Industrial organic waste salt treatment process

A kind of salt treatment and organic technology, applied in the field of industrial organic waste salt treatment process, can solve the problems of high investment and operation cost, complex treatment process, large energy consumption, etc., to reduce investment and operation cost, increase reaction probability, reduce sulfuric acid The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

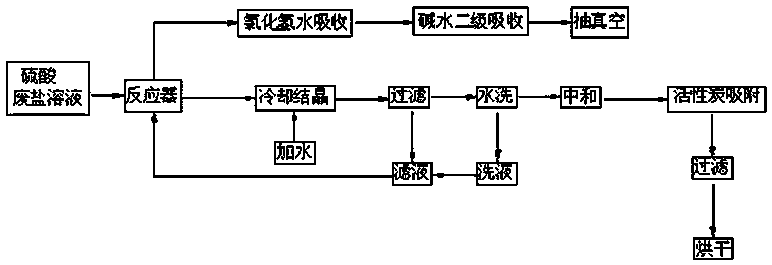

[0017] Embodiment one of the present invention: as figure 1 As shown, an industrial organic waste salt treatment process includes the following steps: (1) Weigh 100KG of organic waste salt slag and pour it into the reactor, add 400L of water and stir to dissolve the organic waste salt slag in water to form a waste salt solution; (2) Add 220KG of sulfuric acid into the reactor, stir to raise the temperature, and use a water pump to evacuate, the temperature T=75°C, the solution boils, and react for 40 minutes, then add 100KG of organic waste salt residue and 400L of water, stir, and react in vacuum for 60 minutes. Under negative pressure, the hydrogen chloride gas is pumped into the absorption tower to be absorbed by water and converted into hydrochloric acid; (3), the sodium sulfate solution formed after the reaction is pumped into another reactor through the pump body, at 10-20°C Stir under low pressure, cool and crystallize for 4 hours, and then filter through a filter press...

Embodiment 2

[0018] Embodiment two of the present invention: as figure 1 As shown, an industrial organic waste salt treatment process includes the following steps: (1) Weigh 150KG of organic waste salt residue and pour it into the reactor, add 600L of water and stir to dissolve the organic waste salt residue in water to form a waste salt solution; (2) Add 220KG of sulfuric acid to the reactor, stir to raise the temperature, and use a water pump to evacuate the solution. The temperature T=75°C boils the solution and reacts for 60 minutes. Then add 50KG of organic waste salt residue and 200L of water and stir for 40 minutes in vacuum. Under negative pressure, the hydrogen chloride gas is pumped into the absorption tower to be absorbed by water and converted into hydrochloric acid, and the incompletely absorbed hydrogen chloride gas is absorbed through the secondary absorption tower with alkaline water; (3), the sodium sulfate formed after the reaction Add water to the solution and pour it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com