Copper removal method

A technology of cuprous sulfite and sodium sulfide, which is applied in the nickel electrolysis anolyte purification process and in the field of copper removal, can solve the problems of high labor intensity, unfavorable environmental protection, complicated process, etc., to reduce labor intensity, facilitate automatic control, increase The effect of reaction probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

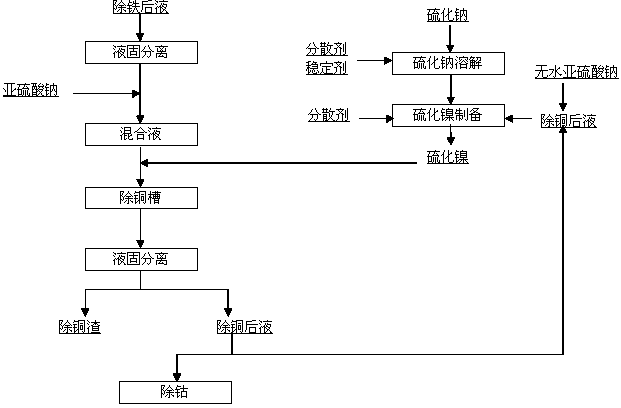

Image

Examples

Embodiment 1

[0032] A method for removing copper, the concrete steps are as follows:

[0033] a, sodium sulfide dissolved

[0034] Add tap water at a temperature of 5~25°C to the sodium sulfide dissolving tank, add a stabilizer, the volume ratio of the stabilizer to tap water is 0.18:100, stir for 10~20 minutes, add industrial sodium sulfide with a purity of 60%, and dissolve the sodium sulfide Control the concentration at 90g / l, stir for 1-1.5 hours, then add dispersant, the volume ratio of dispersant to tap water is 0.15:100, stir for 0.5-1 hour;

[0035] b. Preparation of amorphous nickel sulfide

[0036] Take another container and add the solution after copper removal, the nickel concentration in the solution after copper removal is 75g / l, the temperature is 20~40°C, the pH value is 3.2~3.6, add anhydrous sodium sulfite, stir for 0.5~1 hour, the concentration of sodium sulfite after dissolution is 0.8g / l, then add dispersant, the volume ratio of dispersant to copper solution is 0.2:1...

Embodiment 2

[0042] A method for removing copper, the concrete steps are as follows:

[0043] a, sodium sulfide dissolved

[0044] Add tap water at a temperature of 5~25°C to the sodium sulfide dissolving tank, add a stabilizer, the volume ratio of the stabilizer to tap water is 0.25:100, stir for 10~20 minutes, add industrial sodium sulfide with a purity of 60%, and dissolve the sodium sulfide Control the concentration at 120g / l, stir for 1-1.5 hours, then add dispersant, the volume ratio of dispersant to tap water is 0.2:100, stir for 0.5-1 hour;

[0045] b. Preparation of amorphous nickel sulfide

[0046] Take another container and add the solution after copper removal, the nickel concentration in the solution after copper removal is 85g / l, the temperature is 20~40°C, the pH value is 3.2~3.6, add anhydrous sodium sulfite, stir for 0.5~1 hour, the concentration of sodium sulfite after dissolution is 1g / l, then add dispersant, the volume ratio of dispersant to copper solution is 0.25:10...

Embodiment 3

[0052] A method for removing copper, the concrete steps are as follows:

[0053] a, sodium sulfide dissolved

[0054] Add tap water with a temperature of 5~25°C into the sodium sulfide dissolving tank, add a stabilizer, the volume ratio of the stabilizer to tap water is 0.2:100, stir for 10~20 minutes, add industrial sodium sulfide with a purity of 60%, and dissolve the sodium sulfide Control the concentration at 100g / l, stir for 1-1.5 hours, then add dispersant, the volume ratio of dispersant to tap water is 0.18:100, stir for 0.5-1 hour;

[0055] b. Preparation of amorphous nickel sulfide

[0056] Take another container and add the solution after copper removal, the nickel concentration in the solution after copper removal is 80g / l, the temperature is 20~40°C, the pH value is 3.2~3.6, add anhydrous sodium sulfite, stir for 0.5~1 hour, the concentration of sodium sulfite after dissolution is 0.9g / l, then add dispersant, the volume ratio of dispersant to copper solution is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com