Treatment method and device suitable for treatment of medium and high temperature organic waste gas

A technology of organic waste gas and treatment method, applied in the field of air pollution control, can solve the problems of difficult realization of the reaction and low reaction efficiency, and achieve the effects of reducing the mass transfer resistance of the gas-liquid interface, improving the reaction probability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

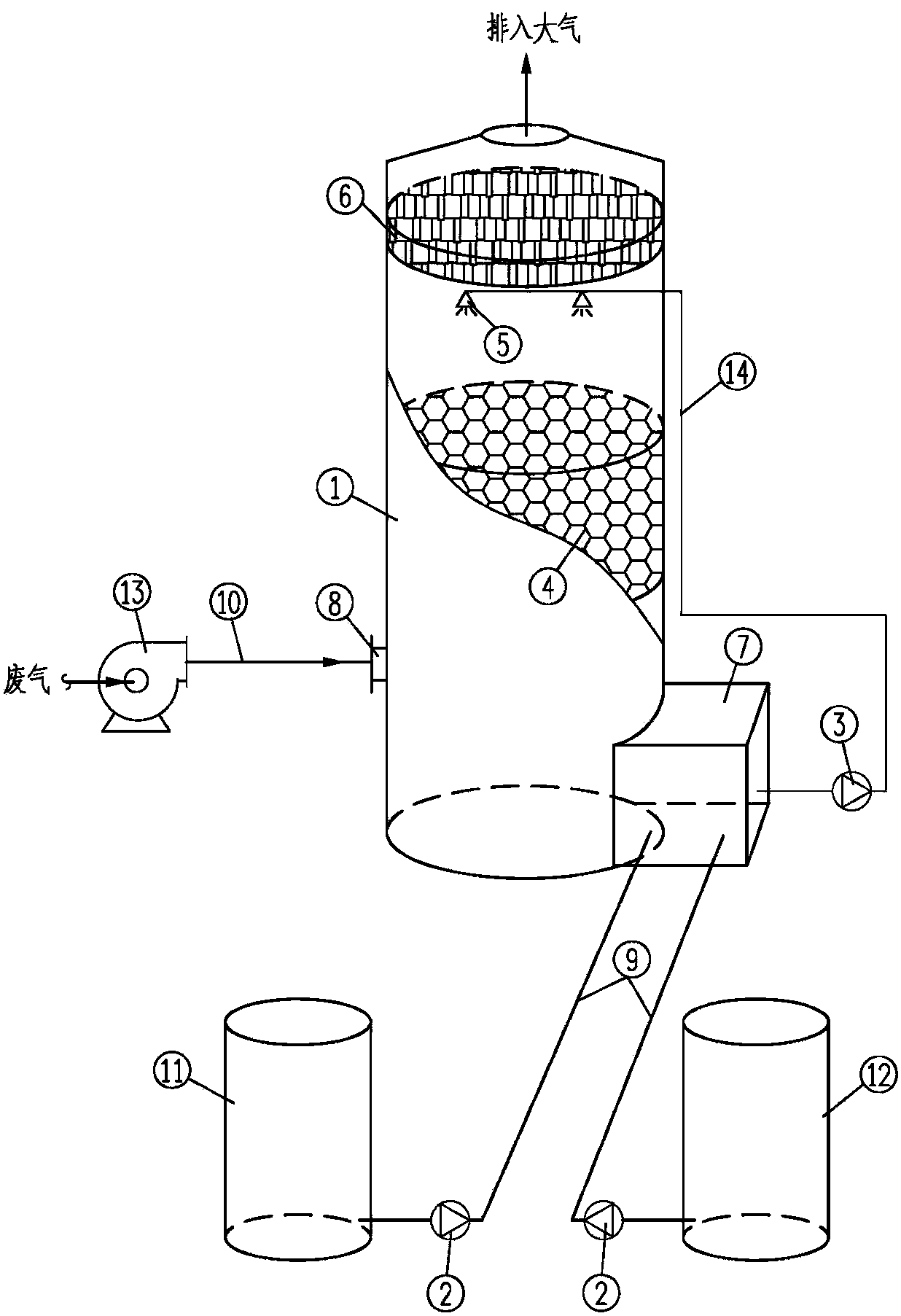

[0027] The waste gas treatment device mainly includes waste gas reaction tower 1, dosing pump 2, circulating water tank 7, circulating pump 3, high temperature resistant packing 4, atomizing nozzle 5 and demister 6, and circulating water tank 7 is set on one side of waste gas reaction tower 1 At the bottom, an air inlet 8 is provided at the bottom of the other side of the waste gas reaction tower 1, and the air inlet 8 is connected with an air inlet pipe 10, and a fan 13 is arranged on the air inlet pipe 10, and the medicine feeding end of the circulating water tank 7 passes through two pipes 9 respectively Connect the medicine storage box B11 and the medicine storage box C12, the atomization end of the circulating water tank 7 is connected to the atomization nozzle 5 through the pipeline 9, the atomization nozzle 5 is set in the waste gas reaction tower 1, and the mist eliminator 6 is set in the waste gas reaction tower 1 The top of the top, the high temperature resistant pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com