Preparation method of aluminized coating for improving lead and bismuth corrosion resistance of ferrite-martensite steel

A martensitic steel, corrosion performance technology, applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of matrix structure coarsening, austenitization, and reducing the mechanical properties of the matrix, and achieve Good binding force, convenient operation, and the effect of improving the corrosion resistance of lead and bismuth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

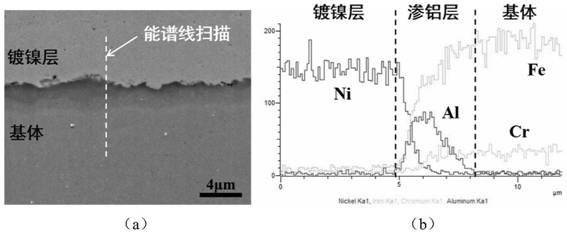

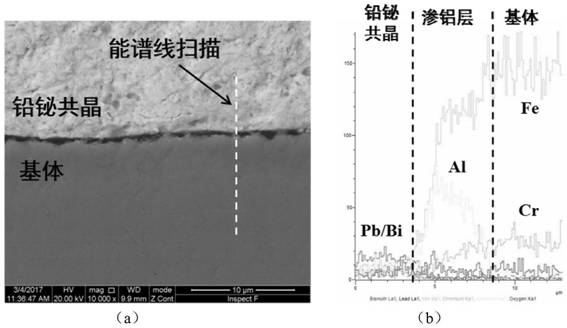

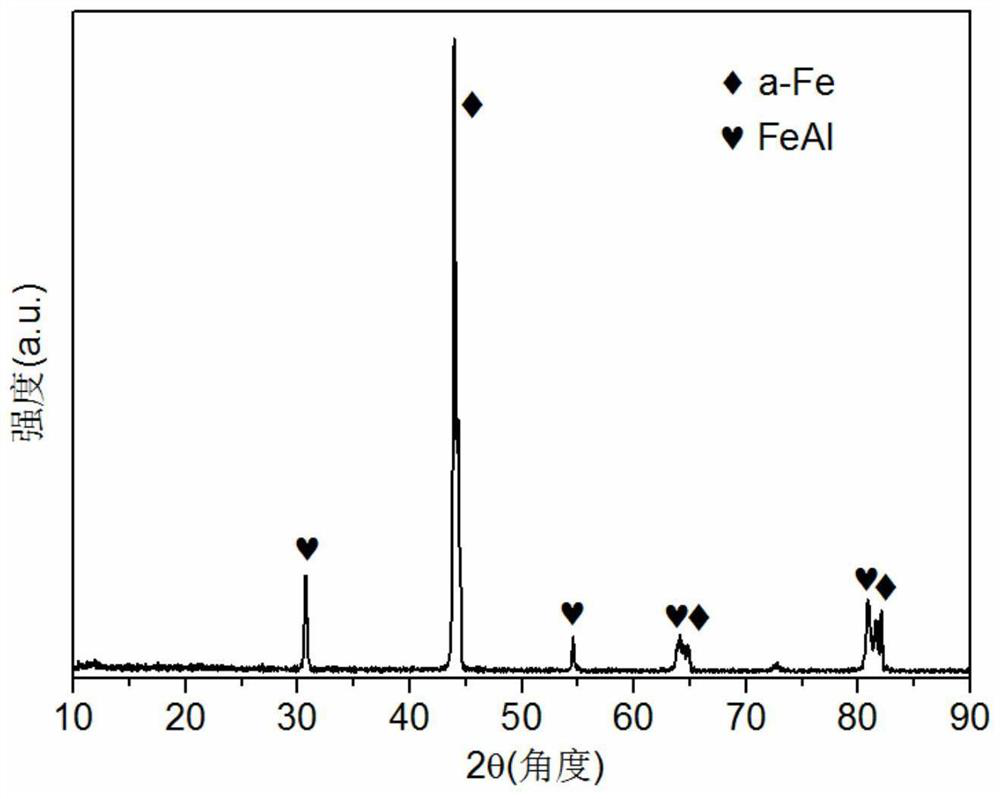

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides 9Cr2WVTa ferrite-martensitic steel plate, chemical composition (wt.%) is: C: 0.11%, Cr: 8.86%, W: 1.62%, V: 0.24%, Ta: 0.11%, Mn : 0.45%, Si: 0.05%, S: 0.005%, P: 0.005%, and the balance is Fe.

[0032] The components of the aluminizing agent used are: 2% NH by mass ratio 4 Cl powder (200 mesh), 98wt.% Fe50Al50 (molar ratio) powder (200 mesh). The specific implementation steps of aluminized coating preparation:

[0033] 1) Heat treatment: Quenching and tempering heat treatment for ferritic-martensitic steel. The quenching treatment is 1020°C for 60 minutes and then water cooling, and the tempering treatment is 750°C for 2 hours and then air cooling.

[0034] 2) Surface treatment: Mechanically polish the surface of the sample with a size of 10mm×10mm×5mm to completely remove the surface oxide skin and make the surface reveal a metallic luster.

[0035] 3) Activation treatment: use HCl solution with a volume fraction of 10% for surface activati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com