Preparation method of high-purity aluminum

A high-purity, aluminum liquid technology, applied in the field of metal aluminum segregation and purification, can solve the problems of high energy consumption and low purification efficiency, and achieve the effects of simplifying process steps, improving purification efficiency and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

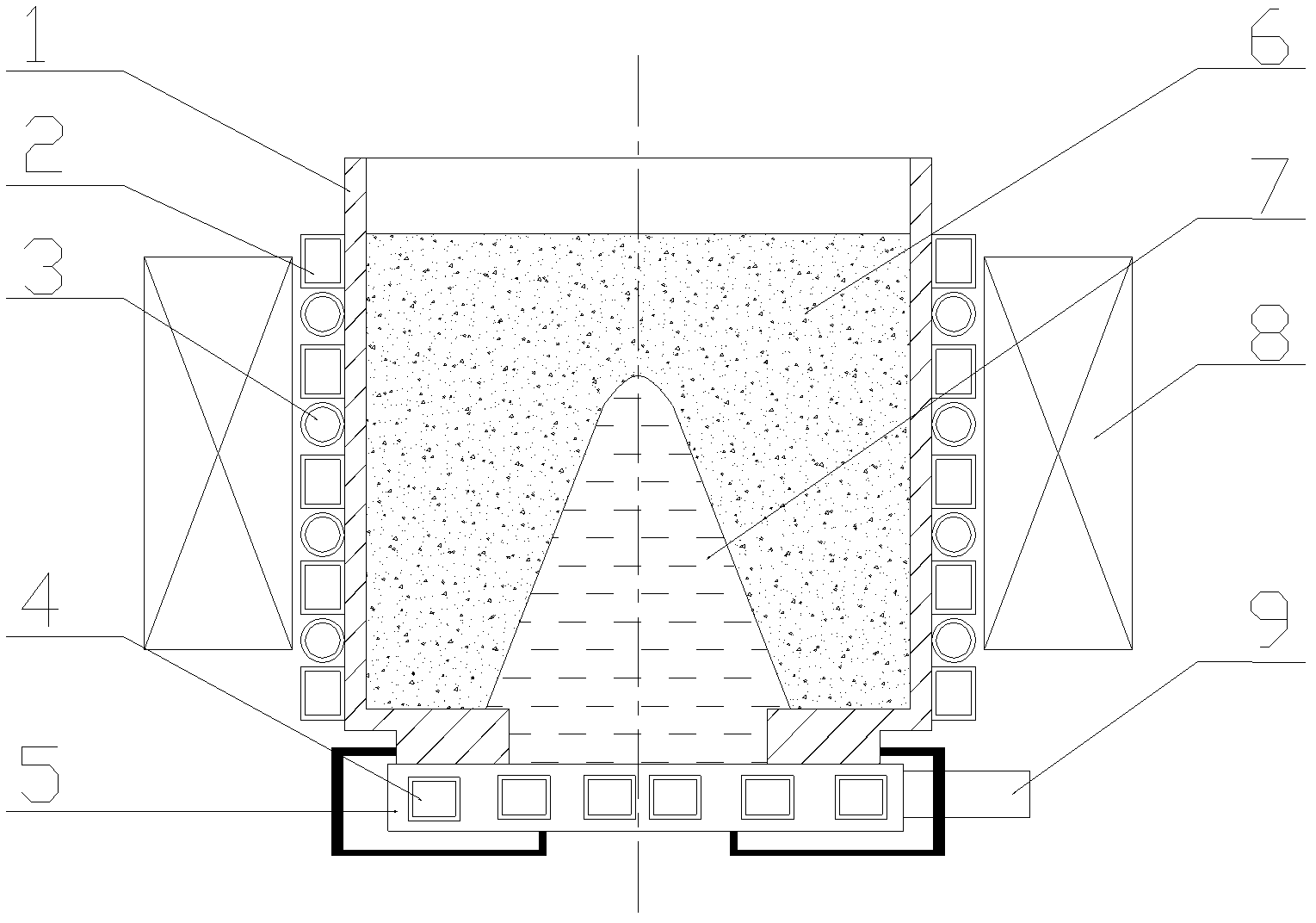

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Take 10kg of aluminum ingot (99.7Al) as the object of purification, use a smelting furnace to heat the metal aluminum to 670°C, keep it warm for 12 minutes to make the temperature of the molten aluminum in the furnace uniform, and reduce the temperature in the furnace at a rate of 0.1°C / min. When the monitoring temperature of the solidified aluminum at the top is 658°C, stop the cooling, and discharge the unsolidified aluminum liquid in the furnace from the bottom of the furnace. The discharged aluminum liquid is about 2kg, and the purity of the solidified metal aluminum in the furnace can reach 99.99Al. Close the bottom of the furnace, reheat the aluminum in the furnace to 670°C, and go through the above-mentioned purification process once more to purify the aluminum in the furnace to 99.9995Al.

Embodiment 2

[0015] Example 2: Take 10kg of molten aluminum (99.7Al) as the object of purification, use a smelting furnace to keep the temperature of the molten aluminum at 675°C, keep it warm for 10 minutes to make the temperature of the molten aluminum in the furnace uniform, and lower the temperature in the furnace at a rate of 0.5°C / min , until the monitoring temperature of the top solidified aluminum is 658°C, stop cooling, and discharge the unsolidified aluminum liquid in the furnace from the bottom of the furnace. The discharged aluminum liquid is about 2kg, and the purity of the solidified metal aluminum in the furnace can reach 99.95Al. Close the bottom of the furnace, reheat the aluminum in the furnace to 675°C, and then go through the above purification process twice to purify the aluminum in the furnace to 99.9995Al.

Embodiment 3

[0016] Example 3: Take 10kg of aluminum ingot (99.7Al) as the object of purification, use a smelting furnace to heat the metal aluminum to 680°C, keep it warm for 15 minutes to make the temperature of the molten aluminum in the furnace uniform, and lower the temperature in the furnace at a rate of 5°C / min. When the monitoring temperature of the solidified aluminum at the top is 658°C, the cooling is stopped, and the unsolidified aluminum liquid in the furnace is discharged from the bottom of the furnace. The discharged aluminum liquid is about 2kg, and the purity of the solidified metal aluminum in the furnace can reach 99.9Al. Close the bottom of the furnace, reheat the aluminum in the furnace to 680°C, and after four times of the above purification process, the aluminum in the furnace can be purified to 99.9995Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com