Process and equipment for removing aluminum by complexing chlorosilane

A chlorosilane and complexation technology, which is applied in the direction of silicon compounds, halosilanes, and silicon halide compounds, can solve the problems of aluminum removal process and equipment introduction without chlorosilane, and achieve the effect of reducing the content of aluminum impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

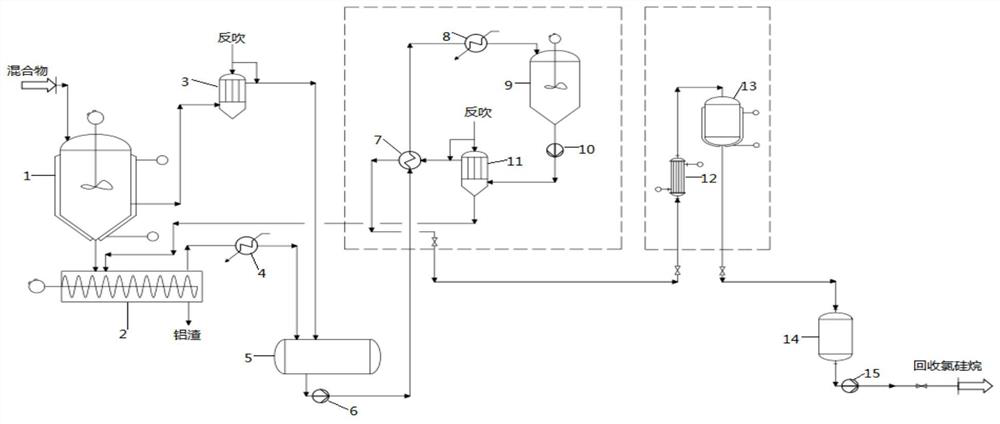

example 1

[0063] The low-temperature complex aluminum removal agent and the liquid phase complex aluminum removal agent use sodium chloride, and the filling amount is 40% of the tank volume.

[0064] The 20°C mixture raw material containing 10ppm aluminum chloride is fed into the top position of the agitating settling tank, settled and separated, and the mixture at the bottom of the tank is dried and separated by a dryer to separate silicon powder and aluminum slag, and then condensed into the raw material buffer tank through the raw material condenser; After the chlorosilane mixture is filtered and separated by the filter of the stirring settling tank, it also enters the raw material buffer tank; the raw material is first pre-cooled to -5°C through the low-temperature complexation and aluminum removal heat exchanger, and then cooled to -30°C by the low-temperature cooler. The low-temperature complexation stirring tank filled with sodium chloride removes aluminum and then filters through...

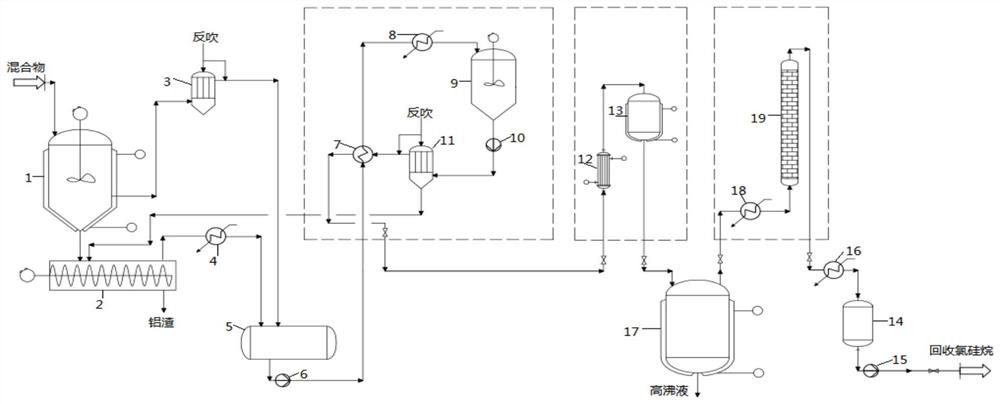

example 2

[0066] Dimethylamine hydrochloride is selected as the low-temperature complexing aluminum removal agent and the liquid phase complexation aluminum removal agent, and the filling amount is 50% of the volume of the tank.

[0067] The 20°C mixture raw material containing 10ppm aluminum chloride is fed into the top position of the agitating settling tank, settled and separated, and the mixture at the bottom of the tank is dried and separated by a dryer to separate silicon powder and aluminum slag, and then condensed into the raw material buffer tank through the raw material condenser; The chlorosilane mixture is filtered and separated by the filter of the stirring and settling tank, and then enters the raw material buffer tank; the raw material is pre-cooled to 0°C through the low-temperature complexation and aluminum removal heat exchanger, and then cooled to -20°C by the low-temperature cooler before entering the storage tank. After the low-temperature complexation stirring tank ...

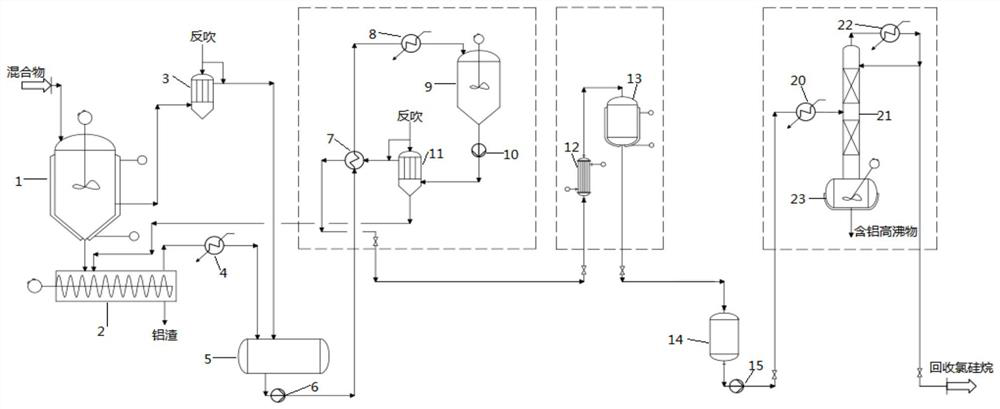

example 3

[0074] The low-temperature complexing aluminum removal agent and the liquid phase complexation aluminum removal agent are potassium chloride, and the gas phase complexation aluminum removal agent is a mixture of dimethylamine hydrochloride and sodium chloride loaded on activated alumina (equal mass mixing, load total mass score is 10%).

[0075]The 20°C mixture raw material containing 10ppm aluminum chloride is fed into the top position of the agitating settling tank, settled and separated, and the mixture at the bottom of the tank is dried and separated by a dryer to separate silicon powder and aluminum slag, and then condensed into the raw material buffer tank through the raw material condenser; After the chlorosilane mixture is filtered and separated by the filter of the stirring settling tank, it also enters the raw material buffer tank; the raw material is first pre-cooled to -5°C through the low-temperature complexation and aluminum removal heat exchanger, and then cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com