Patents

Literature

43results about How to "Meet the purification requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

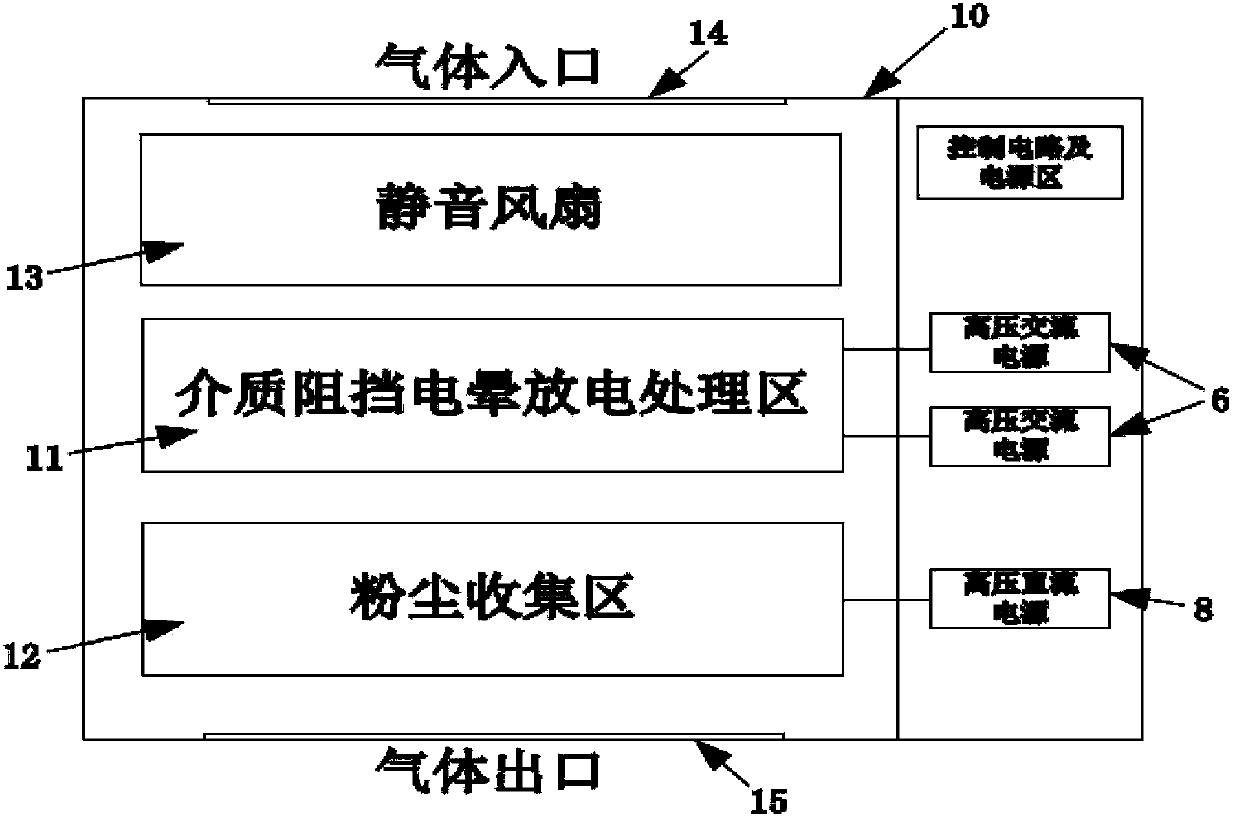

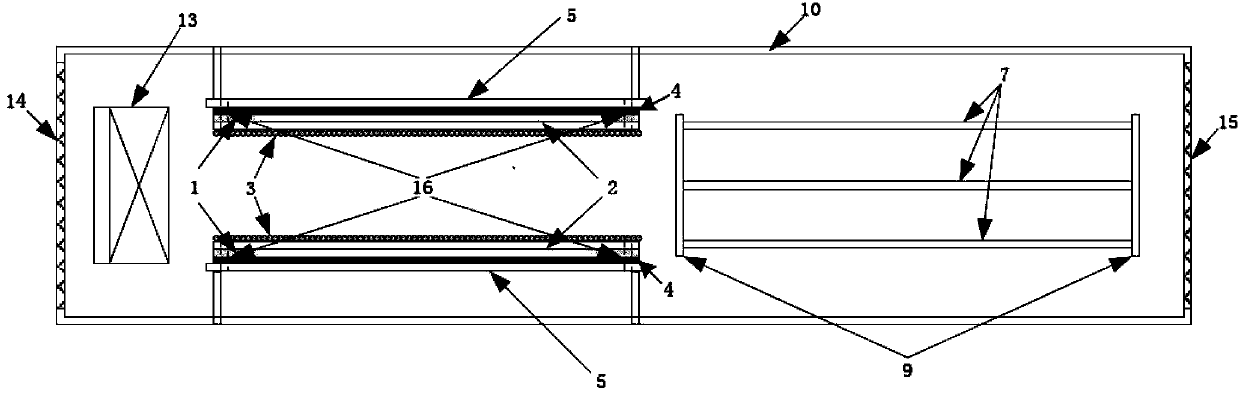

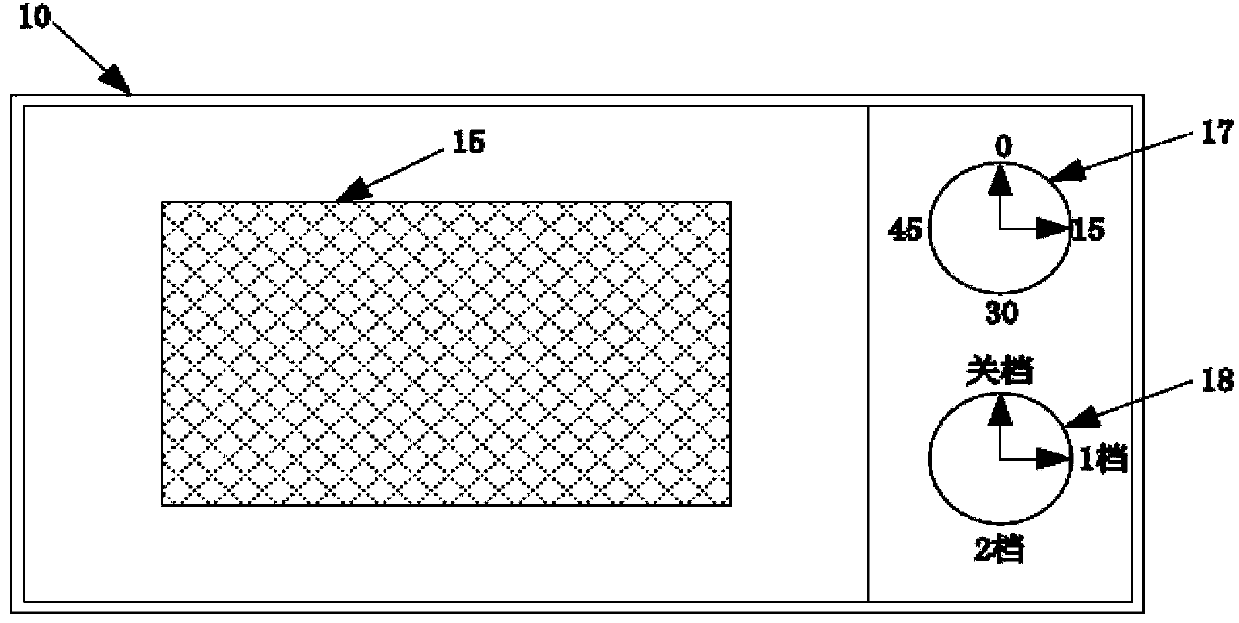

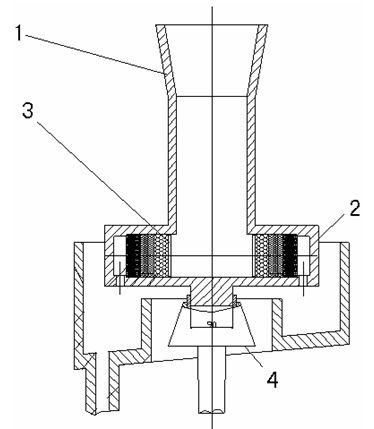

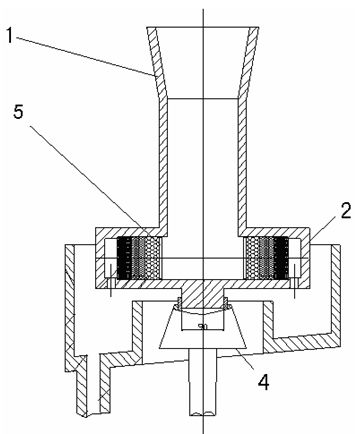

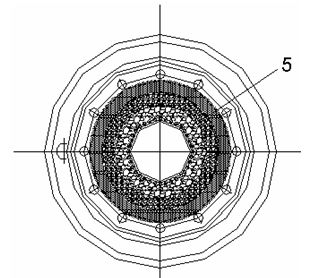

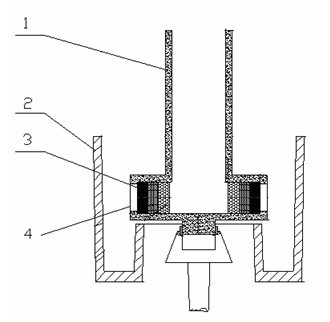

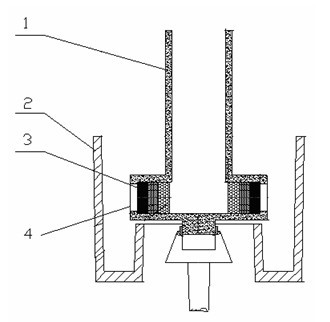

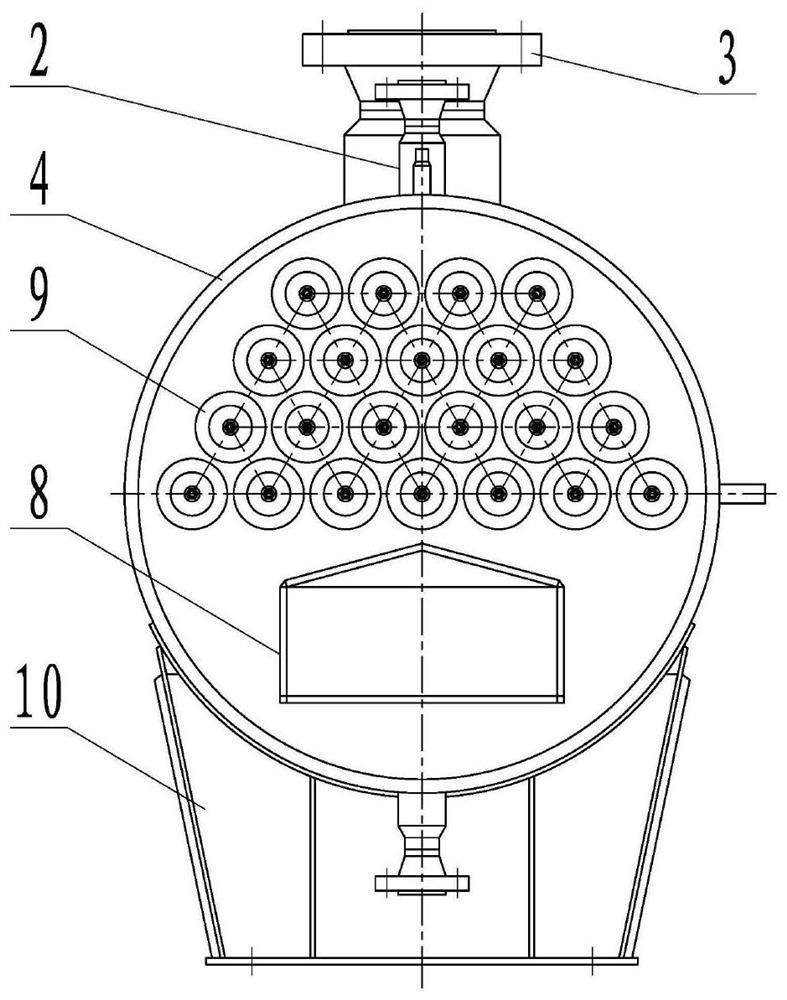

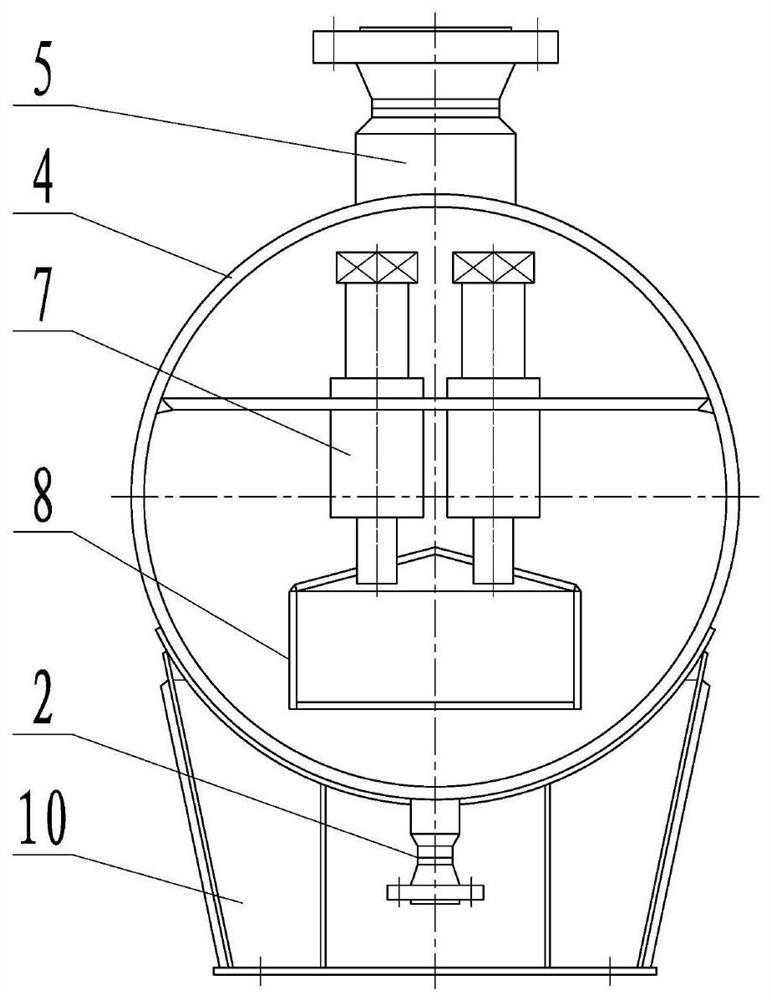

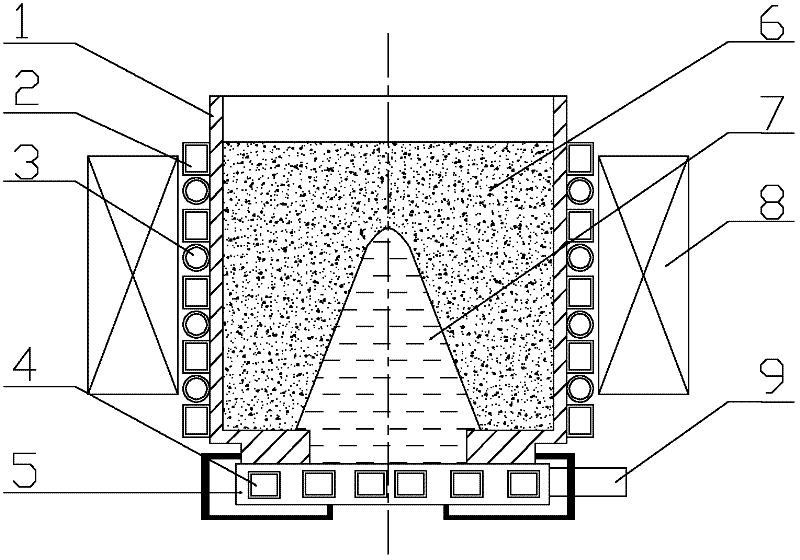

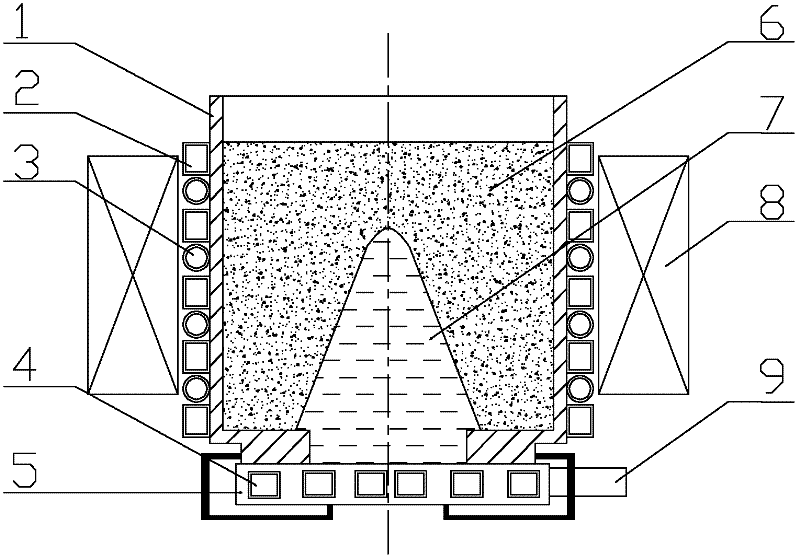

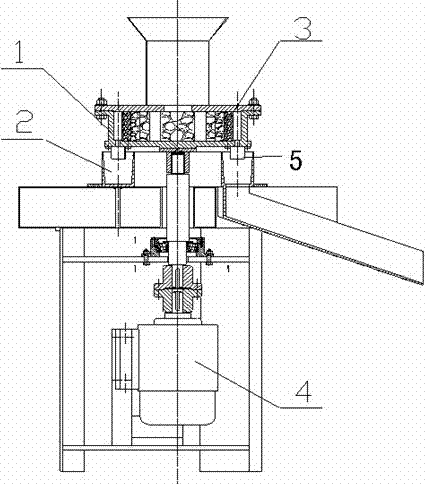

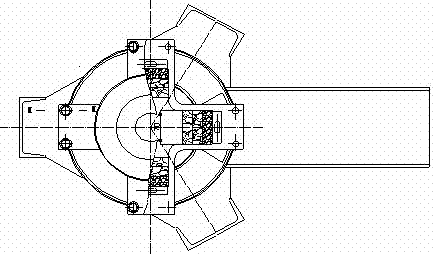

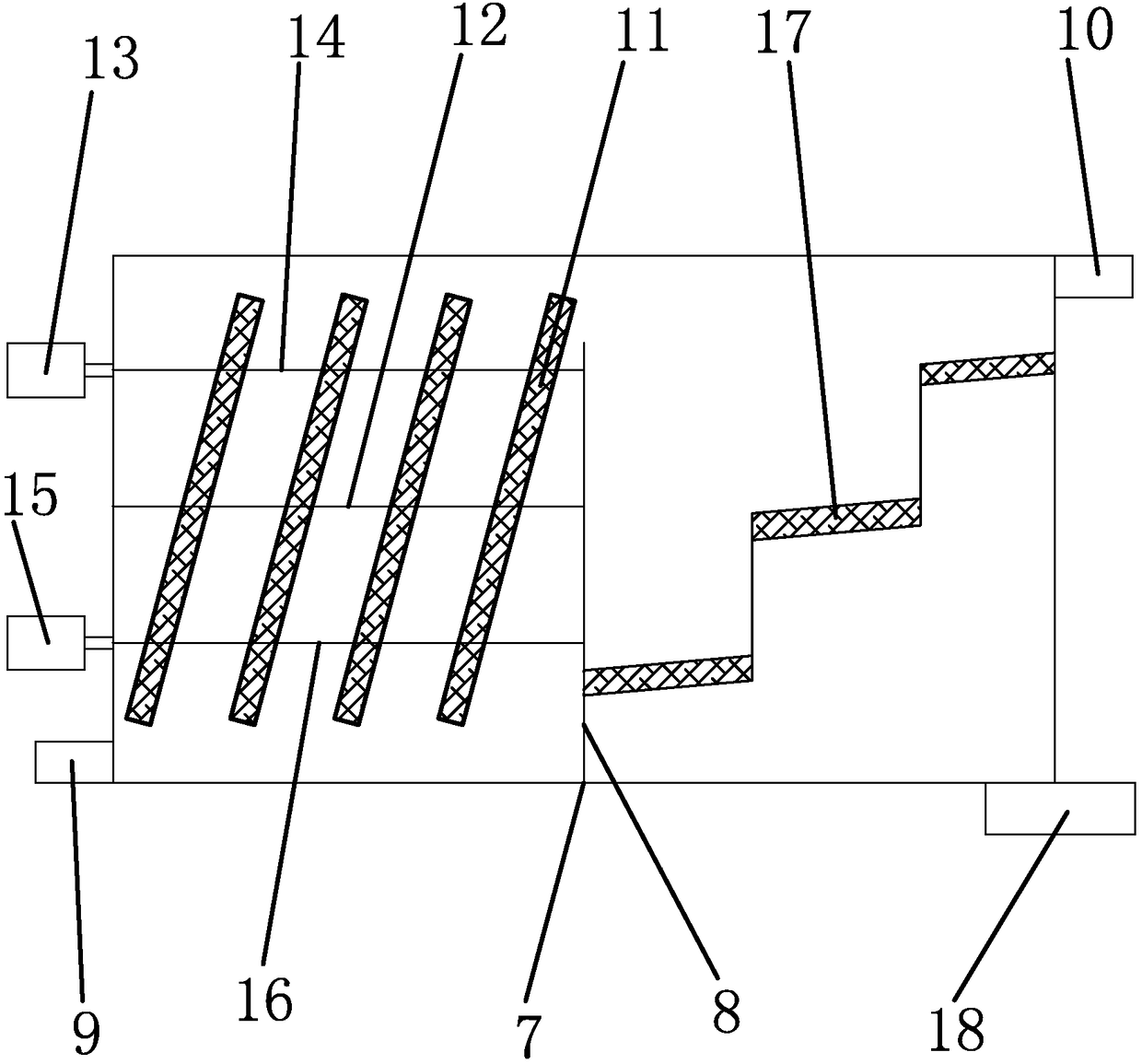

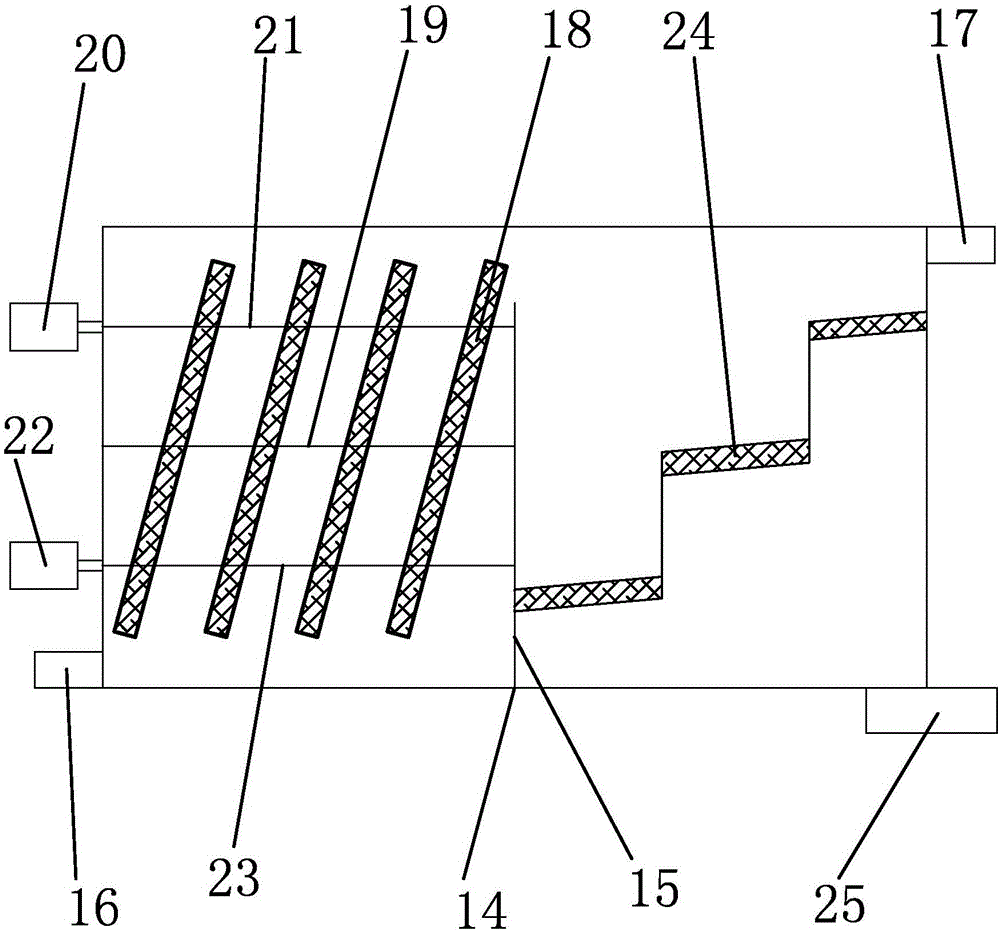

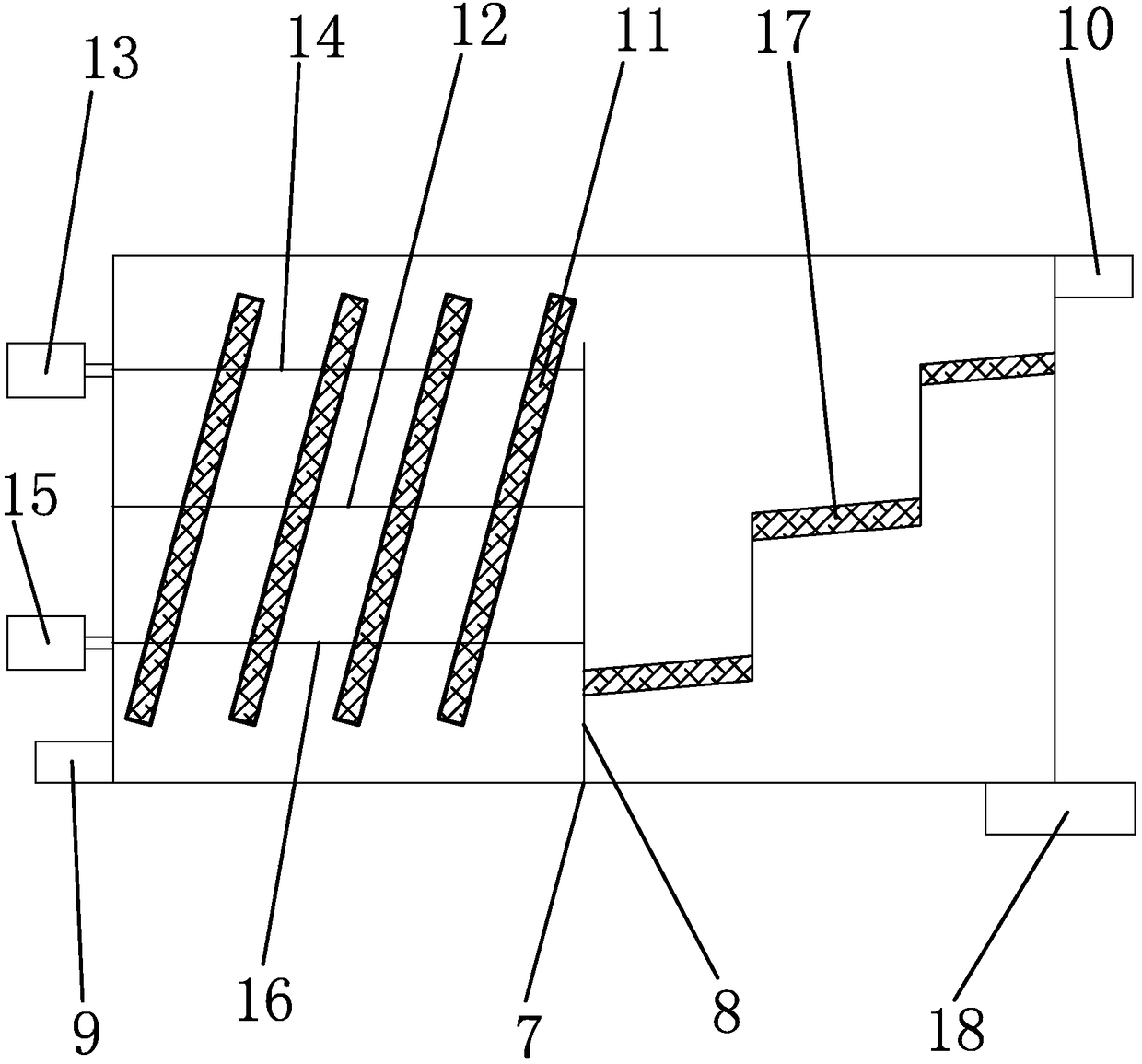

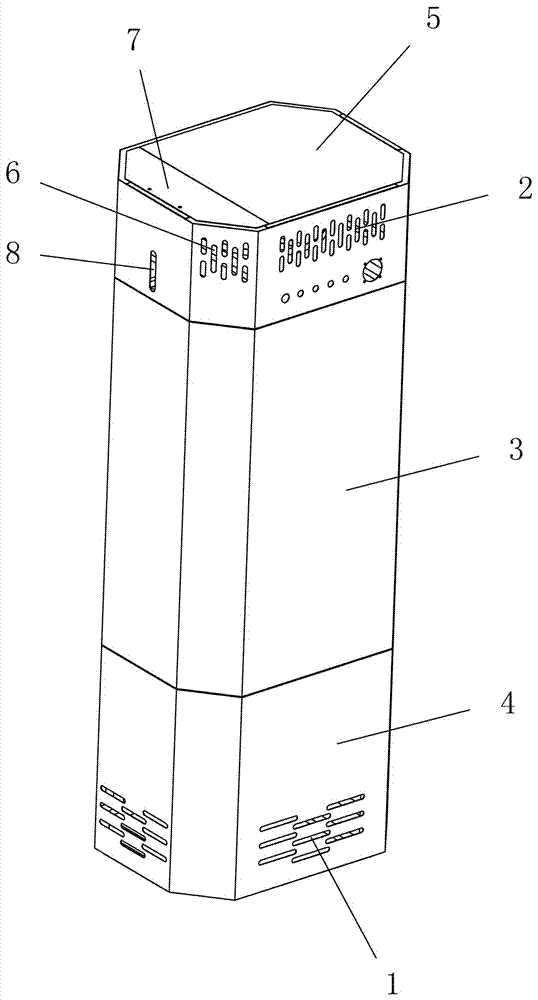

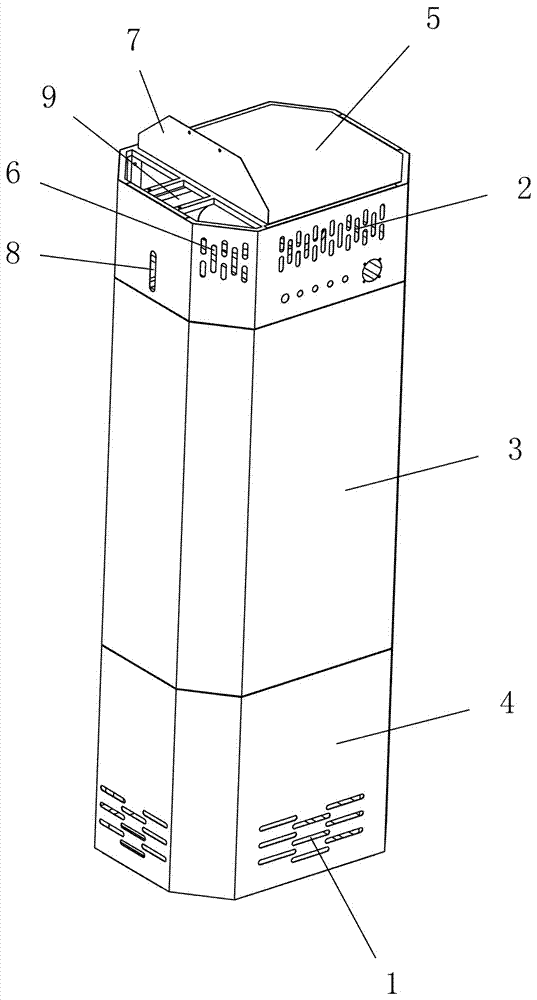

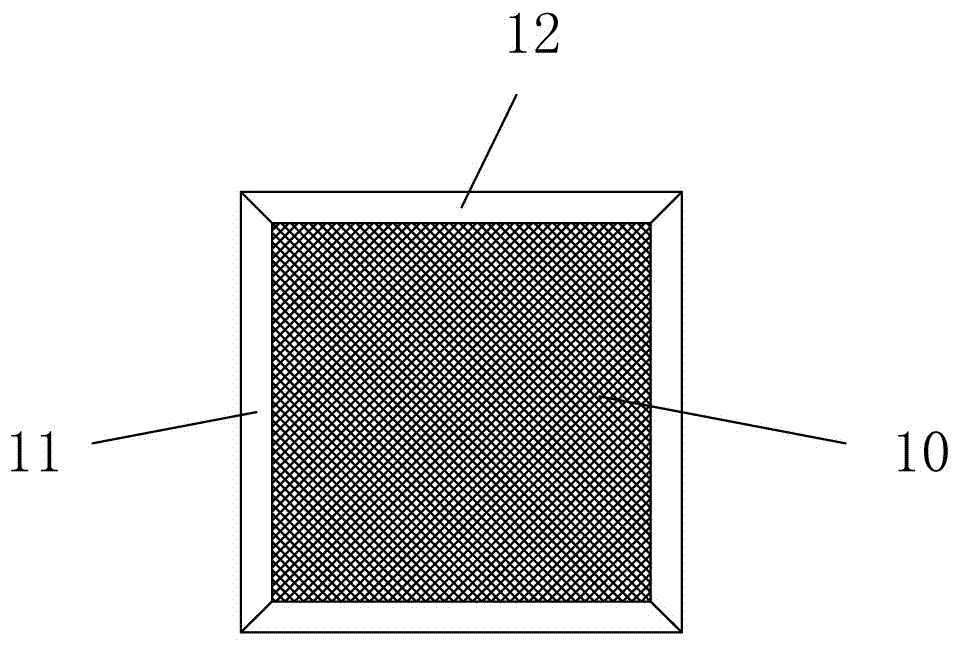

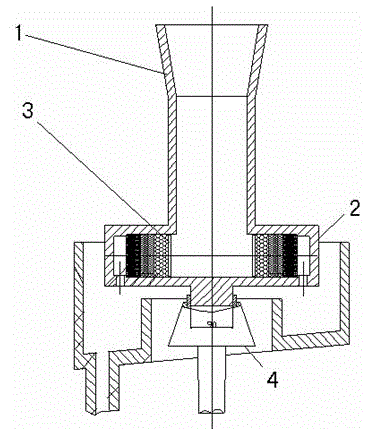

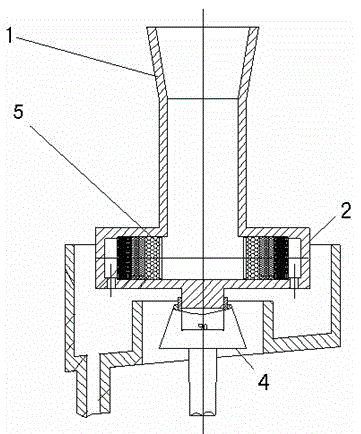

Indoor gas purification device based on discharge plasma

ActiveCN103388858AAchieving heteropolar chargingImprove adsorption capacityLighting and heating apparatusDeodrantsDielectricInhalable particles

The invention discloses an indoor gas purification device based on discharge plasma, comprising a shell provided with a gas inlet and a gas outlet, wherein a fan, a dielectric barrier corona discharge processing region and a dust collecting region are arranged in the shell between the gas inlet and the gas outlet. According to the indoor gas purification device, more uniform low-temperature plasma is generated by two discharge units which are arranged oppositely, oxidation processing is carried out on harmful gas in the dielectric barrier corona discharge processing region, heteropolarity charge electrocoagulation and processing are carried out on inhalable particles, the inhalable particles are collected in the dust collecting region, and the device has the advantages that no chemical agent and no physical additive are used, no special gas atmosphere exists, the energy consumption is low, indoor gas purification is realized under barometric pressure, and the effect is good.

Owner:XI AN JIAOTONG UNIV

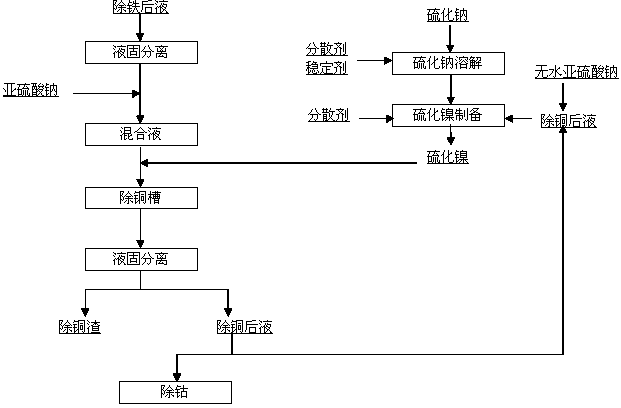

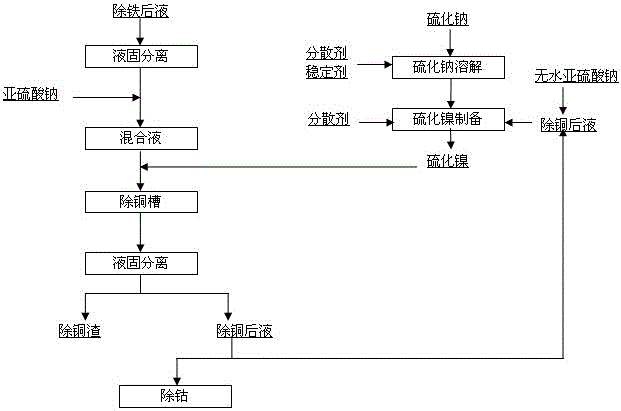

Copper removal method

ActiveCN103820809AIncreased chance of reactionShort processElectrolysis componentsPhotography auxillary processesAutomatic controlElectrolysis

The invention relates to a chemical purification method, especially to a copper removal method which is suitable for a nickel electrolysis anolyte purification process. The copper removal method provided by the invention is obviously different from a copper removal method by adding anode mud in nickel ore concentrate as follows: a sodium hydrosulphite solution is added in an iron-removed liquid to activate copper ions and increase reaction probability between copper ions and amorphous nickel sulfide; as amorphous nickel sulfide is added into a copper removal tank in a slurry form, labor intensity is reduced, it is convenient to realize automatic control, and stabilization and continuity of the copper removal process are guaranteed; and as copper slag can directly enter a copper melting system, the technology is optimized, flow of copper impurity in the system is shortened, copper slag is processed not by the use of chlorine, and the environment is improved. Through detection, a copper-removed liquid contains 0.4-2.5ppm of copper. Thus, purification requirements are met. The mass ratio of copper to nickel in the copper slag is 15-17. The copper slag can be directly melted to produce anode plates.

Owner:JINCHUAN GROUP LIMITED +1

Method for purifying montmorillonite from bentonite ore by twice dispersion method

InactiveCN101391779AReduce viscosityImprove purification efficiencySilicon compoundsSodium BentoniteMontmorillonite

The invention relates to a method for purifying montmorillonite from bentonite ore by using double dispersion method; the method adopts the hydrogen peroxide as dispersant of 'I'-shaped structure, then the hydrogen peroxide is fully mixed with the pulp so as to cause the hydrogen peroxide to be completely infiltrated into each film layer of the 'I'-shaped structure, later sodium pyrophosphate dispersant is added and conclusion is opened so as lower the pulp viscosity, ease the impurities gravity settlement, and provide a relatively 'smooth' path for the impurities settlement inside and outside the 'I'-shaped structure. As the added gas dispersant is provided with stronger oxidation, the hydrogen peroxide is decomposed into gas under slightly-heating circumstance, and the gas is expanded for distracting the 'I'-shaped structure so as to cause the hidden impurities to be precipitated due to the loss of support, thereby eliminating a small amount of organic substances in the natural bentonite by oxidation and simultaneously playing a bactericidal action, and purifying montmorillonite by separation as any pollution is not brought. The method is non-toxic, has simple operation process, and can easily achieve batch production.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

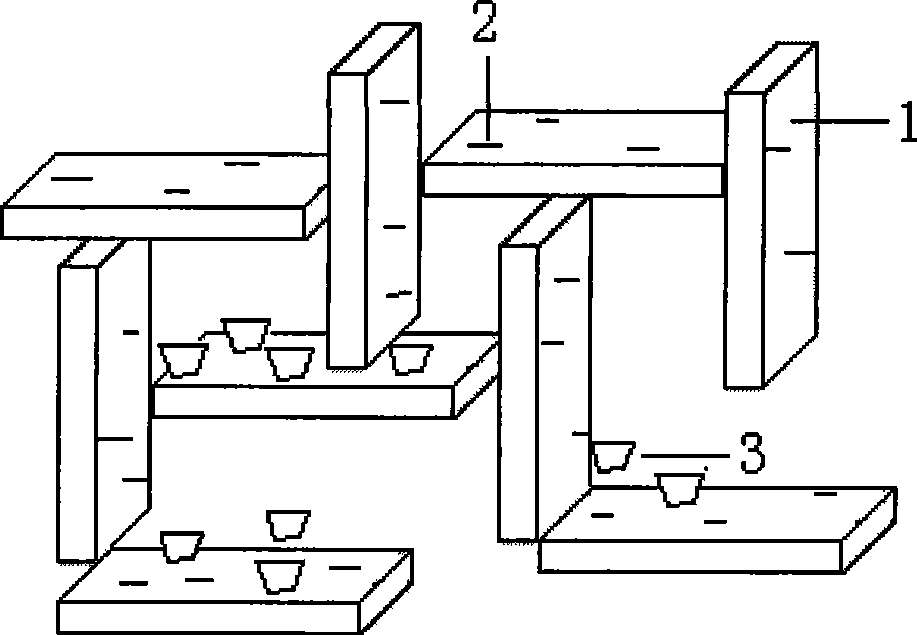

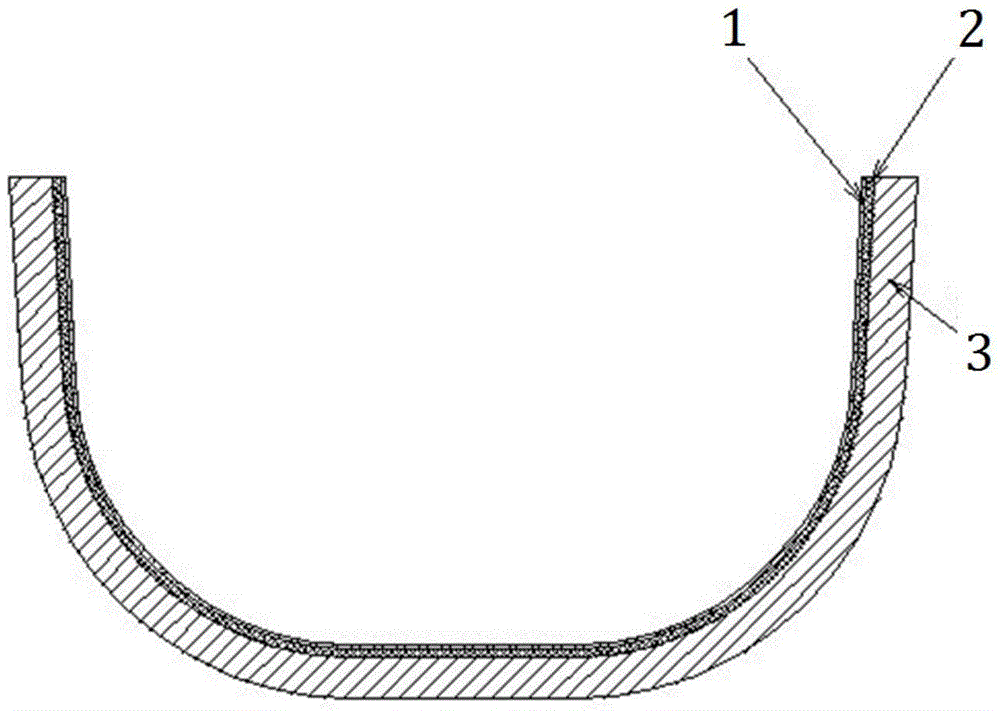

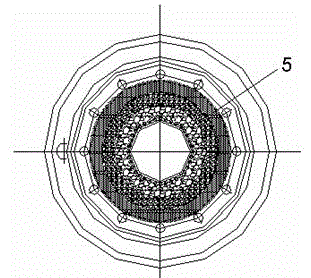

Method for composite-filtering multiple filter media in aluminum-alloy-melt centrifuge field

InactiveCN102069147AMeet the purification requirementsSimple methodFoundry mouldsFoundry coresTemperature resistanceCast iron

The invention discloses a method for composite-filtering foamed ceramics in aluminum-alloy centrifuge field, which comprises the following steps: (1) prefabricating a high-temperature resistance metal sprue, which is made of special-shaped cast iron or steel with a sprue and an export channel vertical to the sprue combined, applying zinc oxide - a water-glass coating or a lining refractory free of aluminium to the inside of the sprue, and placing a plurality of high-temperature resistance ceramic filters in the export channel of the sprue, wherein the ceramic filters are stacked within the export channel and arranged inside-out in an order from big pore to small pore, and the total thickness of the filters is 20-300 mm; (2) fastening the high-temperature resistance metal sprue in a centrifugal device, wherein the sprue axis coincides with a spin axis of the centrifugal device; (3) preheating the sprue and the foamed ceramics to 400 DEG C before pouring; and (4) starting the centrifugal device to rotate the sprue, with the rotary speed of the centrifugal device in a range of 10-3000 r / min, and then pouring the aluminum melt to enable the aluminum-alloy melt to pass through the ceramic filters under the centrifugal force. The method provided by the invention has the advantages that the method is easy to operate, and the clearance rate of oxides of more than 1 mu m can reach over90% after the aluminum alloy is purified.

Owner:NANCHANG HANGKONG UNIVERSITY

Foam ceramic composite filtering method for high-temperature alloy in centrifugal field

InactiveCN102086488ASimple methodEasy to operateProcess efficiency improvementOxideCeramic composite

The invention discloses a foam ceramic composite filtering method for a high-temperature alloy in a centrifugal field. The method comprises the following steps: (1) prefabricating a special-shape refractory ceramic runner combining a sprue and an outlet channel vertical to the sprue, and placing multiple foam ceramic filtering sheets in the outlet channel of the runner; (2) superposing the axis of the sprue on the rotation axis of a centrifuge device; (3) before pouring, preheating the runner and the foam ceramic sheets to over 1000 DEG C; and (4) starting the centrifuge device to rotate the runner, wherein the rotation speed of the centrifuge device ranges from 10 r / min to 3,000 r / min; and pouring the high-temperature alloy melt which passes through the foam ceramic filtering sheets under the action of centrifugal force. The invention has the advantages that: the method is simple and convenient to operate; and after the high-temperature alloy is purified, the removal rate of oxides larger than 1 mu m can reach over 90%, and the purification requirements on the mother alloy or returns of the high-temperature alloy in the manufacturing of modern aircraft engines are completely met.

Owner:NANCHANG HANGKONG UNIVERSITY

Iron-based crucible protection composite coating for refined aluminum purification

ActiveCN104889036AGood paintabilityAvoid erosionPretreated surfacesCrucible furnacesPolyvinyl alcoholIsolation layer

An iron-based crucible protection composite coating for refined aluminum purification comprises an isolation layer and an abrasion reduction layer. The isolation layer comprises aluminum oxide serving as refractory aggregates and aluminum dihydrogen phosphate serving as bonding agents. The abrasion reduction layer comprises boron nitride serving as refractory aggregates, polyvinyl alcohol serving as thermal expansion buffering agents and aluminum dihydrogen phosphate serving as bonding agents. By means of the composite coating, the problem of cracks of acoating layer caused by large differences between thermal expansion coefficients of coatings formed by single substance and blending agents and the iron crucible in the prior art is solved. The composite coating has the advantages that the strength and the compactness are high, and de-molding can be performed easily.

Owner:SHANGHAI JIAO TONG UNIV

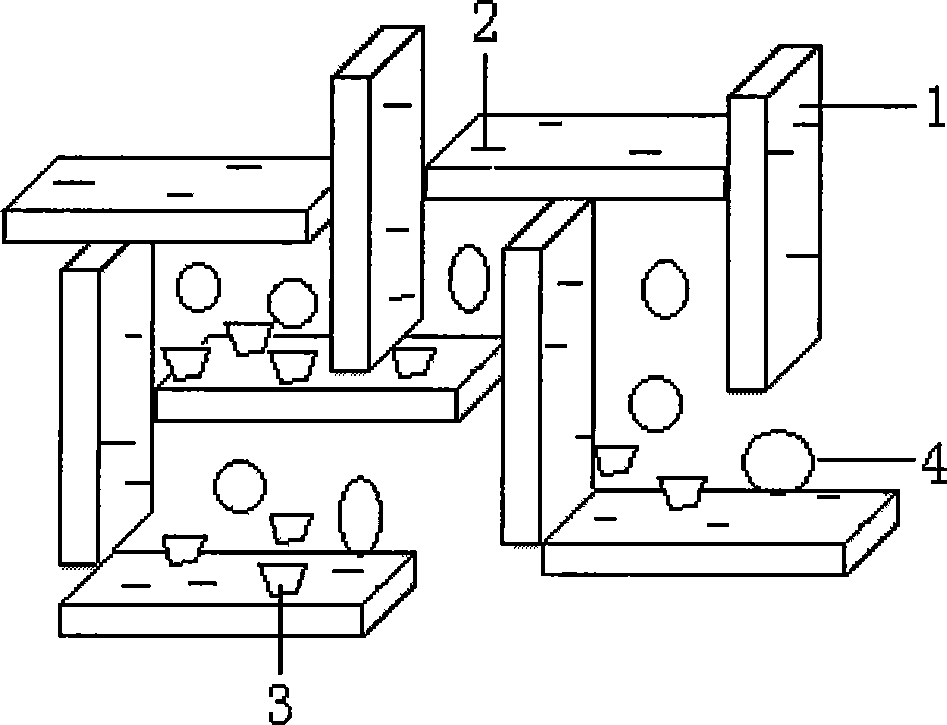

Composite purification method for zinc and zinc alloy

InactiveCN102146517AMeet the purification requirementsNo pollution in the processProcess efficiency improvementPurification methodsNitrogen

The invention discloses a composite purification method for zinc and zinc alloy. The method comprises the following steps of: before zinc melt or zinc alloy melt is fed into a purification chamber from a furnace tank of a smelting furnace, performing primary micron bubble purification, wherein industrial pure nitrogen is adopted in the purification mode, the pressure intensity is 0.3 to 0.8MPa, and the aperture of an air blowing plug is set at 30 microns to 1 micron; after the primary micron bubble purification, making the melt flow through a primary bubble ceramic filter plate to enter a middle purification chamber; and after secondary micron bubble purification and purification with a secondary bubble ceramic filter plate, making the melt enter a sluice front chamber to wait for casting. The device is simple, the cost is low, and the method totally has no environmental pollution and accords with the requirement of modern green production.

Owner:NANCHANG HANGKONG UNIVERSITY

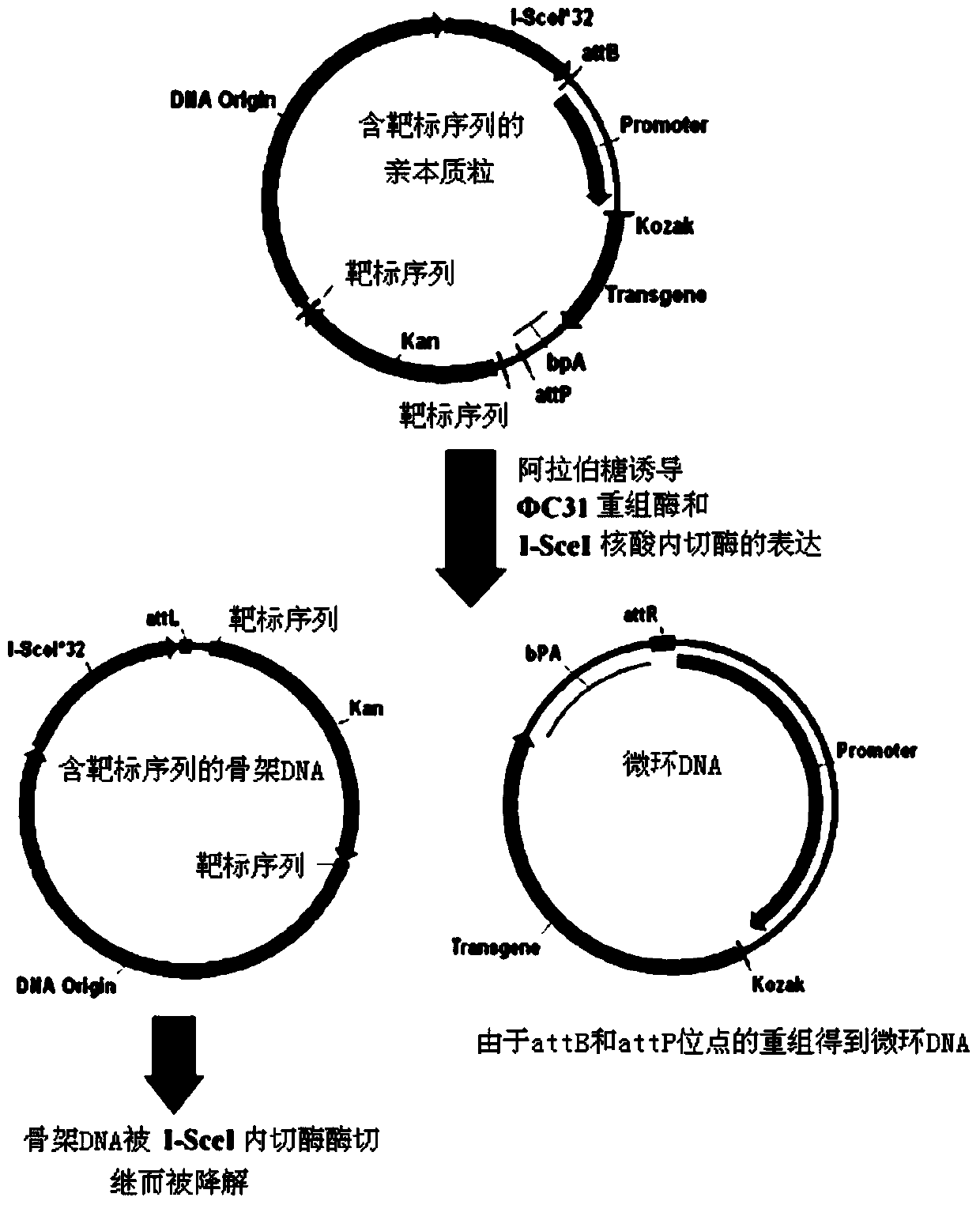

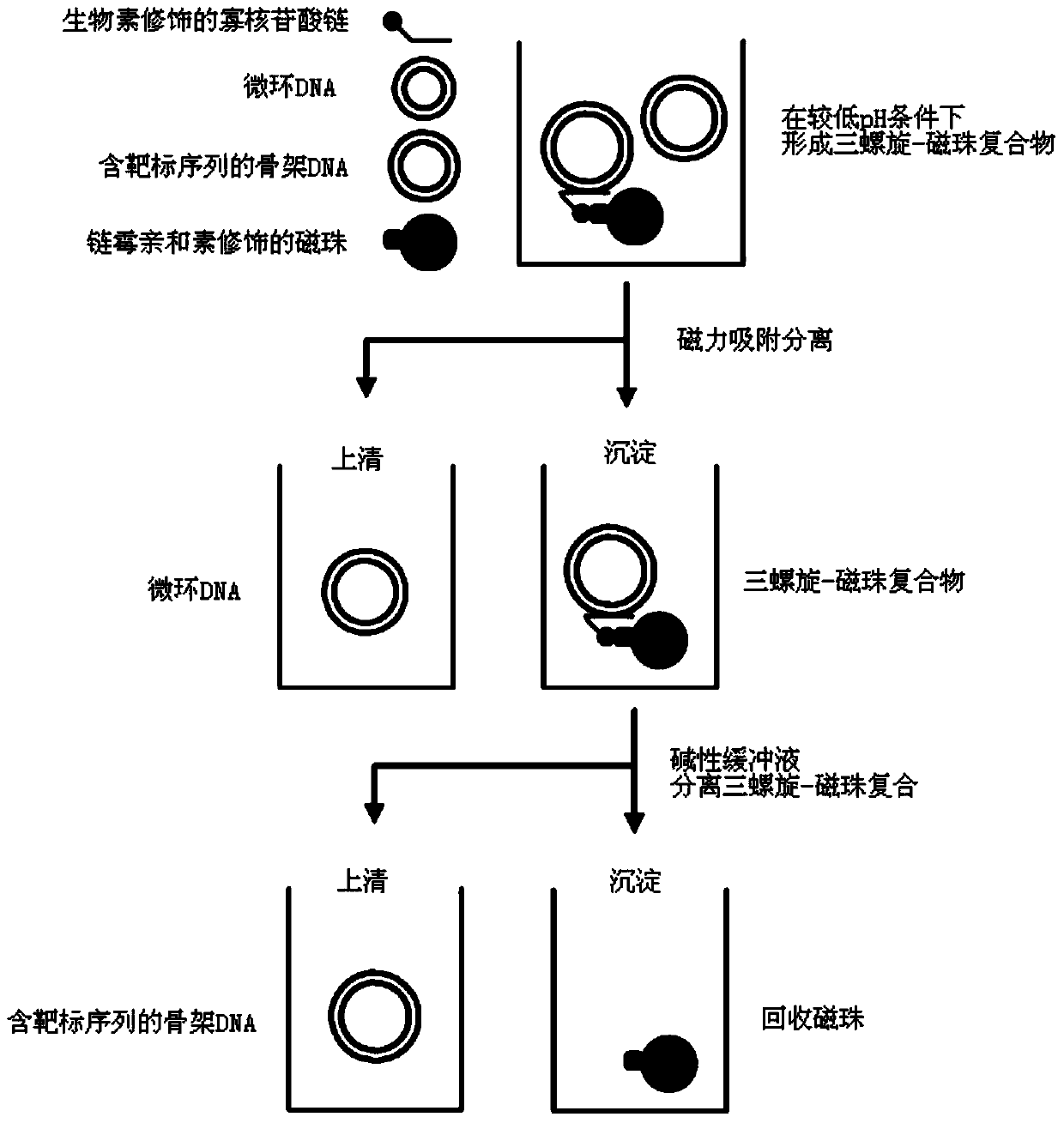

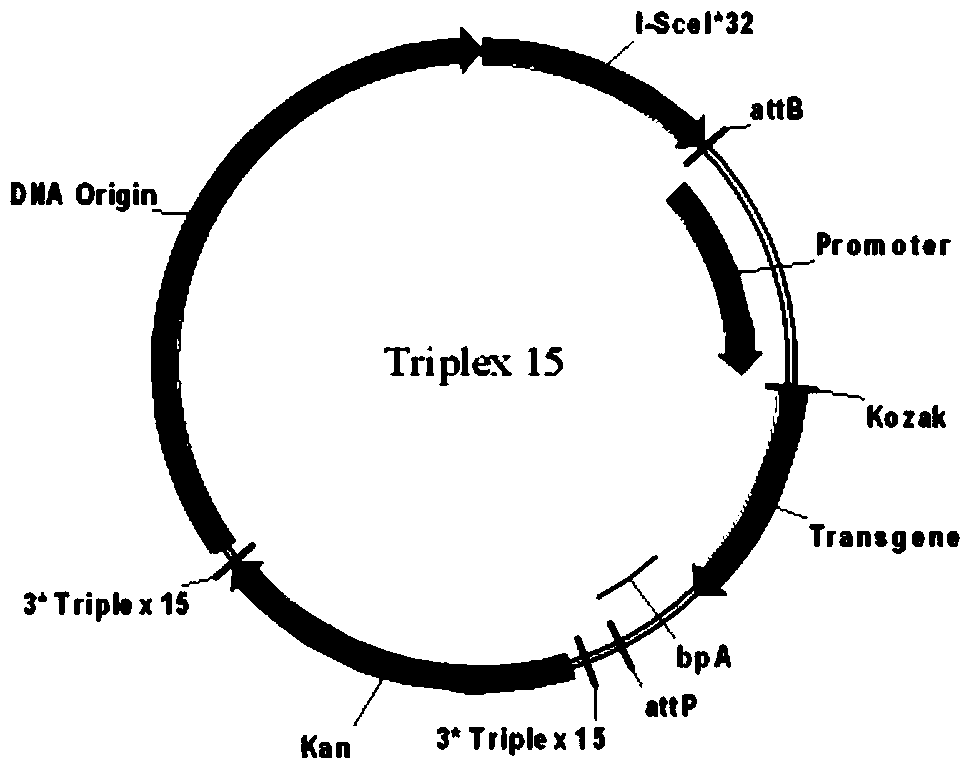

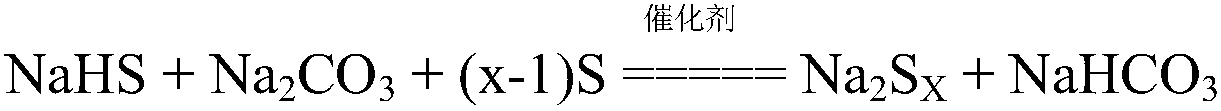

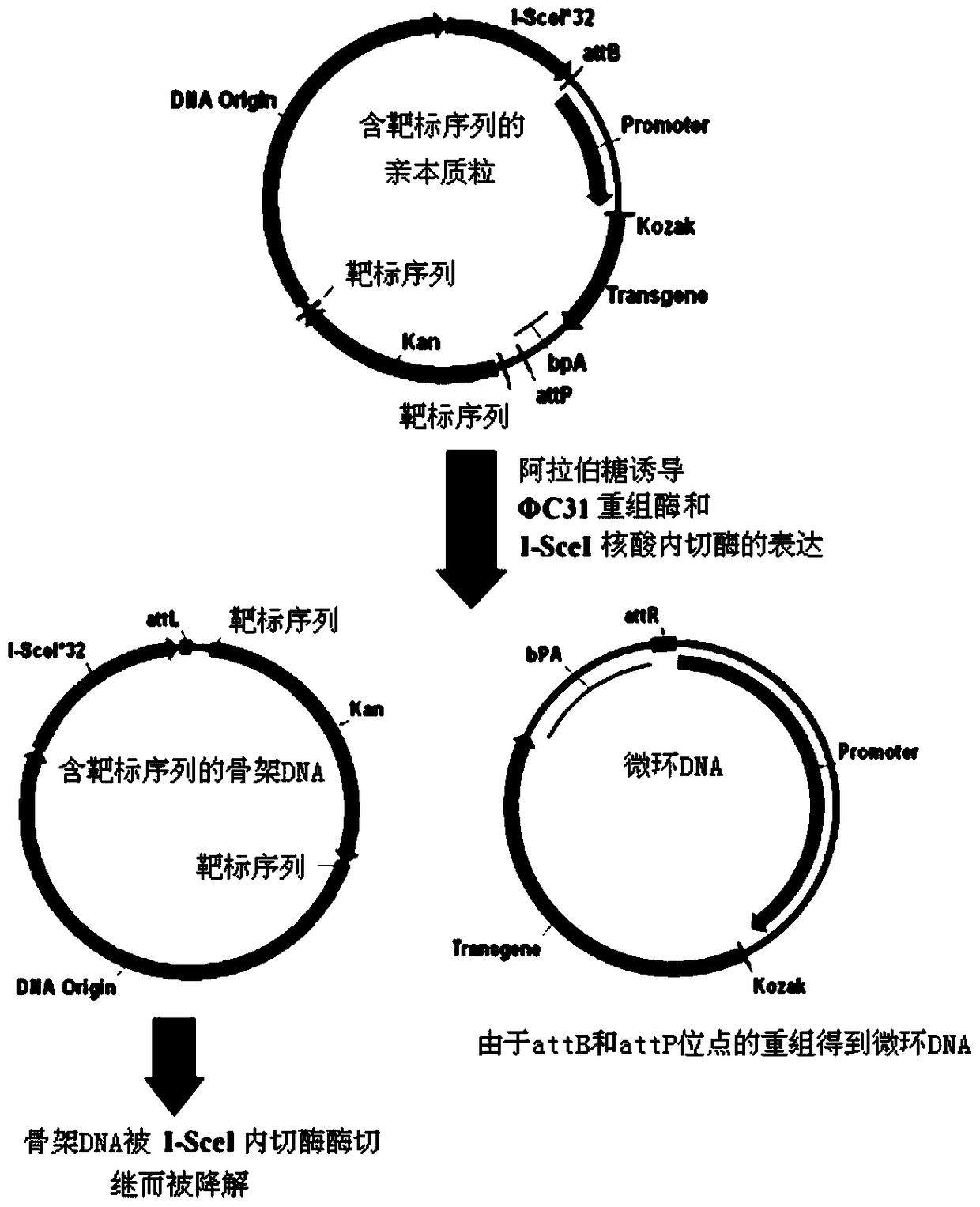

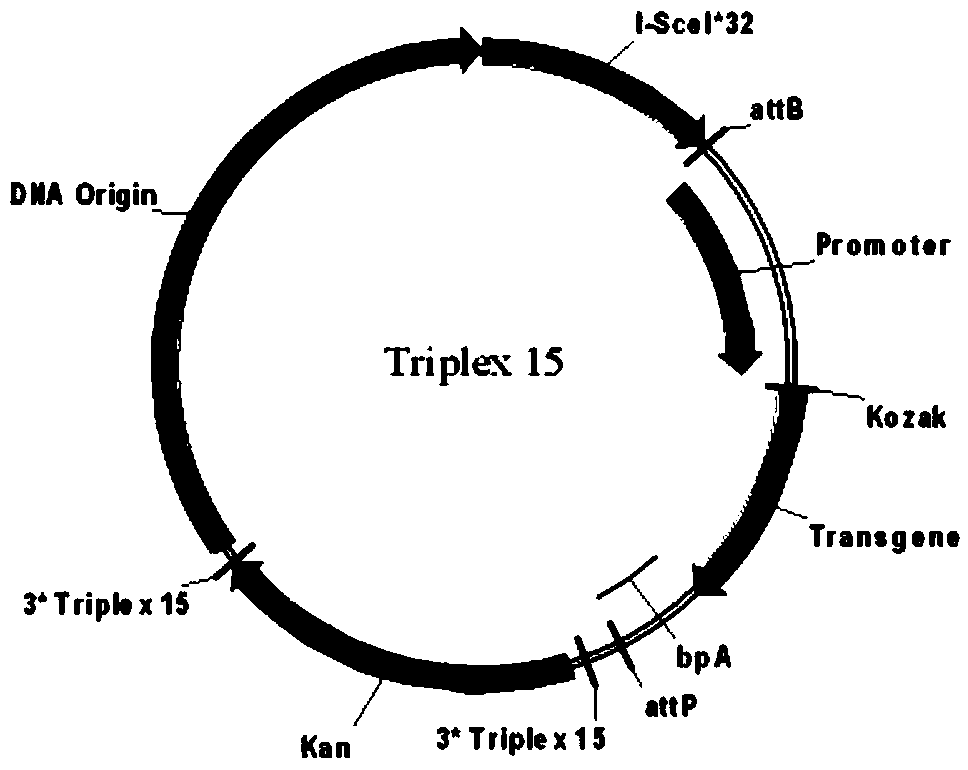

High-purity minicircle DNA (deoxyribonucleic acid) and preparation method and application thereof

ActiveCN105316314AHigh purityMeet the purification requirementsMicrobiological testing/measurementGenetic material ingredientsPurification methodsLysis

The invention provides a high-purity minicircle DNA (deoxyribonucleic acid) and a preparation method and application thereof. The preparation method includes the steps: 1) providing a parental plasmid containing a target sequence, wherein the parental plasmid has a specific recombination site, a nucleotide sequence of a skeleton DNA and a nucleotide sequence of the minicircle DNA; 2) transferring the parental plasmid to a host cell, inducing the parental plasmid to generate the minicircle DNA and the skeleton DNA containing the target sequence under the action of site-specific recombination; 3) subjecting the host cell to lysis, and subjecting plasmids to prepurification to obtain mixed plasmids including the minicircle DNA, the parental plasmid containing the target sequence and / or the skeleton DNA containing the target sequence; 4) removing the parental plasmid containing the target sequence and / or the skeleton DNA containing the target sequence from the mixed plasmids according to a tri-spiral purification method to obtain the high-purity minicircle DNA.

Owner:SYNO MINICIRCLE BIOTECH CO LTD

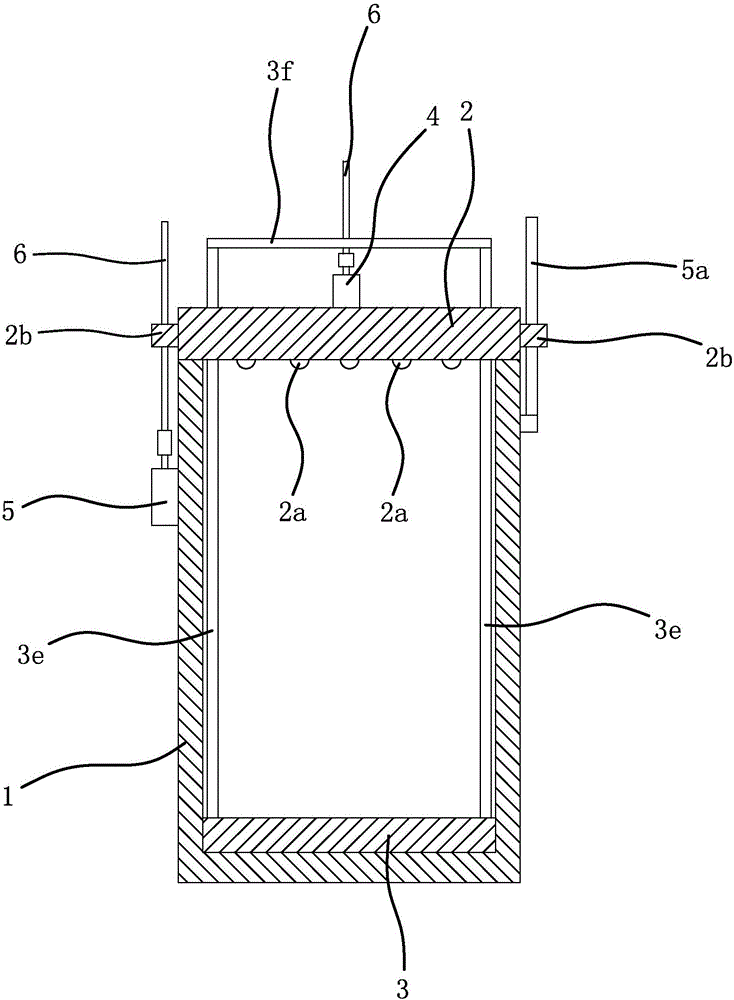

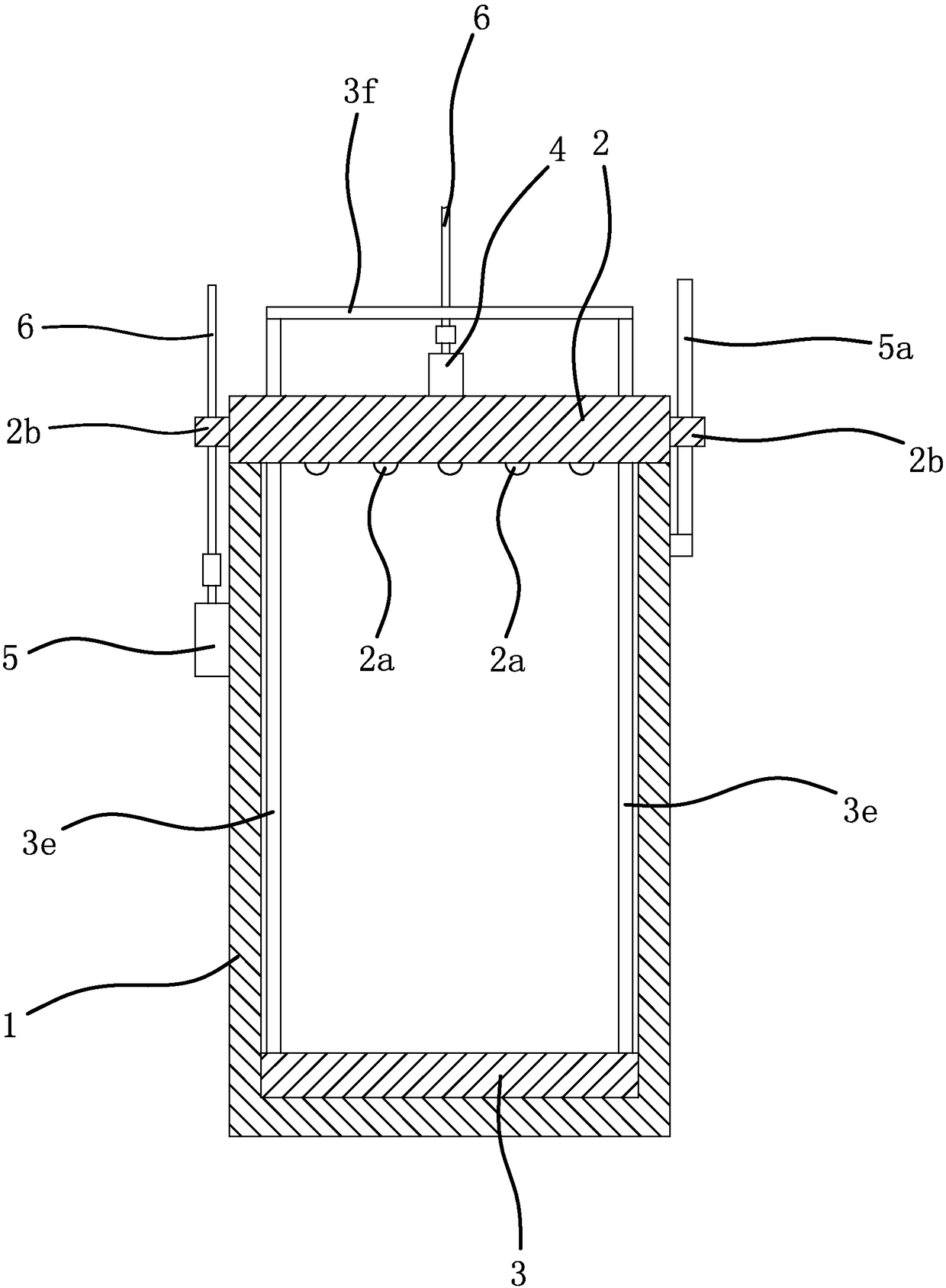

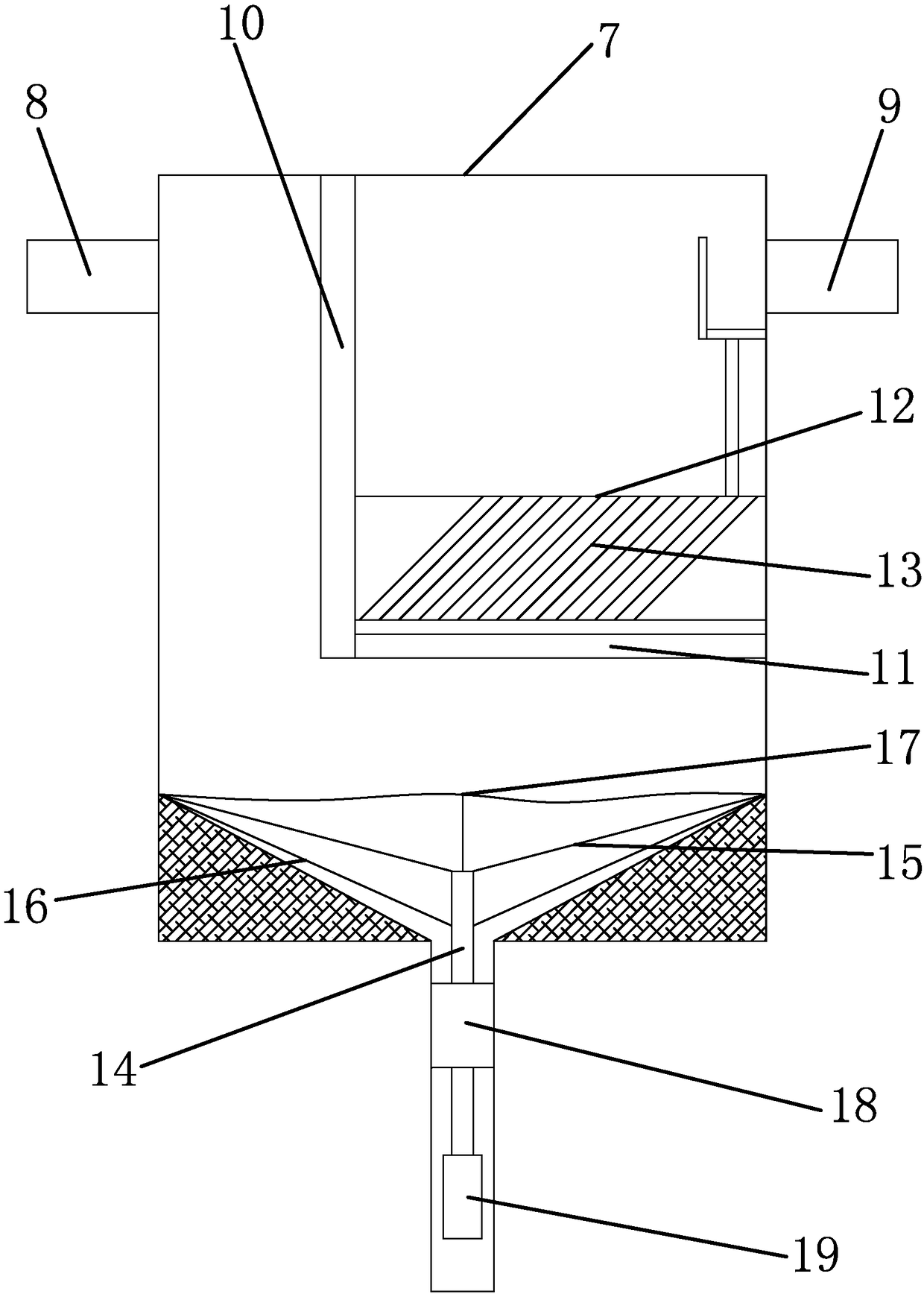

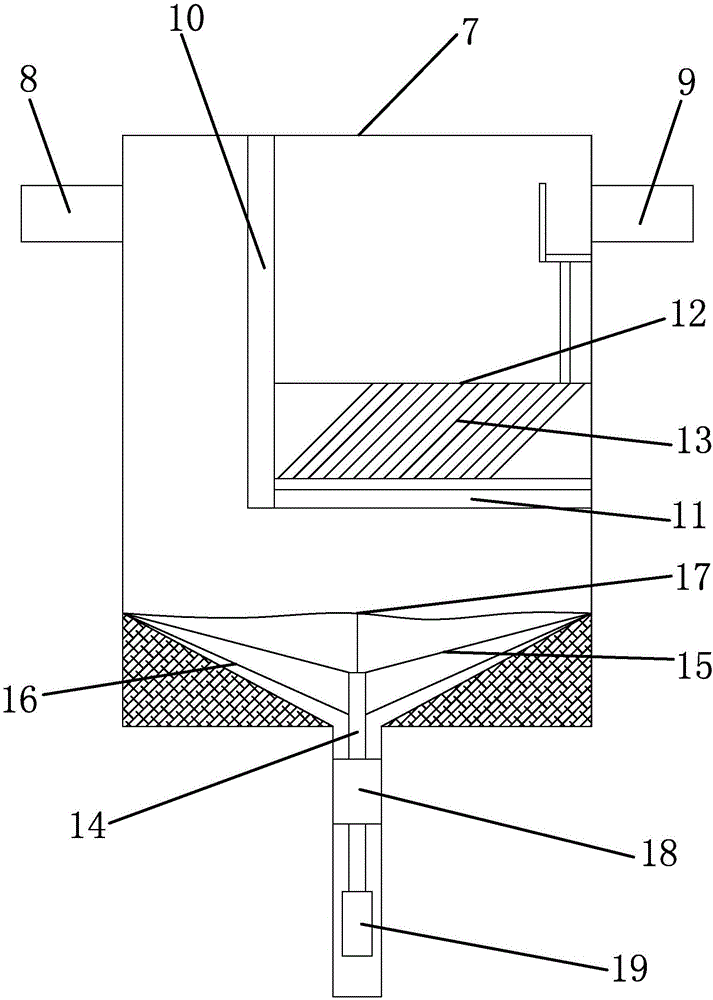

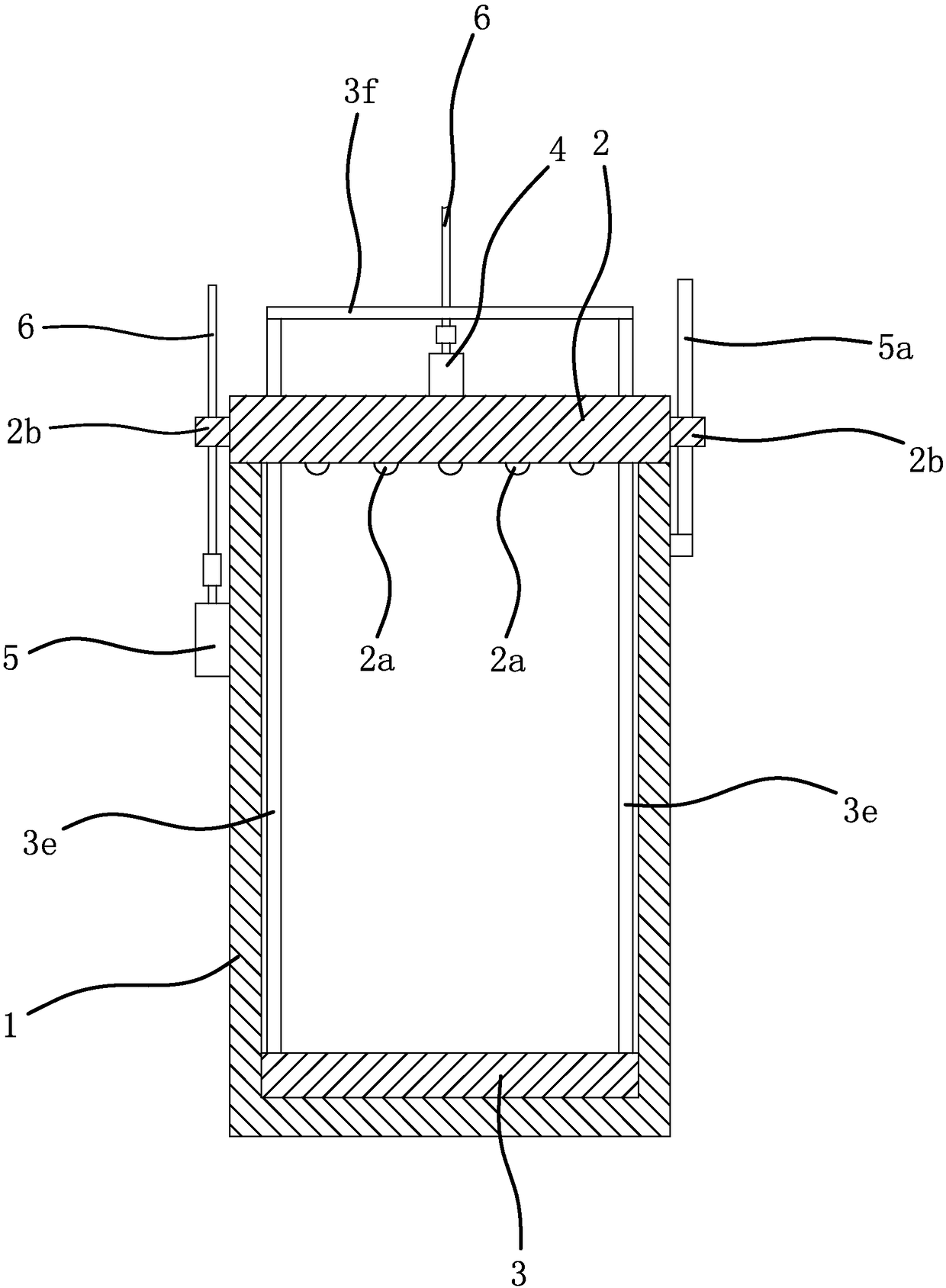

Improved dyeing device

ActiveCN106350955AImprove recycling efficiencySimple structureTextile treatment containersTreatment using aerobic processesFlocculationEngineering

The invention provides an improved dyeing device, and belongs to the technical field of dyeing. Problems in the prior art are solved. The improved dyeing device comprises a dye vat, the dye vat comprises a vat body and a vat cover, a lifting plate is arranged in the vat body and provided with multiple filtering holes, two lifting rods are fixed to the lifting plate and penetrate through the vat cover, and the ends, penetrating out of the vat covers, of the two lifting rods are fixed through a connecting rod; a lifting motor is fixed to the vat cover, a lead screw is connected to the lifting motor and perpendicularly penetrates through the middle of the connecting rod and is in threaded connection with the connecting rod, and a driving structure capable of opening or closing the vat body is arranged on the vat body; the vat body is connected with a flocculation pond, the flocculation pond comprises a settling pond, a water inlet pipe is arranged at the top of one side of the settling pond, a water outlet pipe is arranged at the top of the other side of the settling pond, the water inlet pipe is communicated with the vat body through a water pipe, a settling device is arranged in the settling pond, and a water inlet partition plate is vertically arranged in the settling pond. The improved dyeing device has the advantage of being capable of effectively treating dye liquor.

Owner:浙江华昌新材料股份有限公司

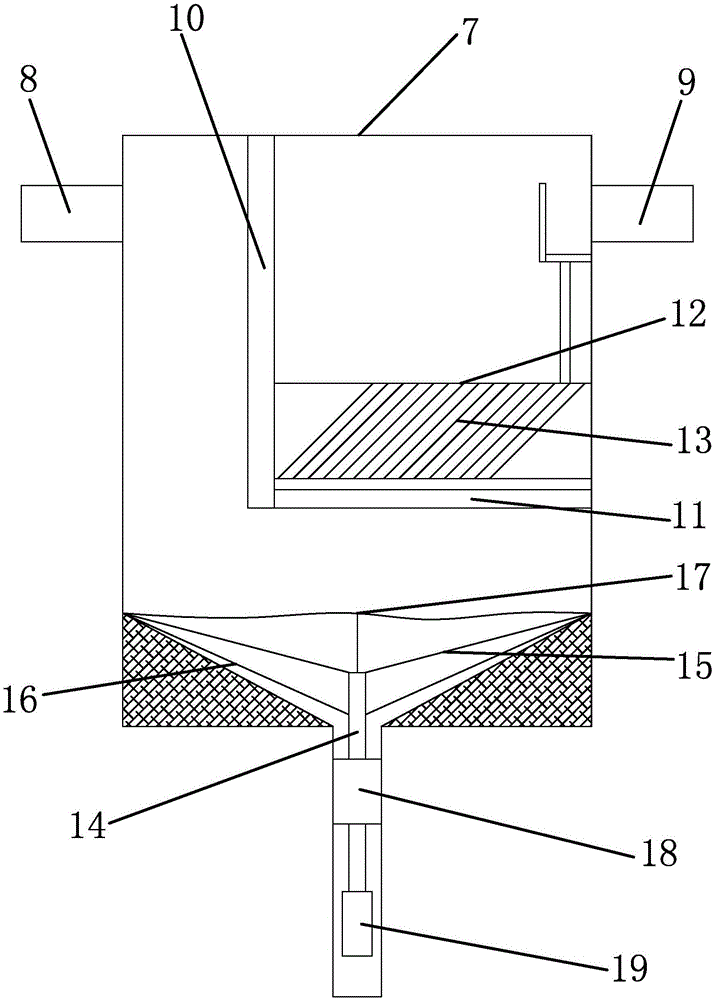

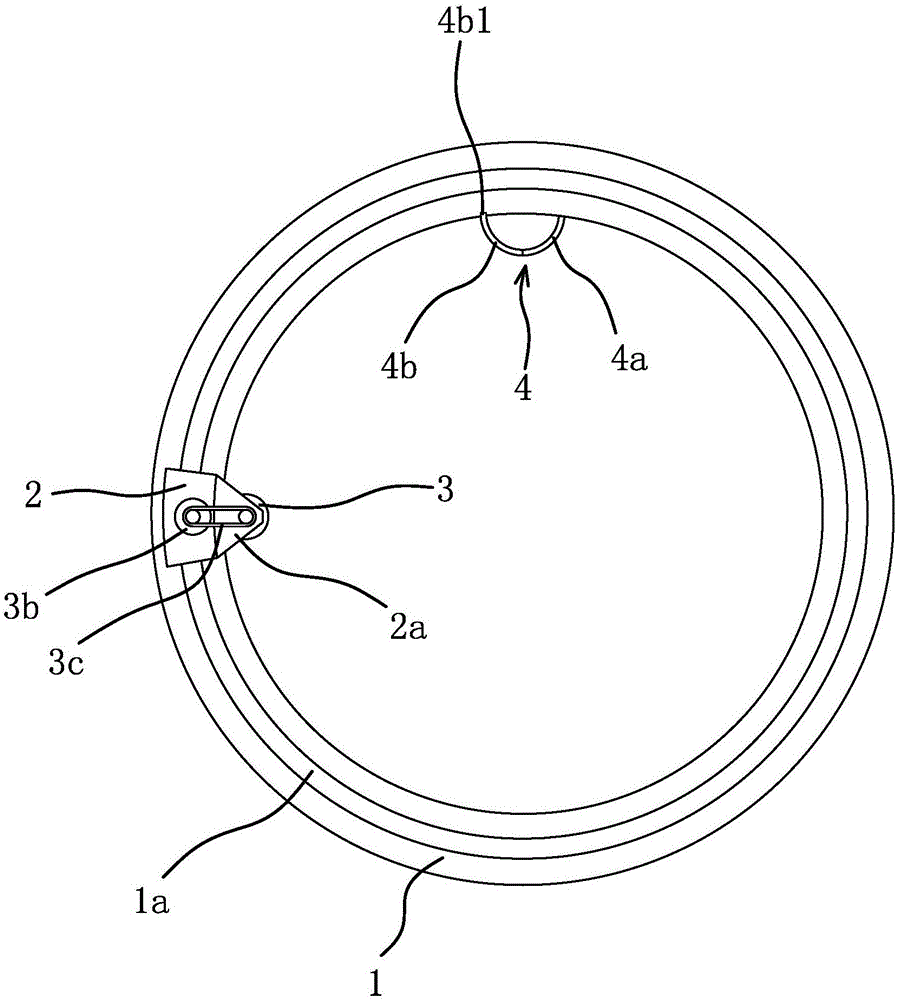

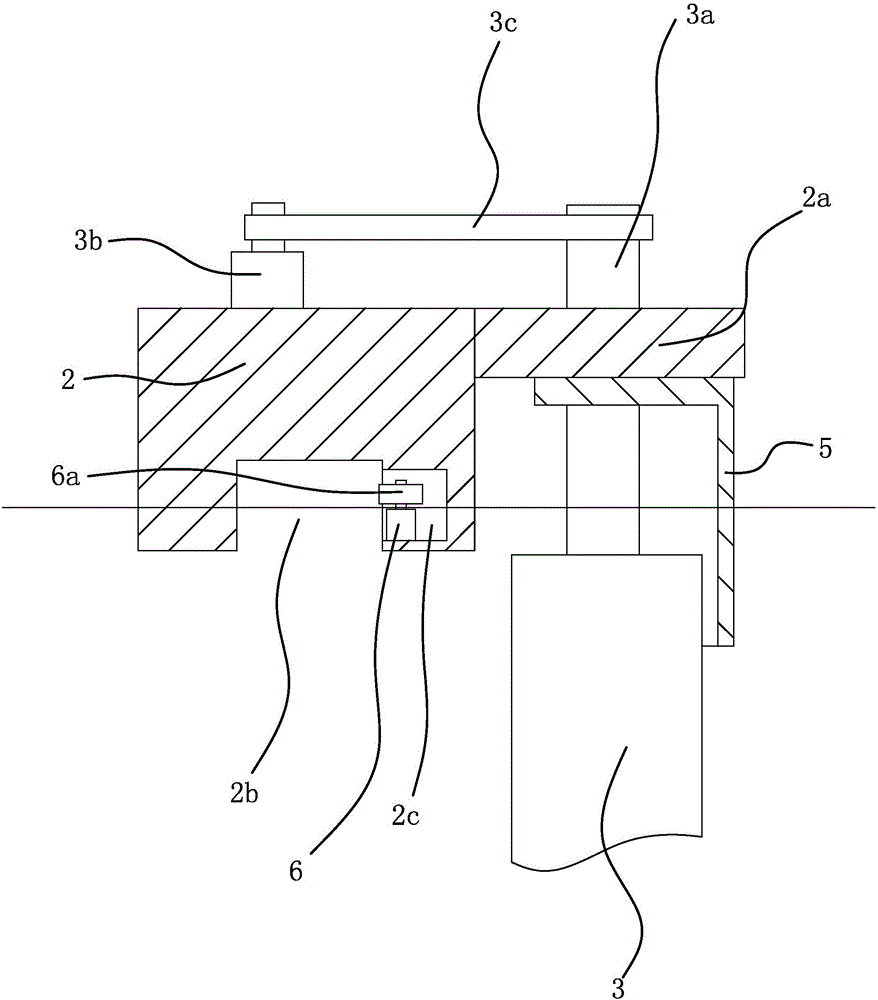

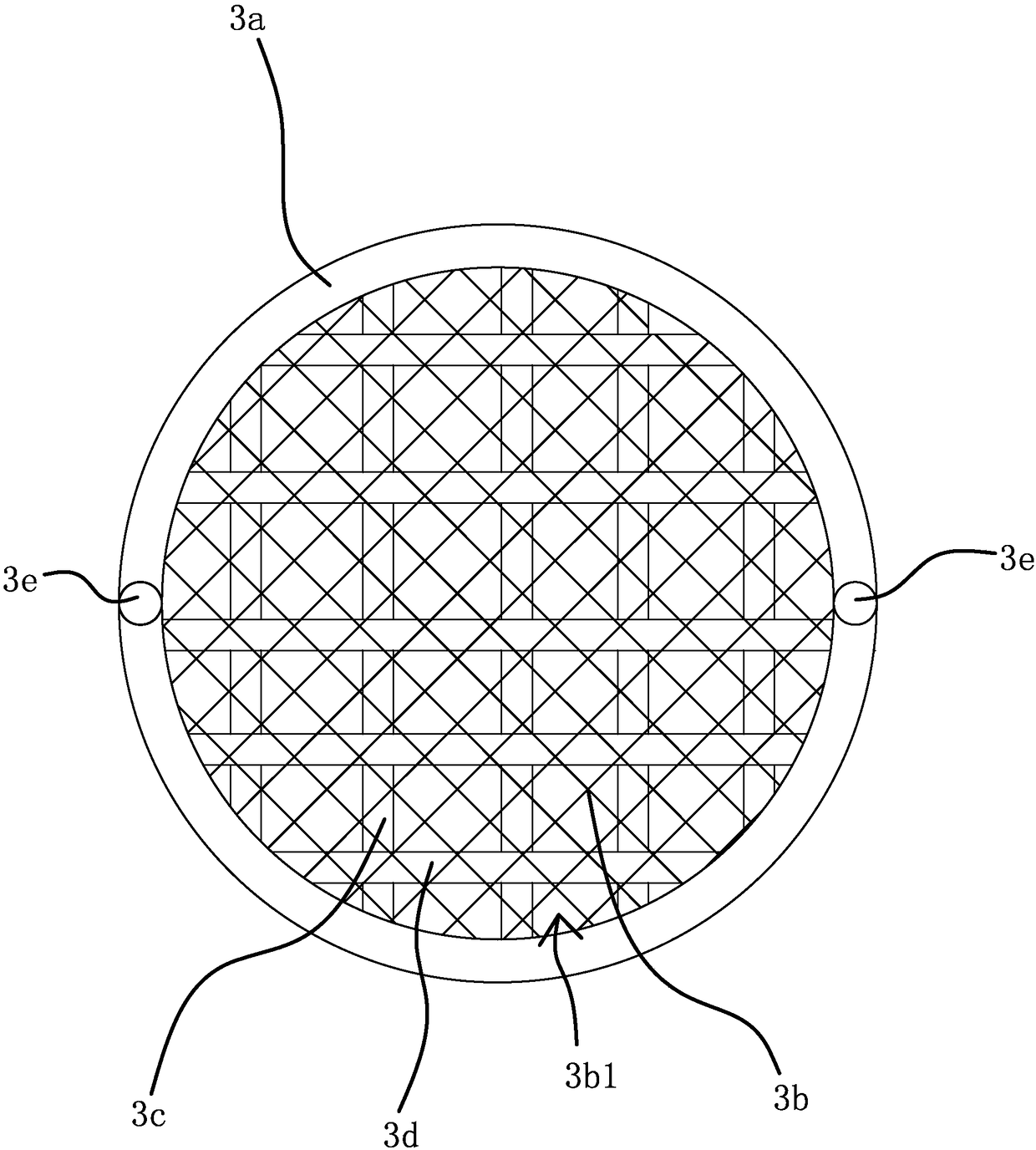

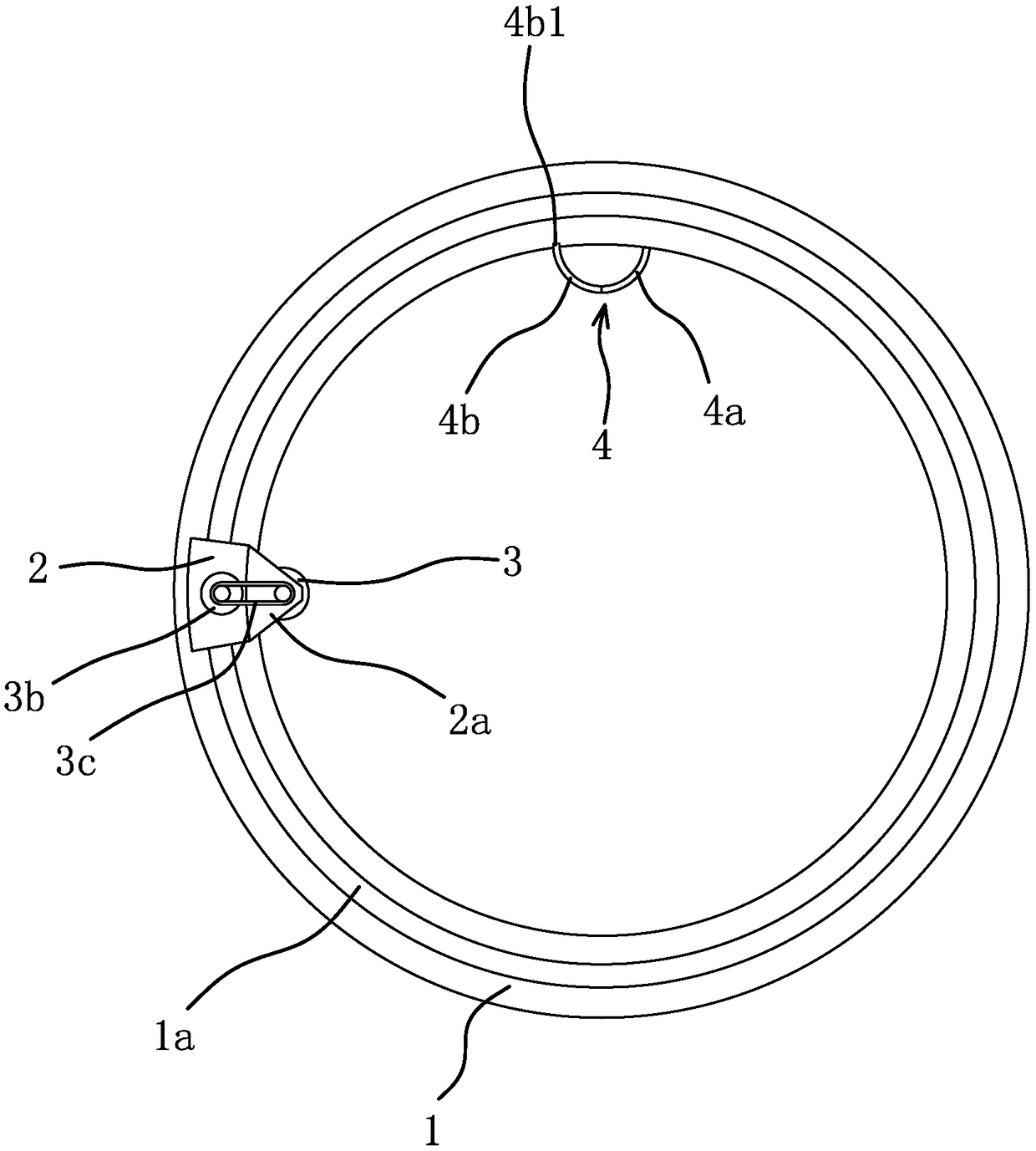

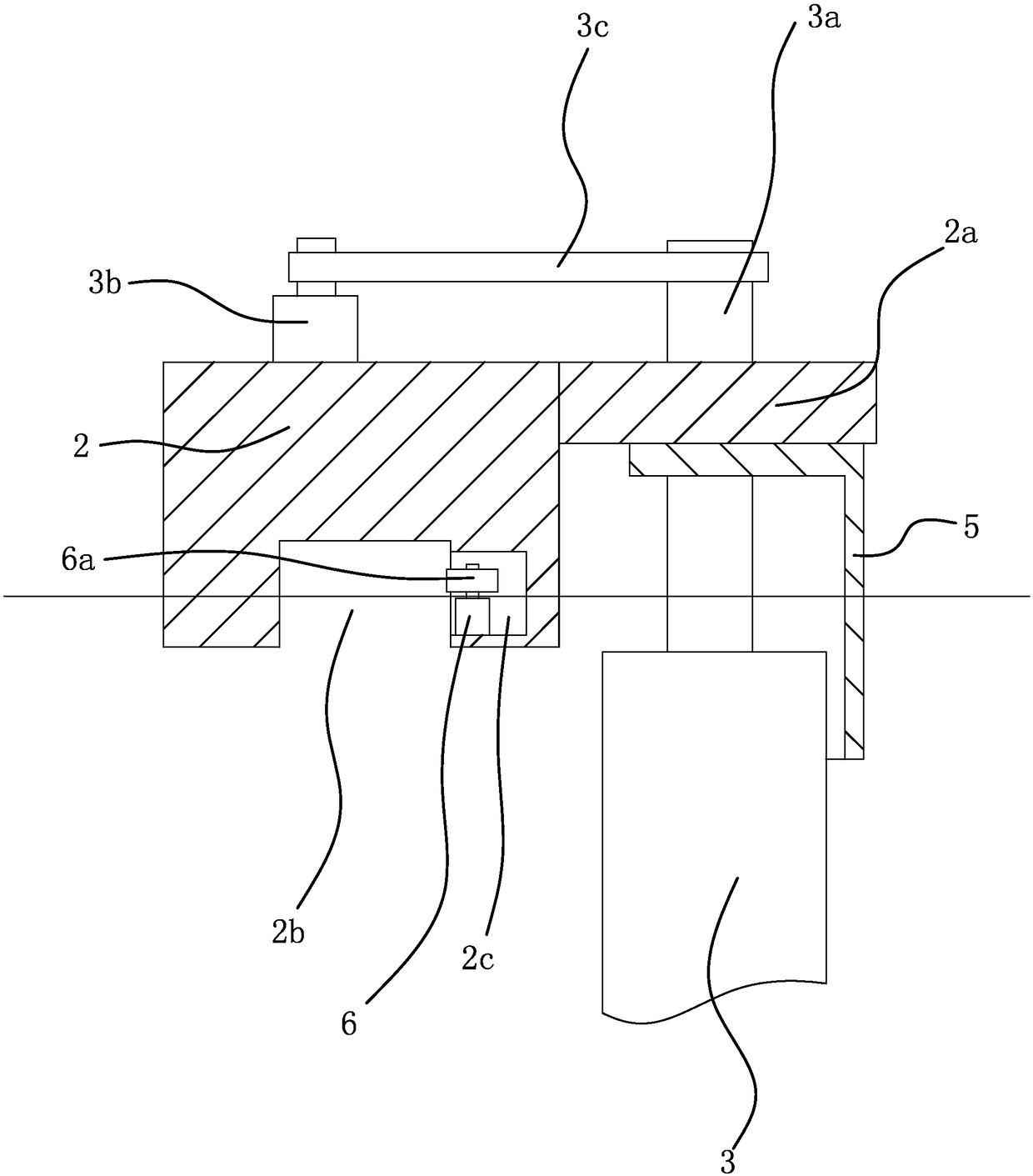

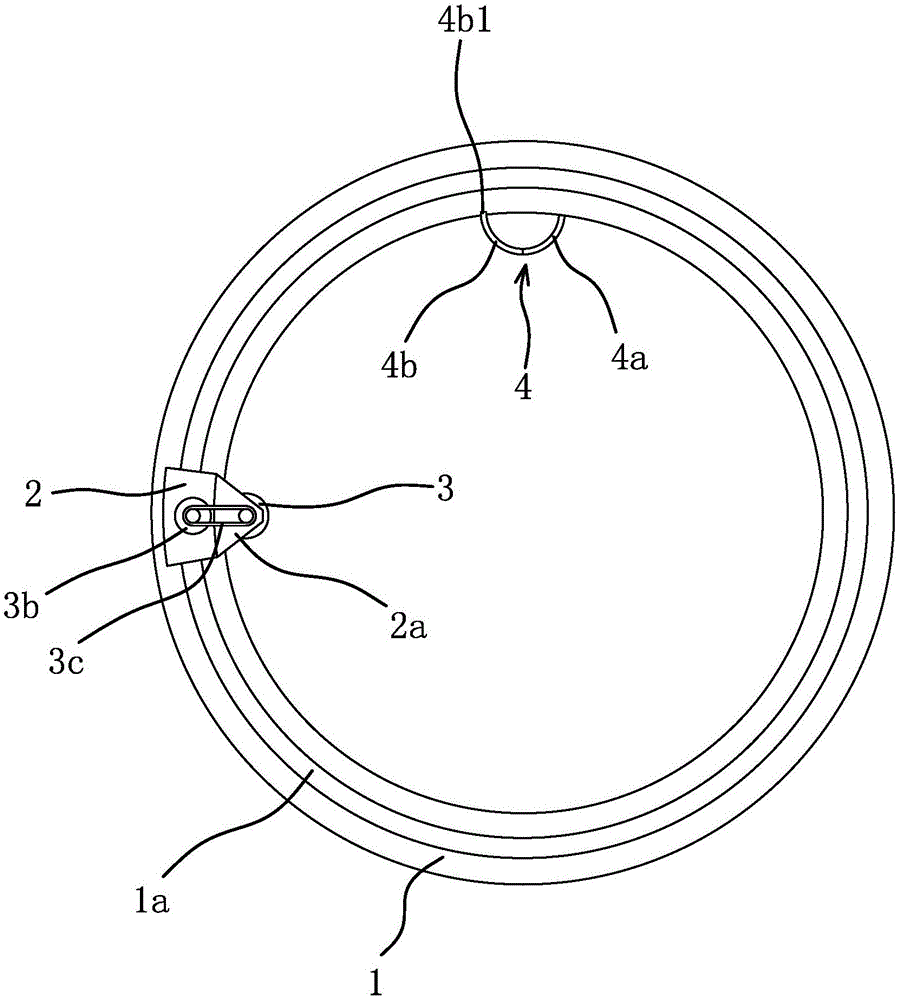

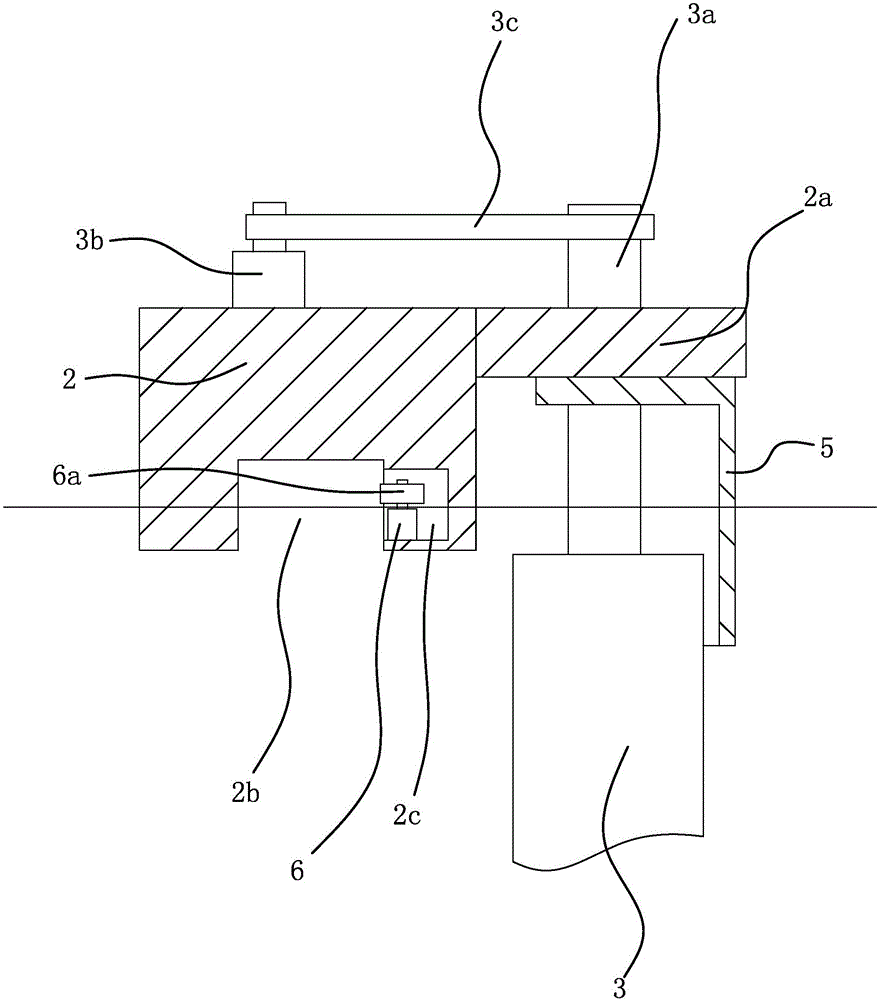

Dye vat for continuous dyeing in reactive dye tie dyeing

ActiveCN106222910AImprove cleaning efficiencyOptimizing the effect of denitrification and nitrogen removalTextile treatment machine arrangementsTextile treatment cleaning apparatusState of artNitrogen removal

The invention provides a dye vat for continuous dyeing in reactive dye tie dyeing, and belongs to the technical field of dyeing. The dye vat solves the problem of low cleaning efficiency in the prior art. The dye vat for continuous dyeing in reactive dye tie dyeing comprises a cylindrical vat body. A circular guide rail is fixed to the end face of the open end of the vat body, a sliding block is arranged on the guide rail and can slide along the guide rail, the sliding block is provided with an extension part extending to the inner side of the vat body, a cleaning roller is connected to the extension part in a rotating mode and is vertically arranged, the circumferential surface of the cleaning roller is attached to the inner wall of the vat body, and a rotating motor driving the cleaning roller to rotate is arranged on the sliding block. The vat body is further connected with a treatment device for denitrification nitrogen removal, the treatment device for denitrification nitrogen removal comprises a denitrification nitrogen removal tank, and the interior of the denitrification nitrogen removal tank is partitioned into a reaction tank and a sedimentation tank. The dye vat has the advantages that the dye vat can be automatically cleaned, and dye liquor can be automatically treated.

Owner:浙江华昌新材料股份有限公司

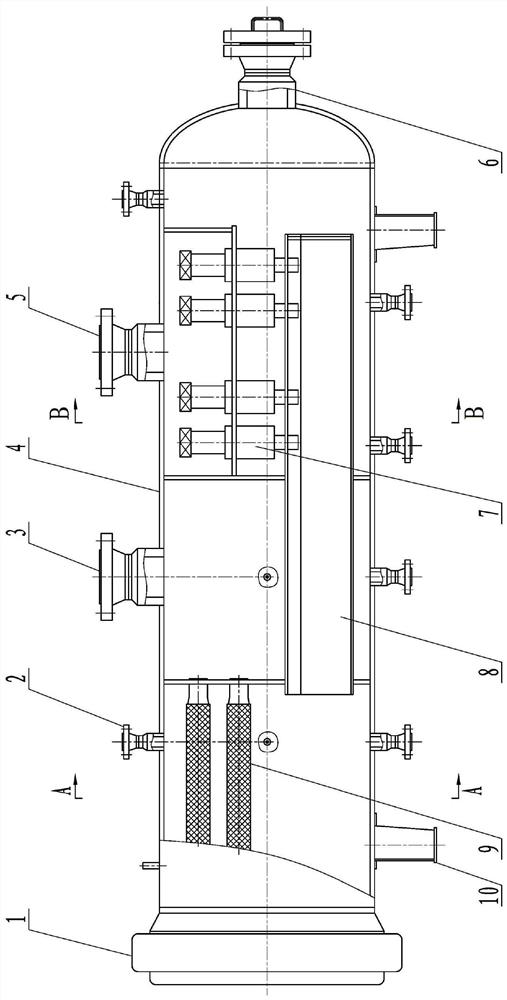

Horizontal combined filtering separator

PendingCN111957159AMeet the purification requirementsCompact structureCombination devicesDispersed particle filtrationEngineeringMechanical engineering

The invention discloses a horizontal combined filtering separator, which comprises a filtering separation assembly, cyclone separators and a housing, wherein the housing is internally a closed cavityand is of a cylindrical structure. The interior of the housing is sequentially divided into a first cavity, a second cavity and a third cavity from the first end to the second end. A fourth cavity with the volume smaller than that of the first cavity is formed in the first cavity. A communicating pipe is also provided, wherein one end of the communicating pipe is open, and the other end of the communicating pipe is closed; and the closed end of the communicating pipe extends into the first cavity, and the open end of the communicating pipe extends into the third cavity. An air inlet connectingpipe communicated with the fourth chamber is arranged on the housing. The number of the cyclone separators is multiple, an air inlet of each cyclone separator is communicated with the fourth cavity,the ash discharge port is communicated with the first cavity, and the exhaust port extends into the communicating pipe. The third chamber is communicated with the second chamber through a filtering and separating assembly, and an air outlet connecting pipe communicated with the second cavity is arranged on the housing. The horizontal combined filtering separator is simple and compact in structureand smaller in occupied area, and the use area of an equipment field can be effectively reduced.

Owner:SHENYANG XINLIAN PETROCHEM EQUIP CO LTD

Preparation method of high-purity aluminum

ActiveCN102534246ARealize continuous repeated purificationThe process steps are simpleCrucibleImpurity

The invention relates to a method for segregation purification of metal aluminum. The method comprises the steps of: forming supercooling at the periphery and top of molten aluminum in a vacuum environment by accurately controlling the thermal field of the molten aluminum in a crucible, pushing the solidification interface from the periphery to center and from the top to the bottom by controlling a proper cooling rate, enriching impurity elements in the melt at the bottom center of the crucible by ingredient segregation, and opening a device at the crucible bottom to discharge the unsolidified molten aluminum at the lower part of the crucible when the impurity elements are enriched to a certain degree, so as to purify the solidified metal aluminum; and then keeping heating and repeating the purification process, thus enhancing the purification effect by several times of continuous purification processes with low energy consumption. According to the invention, the purification requirements can be achieved, the purification efficiency is increased and energy is saved.

Owner:KUNMING METALLURGY INST

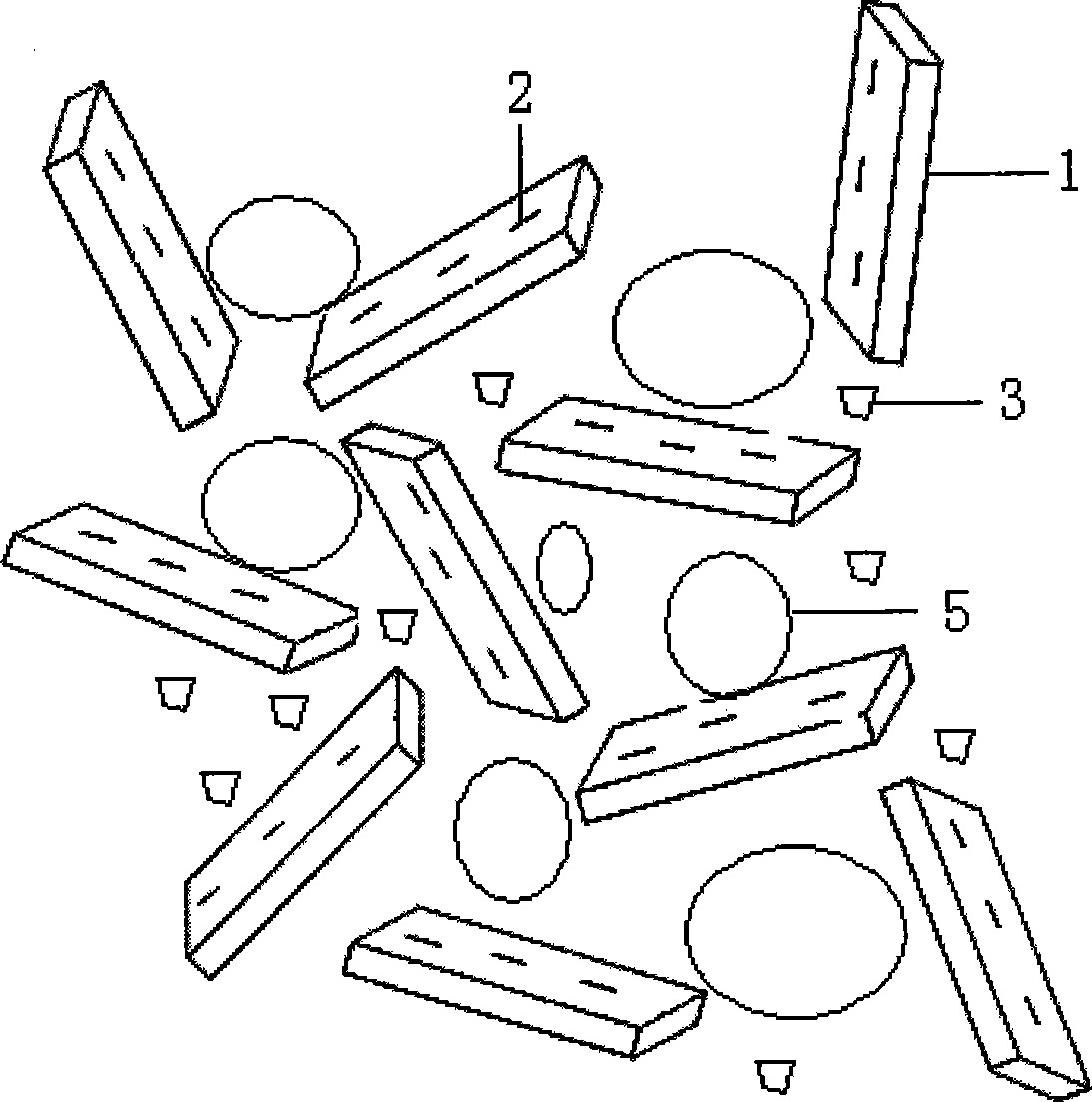

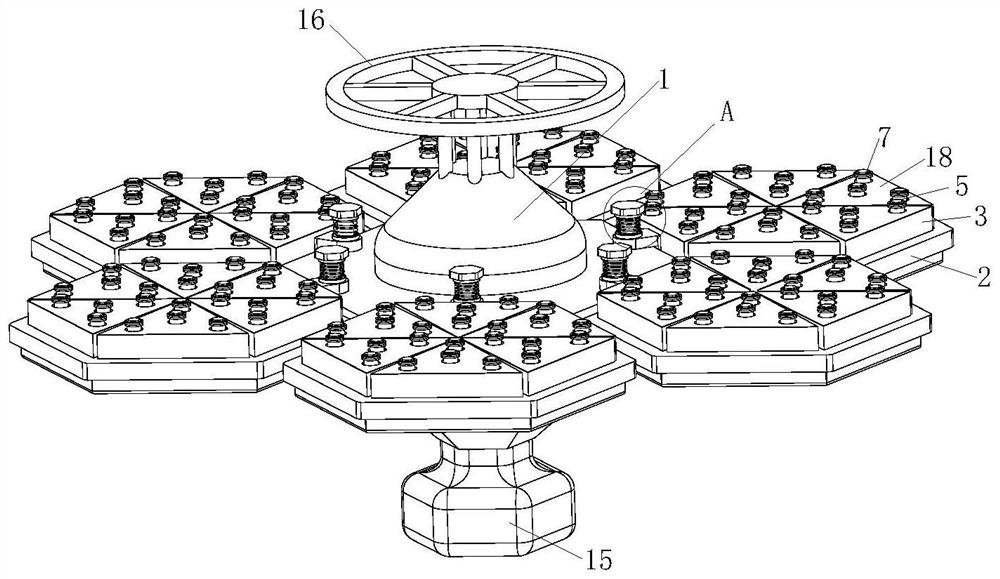

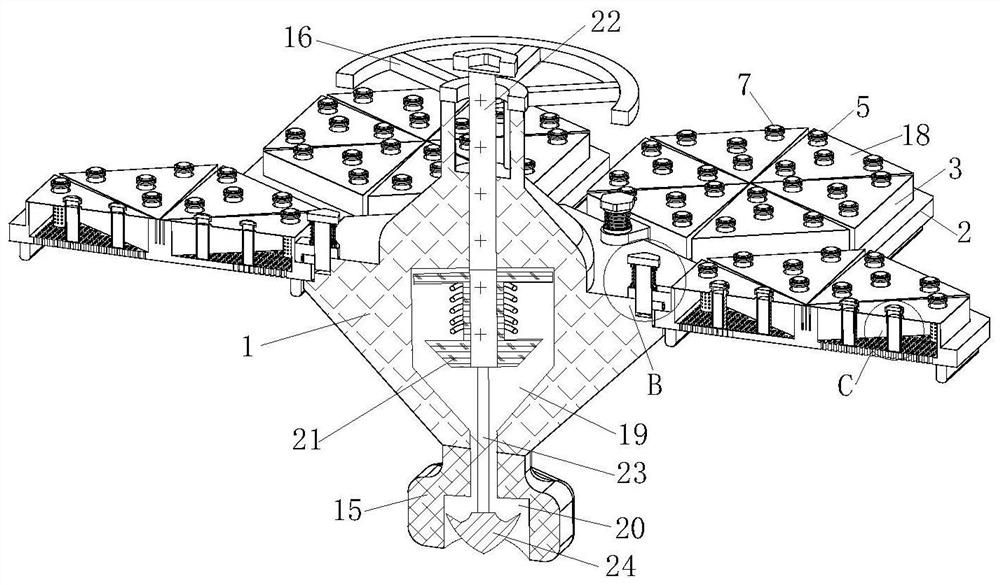

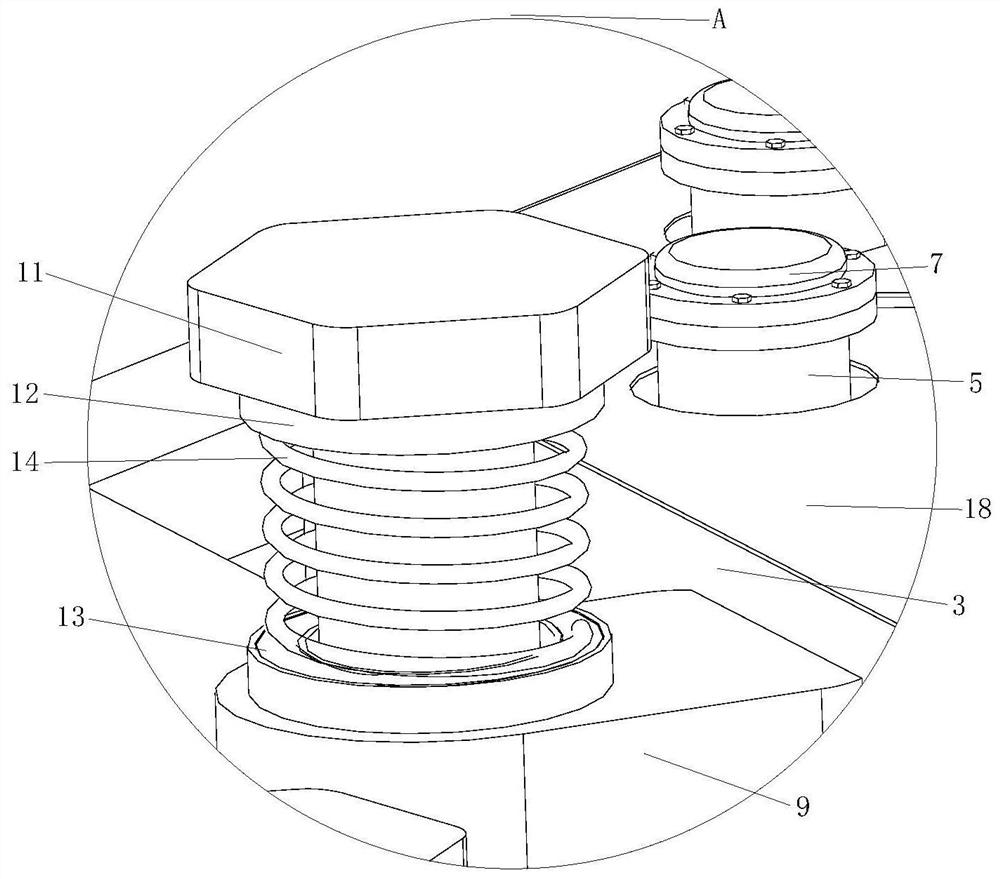

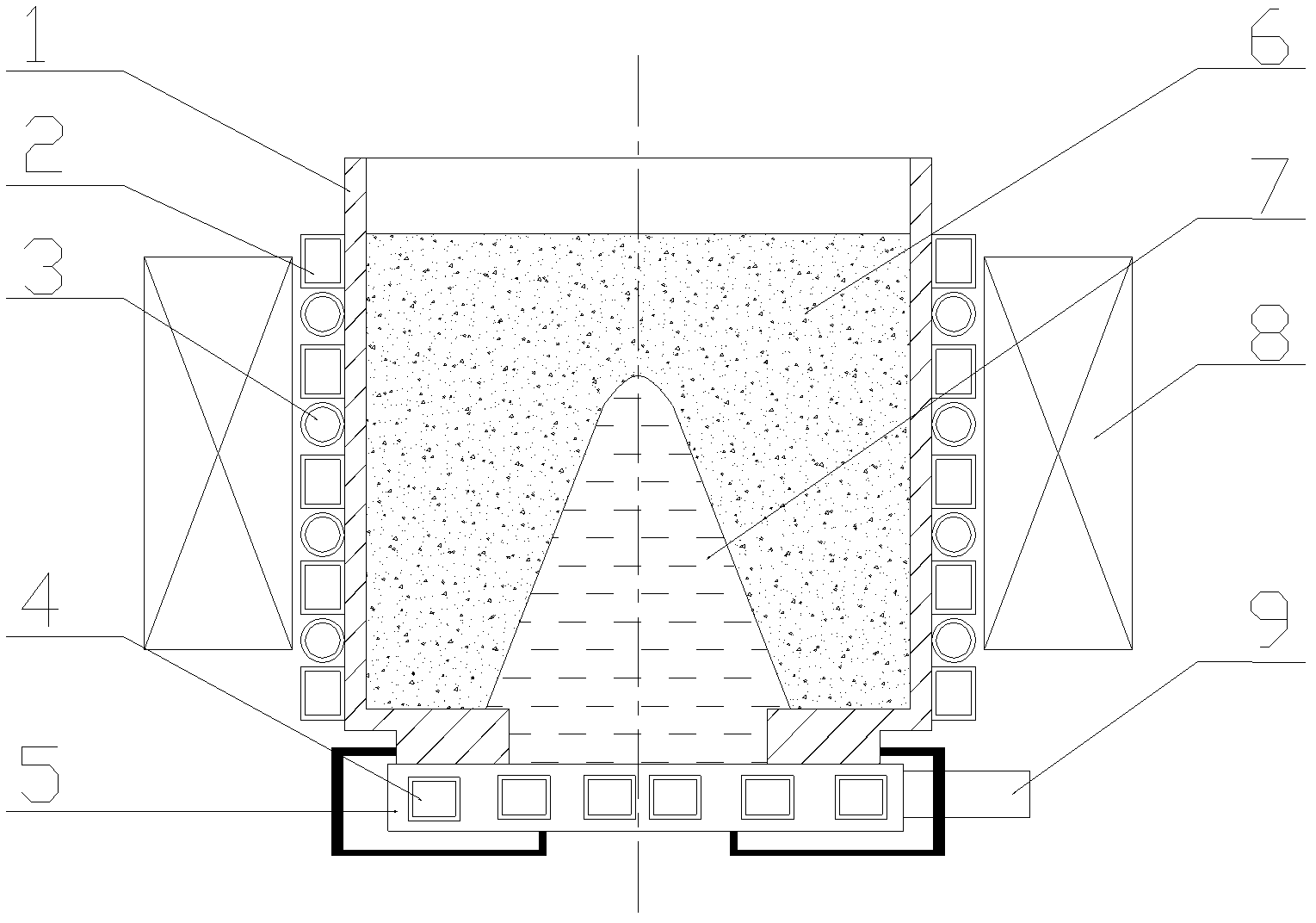

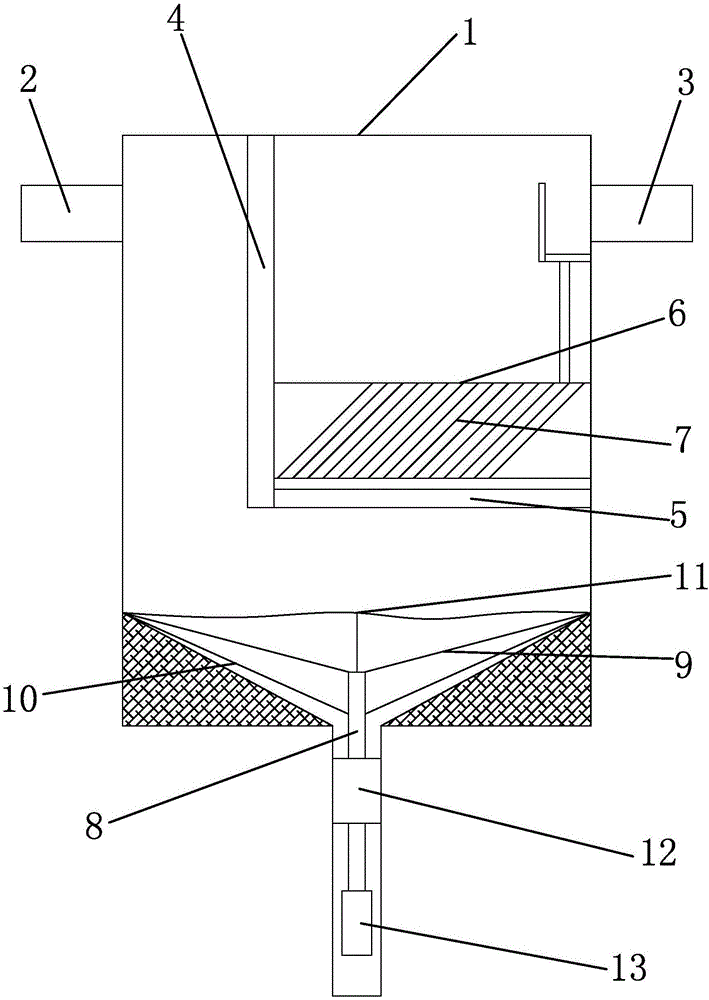

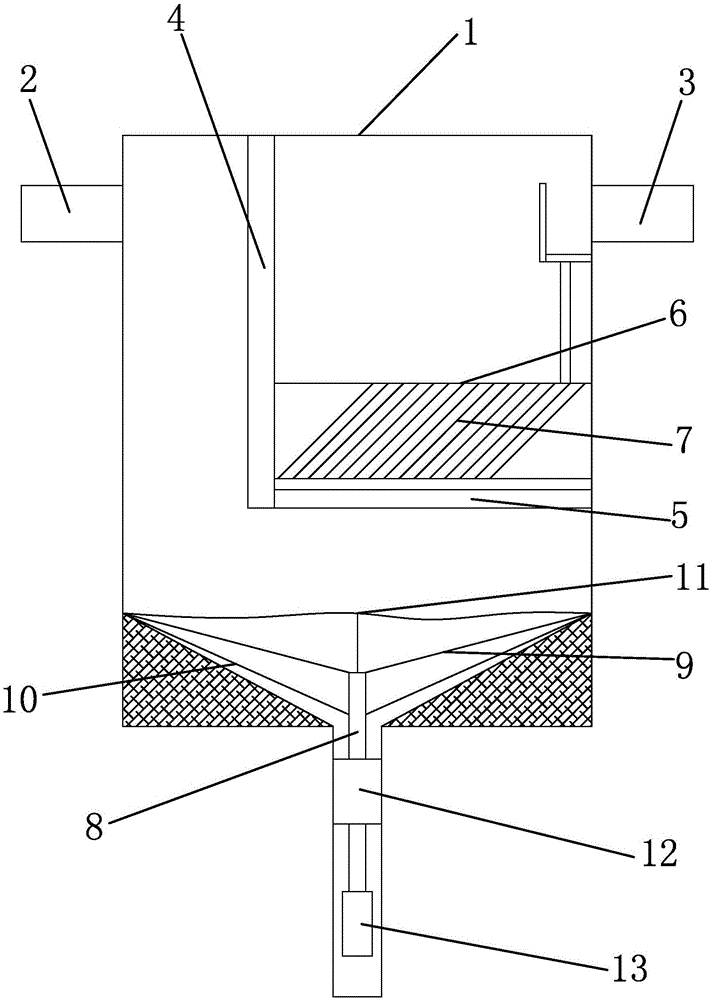

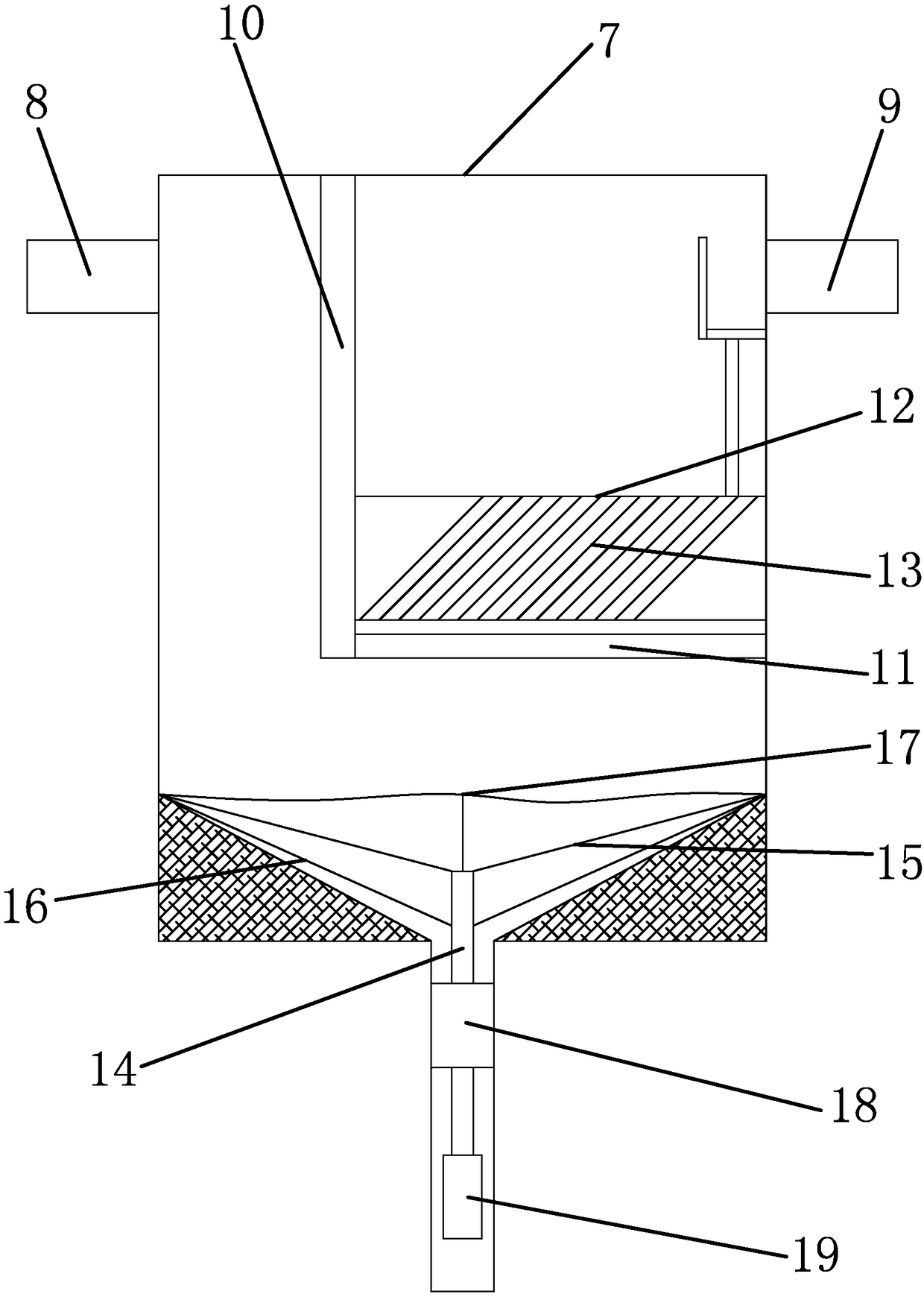

Zinc and zinc alloy melt foamed ceramic centrifugal compound purification device

InactiveCN102888517ASimple installationLow costCentrifugesProcess efficiency improvementGreen productionZinc alloys

The invention relates to a zinc and zinc alloy melt foamed ceramic centrifugal compound purification device. A rotatable pouring channel is made from a heat-resisting steel and consists of a sprue and a runner vertical to the sprue, and the runner is multiple symmetrical channels and keeps in balance around a rotational center; and a flow collection groove is also made from the heat-resisting steel, is in an annular structure and is arranged below a water outlet of the rotatable pouring channel, the water outlet of the rotatable pouring channel extends into the flow collection groove by above 20mm, the rotatable pouring channel is coaxially connected with a motor, and the runner of the rotatable pouring channel is respectively connected with multi-stage foamed ceramic filter sheets. The zinc and zinc alloy melt foamed ceramic centrifugal compound purification device has the substantive features and the creativity, is simple, is low in cost, is not in environmental pollution at all and accords with the modernized green production requirements.

Owner:NANCHANG HANGKONG UNIVERSITY

Floating wetland

PendingCN113620527APurifyGood purification effectTreatment involving filtrationMultistage water/sewage treatmentMicroorganismNutrition

The invention belongs to the technical field of sewage treatment, and particularly relates to a floating wetland. The floating wetland comprises a supporting floating platform and a floating assembly; the floating assembly is installed on the side face of the supporting floating platform; the floating assembly comprises a floating platform, a planting pot, a nutrition cylinder and a sealing cover; the floating platform is installed on the side face of the supporting floating platform, the planting pot is fixedly connected to the top face of the floating platform, a plurality of through holes are formed in the bottom face of the planting pot and the bottom face of the floating platform, a plurality of nutrition cylinders are fixedly connected to the bottom face of the planting pot, a plurality of diffusion holes are formed in the side walls of the nutrition cylinders, and sealing covers are installed on the top faces of the nutrition cylinders through bolts; the floating wetland floats in the water body of the river channel, so that tail water can be well degraded, and the land area is not occupied; and the emergent aquatic plants planted in the floating wetland provide a good growth and reproduction environment for microorganisms in a water area, so that a large number of microorganisms are gathered, the gathered microorganisms can quickly and effectively decompose pollutants in water, and the purposes of improving water quality and ecological management are achieved.

Owner:上源环工生态环境科技(苏州)有限公司

a dyeing device

ActiveCN106245256BImprove recycling efficiencySimple structureTextile treatment containersTreatment using aerobic processesNitrogen removalWater filter

The invention provides a dyeing device and belongs to the technical field of shell fabrics. The dyeing device solves the problems in the prior art. The dyeing device comprises a dye vat. The dye vat comprises a vat body and a vat cover. The vat body is internally provided with a lifting plate. The lifting plate is provided with a plurality of water filtering holes. Two lifting rods are fixed to the lifting plate and penetrate out of the vat cover. The ends, penetrating out of the vat cover, of the two lifting rods are fixed through a connecting rod. A lifting motor is fixed to the vat cover and connected with a lead screw. The lead screw perpendicularly penetrates through the middle portion of the connecting rod and connected with the connecting rod through threads. The vat body is provided with a driving structure which can enable the vat cover to open or close the vat body. The vat body is further connected with a treating device for nitrogen removal by denitrification. The treating device for nitrogen removal by denitrification comprises a pool for nitrogen removal by denitrification, the pool for nitrogen removal by denitrification is internally divided into a reaction pool and a settling pool, a vertical partition plate is arranged between the reaction pool and the settling pool, and a circulation notch is formed in the top of the vertical partition plate.

Owner:浙江华昌新材料股份有限公司

Preparation method of high-purity aluminum

ActiveCN102534246BRealize continuous repeated purificationThe process steps are simpleCrucibleImpurity

Owner:KUNMING METALLURGY INST

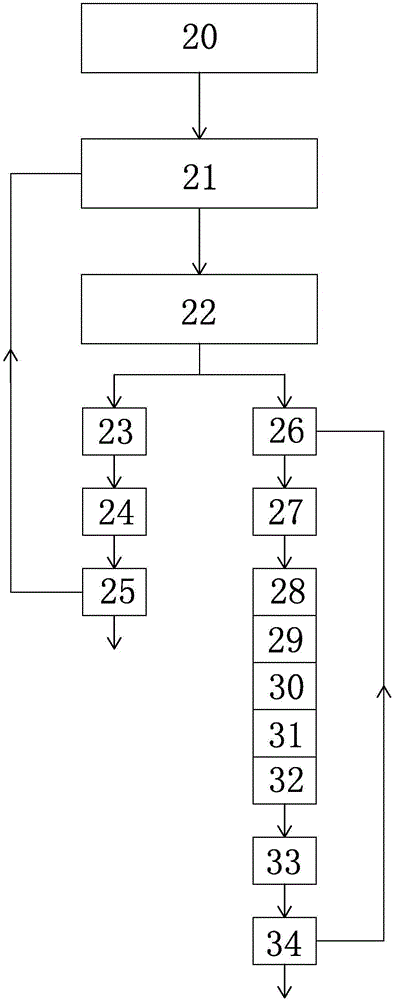

Dyeing wastewater treatment method

InactiveCN106242171AAvoid spreadingEfficient sewage dischargeMultistage water/sewage treatmentWaste water treatment from textile industryHydrolysisAnaerobic treatment

The invention provides a dyeing wastewater treatment method, belongs to the technical field of wastewater purification, and solves the problem that in the prior art, flocculating discharge in a flocculating tank is not complete. The purpose of the invention can be achieved through the technical scheme: the dyeing wastewater treatment method comprises the following steps: a, flocculating: draining dyeing wastewater into the flocculating tank, and flocculating; b, performing anaerobic treatment: performing the anaerobic treatment on flocculated water by using an anaerobic hydrolysis and acidification device; c, performing microbial treatment: enabling water obtained after the anaerobic treatment to enter a microbial oxidization tank, and performing microbial treatment; d, performing denitrification treatment: enabling water treated by the microbial oxidization tank to enter a denitrification treatment device, and performing denitrification treatment; e, performing deep treatment: performing deep treatment on water treated by the denitrification treatment device by using a deep treatment device so as to finish dyeing wastewater treatment. The dyeing wastewater treatment method has the advantage of complete flocculating discharge in the flocculating tank.

Owner:浙江华昌新材料股份有限公司

Printing and dyeing waste water treating system

InactiveCN106242167AAvoid spreading againImprovement effectMultistage water/sewage treatmentWaste water treatment from textile industryPipingWastewater

The invention provides a printing and dyeing waste water treating system and belongs to the technical field of wastewater purification. The printing and dyeing waste water treating system solves the problem that the printing and dyeing waste water treating effect is poor in the prior art. The printing and dyeing waste water treating system comprises a flocculating tank, a denitrification nitrogen removal treating device and a deep treating device. The flocculating tank comprises a settling tank, a water inlet pipe is arranged at the top of one side of the settling tank, a water outlet pipe is arranged at the top of the other side of the settling tank, a settling device is arranged in the settling tank, a water inlet partition plate is vertically arranged in the settling tank, the lower side edge of the water inlet partition plate is fixedly connected with the wall of the settling tank through a supporting beam, the two vertical side edges of the water inlet partition plate are fixedly connected with the wall of the settling tank, the water inlet pipe and the water outlet pipe are communicated with the parts, on the two sides of the water inlet partition plate, of an inner cavity of the settling tank respectively, the settling device is located on the part, between the water inlet partition plate and the water outlet pipe, of the supporting beam and located below an opening of the water outlet pipe, a funnel groove bottom is arranged at the bottom of the settling tank, and a flocculating net assembly is arranged in the funnel groove bottom. The printing and dyeing waste water treating system has the advantage of being good in printing and dyeing waste water treating effect.

Owner:浙江华昌新材料股份有限公司

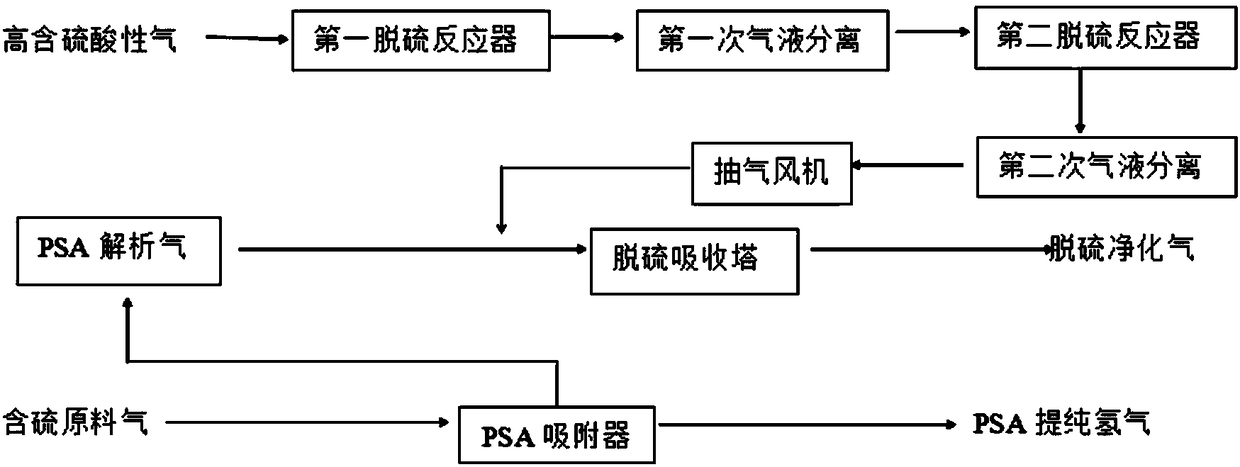

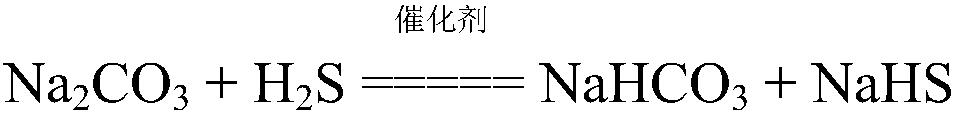

Optimized combined desulfurization technology for PSA analysis gas and coal tar hydrogenation device acid gas

InactiveCN108079782AAchieve recyclingHigh controllability of desulfurization effectDispersed particle separationNitrogen gasDeoxygenation

The invention relates to a low-pressure sulfur tolerant shift and special adsorbent inert gas exhaust technologies for production of hydrogen from raw coke oven gas. Firstly, raw coke oven gas is sequentially subjected to tar removal, desulfurization, dehydration and hydrodeoxygenation and detoxification treatment, two-stage CO sulfur tolerant shift is performed, CO in the raw coke oven gas is shifted into hydrogen, shifted gas containing hydrogen and other impurity gases is obtained, then, first-stage PSA separation is performed on the shifted gas to remove hydrocarbon, CO, CO2, CH4 and H2S in the shifted gas, second-stage PSA separation is performed to remove nitrogen and directly exhaust inert gas, and finally, hydrogen with the purity up to 99.9% is obtained. Besides, compressed heat of the raw coke oven gas is fully utilized, the temperature increases automatically after the raw coke oven gas is compressed, and hydrogenation is realized after cooling. The dehydrated raw coke ovengas is subjected to heat exchange temperature increase by use of heat released during two-stage CO sulfur tolerant shift, deoxygenation and detoxification treatment is performed, so that an additionalheating device is not required and the cost is reduced.

Owner:新疆宣力环保能源股份有限公司

A kind of high-purity microcircle dna and its preparation method and application

ActiveCN105316314BEfficient separationMeet the purification requirementsMicrobiological testing/measurementGenetic material ingredientsPurification methodsLysis

The invention provides a high-purity minicircle DNA (deoxyribonucleic acid) and a preparation method and application thereof. The preparation method includes the steps: 1) providing a parental plasmid containing a target sequence, wherein the parental plasmid has a specific recombination site, a nucleotide sequence of a skeleton DNA and a nucleotide sequence of the minicircle DNA; 2) transferring the parental plasmid to a host cell, inducing the parental plasmid to generate the minicircle DNA and the skeleton DNA containing the target sequence under the action of site-specific recombination; 3) subjecting the host cell to lysis, and subjecting plasmids to prepurification to obtain mixed plasmids including the minicircle DNA, the parental plasmid containing the target sequence and / or the skeleton DNA containing the target sequence; 4) removing the parental plasmid containing the target sequence and / or the skeleton DNA containing the target sequence from the mixed plasmids according to a tri-spiral purification method to obtain the high-purity minicircle DNA.

Owner:SYNO MINICIRCLE BIOTECH CO LTD

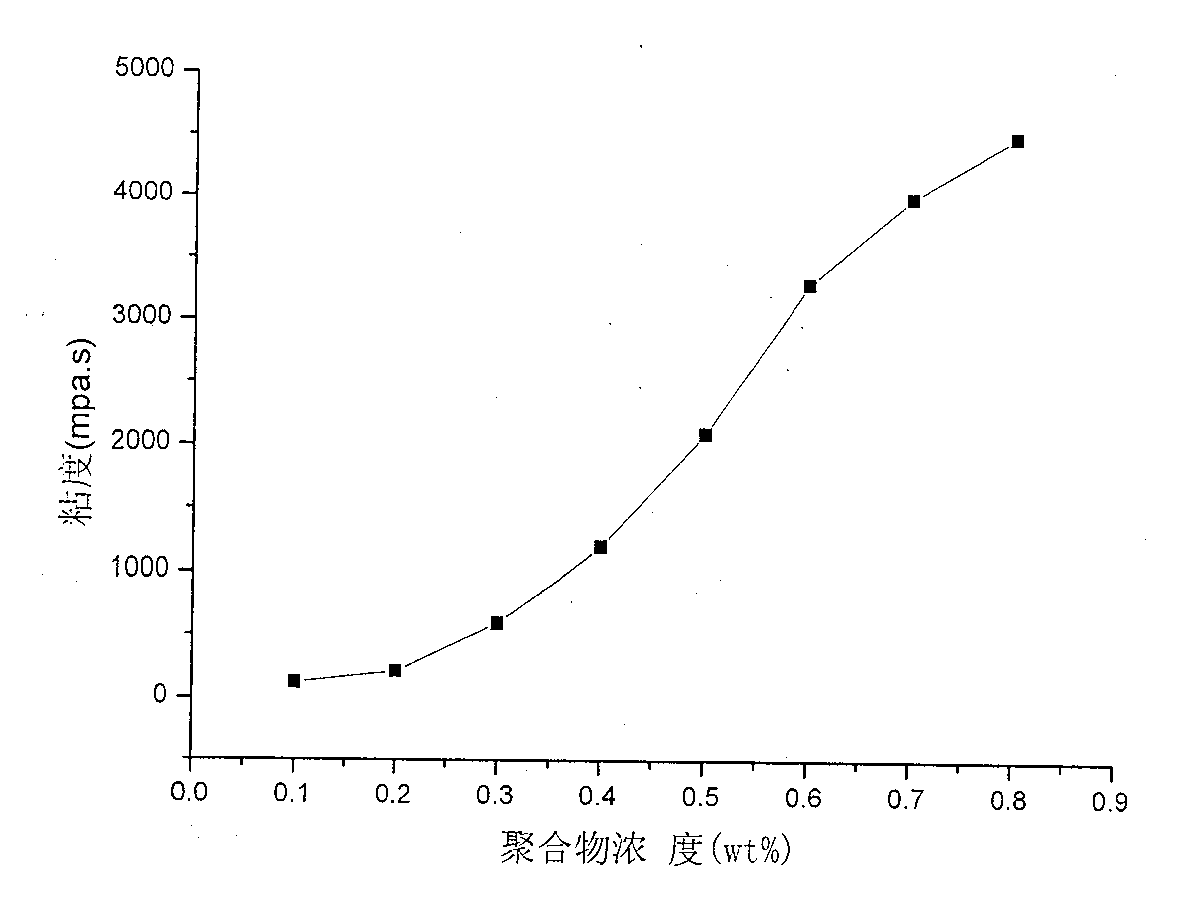

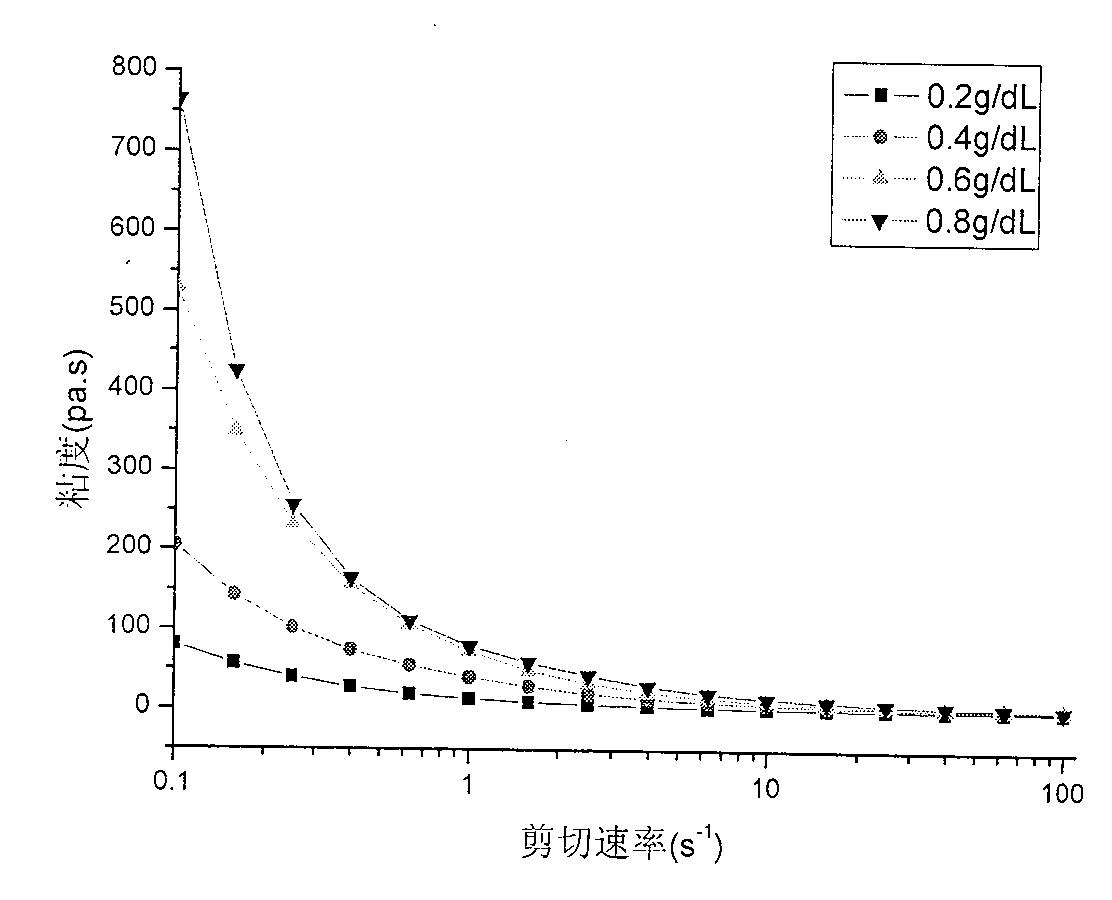

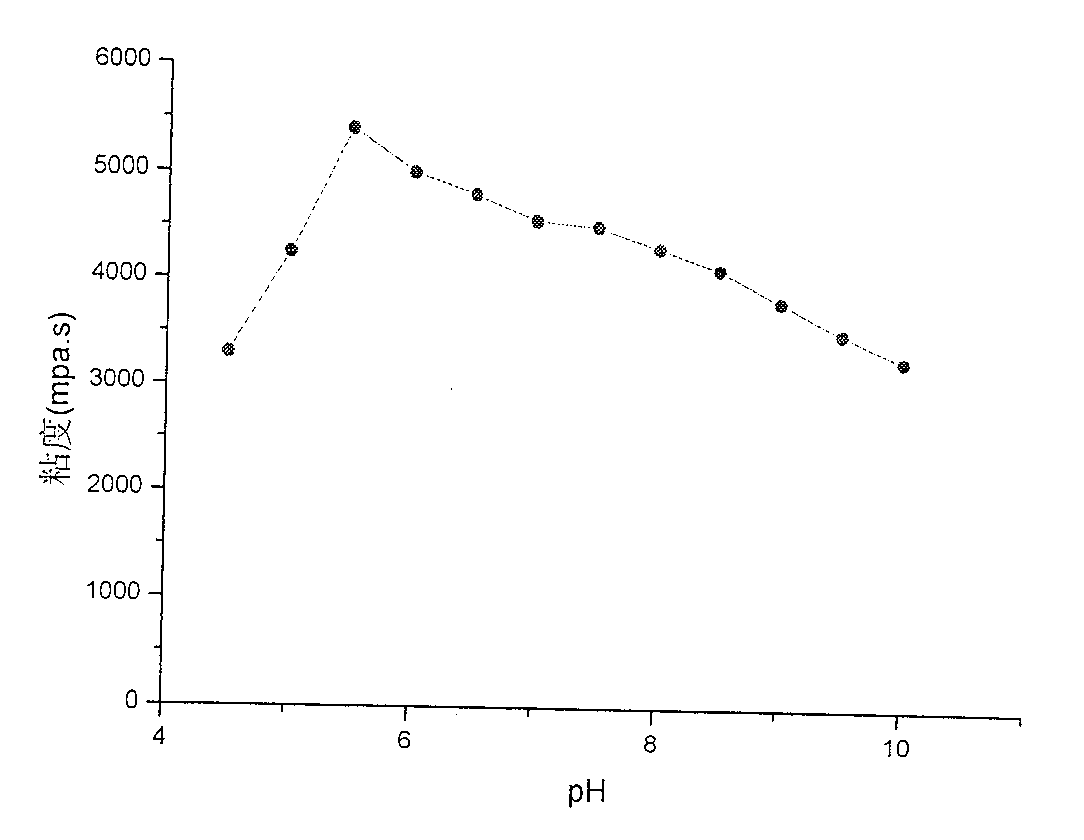

Siloxane group containing polyacrylic acid material and synthesizing technique thereof

InactiveCN100567347CWide variety of sourcesMass transfer rate is fastBulk chemical productionPolymer scienceEmulsion

The invention provides a polyacrylic acid material with oxosilane and the synthesis technology. The material is the polymer of acrylic acid and vinylsiloxane or acrylic ester with oxosilane and acrylic ester. The synthesis technique comprises the following steps: adding acrylic acid and vinylsiloxane or acrylic ester with oxosilane and acrylic ester according to 0.5-99.5:0.1-99.5:0-99.5 in the autoclave; adding 0.01-5.0wt% initiating agent; controlling the pressure of carbon dioxide at 8-25MPa; heating to 40-100Deg. C; reacting for 2-8 hours; extracting the product to the constant weight with carbon dioxide in the original position. The invention solves the difficult problem that the organic oxosilane monomer can't be grafted to the backbone chain, which has the food quality product and no pollution, can be used for tertiary oil extraction, the conversion of solar energy, the water treatment, emulsion paint, soil improvement, food and medical purpose.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

A method for removing copper

ActiveCN103820809BIncreased chance of reactionShort processPhotography auxillary processesElectrolysis componentsElectrolysisCu2 ions

The invention relates to a chemical purification method, especially to a copper removal method which is suitable for a nickel electrolysis anolyte purification process. The copper removal method provided by the invention is obviously different from a copper removal method by adding anode mud in nickel ore concentrate as follows: a sodium hydrosulphite solution is added in an iron-removed liquid to activate copper ions and increase reaction probability between copper ions and amorphous nickel sulfide; as amorphous nickel sulfide is added into a copper removal tank in a slurry form, labor intensity is reduced, it is convenient to realize automatic control, and stabilization and continuity of the copper removal process are guaranteed; and as copper slag can directly enter a copper melting system, the technology is optimized, flow of copper impurity in the system is shortened, copper slag is processed not by the use of chlorine, and the environment is improved. Through detection, a copper-removed liquid contains 0.4-2.5ppm of copper. Thus, purification requirements are met. The mass ratio of copper to nickel in the copper slag is 15-17. The copper slag can be directly melted to produce anode plates.

Owner:JINCHUAN GROUP LIMITED +1

An Improved Dye Vat

ActiveCN106245257BImprove cleaning efficiencyAvoid spreadingTextile treatment containersTreatment using aerobic processesFlocculationMotor drive

Owner:浙江华昌新材料股份有限公司

Improved dye vat

ActiveCN106245257AImprove cleaning efficiencyAvoid spreadingTextile treatment containersTreatment using aerobic processesFlocculationPulp and paper industry

The invention provides an improved dye vat, and belongs to the technical field of dyeing. The improved dye vat solves the problems that in the prior art, a dye vat can not be automatically cleaned, and dye liquor can not be automatically treated. The improved dye vat comprises a cylindrical vat body. A circular guide rail is fixed to the end face of the open end of the vat body, a sliding block is arranged on the guide rail and can slide along the guide rail, an extension part extending to the inner side of the vat body is arranged on the sliding block, a cleaning roller is rotationally connected to the extension part and is vertically arranged, the circumferential surface of the cleaning roller is attached to the inner wall of the vat body, and a rotating motor driving the cleaning roller to rotate is arranged on the sliding block. The vat body is further connected with a flocculation basin, the flocculation basin comprises a sedimentation basin, a water inlet pipe is arranged at the top of one side of the sedimentation basin, a water outlet pipe is arranged at the top of the other side of the sedimentation basin, the water inlet pipe is communicated with the vat body through a first water pipe, a sedimentator is arranged in the sedimentation basin, and a water inlet partition plate is vertically arranged in the sedimentation basin. The improved dye vat has the advantages that the dye vat can be automatically cleaned, and dye liquor can be automatically treated.

Owner:浙江华昌新材料股份有限公司

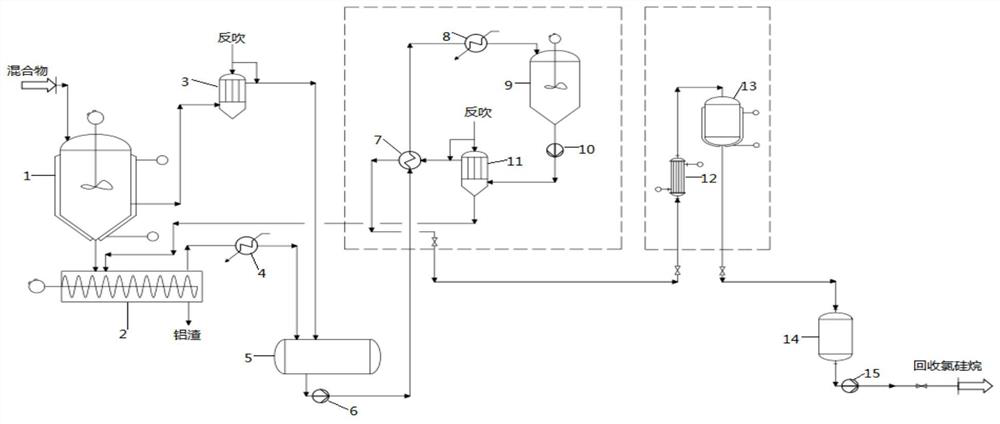

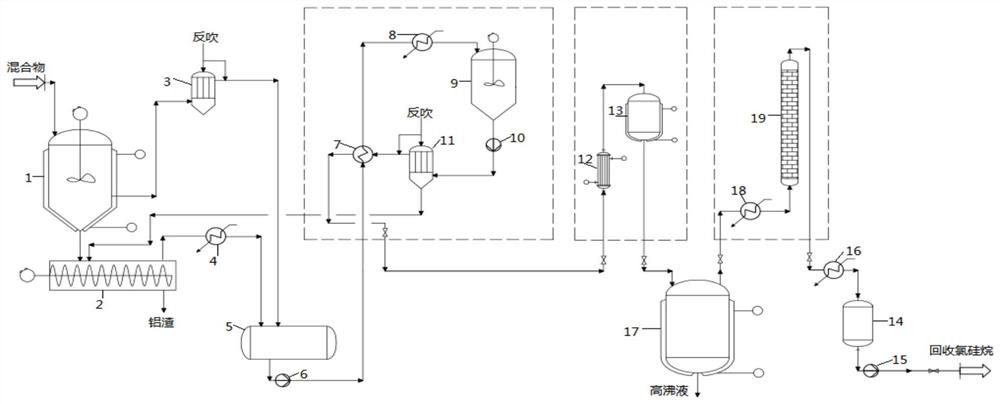

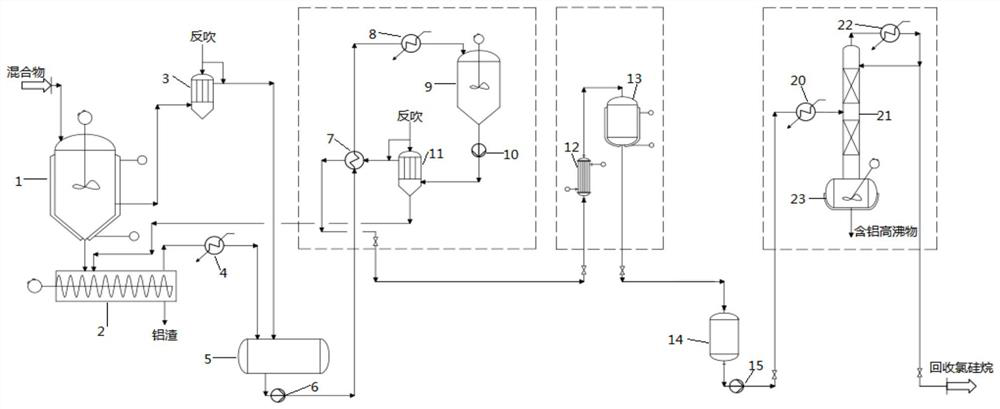

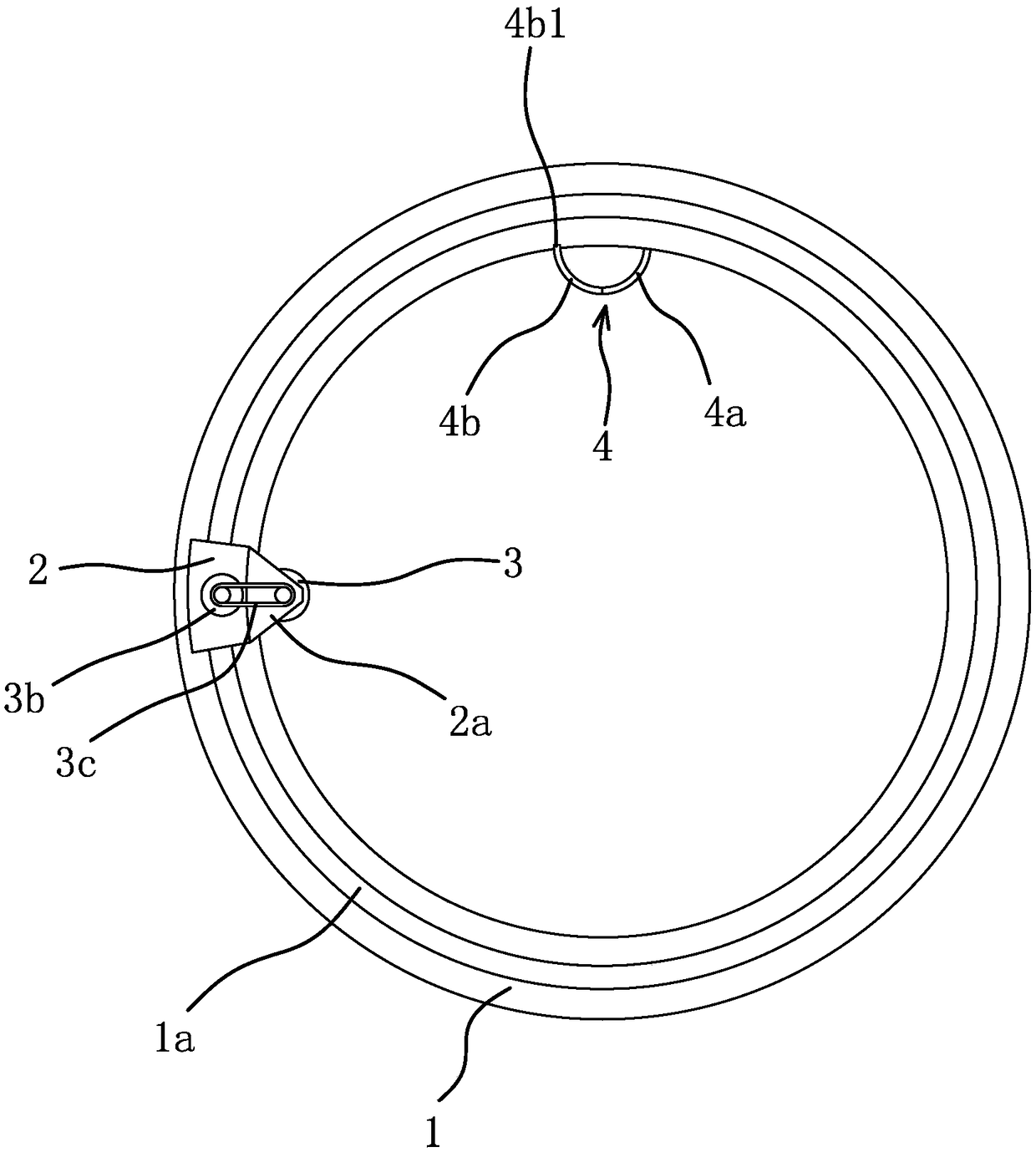

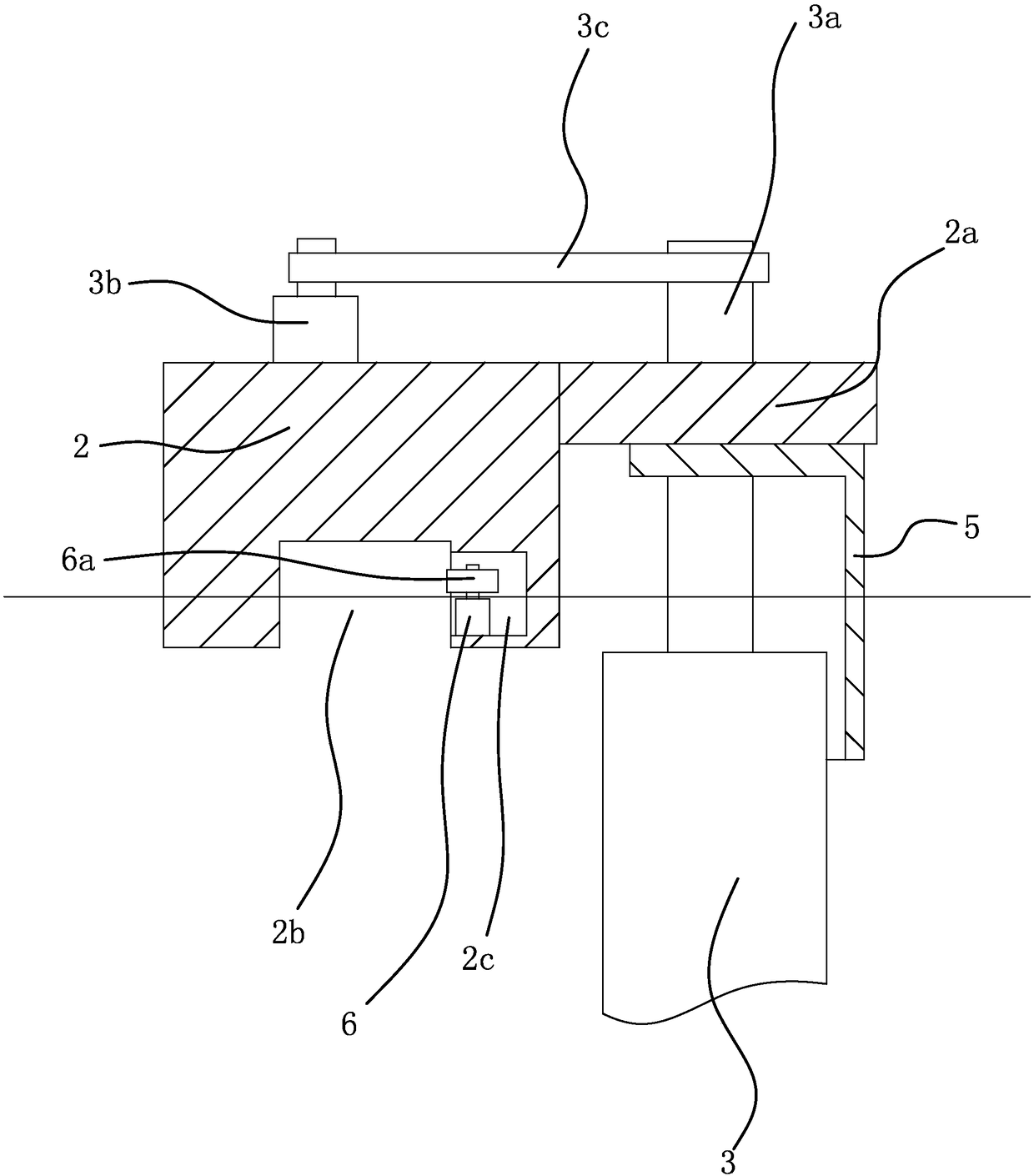

Process and equipment for removing aluminum by complexing chlorosilane

PendingCN112408396AReduce aluminum impurity contentReduce contentHalogenated silanesAluminium chloridePhysical chemistry

The invention relates to a process and equipment for removing aluminum by complexing chlorosilane. The low-temperature complexing aluminum removal process, the liquid-phase complexing aluminum removalprocess, the gas-phase complexing process and the high-pressure rectifying aluminum removal process are operated independently or in a combined mode to meet different chlorosilane purification requirements. A chlorosilane mixture filtered by the low-temperature complexing stirring tank filter and raw materials conveyed by the raw material buffer tank enter and exit the heat exchanger for heat exchange through low-temperature complexing aluminum removal, and effective utilization of energy is achieved. The low-temperature complexing aluminum removing agent, the liquid-phase aluminum removing agent and the gas-phase aluminum removing agent are long in service life and obvious in complexing aluminum removing effect. According to the process, various complexing aluminum removing agents can beselected for use, and high complexing aluminum removing performance can be kept under the condition of the technological operation range. The aluminum removal rate of chlorosilane is improved, the content of aluminum chloride in chlorosilane is reduced through the low-temperature complexing aluminum removal process and the liquid-phase complexing aluminum removal process, and finally the contentof aluminum in chlorosilane can be reduced to 0.001 ppm or below through the series gas-phase complexing aluminum removal process and the high-pressure rectification aluminum removal process.

Owner:TIANJIN UNIV

A dye vat for continuous tie-dyeing with reactive dyes

ActiveCN106222910BImprove cleaning efficiencyOptimizing the effect of denitrification and nitrogen removalTextile treatment machine arrangementsTextile treatment cleaning apparatusNitrogen removalMotor drive

Owner:浙江华昌新材料股份有限公司

An improved dyeing device

ActiveCN106350955BImprove recycling efficiencySimple structureTextile treatment containersTreatment using aerobic processesFlocculationEngineering

Owner:浙江华昌新材料股份有限公司

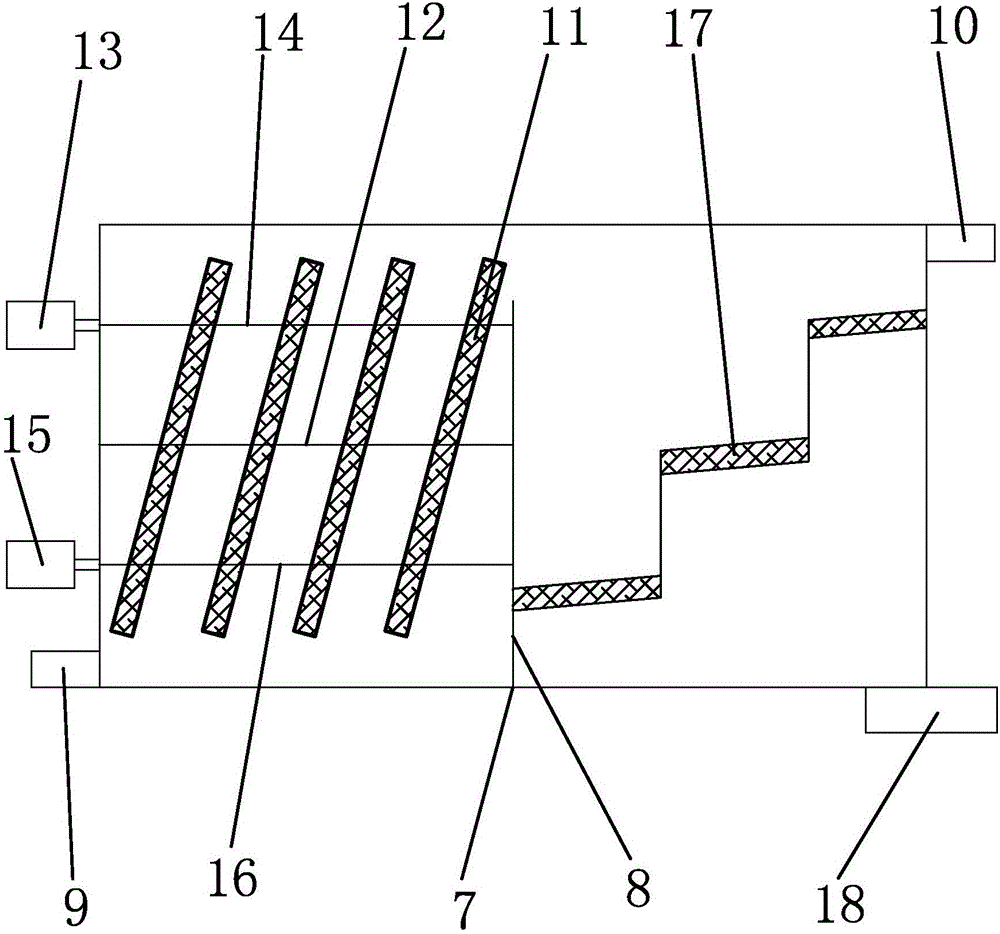

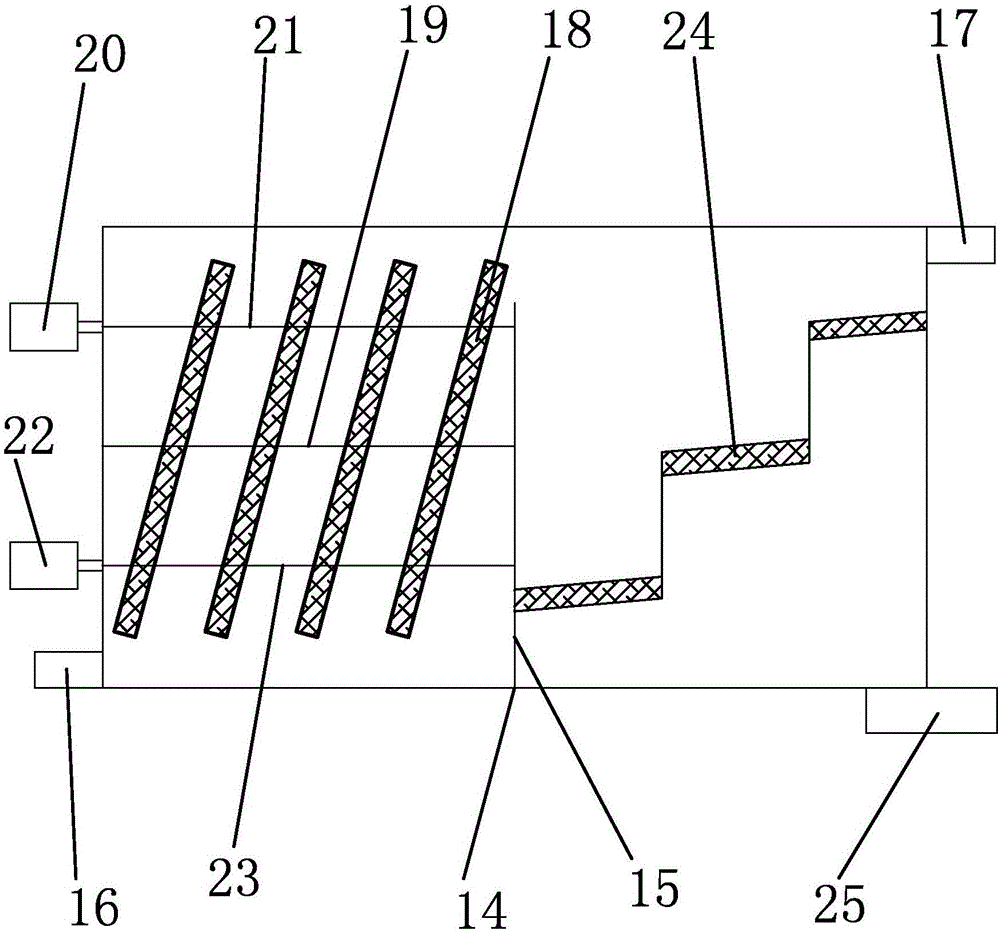

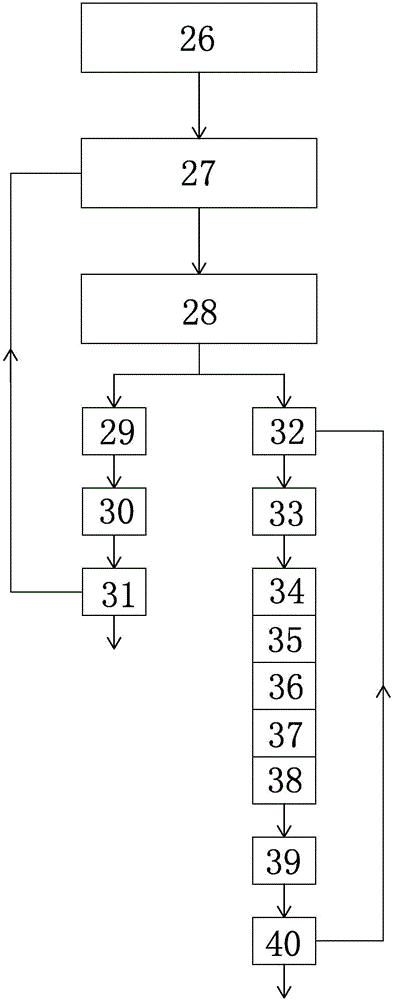

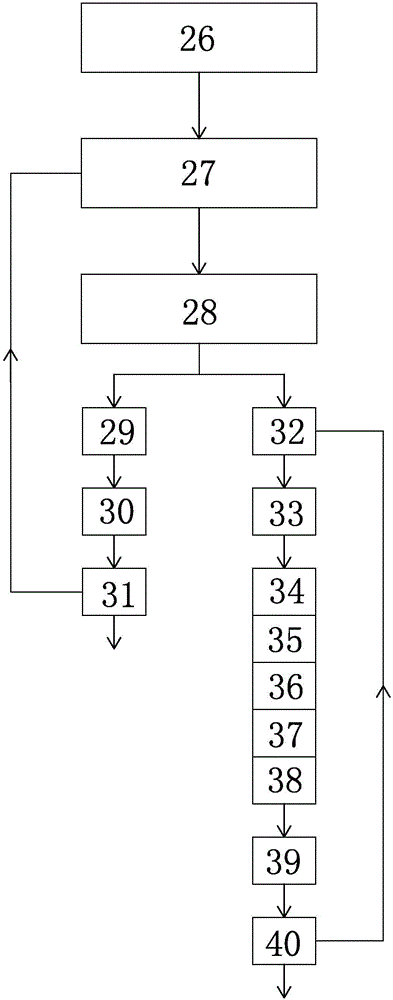

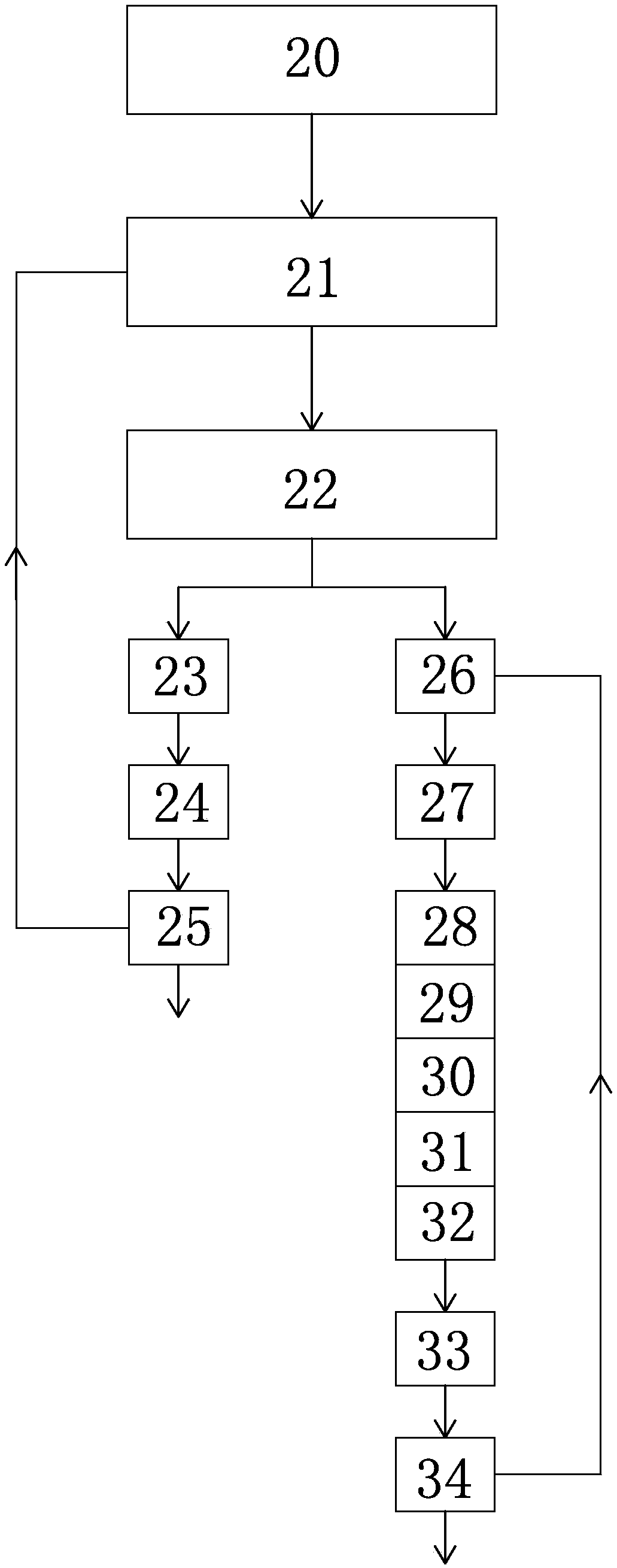

Single type photocatalyst air purifier

PendingCN107314468AExtended stayMeet the purification requirementsMechanical apparatusLighting and heating apparatusAir purifiersUltraviolet

The invention discloses a single type photocatalyst air purifier. The single type photocatalyst air purifier comprises a box and a draught fan arranged in the box. An air inlet is formed in one end of the box, an air outlet is formed in the other end of the box, and a photolysis assembly is arranged in the middle of the box. The photolysis assembly comprises a photocatalyst module and an irradiation device located on the outer side of the photocatalyst module, air flows through the photocatalyst module under the action of the draught fan, an ultraviolet lamp tube is adopted for illumination, VOCs make a photolysis reaction with photocatalyst media, and thus the purification requirements of the VOCs are met. Multiple air purifiers can also be connected in series or in parallel through pipelines, so that series-parallel connection multi-stage photolysis is achieved, the staying time of gas in photolysis chambers is prolonged, and the purification capacity is improved. Besides, adjacent air ventilation holes are distributed in a staggered manner, wind resistance is effectively increased, the staying time of air is longer, reaction time is prolonged, and the purification effect is better.

Owner:夏代超

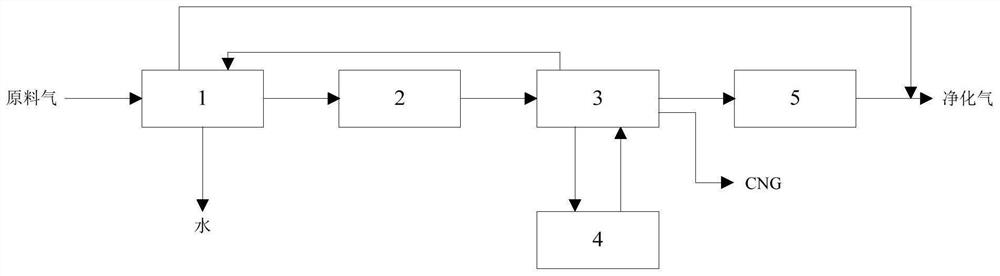

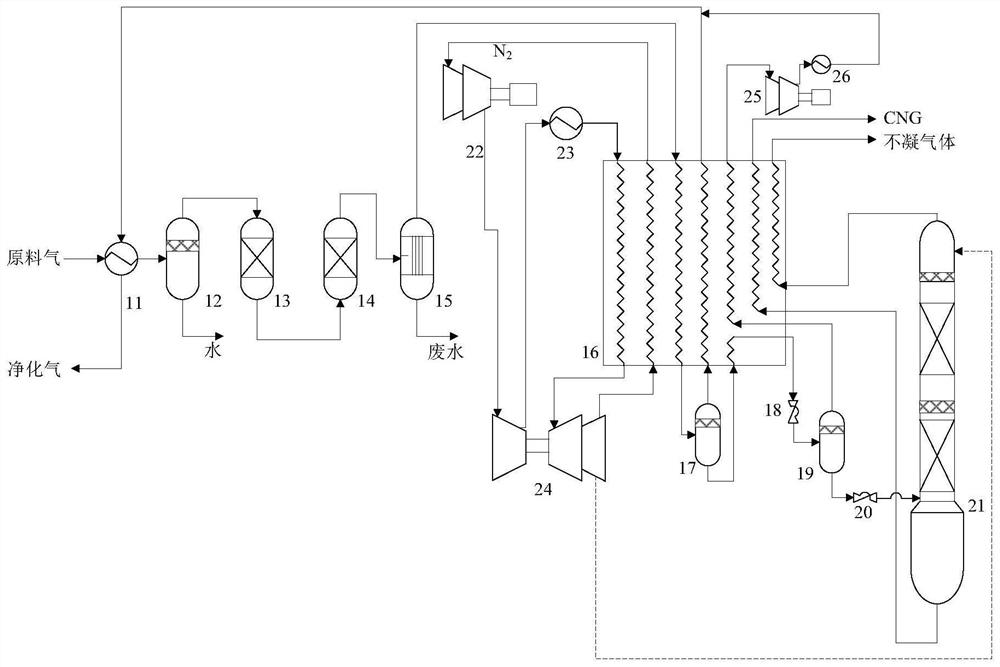

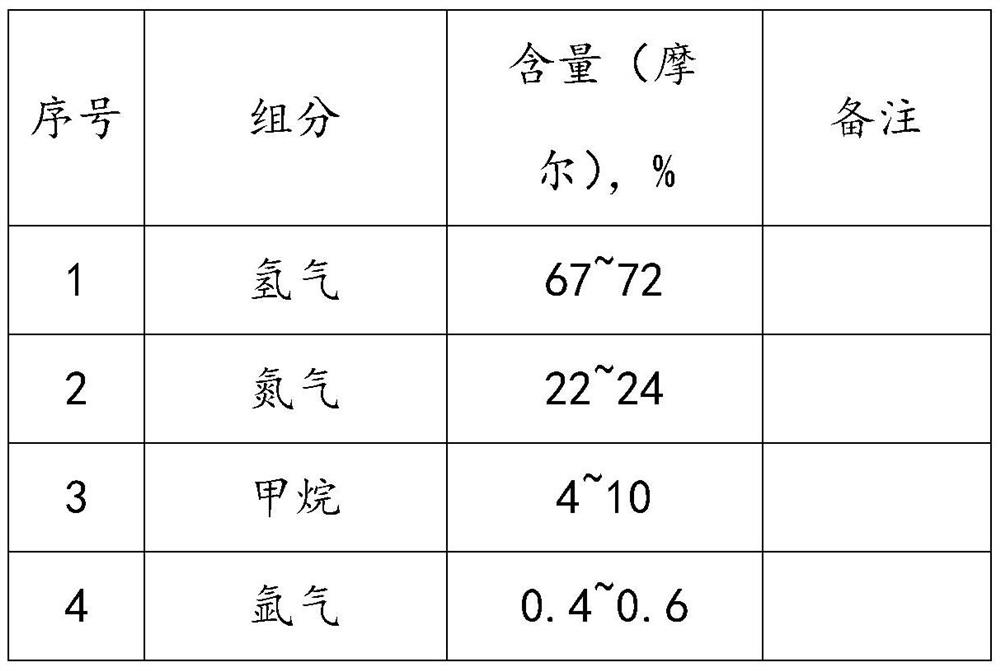

Pretreatment method and system of syngas for synthetic ammonia

PendingCN111634883AMeet the purification requirementsIncrease added valueSolidificationLiquefactionSyngasNitrogen gas

The invention discloses a pretreatment method and system of syngas for synthetic ammonia. The system comprises a dehydration device, a mercury removal device and a cryogenic separation device; the dehydration device is used for cooling and dehydrating the syngas; the mercury removal device is used for mercury removal and purification of the dehydrated syngas output by the dehydration device; the cryogenic separation device comprises a plate-fin heat exchanger group and is used for cooling the purified syngas output by the mercury removal device and outputting low-temperature purified syngas; and the cryogenic separation device further comprises a gas-liquid separation unit, the gas-liquid separation unit is used for carrying out gas-liquid separation on the low-temperature purified syngasoutput by the plate-fin heat exchanger unit to output low-temperature purified gas, and the low-temperature purified gas is heated by the plate-fin heat exchanger unit to obtain purified syngas for synthetic ammonia. Through reasonable arrangement of part structures, impurities in the syngas for synthetic ammonia are efficiently removed, and the impurity gas is made into a CNG product in a rectification and purification mode to be output, so the additional value of the product is increased; and meanwhile, circulating nitrogen is adopted for pressurization and expansion, so the energy efficiency is improved, and the overall device transformation cost and operation consumption are reduced.

Owner:XIAN SHAANGU POWER

Method for composite-filtering multiple filter media in aluminum-alloy-melt centrifuge field

InactiveCN102069147BMeet the purification requirementsSimple methodFoundry mouldsFoundry coresTemperature resistanceCast iron

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com