Dye vat for continuous dyeing in reactive dye tie dyeing

A reactive dye and dye vat technology, applied in the field of dyeing, can solve the problems of low cleaning efficiency, high labor cost, sticking to the inner wall of the dye vat, etc., and achieves the effects of high recovery efficiency, simple structure and high cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

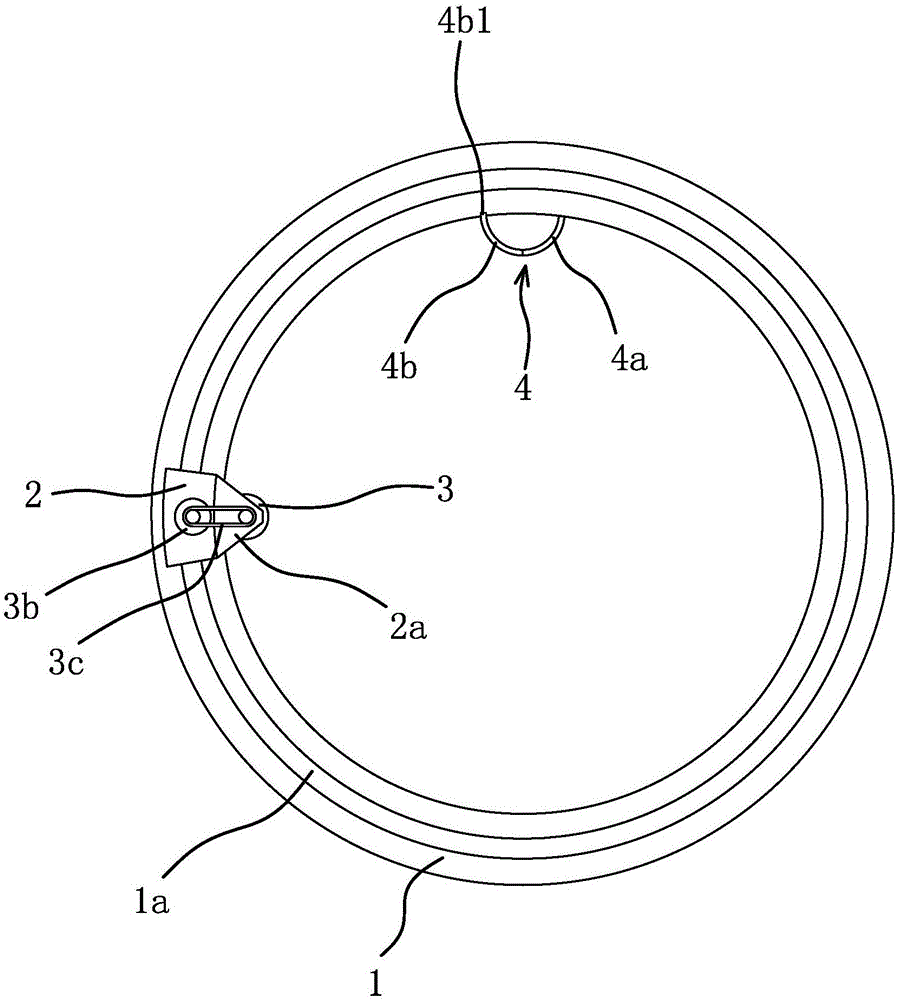

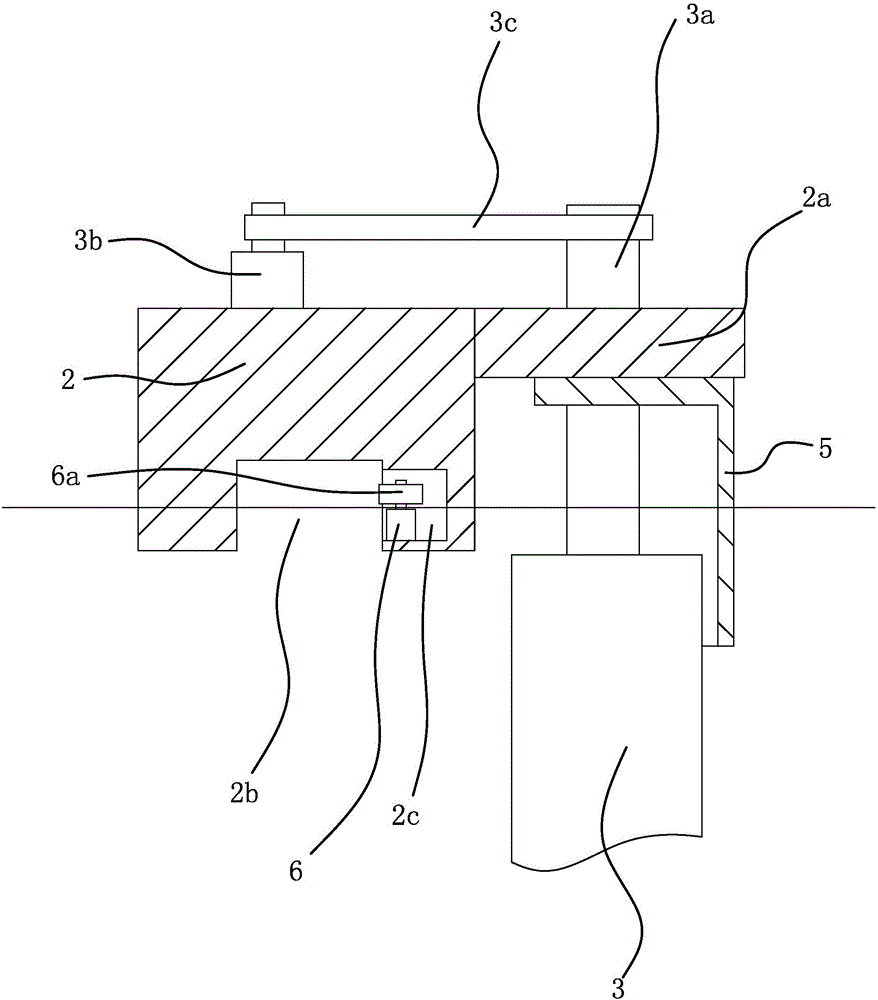

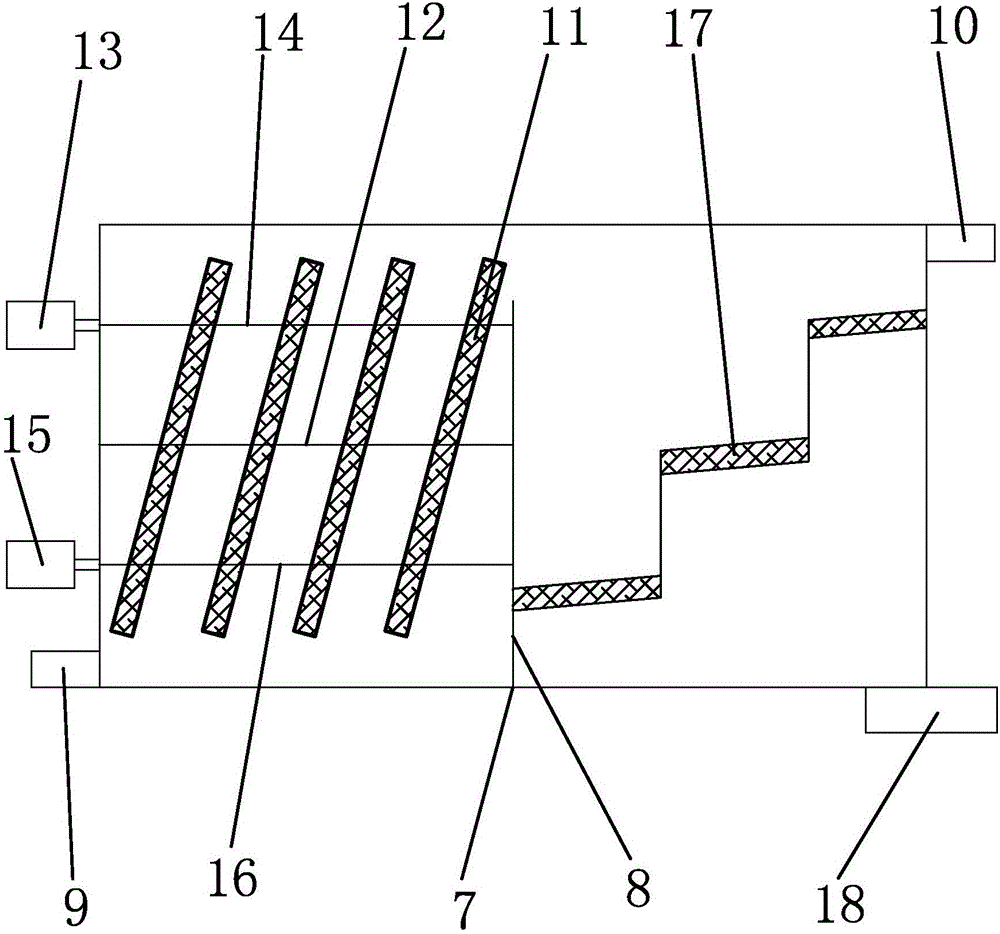

[0030] Such as figure 1 , figure 2 As shown, a dye vat for continuous dyeing of reactive dye tie-dyeing includes a cylindrical cylinder body 1, a circular guide rail 1a is fixed on the open end surface of the cylinder body 1, and a slide block 2 is arranged on the guide rail 1a. The block 2 can slide along the guide rail 1a. The slide block 2 is provided with an extension 2a extending to the inside of the cylinder body 1. The extension 2a is rotatably connected with a cleaning roller 3. The cleaning roller 3 is vertically arranged and the peripheral surface of the cleaning roller 3 is in line with the The inner wall of the cylinder body 1 abuts against, and the slider 2 is provided with a rotating motor 3b for driving th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com