Preparation method for diffusion impervious layer suitable for large member

A technology for large-scale components and barrier layers, which is applied in the field of diffusion barrier preparation, can solve problems such as surface coating failure and interdiffusion, and achieve the effects of high production efficiency, low raw material cost, and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

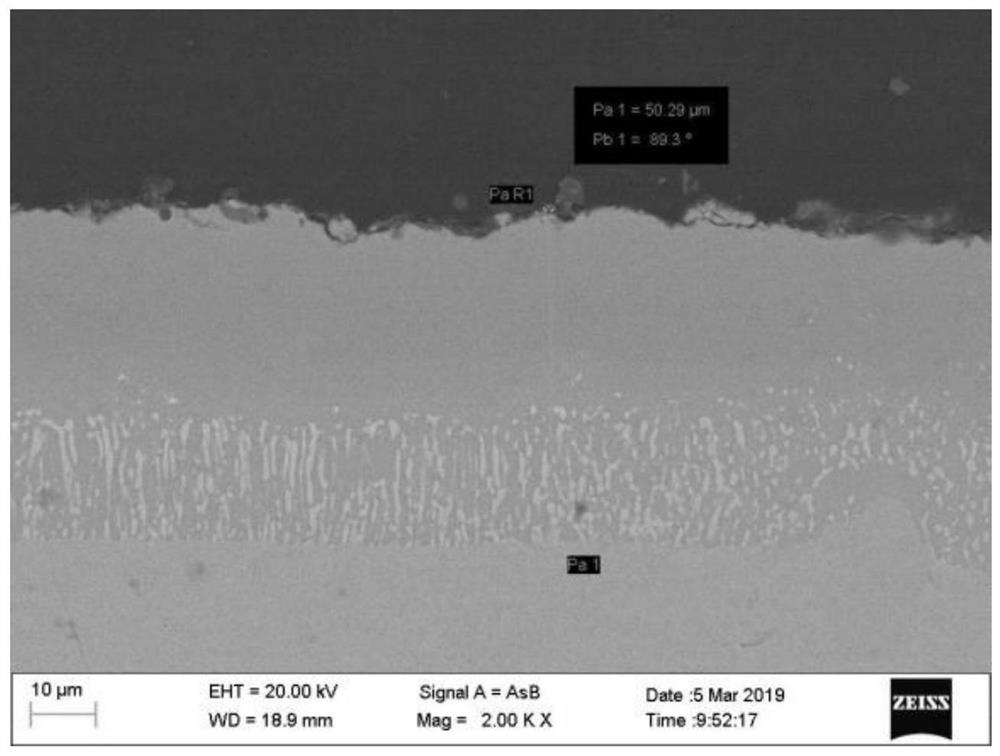

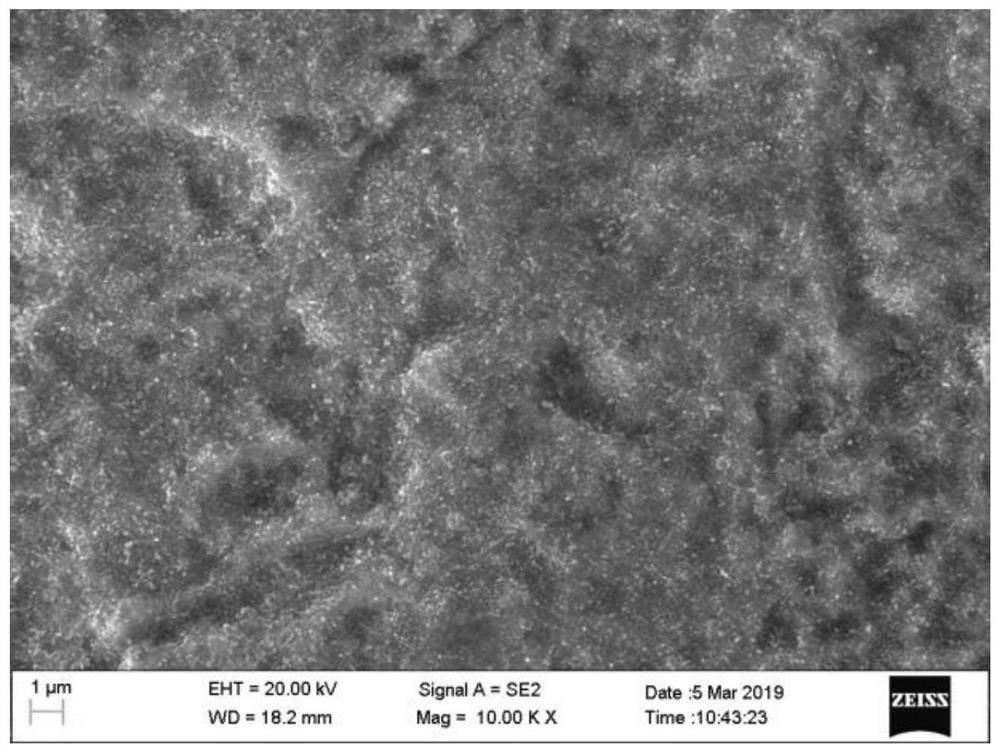

[0028] The invention provides a method for preparing a diffusion barrier layer suitable for large components, characterized in that: the method for preparing a diffusion barrier layer suitable for large components specifically includes the following steps:

[0029] Aluminizing agent preparation:

[0030] Put the aluminum and iron blocks into the container, add ammonium bifluoride with a mass percentage of 0.5% to 1.0% of the aluminum and iron blocks, and then add water until it covers the surface of the aluminum and iron blocks, then heat in a heating furnace and keep it at 270 to 330°C. until it is boiled dry; a roasting at 700-900°C is carried out between two activation treatments;

[0031] Degreasing:

[0032] Clean the parts and components that need aluminizing, including samples, with organic solvents to clean the surface dirt and oil;

[0033] Liquid blasting:

[0034] Before aluminizing, the components need to be sand blasted by liquid, and the wind pressure should n...

Embodiment 2

[0046] The invention provides a method for preparing a diffusion barrier layer suitable for large components, characterized in that: the method for preparing a diffusion barrier layer suitable for large components specifically includes the following steps:

[0047] Aluminizing agent preparation:

[0048] Put the aluminum and iron blocks into the container, add ammonium bifluoride with a mass percentage of 0.5% to 1.0% of the aluminum and iron blocks, and then add water until it covers the surface of the aluminum and iron blocks, then heat in a heating furnace and keep it at 270 to 330°C. until it is boiled dry; a roasting at 700-900°C is carried out between two activation treatments;

[0049] Degreasing:

[0050] Clean the parts and components that need aluminizing, including samples, with organic solvents to clean the surface dirt and oil;

[0051] Liquid blasting:

[0052] Before aluminizing, the components need to be sand blasted by liquid, and the wind pressure should n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com