Recovery method of waste lithium-ion battery electrolyte

A technology for lithium-ion batteries and recovery methods, which is applied in the field of recovery of lithium-ion battery electrolytes, and can solve the problems of low utilization value of by-products of lithium-ion battery electrolytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

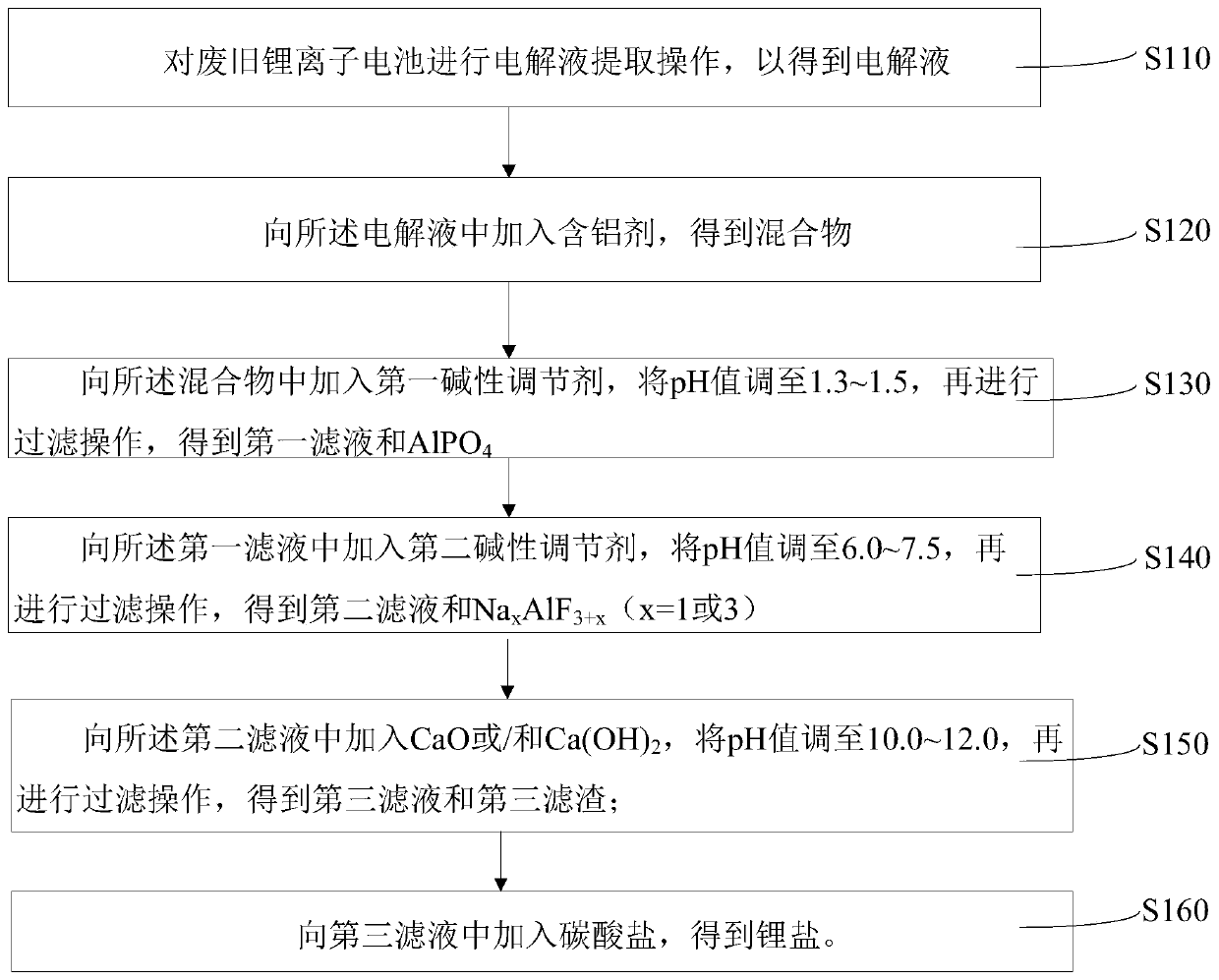

Method used

Image

Examples

Embodiment 1

[0058] (1) Stir and mix 150 cells of used and used lithium-ion batteries with graphite powder, perform deep discharge treatment, then disassemble, and extract the electrolyte for subsequent recovery;

[0059] (2) Add 2.1mol aluminum hydroxide powder to 2mol of the electrolyte to obtain a mixture;

[0060] (3) sodium hydroxide is added in the mixture, the pH value is adjusted to 1.3, and then the filtration operation is carried out to obtain the first filtrate and AlPO 4 ;

[0061] (4) add 2.5mol aluminum hydroxide powder in described first filtrate, pH value is adjusted to 6.0, carry out filtration operation again, obtain the second filtrate and NaAlF 4 ;

[0062] (5) in the second filtrate, add CaO, the pH value is adjusted to 10.0, then carry out filtration operation, obtain the 3rd filtrate and Ca(H 2 PO4) 2 and CaSO 4 mixed solids;

[0063] (6) Add salt of wormwood in the 3rd filtrate, obtain the lithium salt of embodiment 1.

Embodiment 2

[0065] (1) Stir and mix 150 cells of used and used lithium-ion batteries with graphite powder, perform deep discharge treatment, then disassemble, and extract the electrolyte for subsequent recovery;

[0066] (2) Add 2.1mol aluminum sulfate solution to 2mol described electrolyte solution, obtain mixture;

[0067] (3) sodium hydroxide is added in the mixture, the pH value is adjusted to 1.3, and then the filtration operation is carried out to obtain the first filtrate and AlPO 4 ;

[0068] (4) add 2.5mol aluminum hydroxide powder in described first filtrate, pH value is adjusted to 6.2, carry out filtration operation again, obtain the second filtrate and NaAlF 4 ;

[0069] (5) in the second filtrate, add CaO, the pH value is adjusted to 10.0, then carry out filtration operation, obtain the 3rd filtrate and Ca(H 2 PO4) 2 and CaSO 4 mixed solids;

[0070] (6) Add salt of wormwood in the 3rd filtrate, obtain the lithium salt of embodiment 2.

Embodiment 3

[0072] (1) Stir and mix 150 cells of used and used lithium-ion batteries with graphite powder, perform deep discharge treatment, then disassemble, and extract the electrolyte for subsequent recovery;

[0073] (2) Add 1.1mol aluminum hydroxide powder and 1.3mol aluminum sulfate solution to 2mol described electrolytic solution, obtain mixture;

[0074] (3) sodium hydroxide is added in the mixture, the pH value is adjusted to 1.4, and then the filtration operation is carried out to obtain the first filtrate and AlPO 4 ;

[0075] (4) add 2.5mol aluminum hydroxide powder in described first filtrate, pH value is adjusted to 6.5, carry out filtration operation again, obtain the second filtrate and NaAlF 4 and Na 3 AlF 6 ;

[0076] (5) in the second filtrate, add CaO, the pH value is adjusted to 10.0, then carry out filtration operation, obtain the 3rd filtrate and Ca(H 2 PO4) 2 and CaSO 4 mixed solids;

[0077] (6) Add salt of wormwood in the 3rd filtrate, obtain the lithium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com