Patents

Literature

38 results about "Aluminium agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

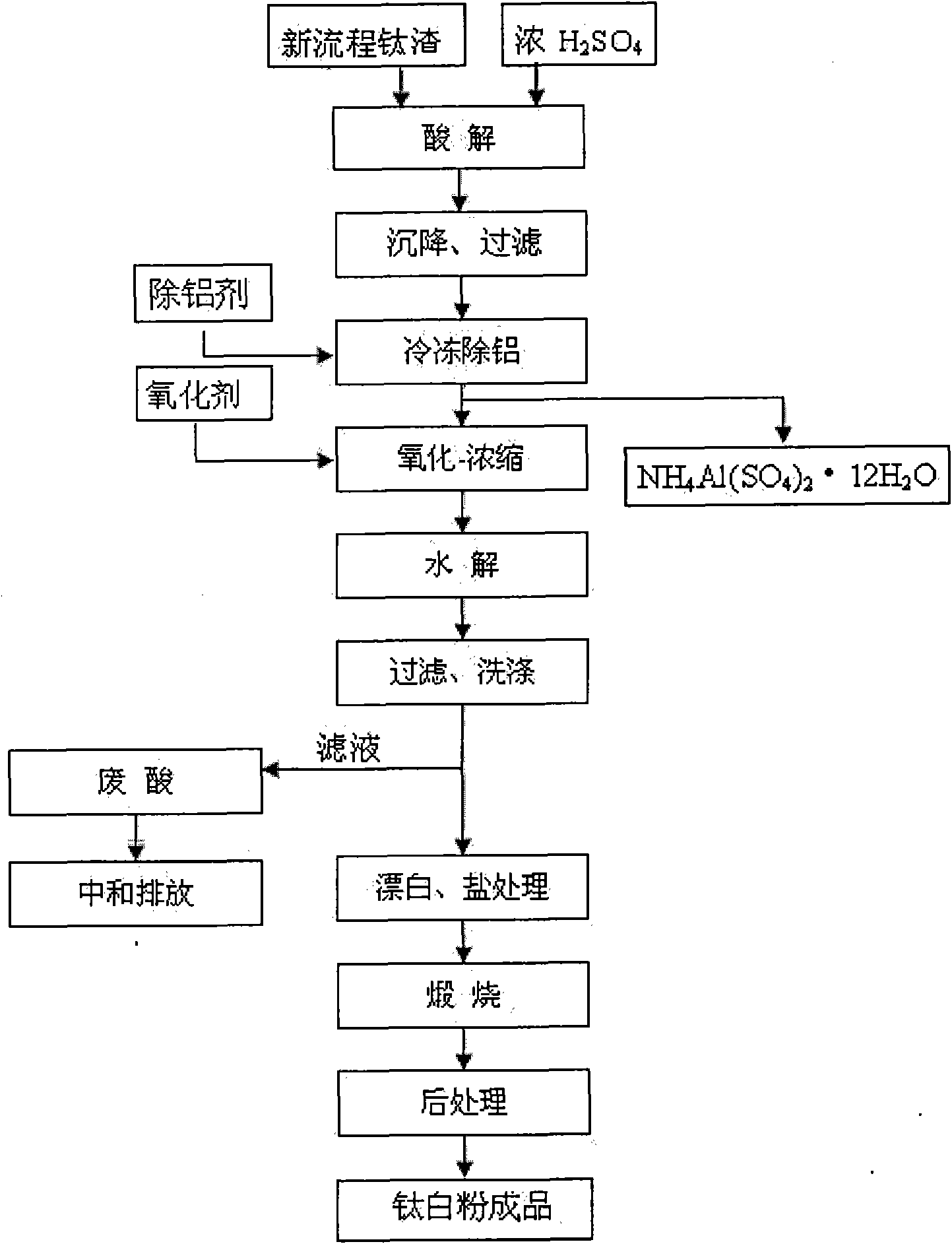

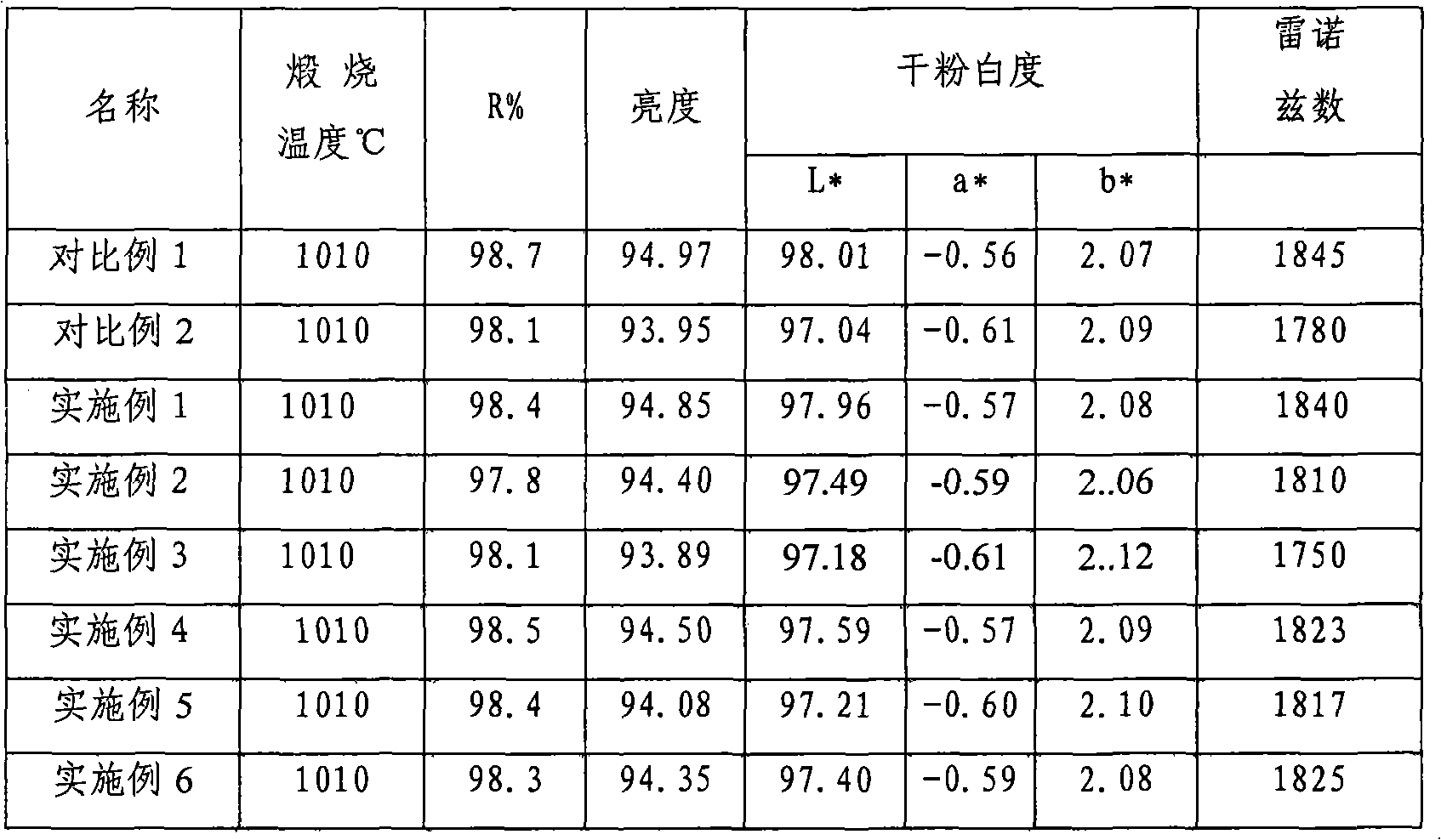

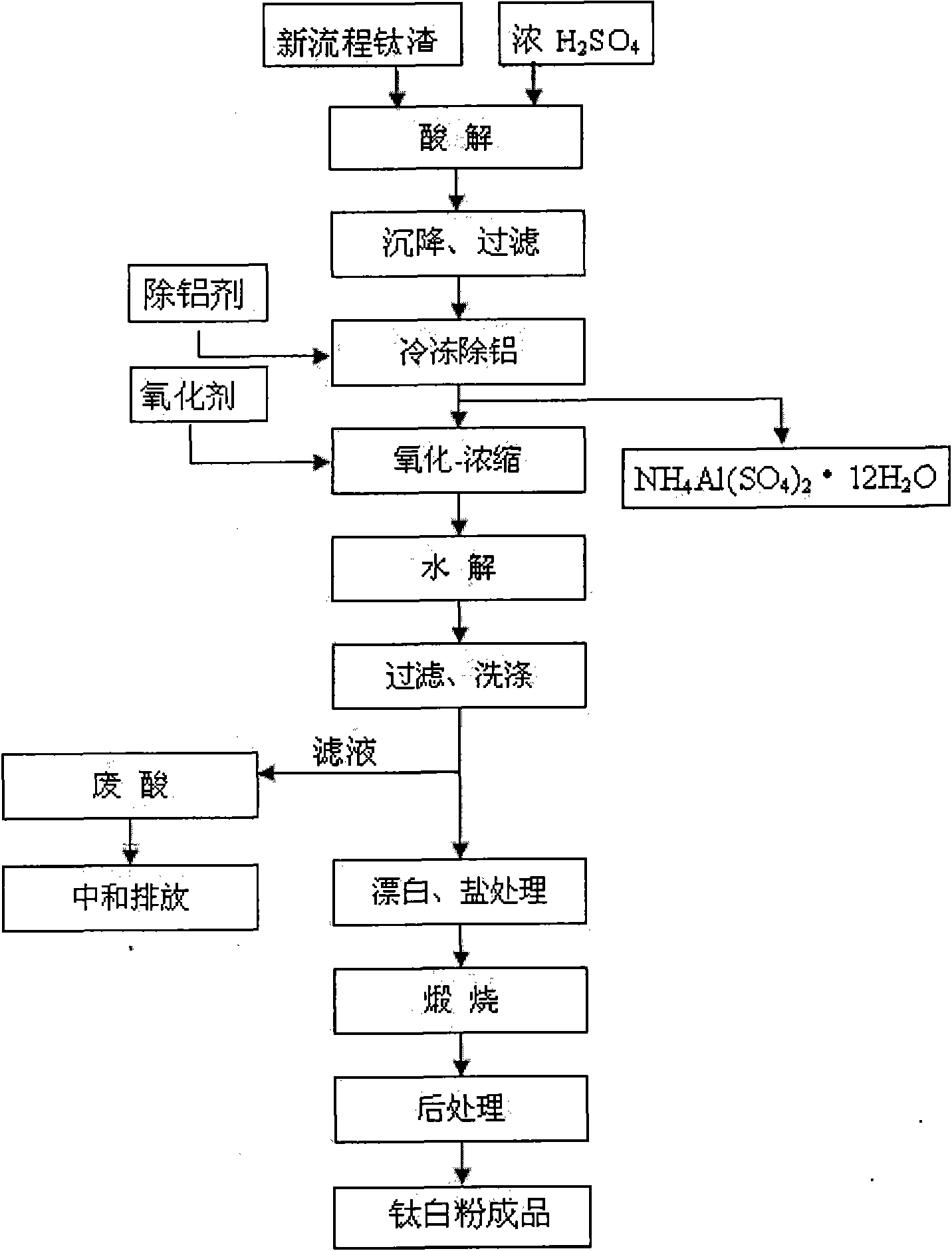

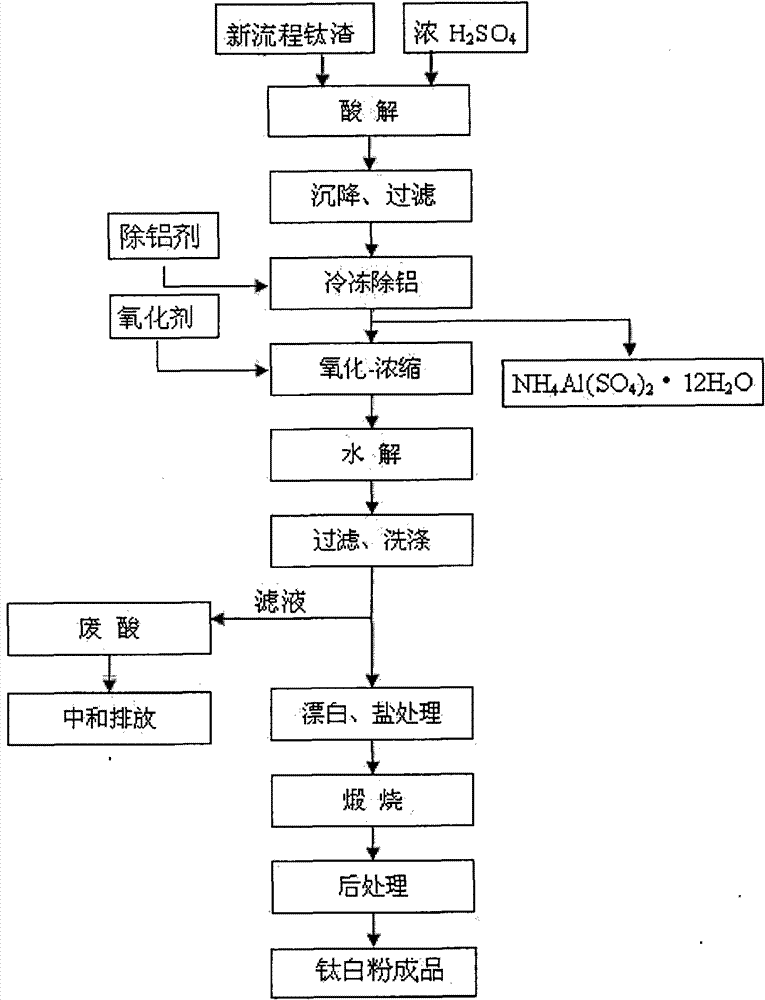

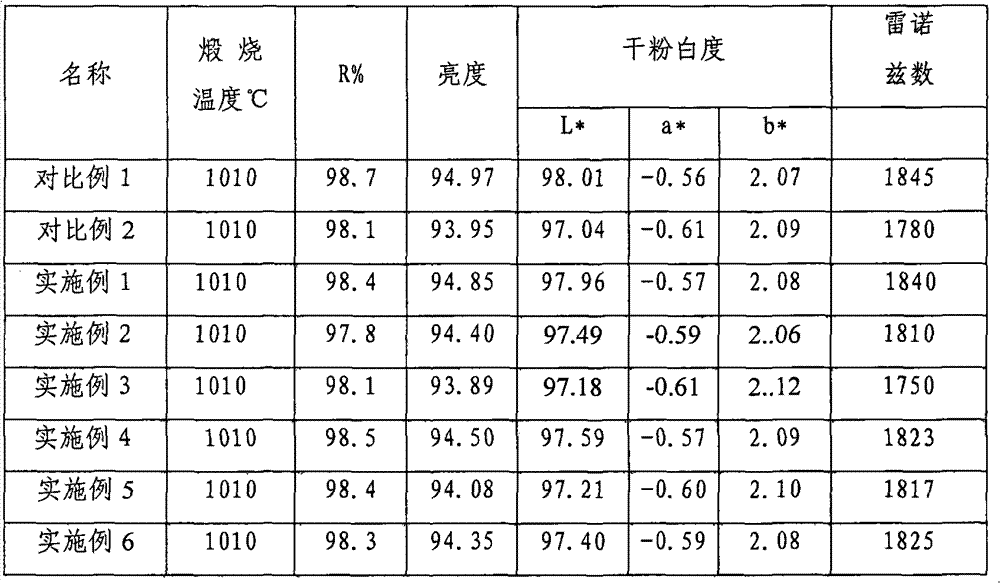

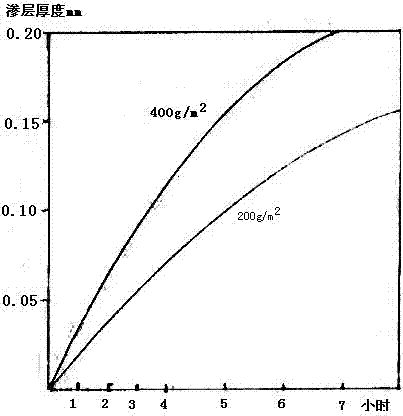

Method for preparing rutile titanium dioxide from new process titanium slag

ActiveCN101898791AIncrease profitReduce manufacturing costSolid waste disposalTitanium dioxideAluminium agentsRutile

The invention discloses a method for preparing titanium dioxide from new process titanium slag, and belongs to the technical field of titanium dioxide production. The method comprises the following steps of: performing acidolysis reaction on the new process titanium slag and concentrated sulfuric acid under certain conditions; leaching, precipitating and filtering the mixture to obtain clear titanium liquid; adding an aluminum removing agent into the clear titanium liquid to recover aluminum by freezing crystallization; adding oxidized trivalent titanium serving as an oxidant into the clear titanium liquid and concentrating the mixture; hydrolyzing, filtering and washing the concentrate by using a process for adding crystal seeds; and bleaching, salting, calcining and post-processing the filter cake to prepare the rutile titanium dioxide which meets the application requirement. The method has the most noticeable characteristic that the rutile titanium dioxide which meets the application requirement is prepared from the new process titanium slag which has the disadvantages of various impurities and difficult acidolysis; and thus a new raw material for producing the titanium dioxide by a sulfuric acid method is developed, various valuable elements are recovered as much as possible, the utilization ratio of the resource is improved and the production cost is reduced.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

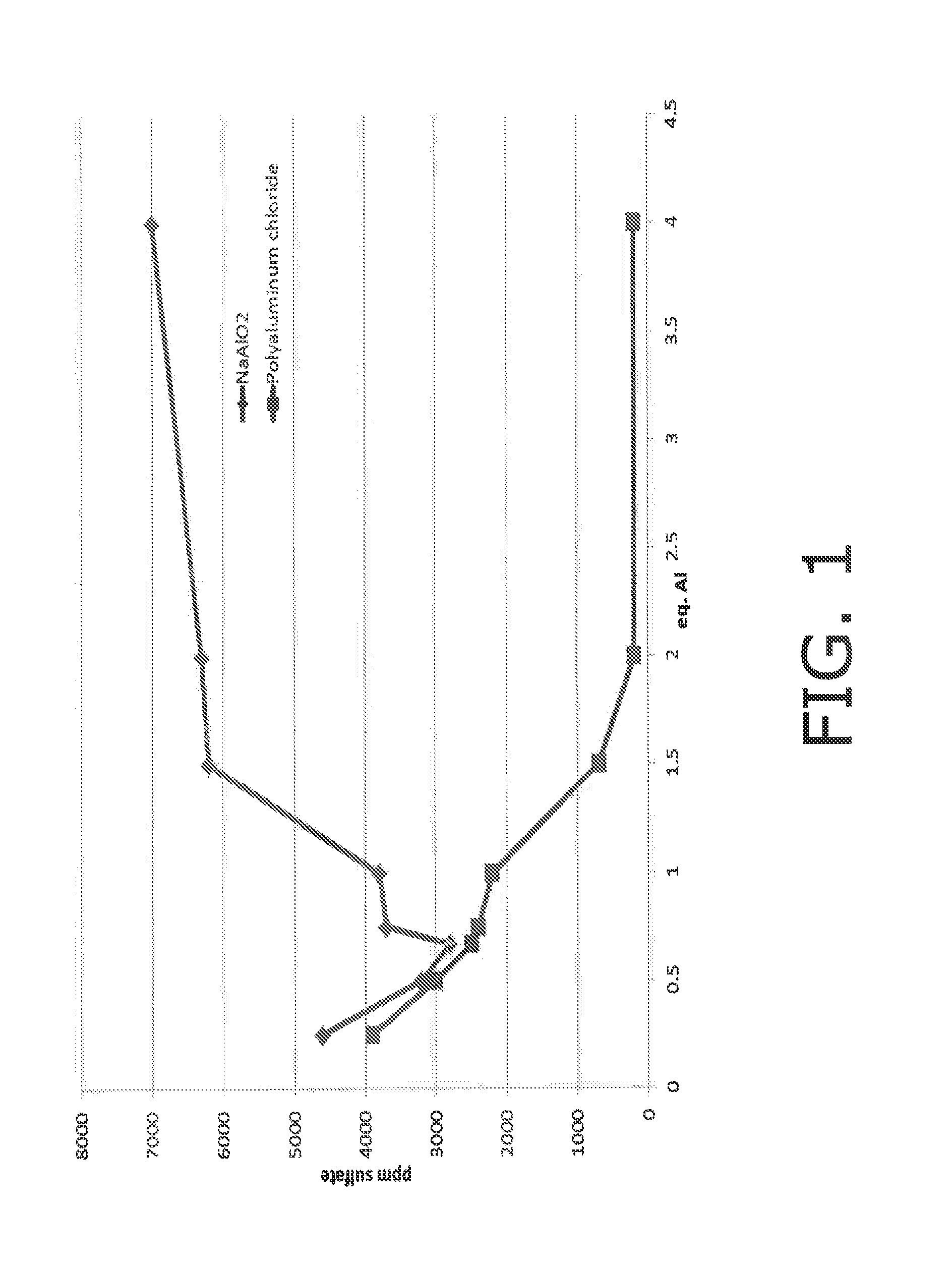

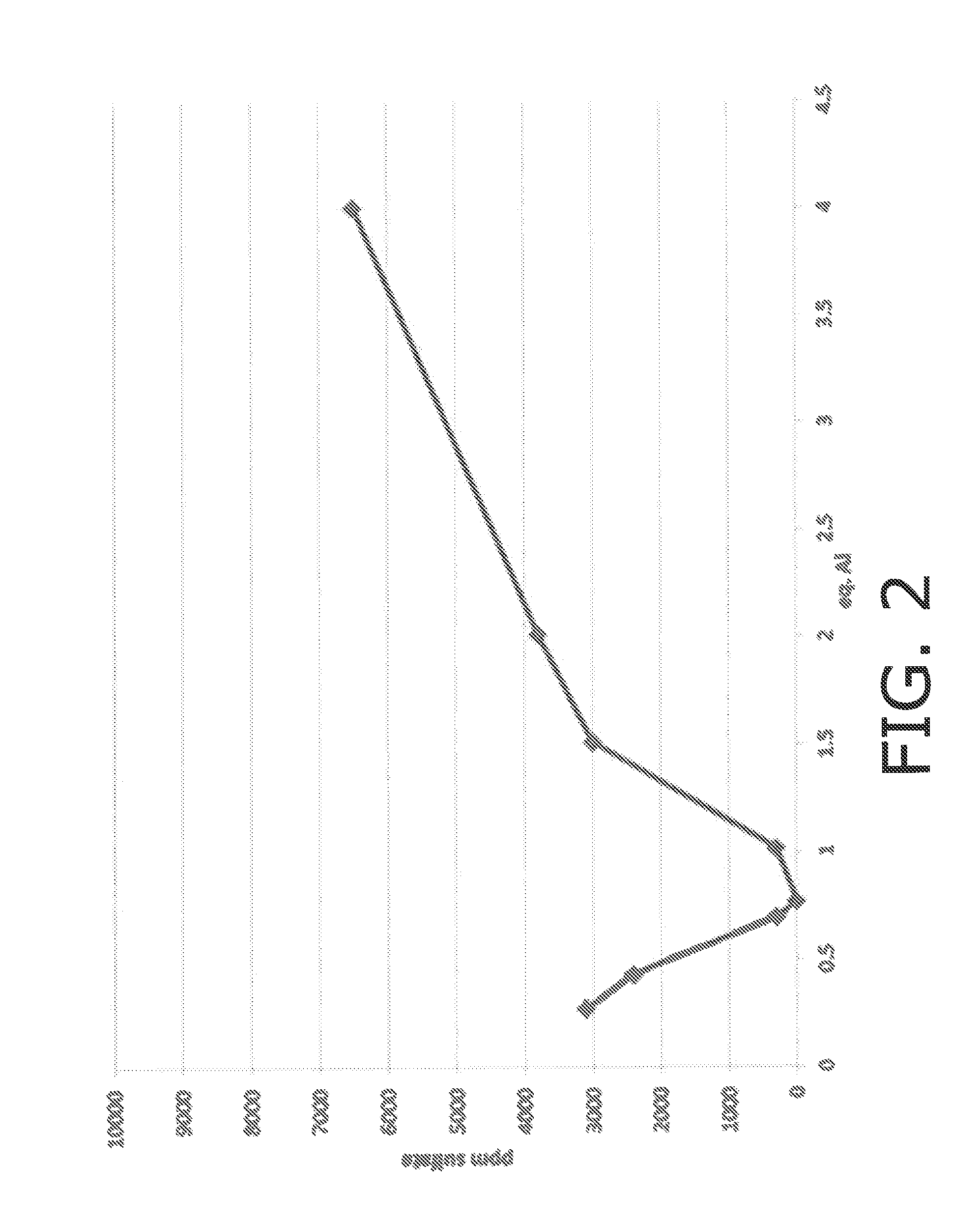

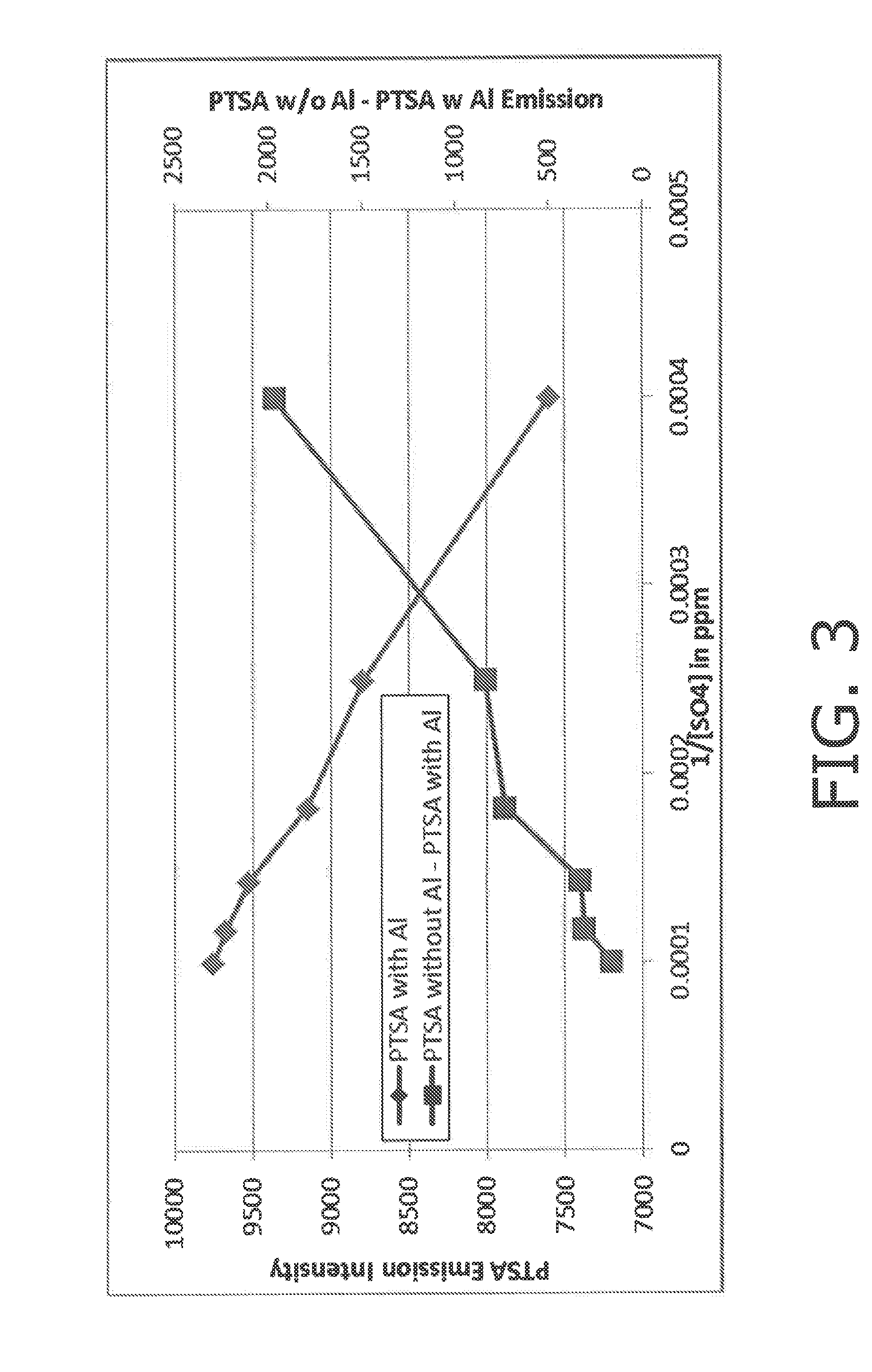

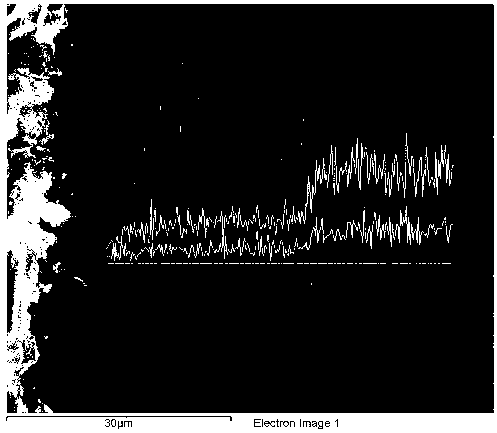

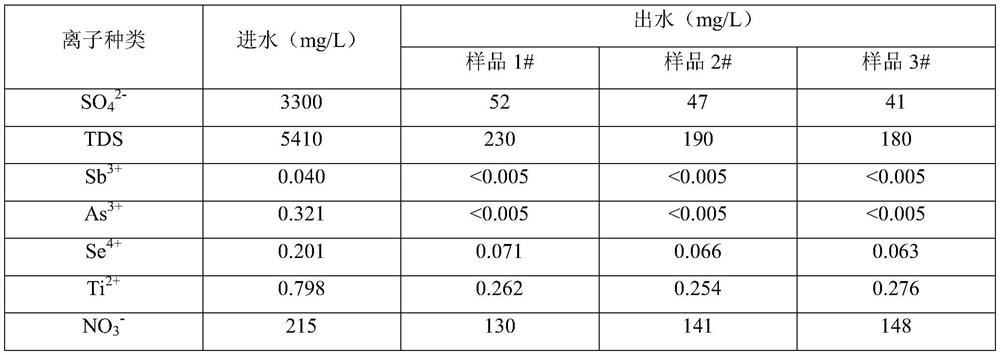

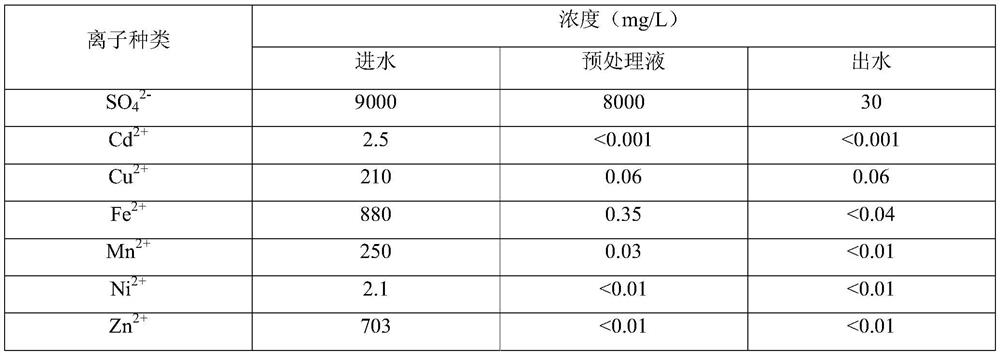

Addition of aluminum reagents to sulfate-containing waste stream reduce sulfate concentration

InactiveUS20140251906A1Solid sorbent liquid separationWater/sewage treatment by ion-exchangeNeutral phWaste stream

The invention provides methods and compositions for detection and removal of sulfate from a liquid. The method provides much faster removal of sulfate than the prior art does and does so while requiring the use of far less aluminum. The method involves sequentially adding an acidic to neutral pH generating aluminum agent to the liquid, an alkaline pH generating aluminum agent to the liquid, after having added the acidic to neutral pH generating aluminum agent, and an alkaline calcium agent to the liquid. The most efficient rate possible can be obtained by also using a fluorophore to precisely determine the amount of sulfate in the liquid.

Owner:ECOLAB USA INC

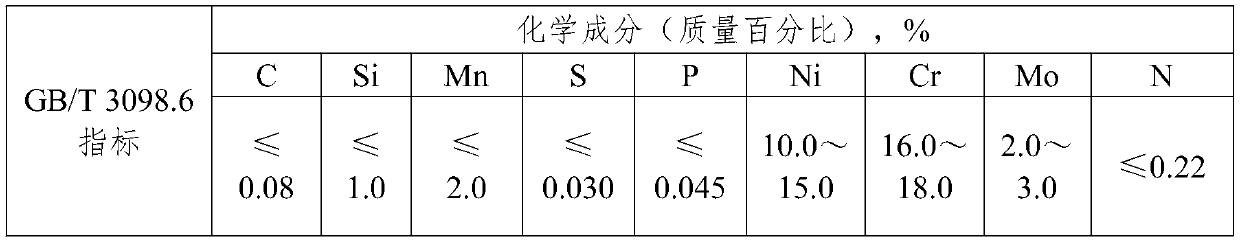

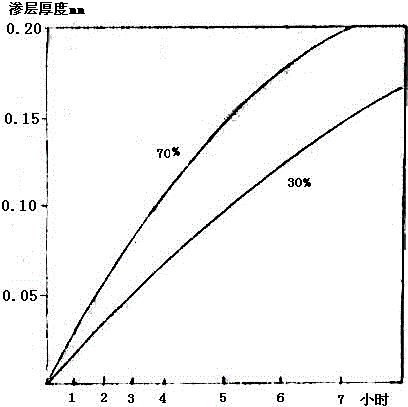

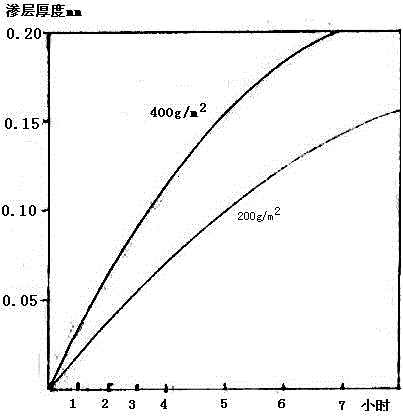

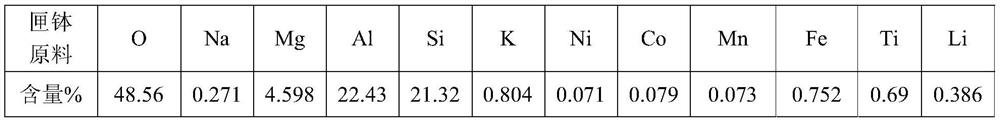

Stainless steel low-temperature powder embedding iron-aluminum co-cementation agent and pack-cementation process method

InactiveCN103266298AImprove protectionImprove bindingSolid state diffusion coatingPtru catalystIron powder

The invention discloses a stainless steel low-temperature powder embedding iron-aluminum co-cementation agent and a pack-cementation process method. The stainless steel low-temperature powder embedding iron-aluminum co-cementation agent is characterized in that aluminum powder is taken as main an aluminum supplying agent, iron powder is a main iron supplying agent, iron-aluminum powder is taken as active filler to replace the conventional inactive ceramic powder filler, aluminum trichloride is taken as an activating agent, and a small amount of rare earth chloride can be added to be used as a catalyst; and a process comprises the following steps of: completely and uniformly mixing the cementation agent, then putting the cementation agent and a stainless steel sample to be subjected to iron-aluminum copermeation processing into a cementation tank, mixing sodium silicate with fire clay, carrying out sealing and drying, so as to obtain an iron-aluminum compound alloy layer with the certain thickness, wherein the alumetizing temperature is 380-600 DEG C, and the temperature is kept for 10 or more than 10 hours. The stainless steel low-temperature powder embedding iron-aluminum co-cementation agent has the advantages that the process method is simple, devices required for low-temperature embedding iron-aluminum co-cementation are simple, the cost is low, the aluminum content of the surface of the obtained iron-aluminum compound alloy layer is high, the iron-aluminum compound alloy layer has a very strong binding force with a matrix and good intermediate temperate oxidation resistance and corrosion resistance and can well protect the matrix.

Owner:NANCHANG HANGKONG UNIVERSITY

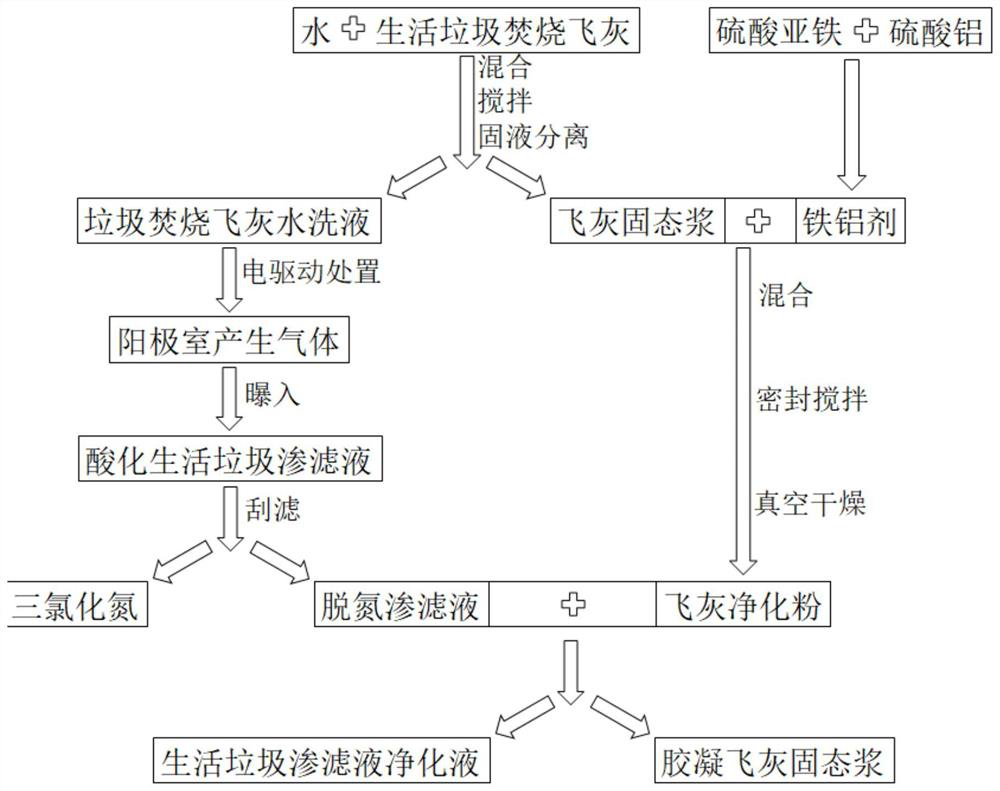

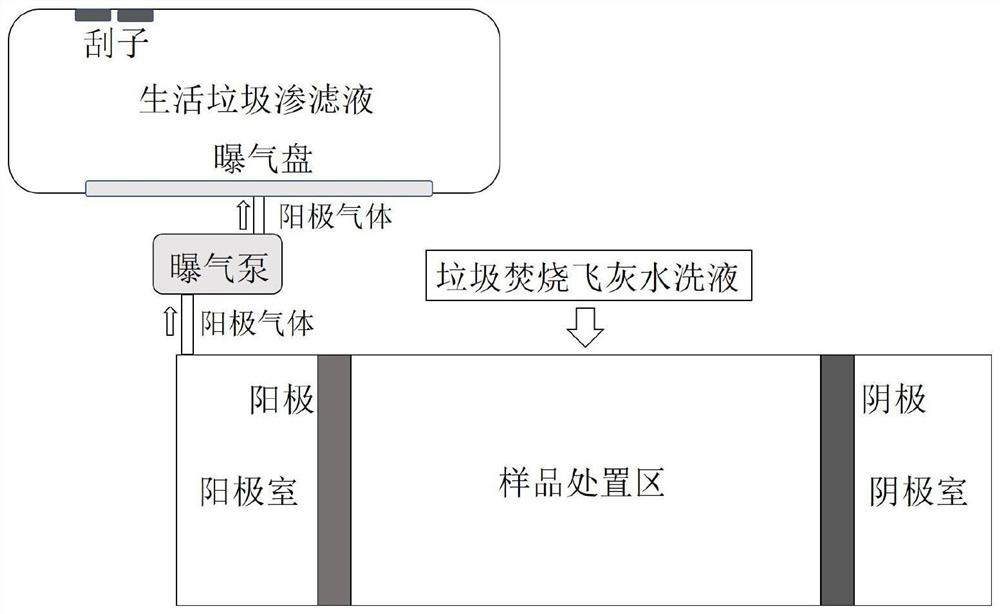

Method for treating household garbage leachate by utilizing household garbage incineration fly ash

InactiveCN111807576AAchieve purificationReduce leaching concentrationWater/sewage treatment by centrifugal separationWater treatment parameter controlWater chlorinationSlurry

The invention discloses a method for treating household garbage leachate by using household garbage incineration fly ash. The method comprises the steps: adding a hydrochloric acid aqueous solution into the household garbage leachate; respectively weighing water and the household garbage incineration fly ash, mixing, stirring and centrifuging for solid-liquid separation to obtain household garbageincineration fly ash water washing liquid and fly ash solid slurry; carrying out electric treatment on the household garbage incineration fly ash water washing liquid, capturing gas generated by an electric anode chamber, directly introducing the gas into the acidified household garbage leachate, and aerating the household garbage leachate; scraping and filtering the household garbage leachate toobtain oily nitrogen trichloride and denitrified leachate; weighing an iron-aluminum agent and the fly ash solid slurry, and carrying out vacuum drying to obtain fly ash purified powder; and weighingthe denitrification leachate and the fly ash purification powder, mixing, stirring, and carrying out solid-liquid separation to obtain the household garbage leachate purification liquid and gelatinized fly ash solid slurry. 86% of nitrogen trichloride can be recycled at most, and 98% of ammonia nitrogen, 97% of COD, 98% of total phosphorus and 98% of mercury in the landfill leachate can be removed.

Owner:浙江中陶环保科技集团有限公司

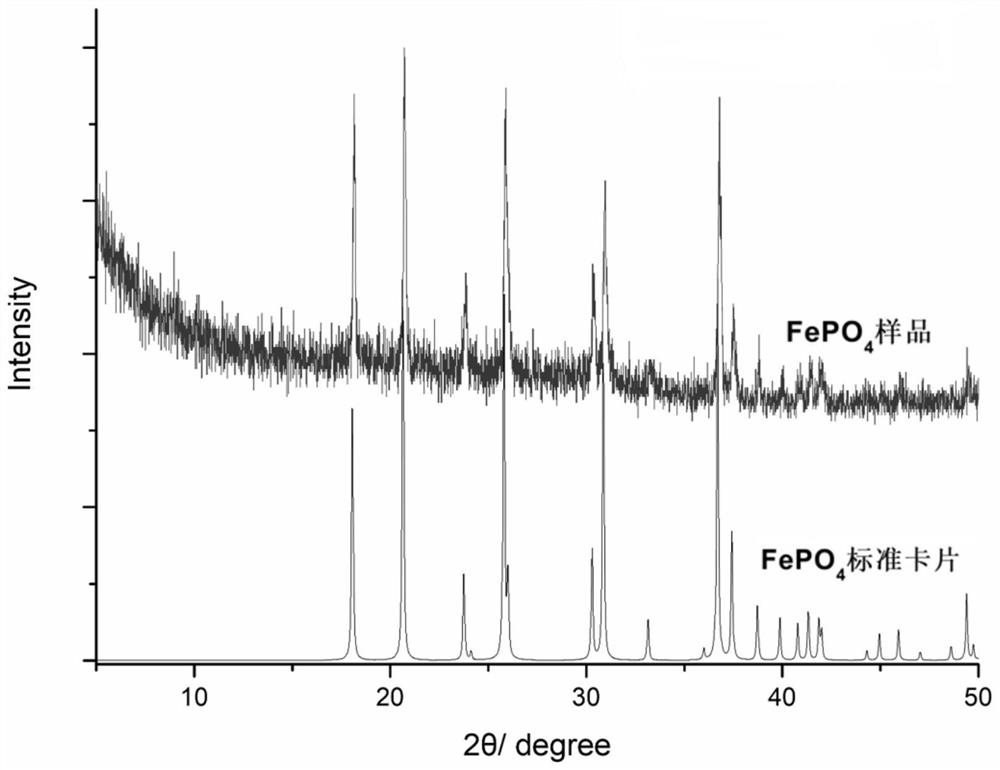

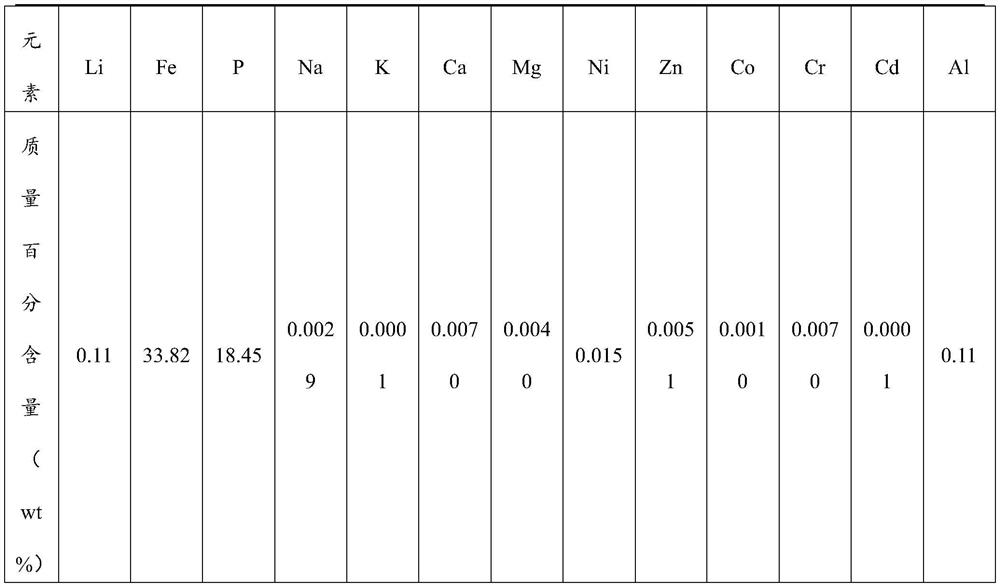

Method for removing aluminum from ferrophosphorus slag after lithium extraction of waste lithium iron phosphate and preparation method of battery-grade iron phosphate

ActiveCN113880063AAmplify the difference in solubilityEfficient removalPhosphorus compoundsBattery recyclingQuinolinePhosphoric acid

The invention relates to a method for removing aluminum from ferrophosphorus slag after lithium extraction of waste lithium iron phosphate and a preparation method of battery-grade iron phosphate. The method for removing aluminum comprises the following steps: mixing ferrophosphorus slag obtained after lithium extraction of waste lithium iron phosphate, elemental iron, acid and water, and carrying out an acid leaching reaction to prepare slurry A; mixing the slurry A with an aluminum removal agent, carrying out an aluminum removal reaction, and then removing solids to obtain aluminum-removed ferrophosphorus liquid; the aluminum removal agent is selected from at least one of picolinic acid compounds, quinolinic acid compounds and isoquinoline-3-formic acid compounds. The organic aluminum removal agent can be complexed with iron and aluminum to form metal organic complex precipitates with different solubility, the solubility difference of iron and aluminum can be effectively amplified, and preferential precipitation of aluminum is ensured so that aluminum impurities are effectively removed, the product purity of iron phosphate is improved, and the high yield of iron phosphate can be ensured. In addition, the method for removing aluminum is easy to operate, low in equipment investment, environmentally friendly, controllable in quality and easy to industrialize.

Owner:GUANGDONG GUANGHUA SCI TECH +1

Method of leaching vanadium from roasted stone coal

InactiveCN106244803AAccelerated destructionReduce dosageProcess efficiency improvementSlagWater vapor

The invention relates to a method of leaching vanadium from roasted stone coal. According to the technical scheme, roasted stone coal is finely ground and is mixed well with water to obtain mixed pulp; concentrated sulfuric acid is added into the mixed pulp and leached under vapor and stirring conditions to obtain acid leaching slurry; the acid leaching slurry is subjected to three-stage leaching: stage I leaching refers to adding calcium fluoride into a first single-stage stirring leaching tank of a stage I leaching apparatus for leaching, stage II leaching refers to 1-2 hours of leaching prior to adding adjusted slag into a last single-stage stirring leaching tank of a stage II leaching apparatus for continued leaching, and stage III leaching refers to adding an aluminum remover into a first single-stage stirring leaching tank of a stage III leaching apparatus for leaching, and final acid leaching slurry is obtained; solid-liquid separation is carried out to obtain final acid leaching liquid and leaching residue; pH of the final acid leaching liquid is adjusted, and solid-liquid separation is carried out to obtain adjusted acid leaching liquid and adjusted residue. The method has low production cost, is easy to industrialize and has the advantages of high vanadium leaching rate and low content of impurity ions in leachate.

Owner:WUHAN UNIV OF SCI & TECH

Low-temperature embedding aluminizing agent and powder embedding aluminizing method

InactiveCN110952062AQuality improvementHigh speedSolid state diffusion coatingCrucibleCerium(IV) oxide

The invention discloses a low-temperature embedding aluminizing agent and a powder embedding aluminizing method, and belongs to the technical field of embedding aluminizing. The low-temperature embedding aluminizing agent is characterized by being prepared from, by mass, 20%-40% of Al powder, 0.5%-2% of CeO2, 2%-4% of an activating agent and the balance Al2O3. The method comprises the following specific preparation steps that (1) the aluminum powder, nano cerium dioxide and aluminum oxide are weighed according to a proportion, and the materials are added into a ball mill for mixing and stirring; (2) the activating agent is added into the ball mill, and stirring is conducted continuously; and (3) the uniformly mixed materials are placed into a crucible and dried in a muffle furnace in an air-isolated manner. A powder embedding aluminizing technology is characterized by comprising the following steps that (1) a small amount of low-temperature embedding aluminizing agent is put into a crucible, and then a workpiece is put into the crucible; (2) the aluminizing agent is continuously filled; (3) the crucible is put into the muffle furnace for heating and heat preservation; (4) the workpiece is taken out and air-cooled to the room temperature.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Method for preparing rutile titanium dioxide from new process titanium slag

ActiveCN101898791BIncrease profitReduce manufacturing costSolid waste disposalTitanium dioxidePhysical chemistryAluminium agents

Owner:SICHUAN LOMON TITANIUM IND CO LTD

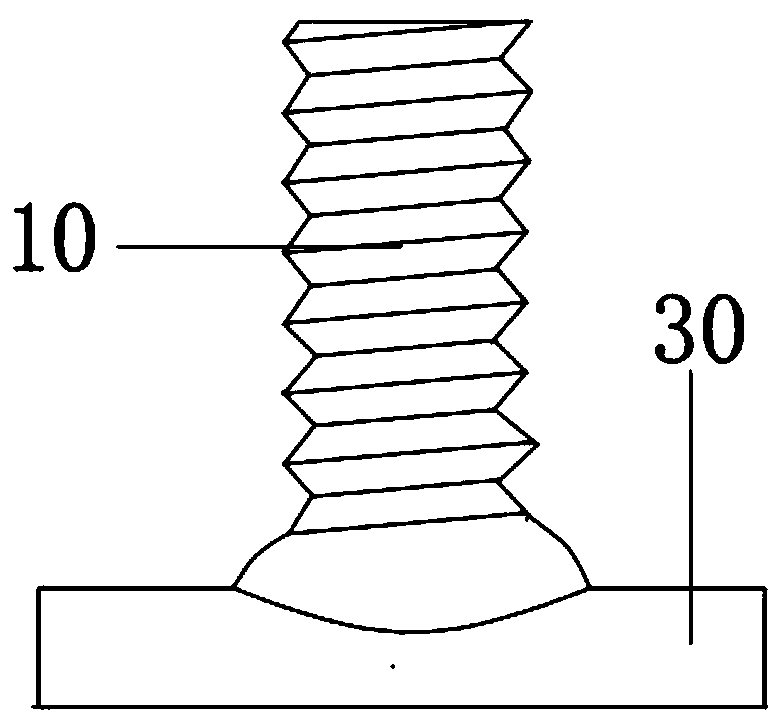

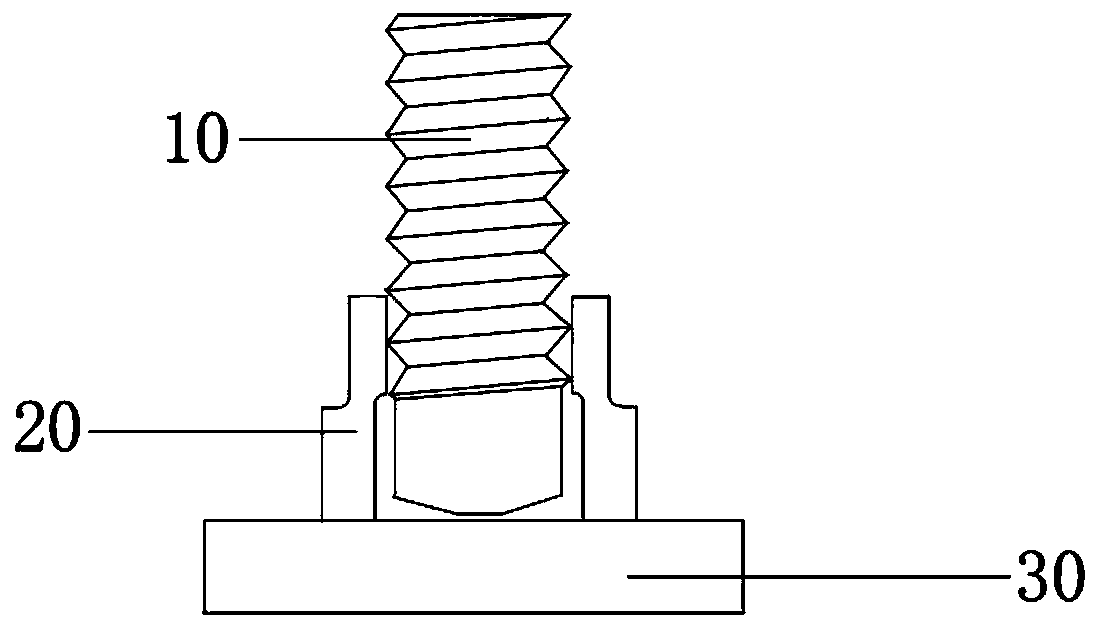

Method of welding between stainless steel stud and steel plate

InactiveCN111069750AThe welding method hasPrevent oxidationWelding accessoriesEngineeringStud welding

The invention discloses a method of welding between a stainless steel stud and a steel plate. A hole is drilled in an end of the steel stud, and is filled with an aluminum agent. Because optimal designing is carried out on the form of the steel stud, and a magnetic ring is adopted for protection on the stainless steel stud, it is effectively avoided that a stainless steel stud is oxidized in the welding process, and the welding quality is guaranteed. Because the stainless steel stud is used instead of a Q235 carbon steel stud, the corrosion resistance of a welding joint of the stainless steelstud is improved, the situation that the stud becomes rusty in the service process of a product is effectively avoided, and service safety of the product is guaranteed; and the welding technology of the stainless steel stud is optimized, the technological parameters such as the welding current, the arc discharge length and the lifting height at the horizontal gesture, the vertical gesture and theposition of facing upward are determined, hot cracks during welding are avoided, the bending performance and the torsion performance of the welding point of the stud are improved, the hardness of thewelding point is reduced, and the comprehensive performance of the welding point is improved.

Owner:WUHAN WUCHUAN MEASUREMENT & TEST

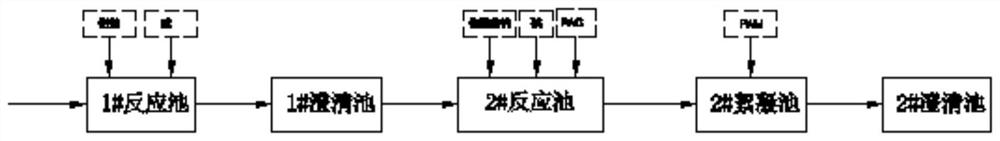

Fluorine and silicon removal method for reverse osmosis concentrated water

PendingCN113480045AReduce dosageReduce addWater treatment parameter controlWater contaminantsFlocculationPhysical chemistry

The invention discloses a fluorine and silicon removal method for reverse osmosis concentrated water, which comprises two stages of softening and clarifying steps. In the first-stage softening and clarifying, the reverse osmosis concentrated water enters a first reaction tank and a first clarification tank in sequence. In the second-stage softening and clarifying, effluent of the first-stage softening and clarifying enters a second reaction tank, a flocculation tank and a second clarification tank in sequence. An aluminum agent is added into the first reaction tank to remove fluorine, and sodium metaaluminate is added into the second reaction tank to remove silicon. According to the method disclosed by the invention, fluorine ions and silicon ions in the concentrated water can be efficiently removed by adding a small amount of agents.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

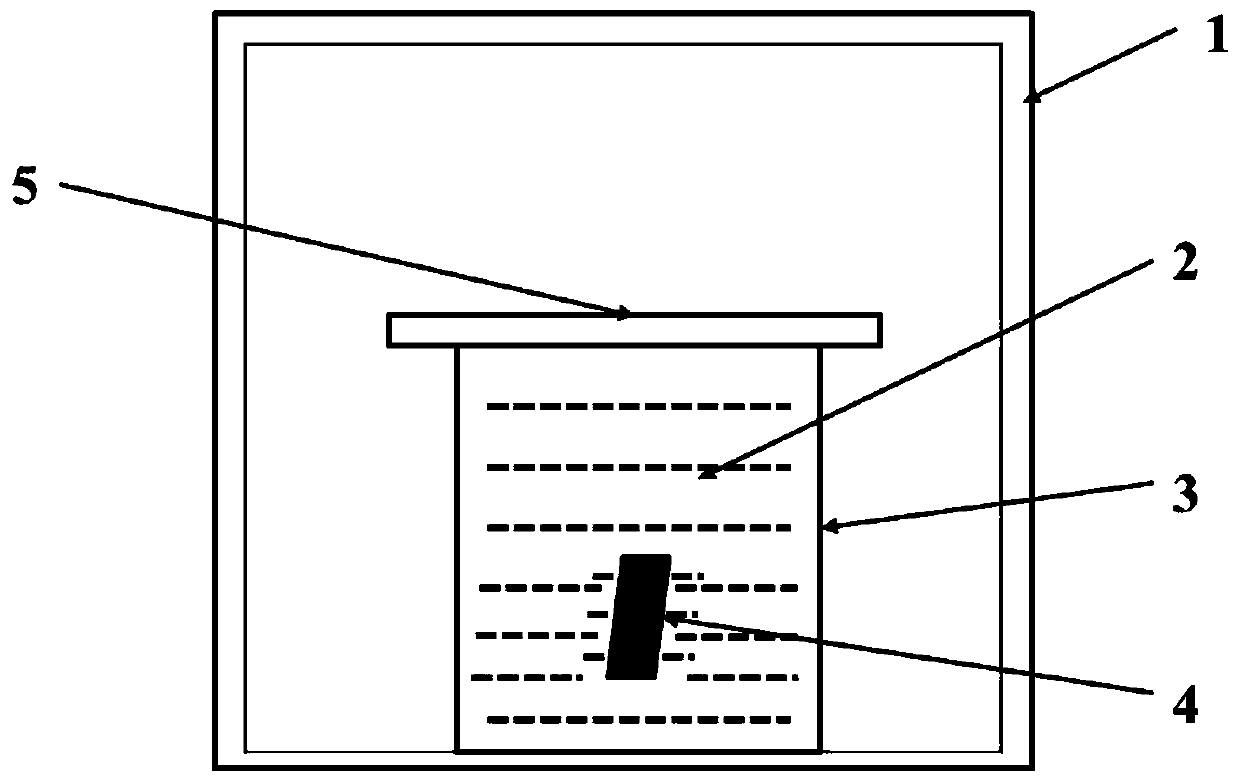

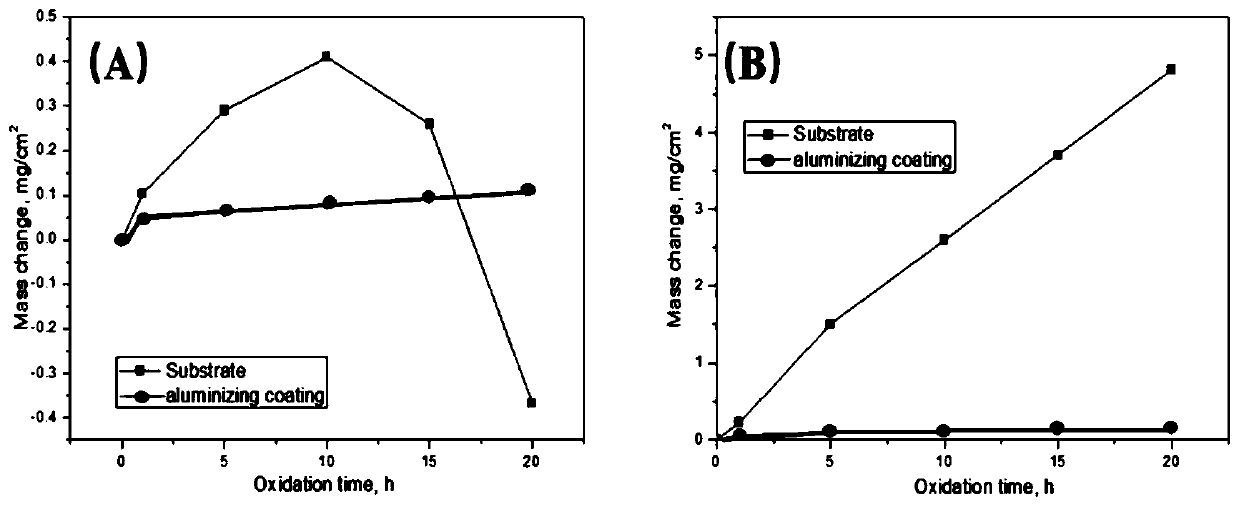

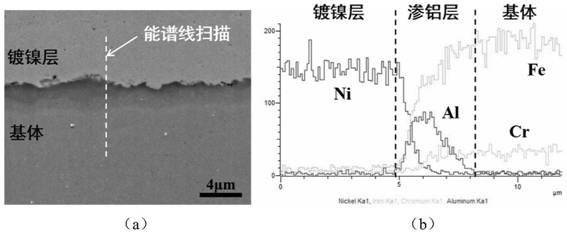

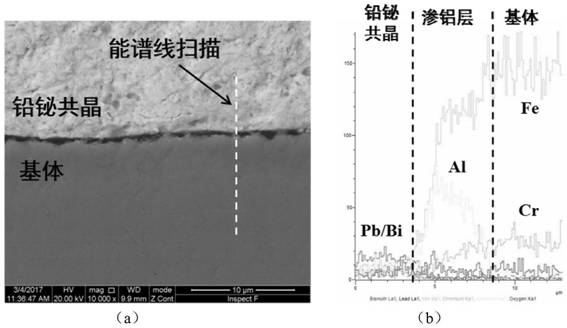

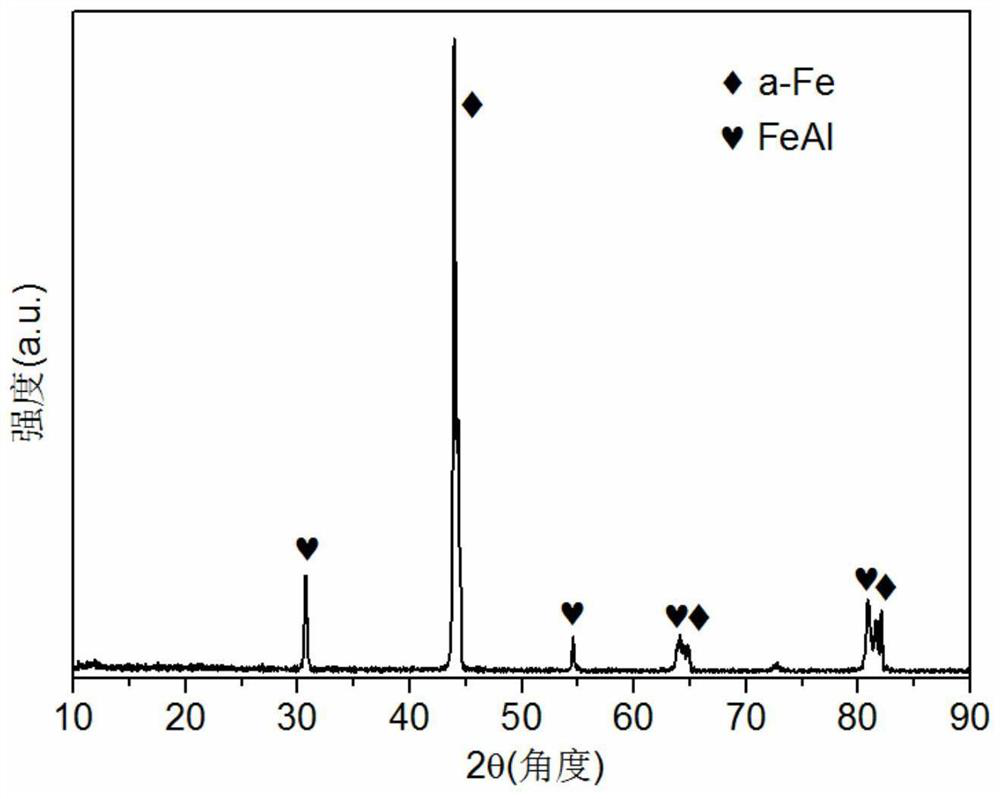

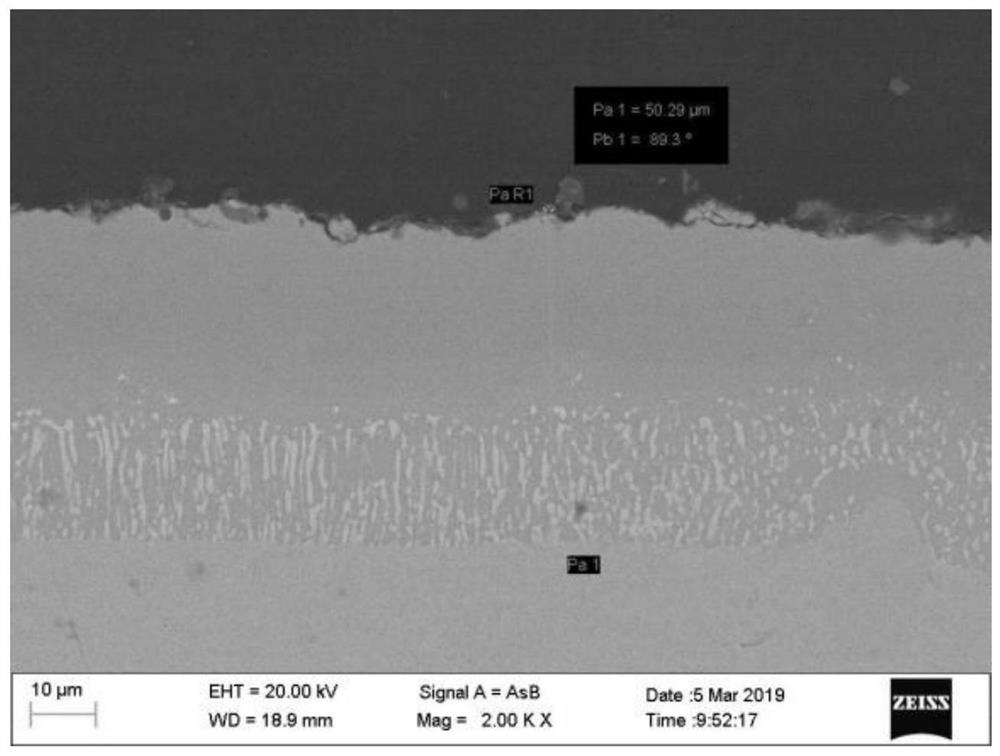

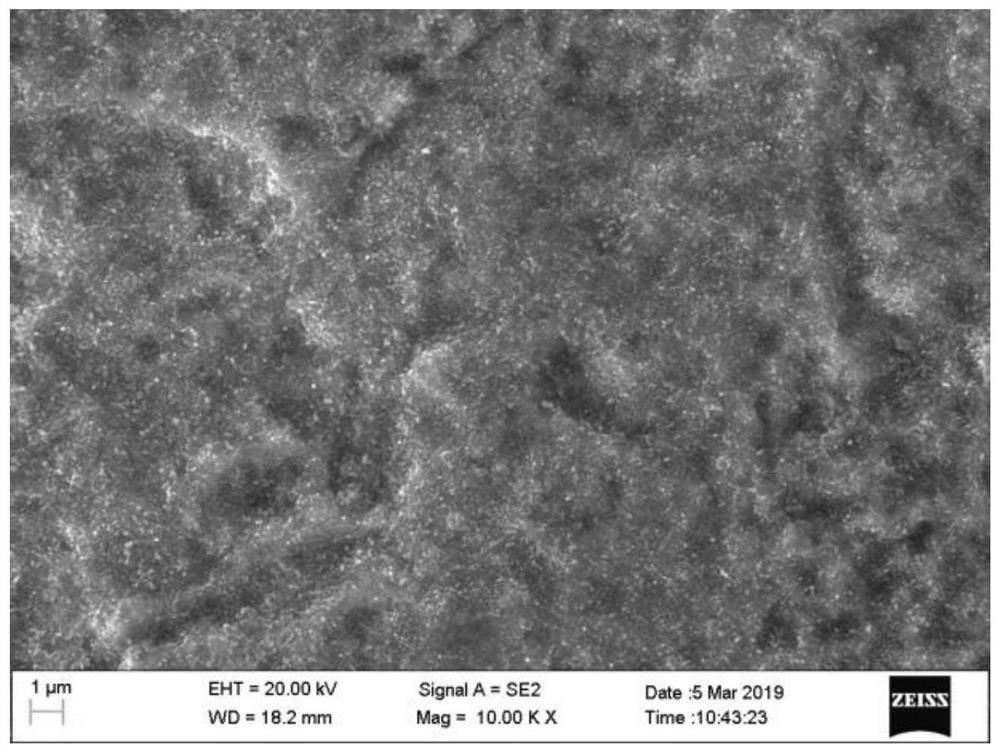

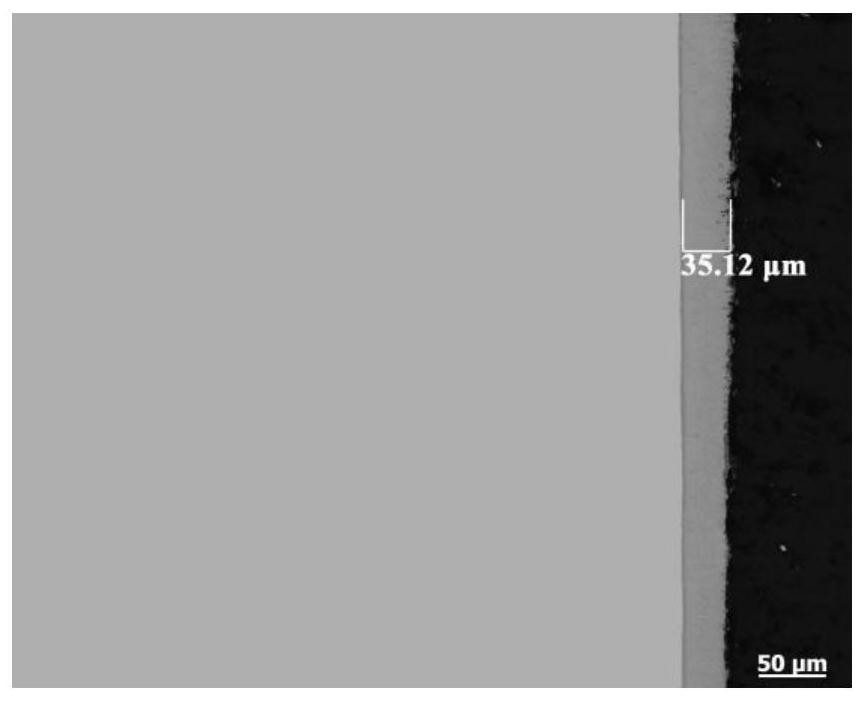

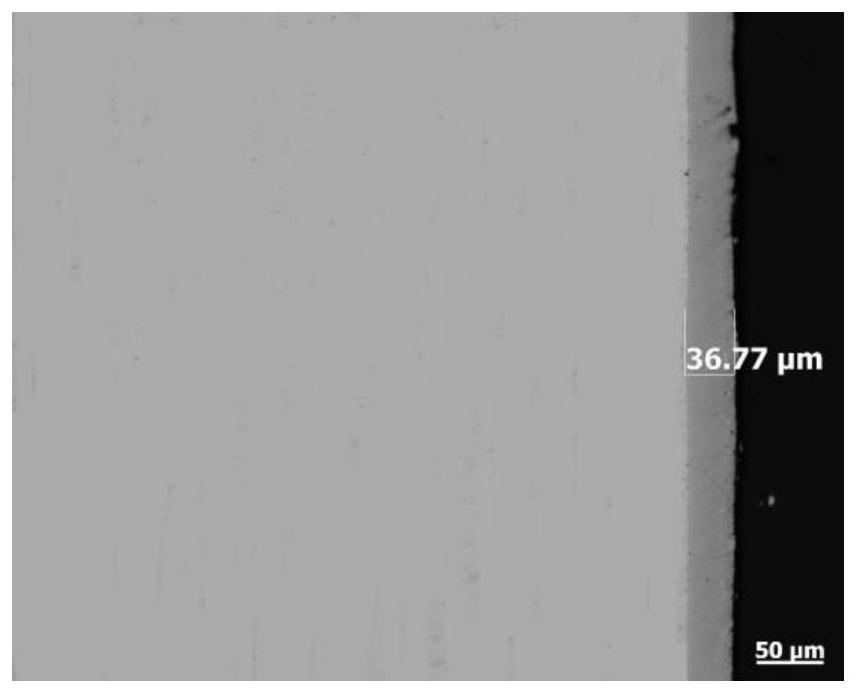

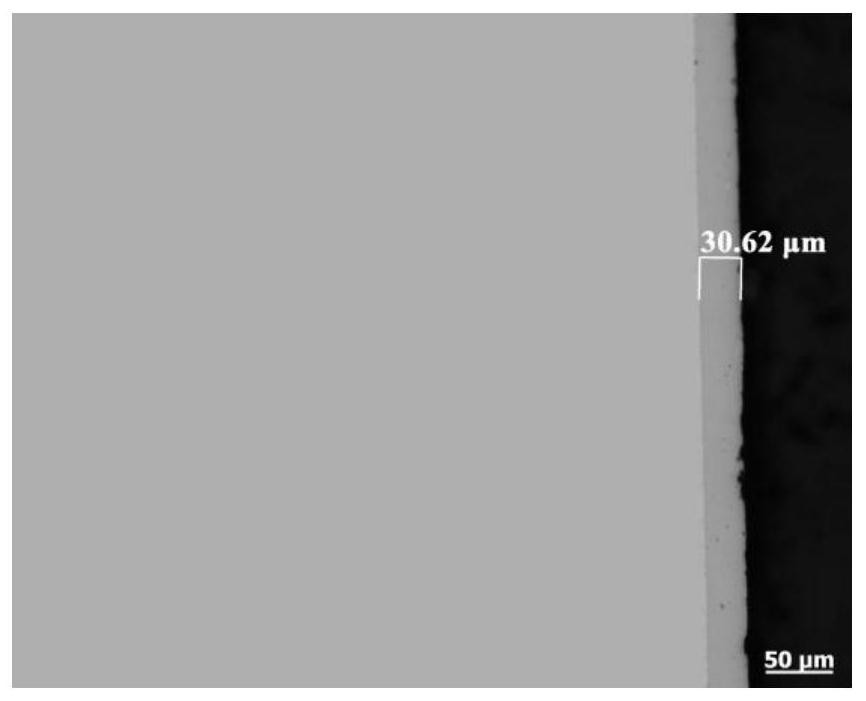

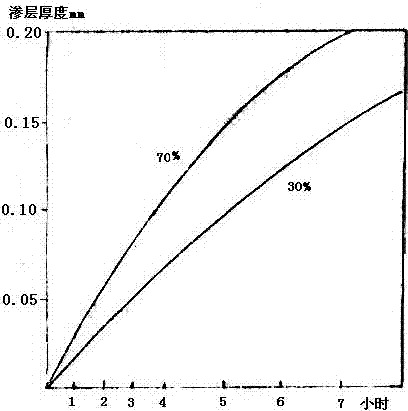

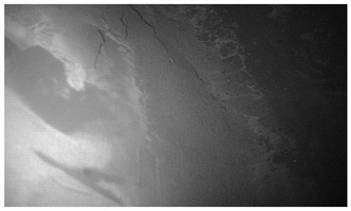

Preparation method of aluminized coating for improving lead and bismuth corrosion resistance of ferrite-martensite steel

ActiveCN113106385AImproving the corrosion resistance of lead and bismuthReduced activitySolid state diffusion coatingTemperingAluminium agents

The invention discloses a preparation method of an aluminized coating for improving lead and bismuth corrosion resistance of ferrite-martensite steel, and belongs to the technical field of corrosion protection of nuclear materials. Firstly, the ferrite-martensite steel is subjected to quenching and tempering thermal treatment including quenching and tempering, and then surface treatment and activating treatment are sequentially carried out; secondly, activated samples are embedded in uniformly-mixed aluminizing agent powder, the enough distances are kept among the samples, and the samples are placed into a double-layer quartz tube aluminizing device; and finally, the aluminizing device is placed into a muffle furnace for aluminizing treatment. The aluminized coating comprising the FeAl phase is prepared through the method, the aluminized coating is uniform and compact, the binding force between the aluminized coating and a matrix is large, and the aluminized coating has good lead and bismuth corrosion resistance; and meanwhile, the mechanical property of the matrix cannot be damaged by the aluminizing technology. The method is convenient to operate and lower in cost, is not limited by sizes and shapes of workpieces, and is convenient for industrial popularization.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

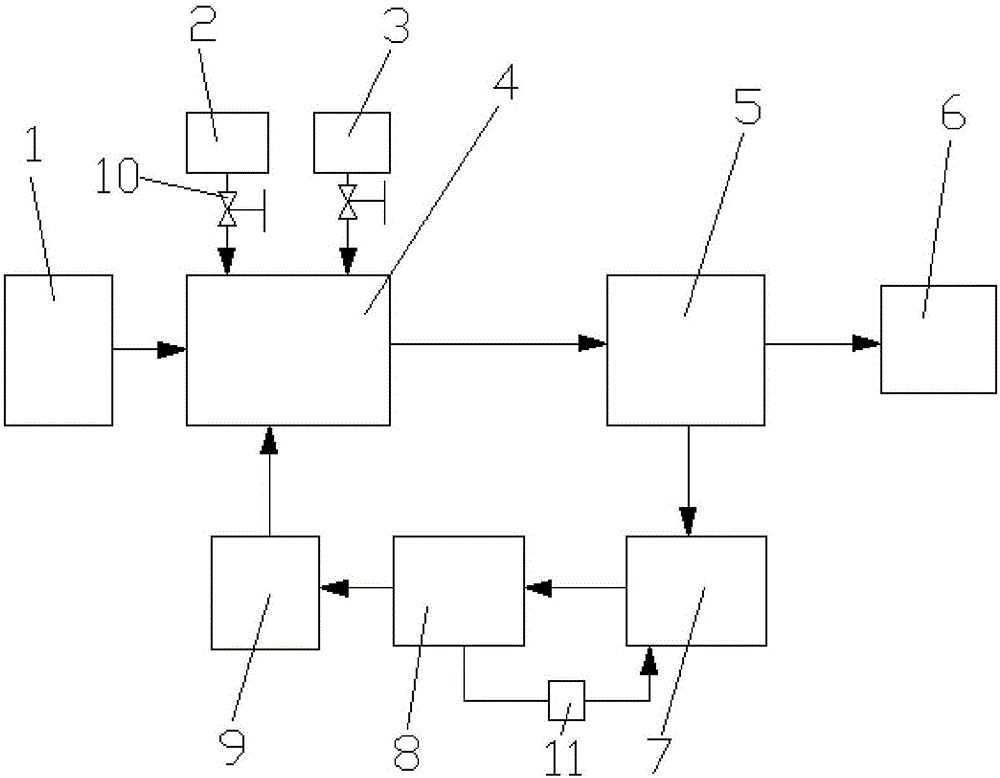

Zinc slag recycling and regenerating system for hot galvanizing

InactiveCN106119572AReduce consumptionNo emissionsPhotography auxillary processesProcess efficiency improvementTemperature controlSlag

The invention discloses a zinc slag recycling and regenerating system for hot galvanizing. The zinc slag recycling and regenerating system for hot galvanizing comprises a zinc slag adding device, an aluminum agent adding device, a protection medium adding device, a temperature control smelting furnace device, a liquid-slag separating device, a molten zinc ingot casting device, a dissolving tank and an electrolytic cell. The zinc slag recycling and regenerating system is characterized in that the zinc slag adding device is connected with the temperature control smelting furnace device, the position above the temperature control smelting furnace device is connected with the aluminum agent adding device and the protection medium adding device, and the liquid-slag separating device is arranged at the bottom of the temperature control smelting furnace device and connected with the molten zinc ingot casting device and the dissolving tank; and the dissolving tank is connected with the electrolytic cell through a pipeline and connected with a washing drying device, and a discharging port of the washing drying device is connected with a feeding port of the temperature control smelting furnace device. According to the zinc slag recycling and regenerating system, raw material and energy consumption can be reduced to a large degree, investment is reduced, and meanwhile by-products in the recycling process can be cyclically utilized. The zinc slag recycling and regenerating system has the beneficial effects that the recycling cost is low, the technology is simple, waste water discharging is avoided, and new pollution is not generated.

Owner:ANHUI JINXING PRESTRESSING ENG TECHCO

Preparation method for diffusion impervious layer suitable for large member

ActiveCN112323066AGuaranteed functionalityImprove antioxidant capacitySolid state diffusion coatingSuperimposed coating processOrganosolvEngineering

The invention relates to a preparation method for a diffusion impervious layer suitable for a large member. The preparation method comprises the following steps: preparation of an aluminizing medium:packing an alumiumn and iron block in a container, adding ammonium hydrogen fluoride which accounts for 0.5-1.0% by mass of aluminum and iron block, then adding water till inundating the surface of the aluminum and iron block, then heating the aluminum and iron block in a heating furnace and keeping the temperature at 270-330 DEG C till the mixture is boiled away; performing roasting at 700-900 DEG C between activating treatment twice; deoiling: cleaning surface dirt and oil stains of parts and assemblies, including test samples, needed to be aluminized with an organic solvent thoroughly; liquid sand-blowing: performing liquid sand-blowing on the parts and assemblies before aluminizing, wherein the air pressure does not exceed 0.3 MPa; and gas phase aluminizing: keeping the temperature for1-3.5 hours at 900-1050 DEG C, wherein the relative pressure in the furnace is controlled at 0.002-0.01 Mpa. The method has the advantages that a formed aluminum oxide impervious layer is intact, continuous and compact and exists stably at a high temperature for a long time, can be used for preparing the diffusion impervious layer of the large member, and is low in cost of raw materials, simple in process and high in production efficiency.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Material slurry colored aluminizing process

InactiveCN104805399AImprove high temperature resistanceAccelerated corrosionSolid state diffusion coatingCelluloseCarboxymethyl cellulose

The invention relates to a colored material slurry aluminizing process, and belongs to the technical field of an aluminizing technology. Material slurry is prepared through the following steps that (1) bonding agent material slurry is prepared from the following ingredients in percentage by weight: 0.1 to 20 percent of polyvinyl alcohol, 0.1 to 10 percent of carboxymethyl cellulose sodium, 0.1 to 10 percent of thickening agents and the balance water; (2) 10 to 65 percent of aluminum supplying agents, 3.5 to 65 percent of bulking agents and 1 to 30 percent of activating agents are mixed and are prepared into the aluminum supplying agents; (3) the aluminum supplying agents are added into the bonding agent material slurry and are mixed, and the aluminizing material slurry is prepared, so that the ratio of the aluminizing agents to the boning agents enters a range being 1: (0.5-1.2); secondary heating processing is carried out after an aluminizing element is coated. The material slurry coating method is used, and dust pollution is avoided. The process has the advantages that the work environment is good, the work intensity is low, the process is relatively simple, the production cost is low, safety production accidents cannot occur, the pollution on environment is little, and the process is favorable for environment protection.

Owner:周振江

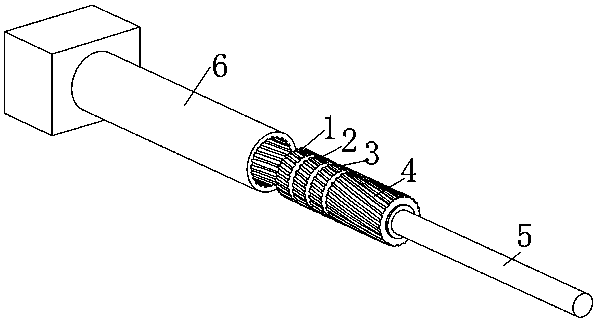

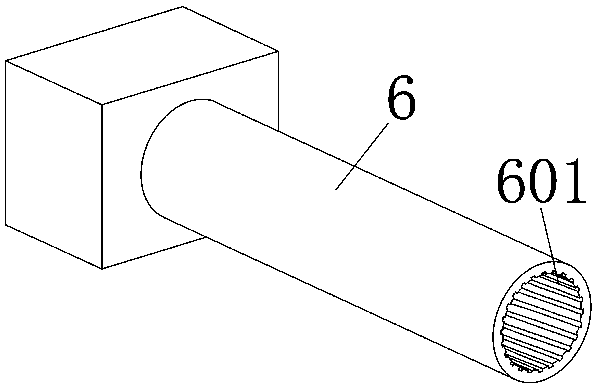

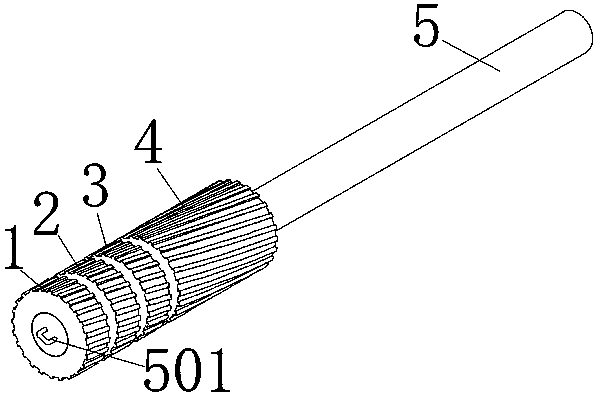

Artillery rifled line maintenance device and application method thereof

The invention relates to the technical field of artillery maintenance equipment, in particular to an artillery rifled line maintenance device and an application method of the artillery rifled line maintenance device. The artillery rifled line maintenance device comprises a carrier combination framework. The artillery rifled line maintenance device is characterized in that the carrier combination framework is a cylindrical pipe, multiple carved grooves are uniformly carved in the outer surface of the carrier combination framework and correspond to the sizes of rifled lines of a bore. A cuttingportion assembly, a grinding portion assembly and a lapping portion assembly are arranged at one end of the carrier combination framework in sequence, and a central shaft rod is arranged in the centerof the carrier combination framework in a rotatable and penetrative mode. The artillery rifled line maintenance device and the application method of the artillery rifled line maintenance device havethe beneficial effects that the metal adhering to the rifled lines are removed by mechanical cutting tools, the removal mechanism is opposite to the acting force forming the metal adhering to the rifled lines, the friction extrusion mode is changed in the cleaning mode, the rising winding cutting type removal mode is adopted, the counterforce and the cutting tools are combined to cut away the metal adhering to the rifled lines, the cleaning efficiency is improved, the soaking operation of chemical agents such as copper removal agents and aluminum removal agents can be omitted, and the cleaningrequirements that the time and the labor are saved, and the consumable items are saved can be met.

Owner:中国人民解放军32286部队50分队 +1

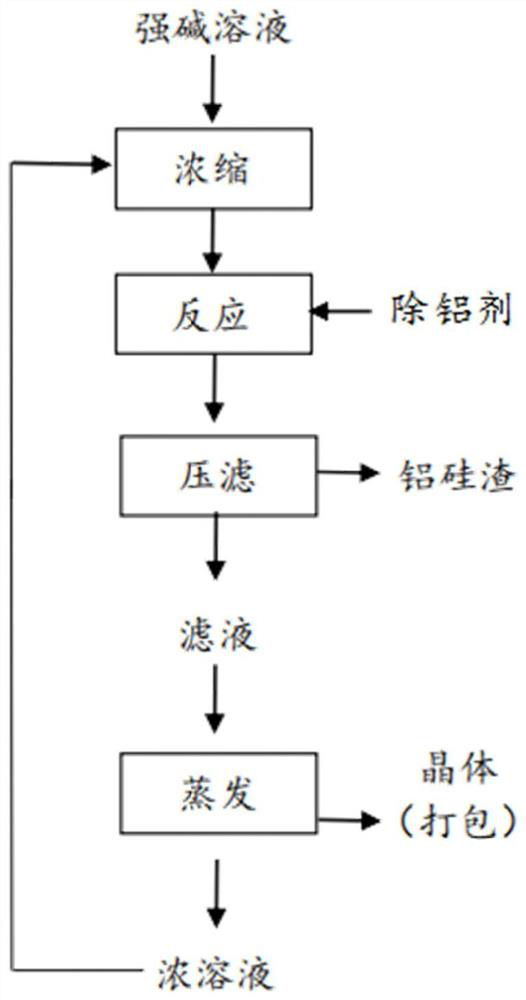

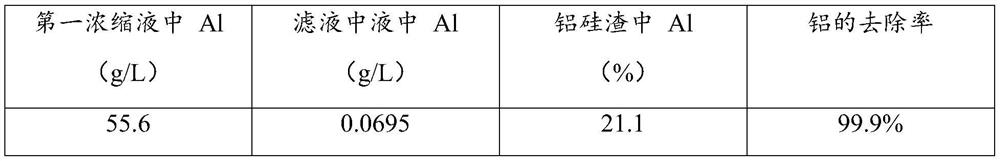

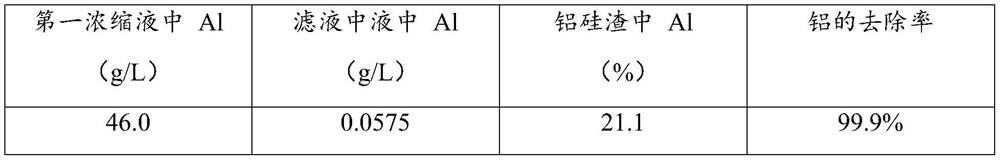

Method for removing aluminum from strong alkali solution and application

PendingCN114480853AWide applicabilityReclaiming serviceable partsWaste accumulators reclaimingAluminateLithium hydroxide

The invention belongs to the technical field of environmental protection, and discloses a method for removing aluminum from a strong alkali solution and application, the method comprises the following steps: concentrating and filtering the strong alkali solution, taking a first concentrated solution, adding the first concentrated solution into an aluminum removal agent, reacting, cooling, and carrying out solid-liquid separation to obtain silicon slag and filtrate; concentrating and filtering the filtrate to obtain a metal hydroxide crystal and a second concentrated solution; the aluminum removal agent comprises the following components: silicate and silicon dioxide; the strong alkali solution contains aluminate ions. According to the method, silicate and silicon dioxide are used as aluminum removal agents in the strong alkali solution, aluminum is made to generate water-insoluble aluminosilicate under the condition that the original pH of the solution is not changed, aluminum in the strong alkali solution is removed to 30-100 ppm, corresponding sodium hydroxide, potassium hydroxide or lithium hydroxide crystals can be recycled, and mother liquor is recycled.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

Reusable low-temperature aluminizing agent and aluminizing method

PendingCN114481013AImprove high temperature oxidation resistanceAccelerated corrosionSolid state diffusion coatingAluminium agentsPenetration enhancer

The invention relates to a reusable low-temperature aluminizing agent and an aluminizing method. The aluminizing agent comprises the following components in percentage by mass: 6-25% of an aluminum supply agent; 1-15% of a penetration enhancer; 1-6% of a brightener; and 54-92% of a dispersant. The aluminizing method comprises the following steps: a) contacting a to-be-treated metal part with the aluminizing agent for aluminizing treatment, and providing the aluminized metal part and the used aluminizing agent. The aluminizing agent has the advantages of simple components, easily available materials, reusability, reduction of the aluminizing cost, low aluminizing temperature, simple preparation process, improvement of the aluminizing efficiency, improvement of the high-temperature oxidation resistance and corrosion resistance of metal parts, improvement of the service temperature of the metal parts, and improvement of the service life of the metal parts.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD +1

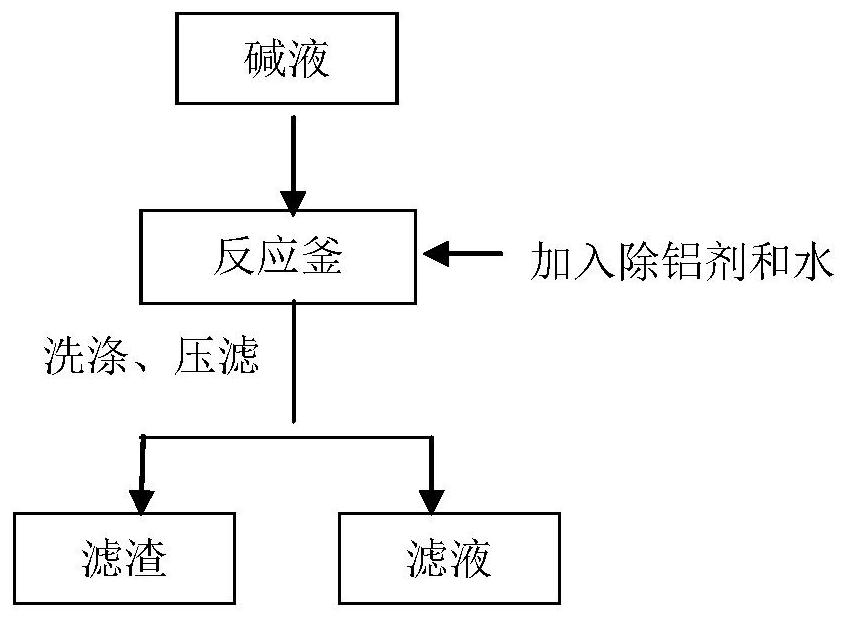

Efficient aluminum removing agent for alkali recovery and using method thereof

InactiveCN112408572AIncrease reaction rateReduce the concentration of aluminum ionsWater treatment compoundsWaste water treatment from metallurgical processCalcium hydroxideEnvironmental engineering

The invention belongs to the field of environmental protection, and relates to an efficient aluminum removing agent for alkali recovery and a using method thereof. The aluminum removing agent comprises calcium oxide, calcium hydroxide, calcium peroxide, sodium peroxide, hydrogen peroxide and sodium percarbonate, and specifically comprises, by mass, 20-40% of calcium oxide; 10-30% of calcium hydroxide; 10-20% of calcium peroxide; 5-10% of sodium peroxide; 2-8% of hydrogen peroxide; and 1-5% of sodium percarbonate, totaling 100%. The aluminum removing agent can increase the aluminum removing rate, shorten the reaction time and improve the recovery treatment efficiency of waste alkali liquor.

Owner:CHINA ZHONGWANG

Ferrovanadium slag refining agent and preparation method thereof and method of removing vanadium from slag

The invention belongs to the technical field of vanadium alloy smelting and in particular relates to a ferrovanadium slag refining agent and a preparation method thereof and a method of removing vanadium from slag. The invention aims to provide the ferrovanadium slag refining agent and the method of removing vanadium from slag to overcome the problem of high residual vanadium in ferrovanadium smelting slag. The ferrovanadium slag refining agent provided by the invention is prepared from the following raw materials in mass ratio: metallic aluminum: metallic ferrum: slow release reducer 1: calcium oxide=(20-40):(0-20):(10-20):(30-60), wherein the slow release reducer 1 is at least one of an aluminum iron alloy, steel grit aluminum or steel-cored aluminum. The ferrovanadium slag refining agent can improve the vanadium removal effect of slag refining, reduce the loss of an aluminum agent and lower the cost of raw materials and can remove all-vanadium elements left in slag after ferrovanadium smelting effectively, and reduce the residual vanadium content in the slag to below 1.2% effectively.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

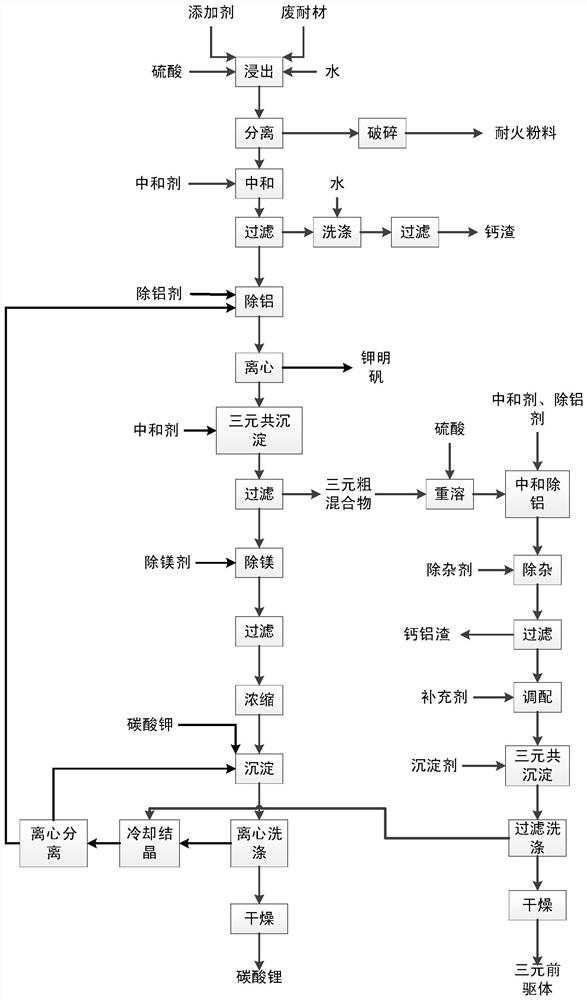

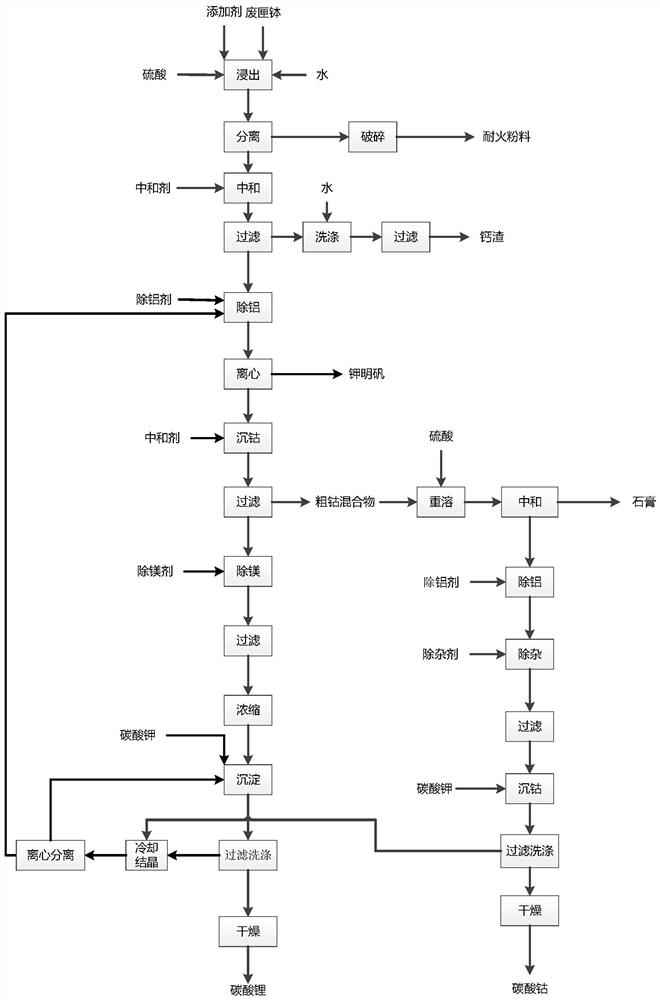

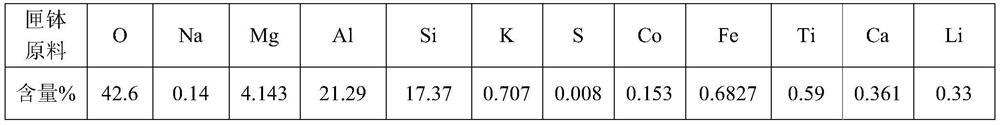

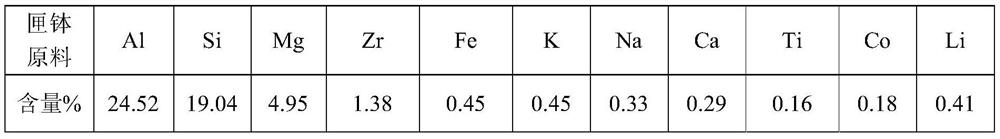

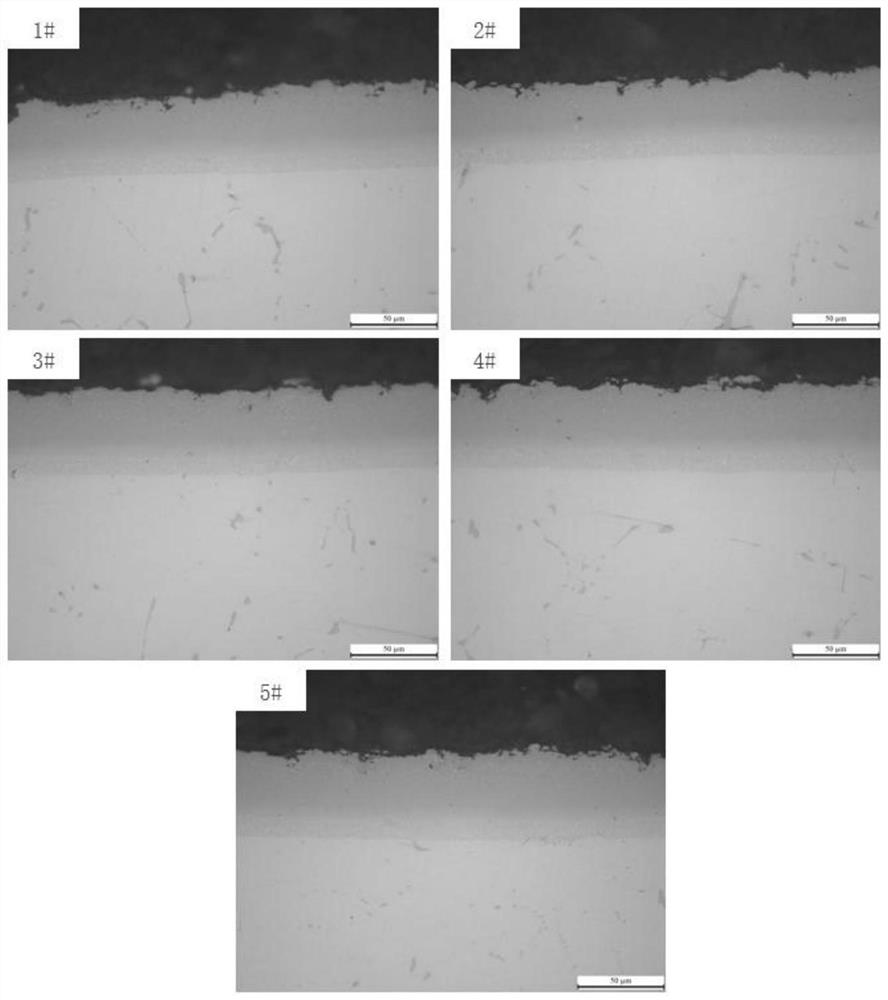

A method for recycling waste refractory materials during the preparation of ternary cathode materials

ActiveCN109921120BAchieve recyclingWide variety of sourcesWaste accumulators reclaimingBattery recyclingPregnant leach solutionLithium

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A color slurry aluminizing process

InactiveCN104805399BImprove high temperature resistanceAccelerated corrosionSolid state diffusion coatingCellulosePolyvinyl alcohol

A color slurry aluminizing process belongs to the technical field of aluminizing. The preparation steps of the slurry are as follows: 1) according to 0.1-20% of polyvinyl alcohol, 0.1-10% of sodium hydroxymethyl cellulose, and 0.1-10% of thickener %, the balance is the weight percentage of water to prepare a binder slurry; 2) Mix according to the ratio of aluminum supply agent: 10-65%, loosening agent: 3.5-65%, activator: 1-30%, and prepare Aluminum supplying agent; 3) Add aluminum supplying agent to the above-mentioned binder slurry and mix it, adjust aluminizing slurry so that the ratio of aluminizing agent and binder is in the range of 1:0.5-1.2; A secondary heat treatment is performed after coating. Using the slurry coating method, there is no dust pollution. This process has good labor environment, low labor intensity, relatively simple process, low production cost, no safety production accident, little environmental pollution, and is conducive to environmental protection.

Owner:周振江

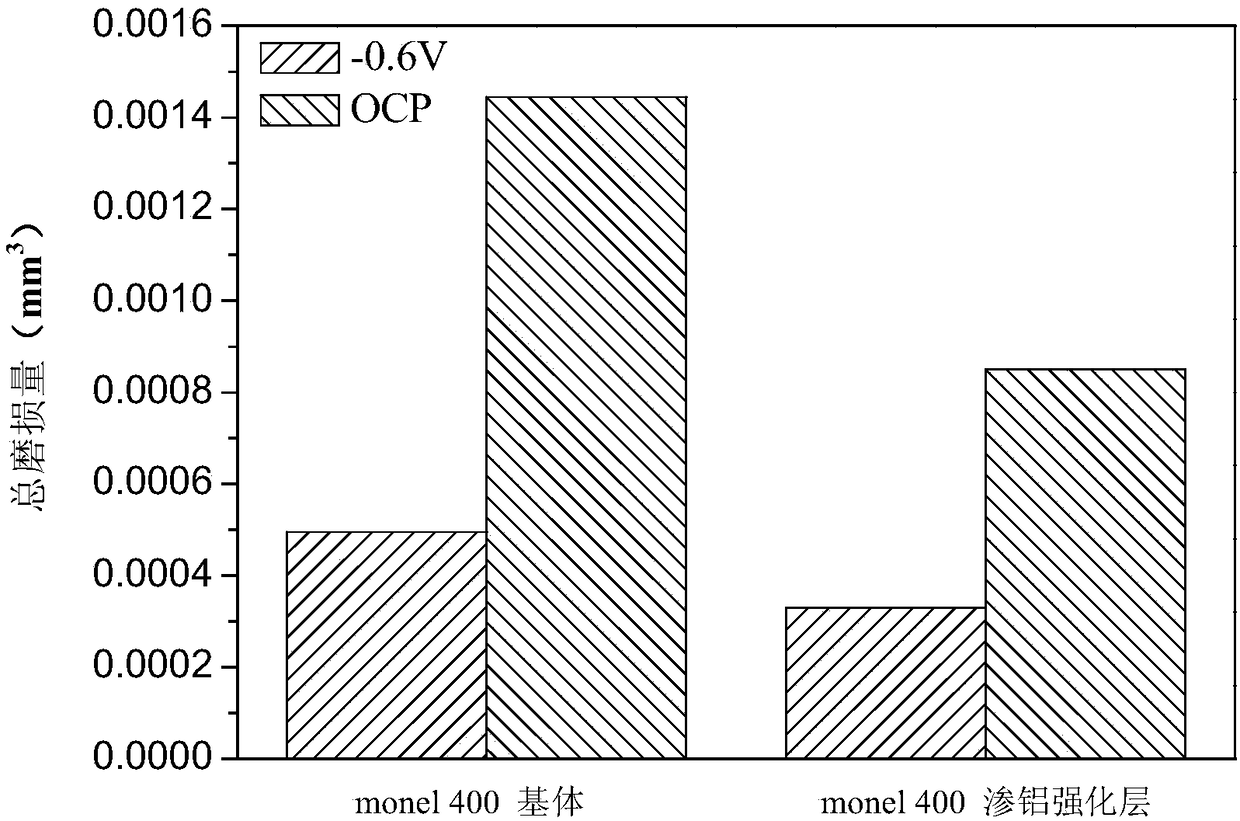

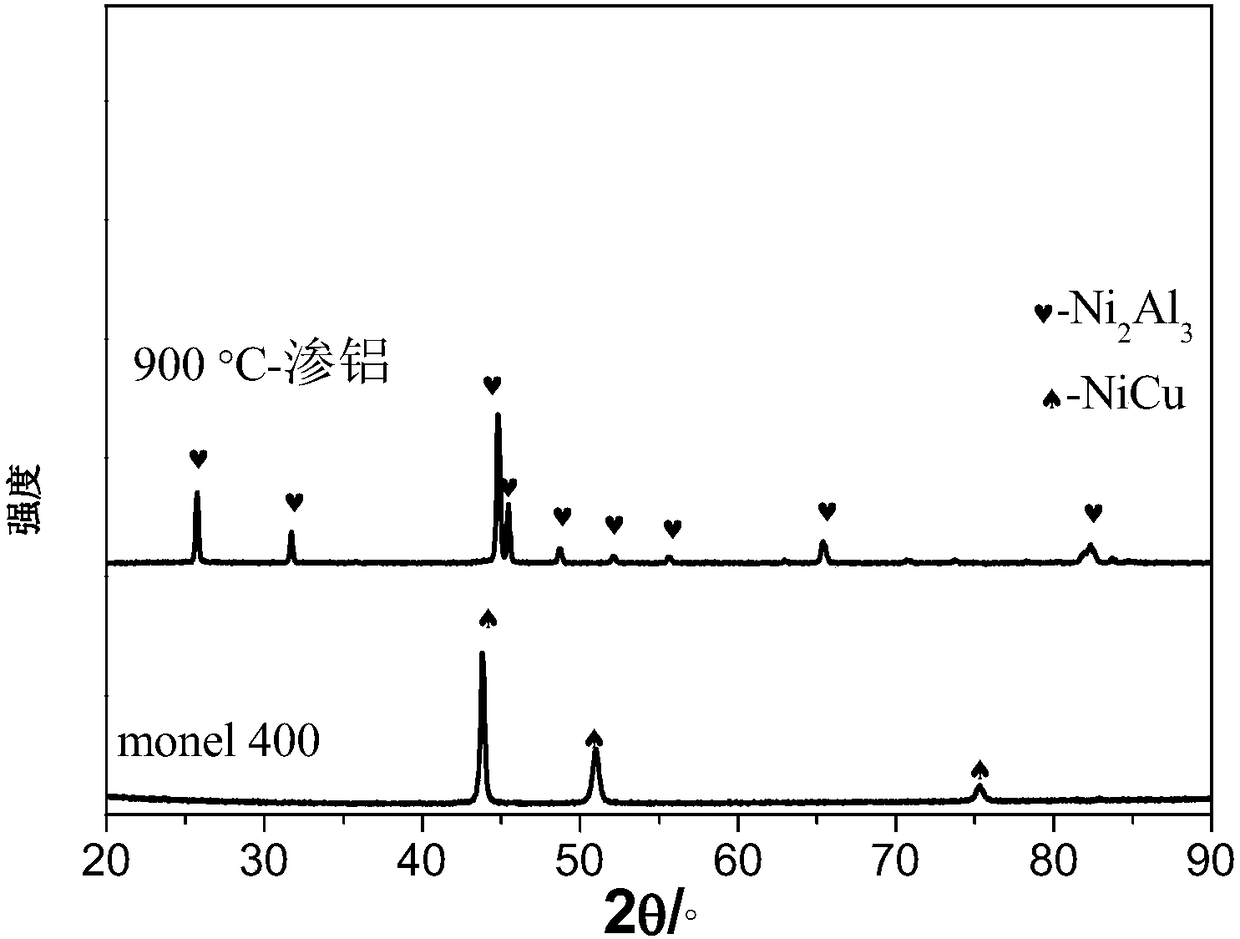

Positive pressure atmosphere aluminizing reinforcing method for nickel-based alloy, nickel-based alloy workpiece and application

InactiveCN108239739AInsulate the influenceQuality improvementSolid state diffusion coatingPositive pressureHardness

The invention discloses a positive pressure atmosphere aluminizing reinforcing method for a nickel-based alloy, a nickel-based alloy workpiece and application. The aluminizing reinforcing method comprises the following steps: placing a nickel-based alloy matrix with the local surface covered with an aluminizing agent at least in protective atmosphere, aluminizing at the temperature of 900-1100 DEGC, and enabling the protective atmosphere to be at positive pressure in an aluminizing process, wherein a surface metallurgically bonded Ni-Al reinforcing layer with high hardness, high abrasion resistance and high corrosion resistance can be obtained by controlling technological conditions such as aluminizing temperature and aluminizing time. The method disclosed by the invention has the advantages that influence of oxygen and the like on an aluminizing layer is isolated, aluminizing rate and aluminizing layer quality are obviously improved, and corrosion resistance and oxidation resistanceof the aluminizing layer can be guaranteed; meanwhile, the limit of the method on shape and size of a workpiece is low, a nickel-based alloy surface reinforced layer with the characteristics of high hardness, high abrasion resistance and high corrosion resistance can be obtained, the surface protection of the nickel-based alloy is effectively realized, and the performance of the nickel-based alloymatrix is hardly damaged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Ferrovanadium slag refining agent, preparation method thereof, and method for removing vanadium from slag

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

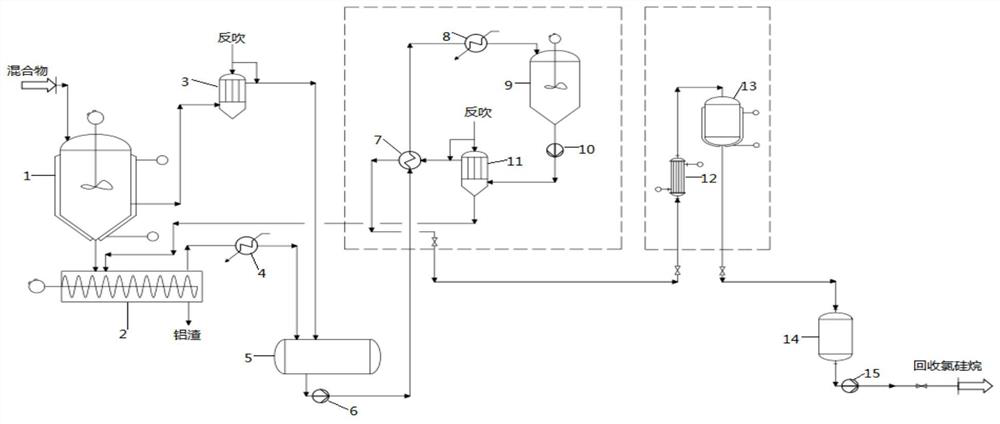

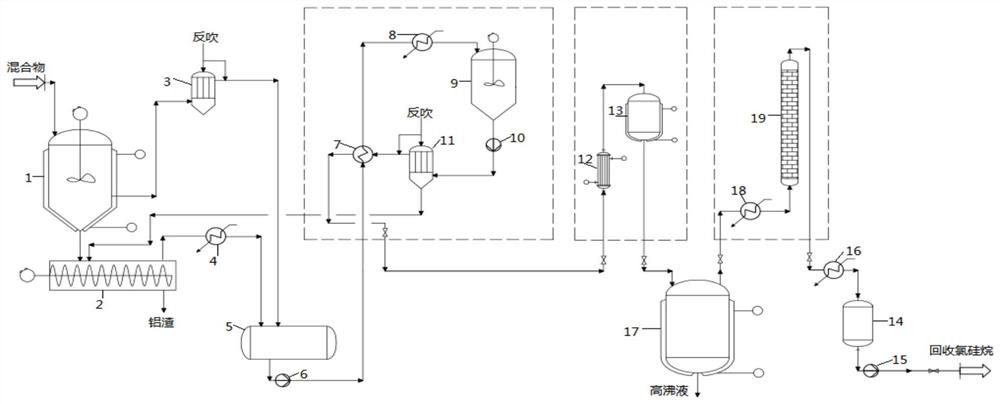

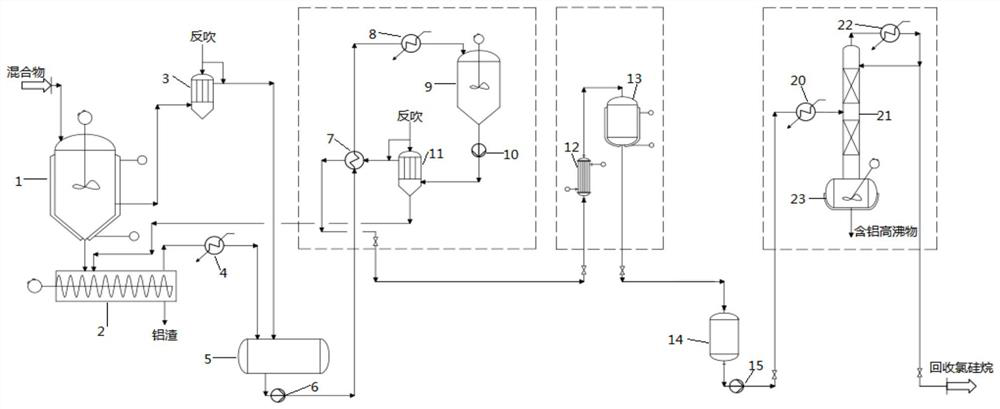

Process and equipment for removing aluminum by complexing chlorosilane

PendingCN112408396AReduce aluminum impurity contentReduce contentHalogenated silanesAluminium chloridePhysical chemistry

The invention relates to a process and equipment for removing aluminum by complexing chlorosilane. The low-temperature complexing aluminum removal process, the liquid-phase complexing aluminum removalprocess, the gas-phase complexing process and the high-pressure rectifying aluminum removal process are operated independently or in a combined mode to meet different chlorosilane purification requirements. A chlorosilane mixture filtered by the low-temperature complexing stirring tank filter and raw materials conveyed by the raw material buffer tank enter and exit the heat exchanger for heat exchange through low-temperature complexing aluminum removal, and effective utilization of energy is achieved. The low-temperature complexing aluminum removing agent, the liquid-phase aluminum removing agent and the gas-phase aluminum removing agent are long in service life and obvious in complexing aluminum removing effect. According to the process, various complexing aluminum removing agents can beselected for use, and high complexing aluminum removing performance can be kept under the condition of the technological operation range. The aluminum removal rate of chlorosilane is improved, the content of aluminum chloride in chlorosilane is reduced through the low-temperature complexing aluminum removal process and the liquid-phase complexing aluminum removal process, and finally the contentof aluminum in chlorosilane can be reduced to 0.001 ppm or below through the series gas-phase complexing aluminum removal process and the high-pressure rectification aluminum removal process.

Owner:TIANJIN UNIV

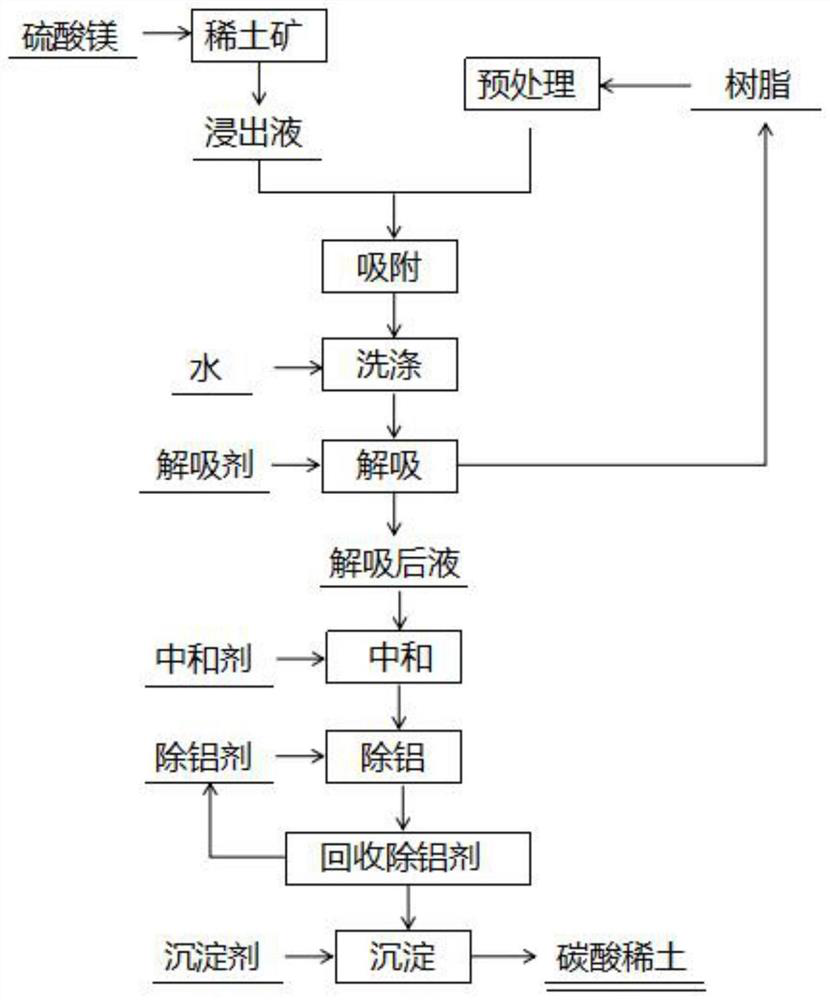

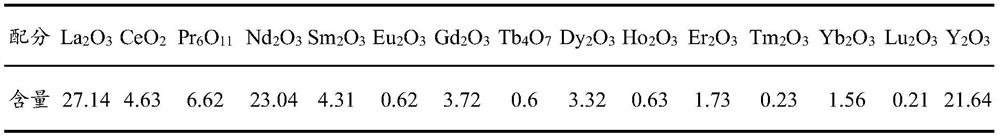

Method for preparing rare earth carbonate from ionic rare earth ore

The invention provides a method for preparing rare earth carbonate from ionic rare earth ore, and belongs to the technical field of rare earth metallurgy. According to the method, the extraction resin is used for adsorption-desorption, impurities Mg and Fe and most Si and Ca can be removed, the extraction resin can be recycled, Al can be efficiently removed through the procedures of liquid residual acid neutralization after desorption and Al removal through the aluminum removal agent, rare earth loss is small, and the aluminum removal agent can be recycled. And finally, precipitating to obtain a rare earth carbonate product with the rare earth content of more than 93wt% after burning. The method is good in production environment, high in impurity removal rate, low in chemical reagent consumption, high in rare earth precipitation product purity, low in impurity content and low in later rare earth smelting separation cost.

Owner:江西离子型稀土工程技术研究有限公司

Method for preventing internal corrosion of gas turbine by adopting aluminizing process

PendingCN114262865AGuaranteed normal coatingSolid state diffusion coatingSurface cleaningHeat conservation

The invention provides a method for preventing internal corrosion of a gas turbine combustor by adopting an aluminizing process, which comprises the following steps: S1, surface cleaning: selecting a workpiece made of ferrite alloy steel containing 0.08-0.3% by mass of Mo, and cleaning impurities on the surface of the workpiece through heat treatment at the temperature of 200-500 DEG C for 1-3 hours; performing ultrasonic cleaning on the workpiece by adopting an acid solution; s2, sample embedding: embedding the cleaned workpiece in an aluminizing agent, and then placing the workpiece in a double-layer quartz tube aluminizing high-temperature heat treatment device; the double-layer quartz tube aluminizing high-temperature heat treatment device containing the workpiece is placed in a high-temperature heat treatment furnace, the heating rate is controlled to be 30-50 DEG C / h, the temperature is increased to 700-750 DEG C, and heat preservation is conducted for 3-5 h; and then the furnace is cooled to the room temperature, the cooling rate is controlled to be 40-50 DEG C / h, and then the workpiece is taken out. The method has the beneficial effects that the aluminum coating on the surface of the product is normally coated on the basis that the performance of the raw materials is not obviously attenuated, and the coating thickness and the surface deposition rate both meet the requirements.

Owner:SHANGHAI ELECTRIC GAS TURBINE CO LTD

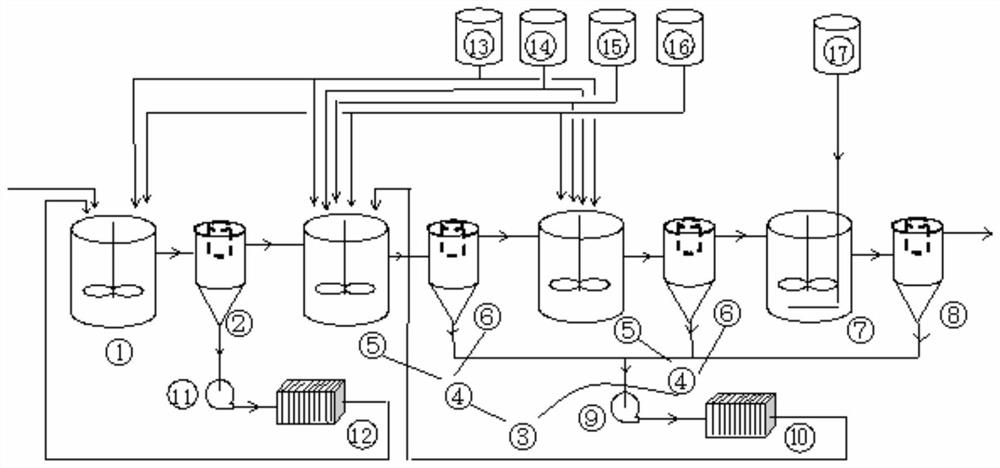

Multistage crystallization and precipitation treatment method and system for wastewater desalination

PendingCN111943337ALess quantityReduce processing costsSludge treatment by de-watering/drying/thickeningWater contaminantsDesalinationWastewater

The invention provides a multistage crystallization precipitation treatment method for wastewater desalination. The method comprises the following steps: 1) adding a calcium agent, an auxiliary agentand an aluminum agent into salt-containing wastewater, carrying out precipitation reaction, and carrying out solid-liquid separation to obtain a supernatant; 2) adding a calcium agent, an auxiliary agent and an aluminum agent into the supernatant at least once to perform precipitation reaction, and performing solid-liquid separation to obtain a clarified liquid; and 3) adding a neutralizer into the clarified liquid, carrying out neutralization reaction, and carrying out solid-liquid separation to provide the desalted wastewater. The invention further provides a multistage crystallization and precipitation treatment system for wastewater desalination. According to the multistage crystallization and precipitation treatment method and system for wastewater desalination, salt in wastewater isremoved through the crystallization and precipitation effect of calcium-aluminum crystals, and the method has the advantages that energy consumption and treatment cost are reduced, the method is not affected by the content of organic matter in water, and the method can be used for pretreatment of wastewater biochemical treatment.

Owner:上海中耀环保实业有限公司

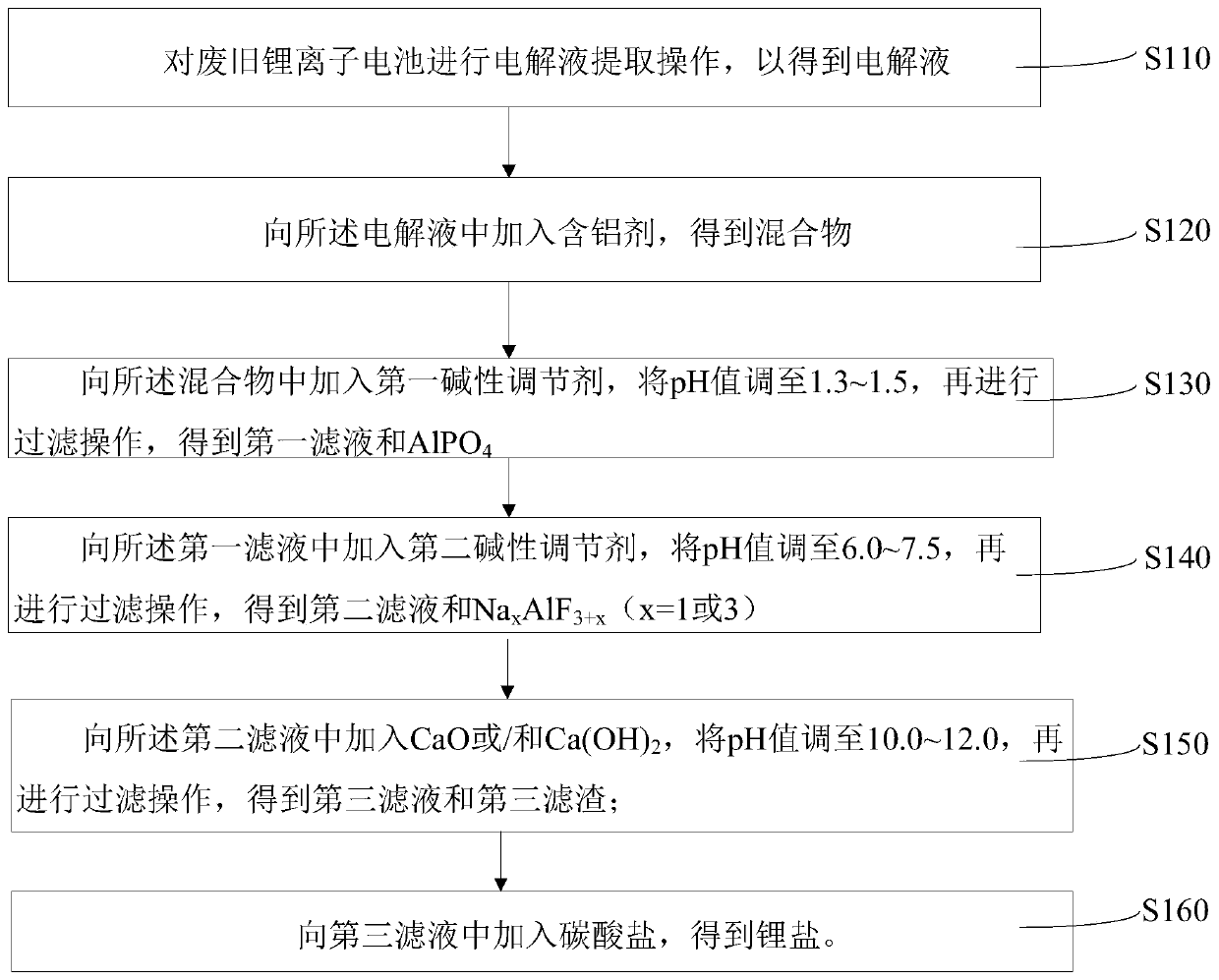

Recovery method of waste lithium-ion battery electrolyte

ActiveCN108631017BHigh recovery rateRaise the utilization priceWaste accumulators reclaimingBattery recyclingElectrolytic agentPhysical chemistry

The invention provides a recycling method of electrolyte of waste lithium ion batteries. The method comprises the following steps: extracting electrolyte of waste lithium ion batteries to obtain electrolyte, successively adding an aluminum-containing agent and an alkali regulator into the electrolyte, carrying out segmented regulation of a pH value of a reaction system and filtering to successively obtain AlPO4, NaxAlF3+x (x is 1 or 3) and second filtrate, then adding CaO and / or Ca(OH)2 into the second filtrate, regulating the pH value of the reaction system and filtering to obtain third filter residues and third filtrate, then adding carbonate into the third filtrate to obtain lithium salt. Through the recycling method of the electrolyte of the waste lithium ion batteries, the recycled materials such as AlPO4, NaxAlF3+x (x is 1 or 3), the third filter residues and the lithium salt and the like are obtained; the recycled materials have different use and can be further recycled; the recovery rate of the electrolyte of the lithium ion batteries and the utilization values of the by-products are greatly increased.

Owner:EVE ENERGY CO LTD

A method for recycling waste saggers in the preparation process of lithium cobalt oxide battery materials

ActiveCN109911946BAchieve recyclingWide variety of sourcesAlkaline-earth metal silicatesCalcium/strontium/barium sulfatesPhysical chemistryAluminium agents

The invention provides a method for carrying out recovery treatment on a waste saggar in a lithium cobaltate battery material preparation process, wherein the waste saggar contains silicon, aluminum and magnesium impurities. The method comprises: 1) mixing a waste saggar, an acid solution and an additive, carrying out a leaching reaction, and separating to obtain a purified saggar and a leachate;2) adjusting the pH value of the leachate to 2-5, and separating to obtain solid residue and a separated liquid; 3) adding an aluminum removing agent to the separated liquid, crystallizing, and separating to obtain solid residue and an aluminum removed liquid; 4) adjusting the pH value of the aluminum removed liquid to more than or equal to 8.5, and separating to obtain a cobalt-containing substance and a cobalt precipitation liquid; 5) adding a magnesium removing agent to the cobalt precipitation liquid, adjusting the pH value to more than or equal to 11, and separating to obtain solid residue and a magnesium removed liquid; and 6) adding a precipitating agent to the magnesium removed liquid, carrying out a reaction, and separating to obtain a lithium-containing substance and a lithium precipitation liquid. According to the present invention, with the method, the recovery and utilization of cobalt and lithium in the waste saggar is achieved, the waste saggar is purified, and the method is suitable for industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com