Gas mixing method

A technology of gas mixing and gas mixer, which is applied in the direction of mixing method, gas and gas/steam mixing, mixer, etc., can solve problems such as stall instability, dust accumulation, flue wear, etc., and achieve the effect of reducing airflow resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

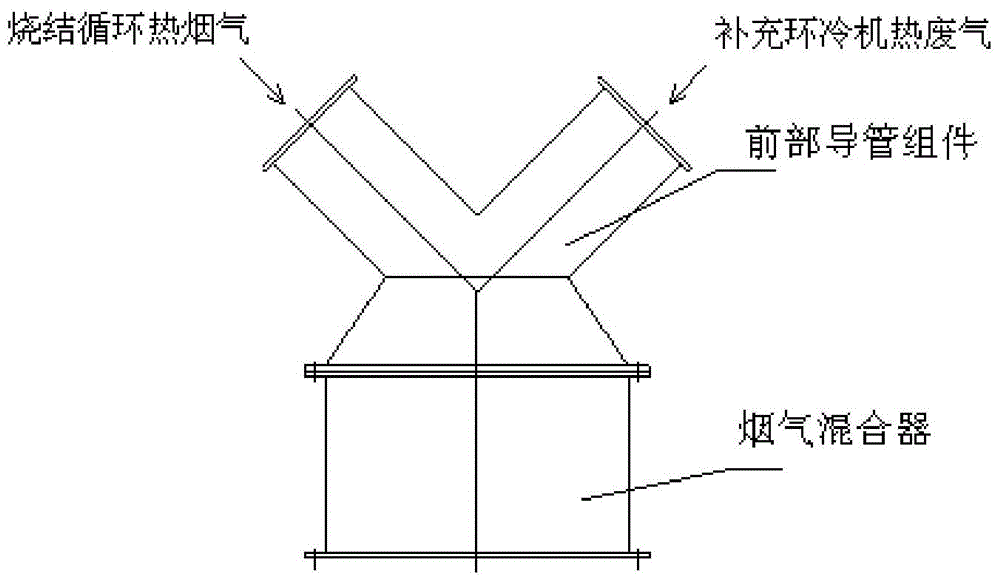

[0044] Embodiment 1 A kind of gas mixer

[0045] This embodiment provides a gas mixer, including a mixing cylinder 1, and a guide body 2 located in the mixing cylinder, coaxially arranged on the same bottom surface as the mixing cylinder; 6. At the lower end of the side wall of the mixing cylinder, two air inlet pipes 4 and 5 are arranged symmetrically with the center of the bottom surface of the mixing cylinder as a symmetrical point, and the air inlet directions of the two air inlet pipes are opposite.

[0046] The length Y of the mixing cylinder is in a certain proportion to the diameter X, and the optimum ratio is Y=(1.5~2)X; the mixing cylinder can be used vertically, horizontally, or tilted. The placement does not affect the mixing effect.

[0047] The diameters a and b of the inlet pipe are both determined by the total amount of gas and the flow rate, so as to ensure that the two airflows can rotate in the same direction after entering the mixing cylinder; correspondin...

Embodiment 2

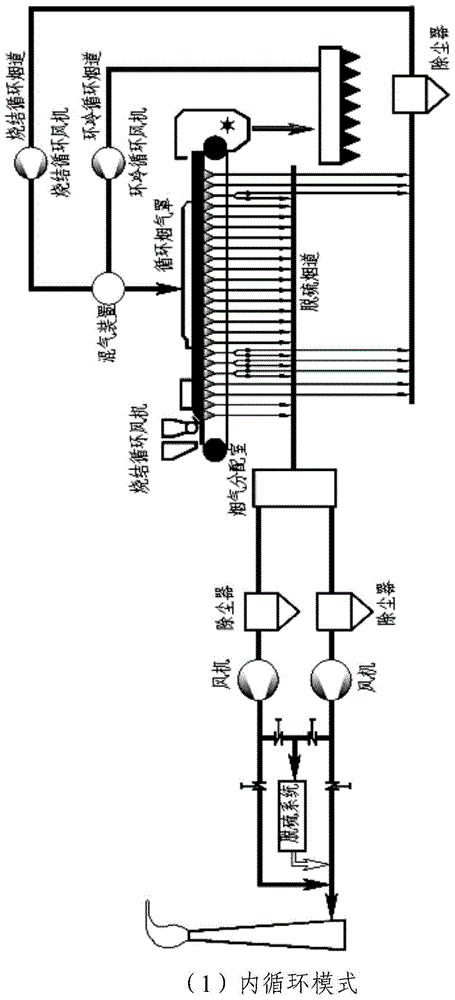

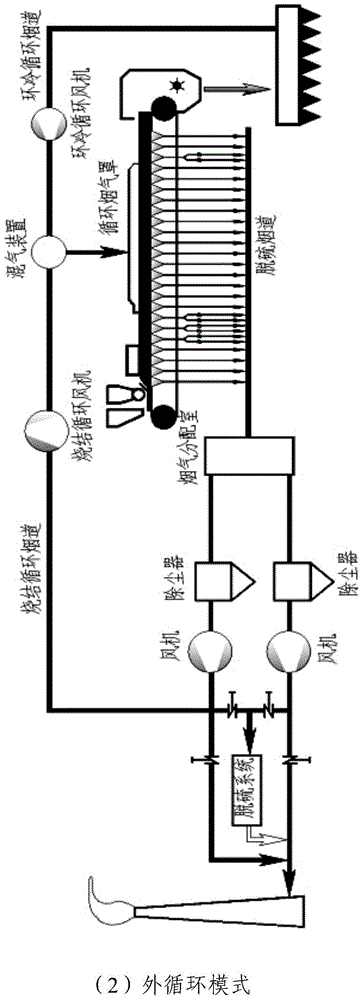

[0051] Embodiment 2 A method of gas mixing in a sintering flue gas circulation process

[0052] This embodiment provides a method for using the gas mixer described in the above embodiment 1 for gas mixing in the sintering flue gas circulation process, which specifically includes the following steps:

[0053] (1) Determine the size of the gas mixer:

[0054] According to the actual production requirements, the sintering circulation flue gas is 8000m 3 / min, the flow rate is 16.7m / s, and the hot exhaust gas of the ring cooling cycle is 8500m 3 / min, the flow rate is 16.7m / s; the mixed gas flow rate is 24m / s;

[0055] After calculation, the diameter of the intake pipe of the sintering cycle flue gas is a=3.2m, the diameter of the intake pipe of the hot exhaust gas of the ring cooling cycle is b=3.3m, the diameter of the bottom of the mixing cylinder of the entire flue gas mixer is X=8m, and the height Y=12m , the diameter of the bottom surface of the guide body Z=4m, the slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com