and sequentially dispersing and drying; and 2, soaking and washingthe dry product in the step 1 with diluted hydrochloric acid, wherein the soaking temperature is -10 to 15 DEG C, the soaking time is 1 to 4 hours, and the mass ratio of the diluted hydrochloric acidto the graphite is (1-2.5):1, adding a compound of potassium dichromate and hydroperoxide, performing oxidation reaction at the reaction temperature of 10 to 85 DEG C for 2.5 to 6 hours, and sequentially performing water washing, suction filtration and drying after reaction to obtain graphene oxide powder. An aminated graphene sheet obtained by the preparation method of the graphene has small diameter and small layer number, is favorable for being dispersed in a base material when a macromolecular material is modified, avoids aggregation and can achieve a good modification effect under the condition of small adding amount.

Owner:中山市悦泰汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com