Venturi type desulfurizing device adopting spray drying method and desulfurizing method of desulfurizing device

A technology of spray drying method and desulfurization device, which is applied in the field of environmental engineering, can solve the problems of uniform distribution of flue gas, affect the stability of operation, uniformity and other problems, and achieve the effect of ensuring stability, improving reaction probability and increasing total surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

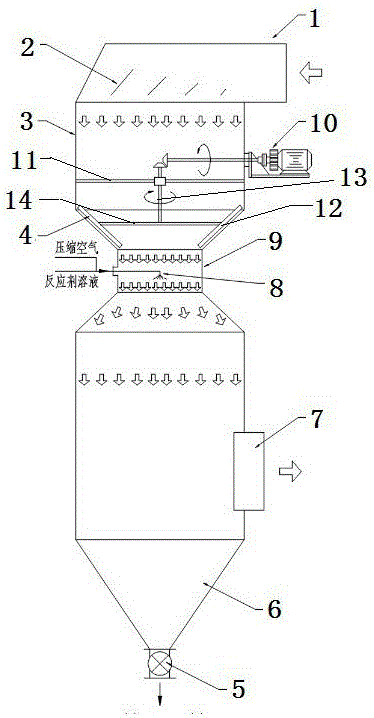

[0031] This embodiment provides a Venturi spray drying desulfurization device, such as figure 1 As shown, it includes the shell 3 of the desulfurization tower. The shell 3 of the desulfurization tower adopts a vertical cylindrical tower-shaped structure. The ash hopper outlet 6 is arranged on the body and the air outlet 7 is arranged on the side wall of the lower part of the tower body; the venturi throat 9 is connected to the upper part of the tower body and the tower body respectively upwards and downwards in a variable diameter connection. In the lower body shell, a nozzle 8 is arranged in the venturi throat 9, and the connecting pipeline of the nozzle 8 passes through the pipe wall of the Venturi throat 9 to externally connect the jet pump and the air compressor.

[0032] The device of this embodiment mainly uses the reactant solution to remove SO in the flue gas through chemical reaction. 2 , the pH value of the solid reaction by-products is neutral or alkaline, no waste...

Embodiment 2

[0034] This embodiment is further improved on the basis of Embodiment 1. The internal cross-sectional area of the Venturi throat 9 is 1 / 3 to 1 / 4 of the internal cross-sectional area of the desulfurization tower shell 3. Due to the rapid reduction of the cross-sectional area , the flue gas velocity is greatly increased.

[0035] The angle between the variable-diameter side wall of the variable-diameter section where the throat of the Venturi pipe 9 is connected to the upper shell of the tower body and the lower shell of the tower body and the flow direction of the flue gas is 45-60°. The diameter change of the upper part of the tower acts as a flow guide to reduce the resistance loss at the venturi throat 9; after the diameter reduction of the lower part of the tower, the flue gas can be evenly distributed in the cross-section of the desulfurization tower under the action of airflow diffusion.

Embodiment 3

[0037] In this embodiment, a dust-scraping device is added on the basis of Embodiment 1 and Embodiment 2. Specifically, a dust-scraping device 4 is provided at the inner wall of the variable-diameter end where the Venturi throat 9 is connected to the upper shell of the tower body.

[0038] The dust scraping device 4 includes a bracket 11, a scraper 12 and a motor 10. The bracket 11 is braced on the inner wall of the upper shell of the tower body, and the scraper 12 is attached to the variable distance between the venturi throat 9 and the upper shell of the tower body. On the inner wall of the radial section, the output shaft of the motor 10 is connected to a vertically arranged transmission shaft 13 with a helical gear at the end through a helical gear, and the other end of the transmission shaft 13 is connected to the scraper 12 through a connecting piece 14, and the transmission shaft 13 passes through Pass the bracket 11 and be installed on the bracket 11 through the bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com