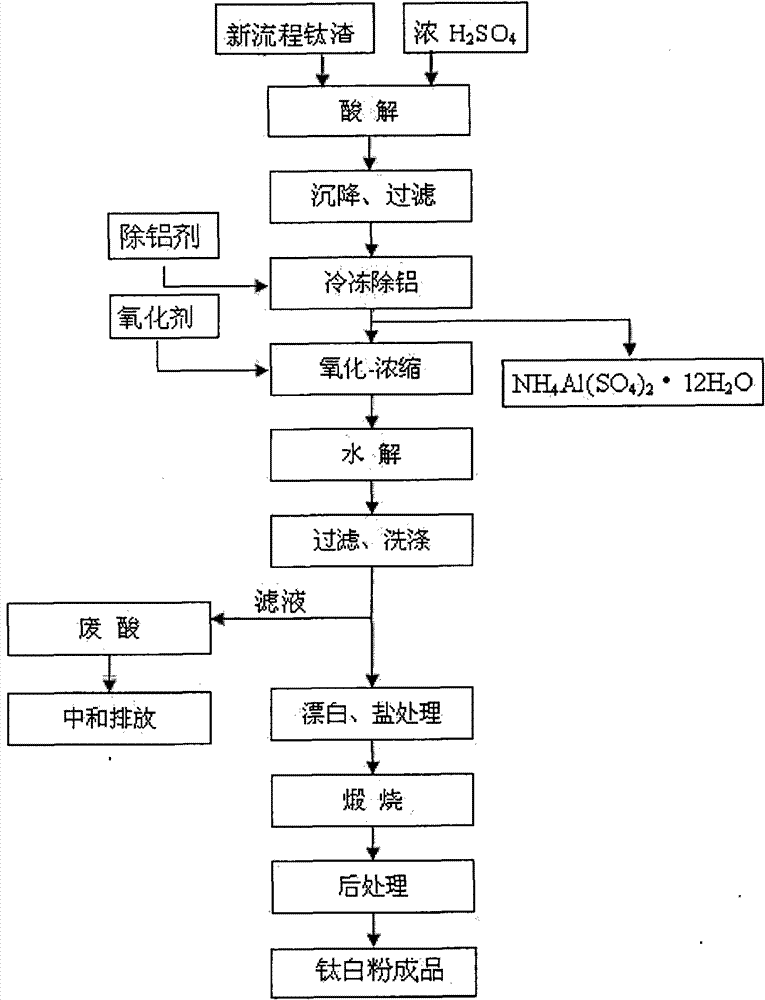

Method for preparing rutile titanium dioxide from new process titanium slag

A technology of rutile titanium dioxide and process, applied in the direction of titanium dioxide, solid waste removal, titanium oxide/hydroxide, etc., can solve the problems of low acidolysis rate, difficult crystal structure, quality limitation of titanium dioxide, etc., to reduce production Cost, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

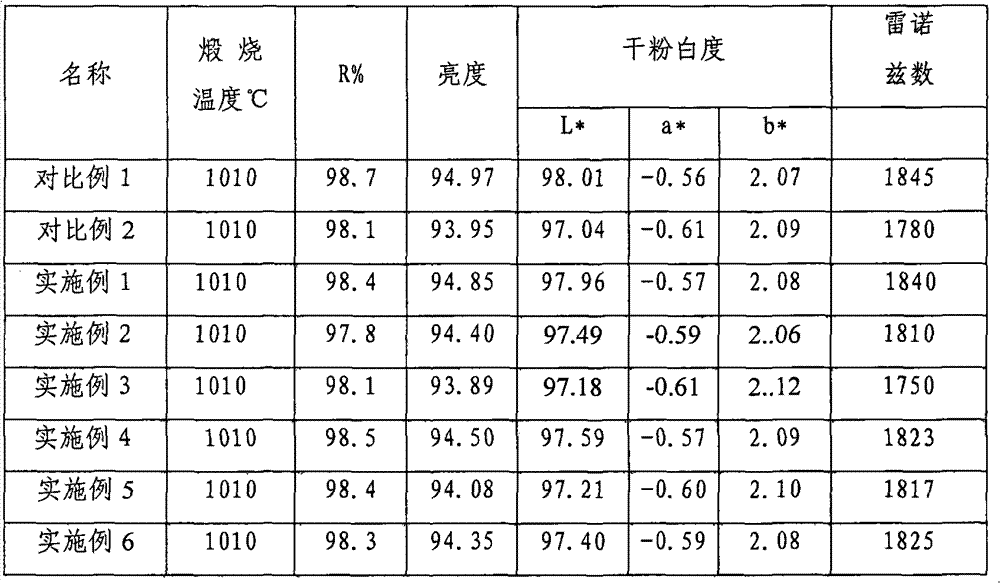

[0052] After the leaching is completed, add 2 grams of FeS first, then add 15 ppm flocculant formaldehyde dimethyl ammonium modified polyacrylamide (same as Comparative Example 1) for sedimentation, filter and separate to obtain clear titanium solution, add 150 g of ammonium sulfate, and cool the solution to 12 °C Crystallize for 1 hour, filter and separate to obtain about 450g of aluminum ammonium sulfate and titanium solution, and recover the obtained aluminum ammonium sulfate; add 150g of sodium nitrite to the obtained titanium solution to oxidize trivalent titanium to 2g / L, and concentrate to obtain a concentration of 200g / L 2 liters of concentrated titanium solution.

[0053] Adding additional seed crystal titanium tetrachloride to the obtained concentrated titanium solution for hydrolysis, the quality of the added titanium tetrachloride is 2% of the mass of titanium dioxide in the concentrated titanium solution, the hydrolysis temperature is 90-95 °C, and the initial reac...

Embodiment 2

[0057] As can be seen from Table 3, for the present embodiment, the chromium, vanadium, and aluminum contents are higher than that of Example 1, which has a relatively large influence on the pigment performance of the product, and the resulting pigment performance is slightly worse than that of Example 1.

[0058] Example 3

Embodiment 3

[0060] Find by table 3, to present embodiment, chromium, vanadium, aluminum content are higher than embodiment 2, and the pigment property influence of product is bigger, and the pigment property of gained is worse than embodiment 2, and the chromium of solid requirement new flow process titanium slag, The content of vanadium and aluminum impurities is as low as possible.

[0061] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com