Zinc and zinc alloy melt foamed ceramic centrifugal compound purification device

A technology of foam ceramics and centrifugal compounding, which is applied in the direction of centrifuges, filtration separation, separation methods, etc., can solve the problems of large flow resistance, large pressure head, and blockage of metal melt, and achieve the effect of simple device and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

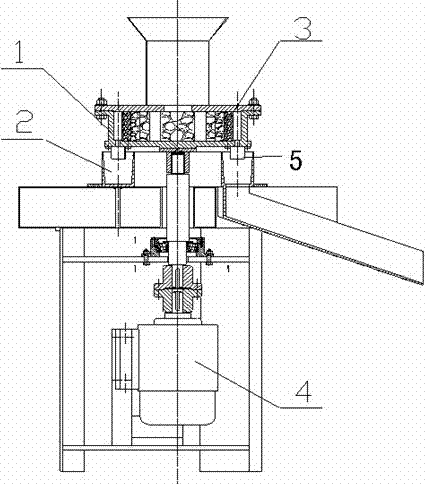

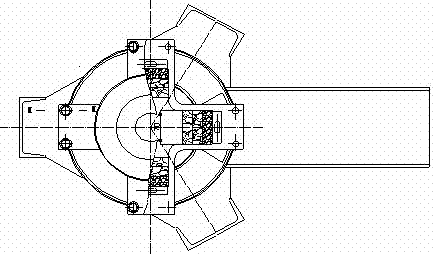

[0015] Such as figure 1 , figure 2 As shown, the present invention is realized in this way, the rotatable runner 1 is made of heat-resistant steel, the rotatable runner 1 includes a sprue and a runner perpendicular to the sprue, and the runner is a symmetrical multi-channel , to maintain a balance to the center of rotation, the collecting tank 2 is also made of heat-resistant steel, and is a ring structure, the collecting tank 2 is arranged below the water outlet 5 of the rotatable runner 1, and the water outlet 6 of the rotatable runner 1 extends The rotatable runner 1 is coaxially connected to the motor 4, and the runners of the rotatable runner 1 are respectively connected with multi-stage foam ceramic filter pieces 3.

[0016] The settings of the multi-stage ceramic foam filter are as follows: the first stage aperture is 10ppi and the thickness is 20~40mm; the second stage aperture is 20ppi thickness; the third stage aperture is 40 ppi and the thickness is 2020~40mm; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com