Optimized combined desulfurization technology for PSA analysis gas and coal tar hydrogenation device acid gas

A hydrogenation device and acid gas technology, applied in the field of coal chemical industry, can solve the problems of large investment and achieve the effect of high controllability of desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

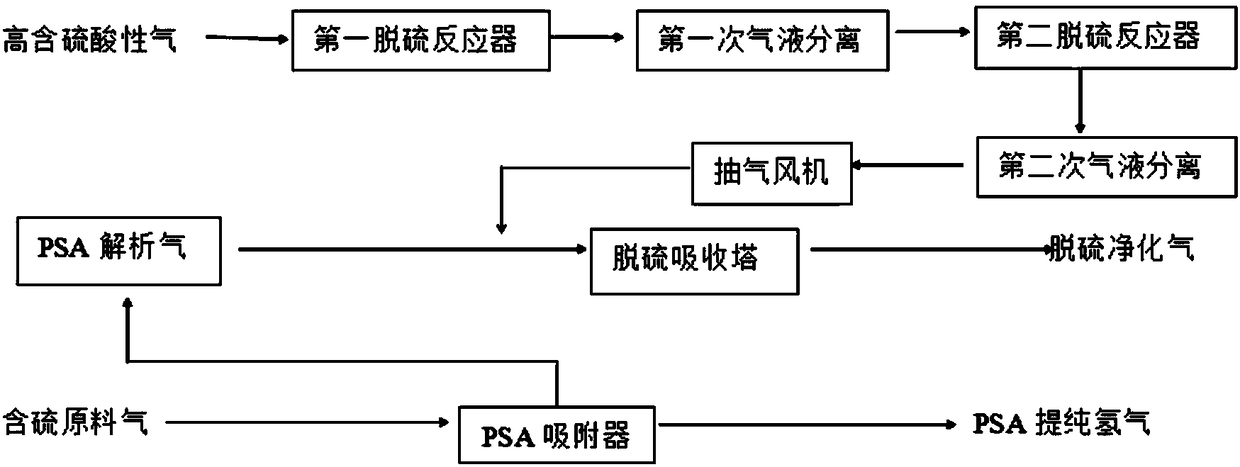

[0041] Such as figure 1 As shown, this embodiment provides a PSA analysis gas and coal tar hydrogenation unit acid gas optimization joint desulfurization technology, including the following steps:

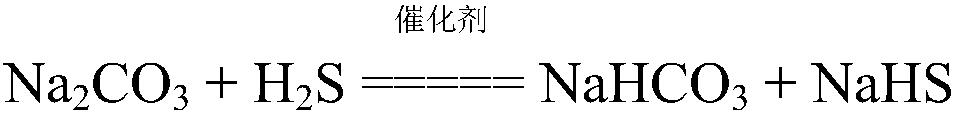

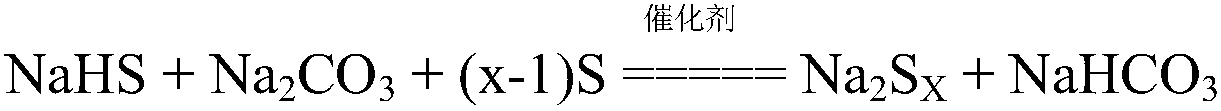

[0042] (1) High sulfuric acid gas (H 2 S concentration as high as 97%) is passed into the first desulfurization reactor, sodium carbonate (analytical pure) is used as the desulfurization liquid, phthalocyanine cobalt sulfonate DKT-6 is used as the catalyst, and the gas with high sulfuric acid content is desulfurized at 40°C. The first desulfurization treatment 8s; absorb H 2 The desulfurized liquid after S is passed into the oxidation regenerator for desorption reaction to produce elemental sulfur, and at the same time the desulfurized liquid resumes absorbing H 2 The ability of S, the generated elemental sulfur is melted by heating, discharged and solidified by cooling, so as to realize the recovery of sulfur;

[0043] (2) the tail gas discharged from the outlet of the first de...

Embodiment 2

[0047] This embodiment provides a PSA analysis gas and coal tar hydrogenation unit acid gas optimization joint desulfurization technology, including the following steps:

[0048] (1) High sulfuric acid gas (H 2 S concentration as high as 96%) is passed into the first desulfurization reactor, with sodium carbonate as the desulfurization liquid and cobalt phthalocyanine sulfonate as the catalyst, the first desulfurization treatment is performed on the high sulfuric acid gas at 45°C for 2s; absorb H 2 The desulfurized liquid after S is passed into the oxidation regenerator for desorption reaction to produce elemental sulfur, and at the same time the desulfurized liquid resumes absorbing H 2 The ability of S, the generated elemental sulfur is melted by heating, discharged and solidified by cooling, so as to realize the recovery of sulfur;

[0049] (2) the tail gas discharged from the outlet of the first desulfurization reactor is subjected to gas-liquid separation for the first ...

Embodiment 3

[0053] This embodiment provides a PSA analysis gas and coal tar hydrogenation unit acid gas optimization joint desulfurization technology, including the following steps:

[0054] (1) High sulfuric acid gas (H 2 The S concentration is as high as 98%) into the first desulfurization reactor, using sodium carbonate as the desulfurization solution, and using cobalt phthalocyanine sulfonate as the catalyst, to carry out the first desulfurization treatment on the high sulfuric acid gas at 42°C for 5s; absorb H 2 The desulfurized liquid after S is passed into the oxidation regenerator for desorption reaction to produce elemental sulfur, and at the same time the desulfurized liquid resumes absorbing H 2 The ability of S, the generated elemental sulfur is melted by heating, discharged and solidified by cooling, so as to realize the recovery of sulfur;

[0055] (2) the tail gas discharged from the outlet of the first desulfurization reactor is subjected to gas-liquid separation for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com