Disinfecting and sterilization method of water for making ice

A technology for disinfection and ice-making water, which is applied in the direction of oxidized water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. It can solve the problems of no killing effect on spores, small amount of treated water, and easy to produce dead ends. Achieve the effect of light weight, stable performance and uniform diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

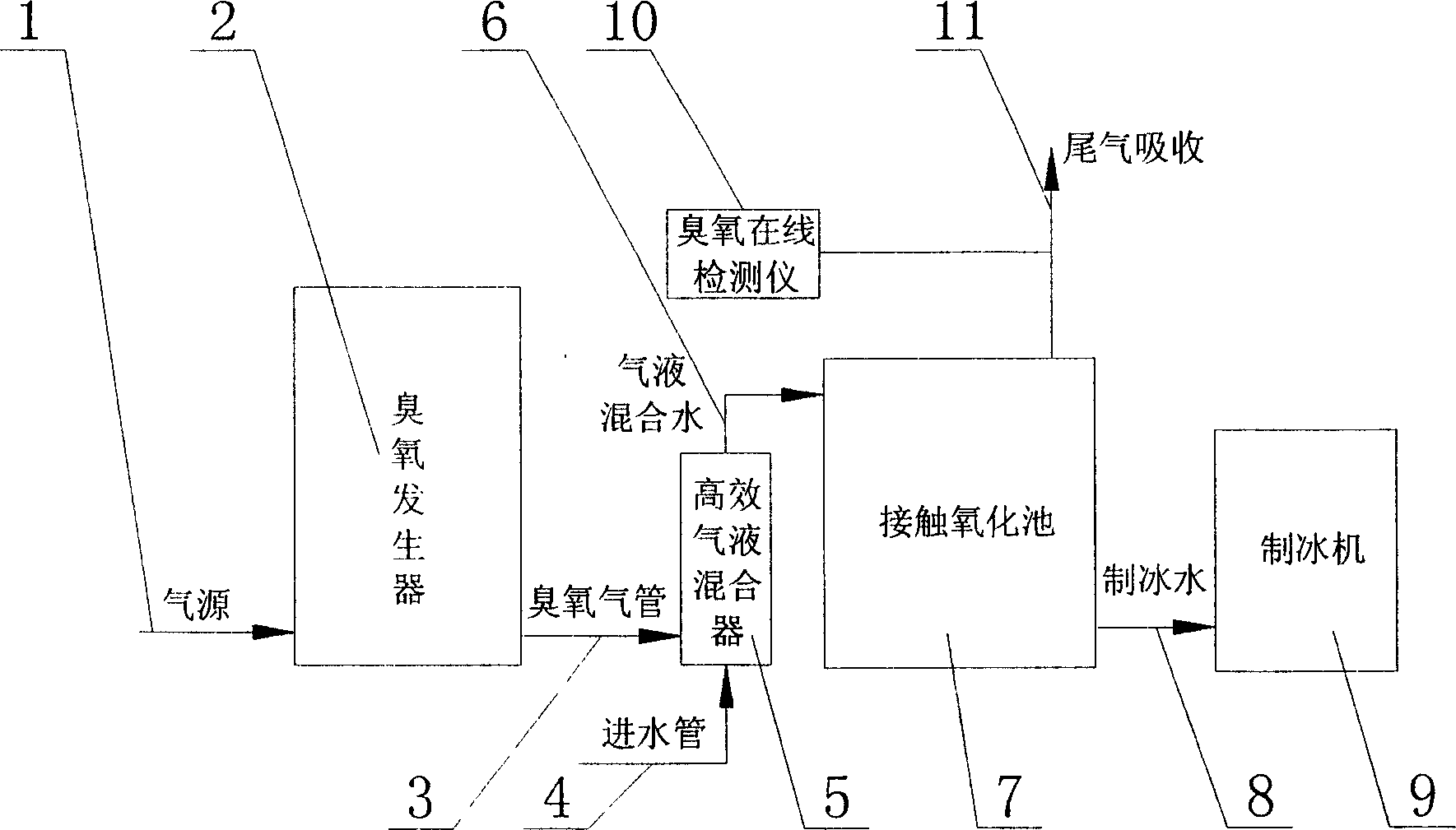

[0014] As shown in the figure, the ice-making water disinfection device of the present invention includes parts such as an ozone generator 2, a water inlet pipe 4, a high-efficiency gas-liquid mixer 5, a contact oxidation tank 7, an ice maker 9, and an online ozone detector 10. The ozone generator 2 described above is composed of a chassis, a high-voltage control power supply board, an ozone generating tube, a fan and a circulating water cooling system, a gas source flow control pipeline, and an electrical control system. When the ozone generator is powered on, the high-voltage power supply supplies the ozone generating tube to work, and the gas source 1 is adjusted and input to the ozone generating tube through the flow meter. 3 and the water entering the water inlet pipe 4 enter the high-efficiency gas-liquid mixer 5 at the same time, and the high-efficiency gas-liquid mixer is developed according to the principle of the Venturi tube. The mixer is made of stainless steel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com