Zinc slag recycling and regenerating system for hot galvanizing

A regenerative system, hot-dip galvanizing technology, applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of carcinogenicity, teratogenicity, induced gene mutation, etc., to reduce raw material and energy consumption, low recycling cost, no The effect of wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

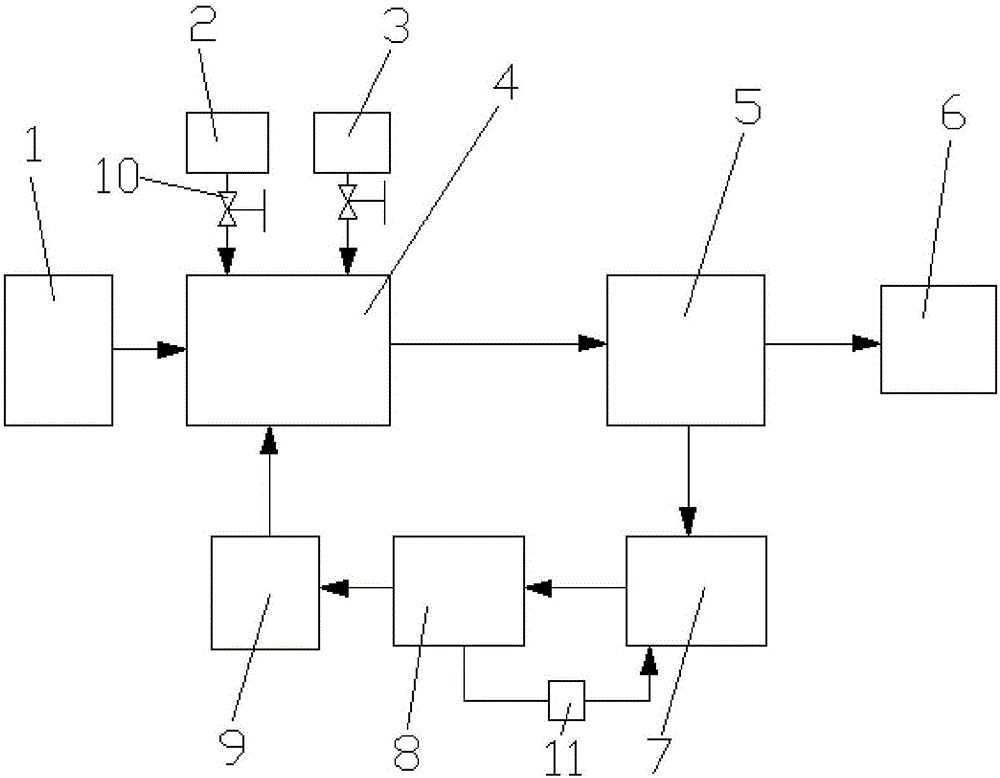

[0012] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a hot-dip galvanized zinc slag recovery and regeneration system according to the present invention includes a zinc slag adding device 1, an aluminum agent adding device 2, a protective medium adding device 3, a temperature-controlled melting furnace device 4, and a liquid slag separating device 5 , zinc liquid ingot casting device 6, dissolving tank 7, electrolytic cell 8, it is characterized in that: described zinc slag adding device 1 is connected with temperature control melting furnace device 4, and the top of described temperature controlling melting furnace device 4 is connected with aluminum agent adding device 2 and a protective medium adding device 3, the bottom of the temperature-controlled melting furnace device 4 is provided with a liquid slag separation device 5, and the liquid slag separation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com