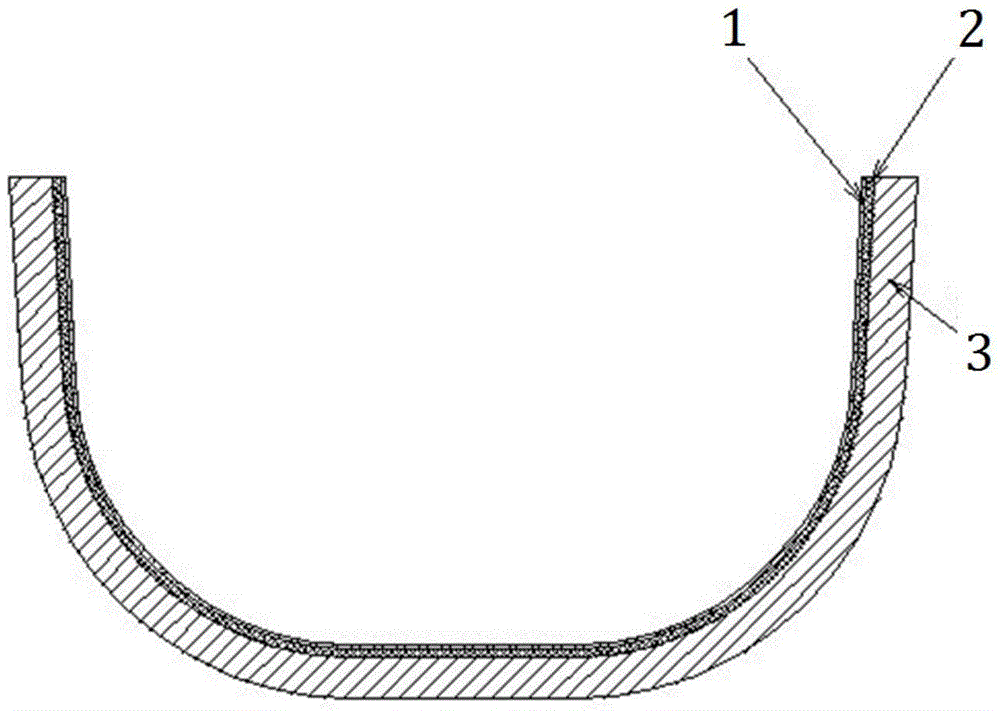

Iron-based crucible protection composite coating for refined aluminum purification

A composite coating and crucible technology, which is applied in the field of metallurgy, can solve problems such as thermal expansion coefficient coating layer cracks, and achieve the effects of improving service life, avoiding pollution, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment includes the following steps:

[0038] 1) Prepare the isolation layer, the specific steps are as follows:

[0039] a. Weigh 15% of aluminum oxide, 15% of aluminum dihydrogen phosphate and 70% of water by weight percentage, add aluminum dihydrogen phosphate and aluminum oxide powder into the water, and ball mill for half an hour to mix evenly to obtain the isolation layer slurry.

[0040] b. Thoroughly remove rust and dirt on the surface of a cast iron crucible to be coated with dilute acid, then heat it to 200-300°C and keep it warm for 1 hour.

[0041] c. Spray the slurry prepared in step a evenly on the inner wall of the crucible with a thickness of 0.2mm.

[0042] d. Carry out curing heat treatment at 80-120°C for 24 hours and 350-500°C for 1 hour to obtain the isolation layer.

[0043] 2) Prepare the anti-friction layer, the specific steps are as follows:

[0044] a. Weigh 20% of boron nitride, 5% of aluminum dihydrogen phosphate, 5% of polyvinyl ...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] 1) Prepare the isolation layer, the specific steps are as follows:

[0050] a. Weigh 18% of aluminum oxide, 12% of aluminum dihydrogen phosphate and 70% of water by weight percentage, add aluminum dihydrogen phosphate and aluminum oxide powder into the water, and ball mill for half an hour to mix evenly to obtain the isolation layer slurry.

[0051] b. Thoroughly remove rust and dirt on the surface of a cast iron crucible to be coated with dilute acid, then heat it to 200-300°C and keep it warm for 1 hour.

[0052] c. Spray the slurry prepared in step a evenly on the inner wall of the crucible with a thickness of 0.2mm.

[0053] d. Carry out curing heat treatment at 80-120°C for 24 hours and 350-500°C for 1 hour to obtain the isolation layer.

[0054] 2) Prepare the anti-friction layer, the specific steps are as follows:

[0055]a. Weigh 25% of boron nitride, 5% of aluminum dihydrogen phosphate, 5% of polyvinyl a...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] 1) Prepare the isolation layer, the specific steps are as follows:

[0061] a. Weigh 20% of alumina, 10% of aluminum dihydrogen phosphate and 70% of water by weight percentage, add aluminum dihydrogen phosphate and alumina powder into the water, and ball mill for half an hour to mix evenly to obtain the isolation layer slurry.

[0062] b. Thoroughly remove rust and dirt on the surface of a cast iron crucible to be coated with dilute acid, then heat it to 200-300°C and keep it warm for 1 hour.

[0063] c. Spray the slurry prepared in step a evenly on the inner wall of the crucible with a thickness of 0.2 mm.

[0064] d. Carry out curing heat treatment at 80-120°C for 24 hours and 350-500°C for 1 hour to obtain the isolation layer.

[0065] 2) Prepare the anti-friction layer, the specific steps are as follows:

[0066] a. Weigh 30% of boron nitride, 5% of aluminum dihydrogen phosphate, 5% of polyvinyl alcohol and 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com