A Method for Improving the Lead-Bismuth Corrosion Resistance of Low-Activation Ferrite/Martensitic Steel

A low-activation ferritic and martensitic steel technology, applied in the field of metal protection, can solve the problems of poor lead-bismuth corrosion resistance, difficult to use for a long time, etc., so as to improve lead-bismuth corrosion resistance and high temperature oxidation resistance. and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

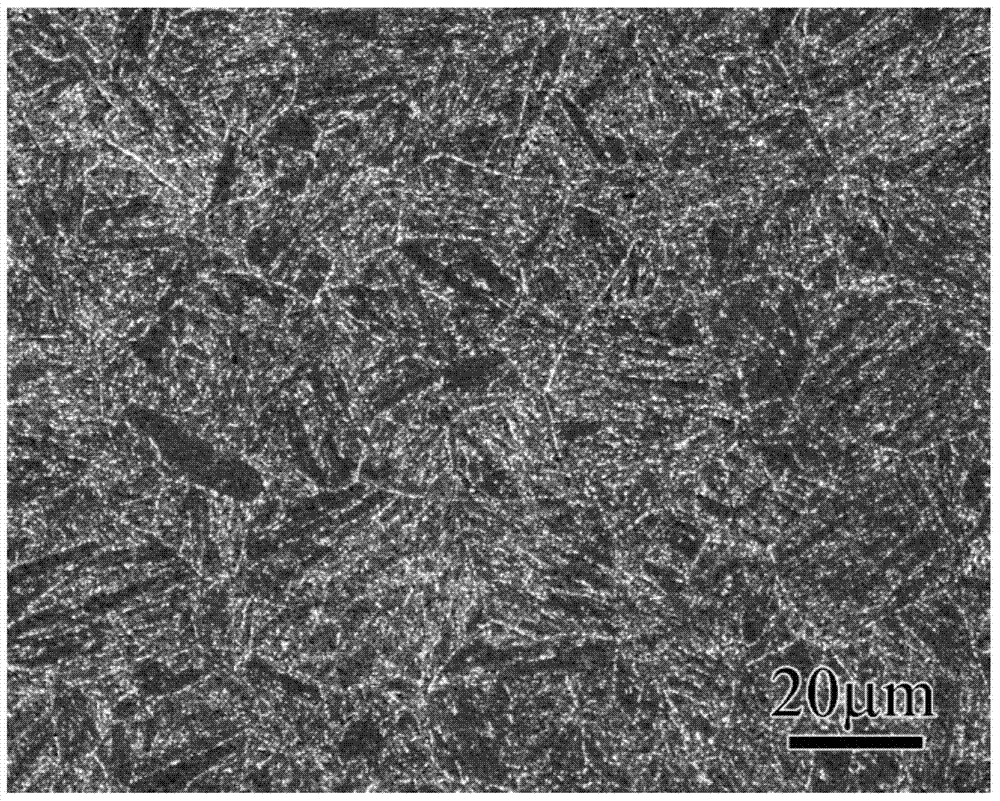

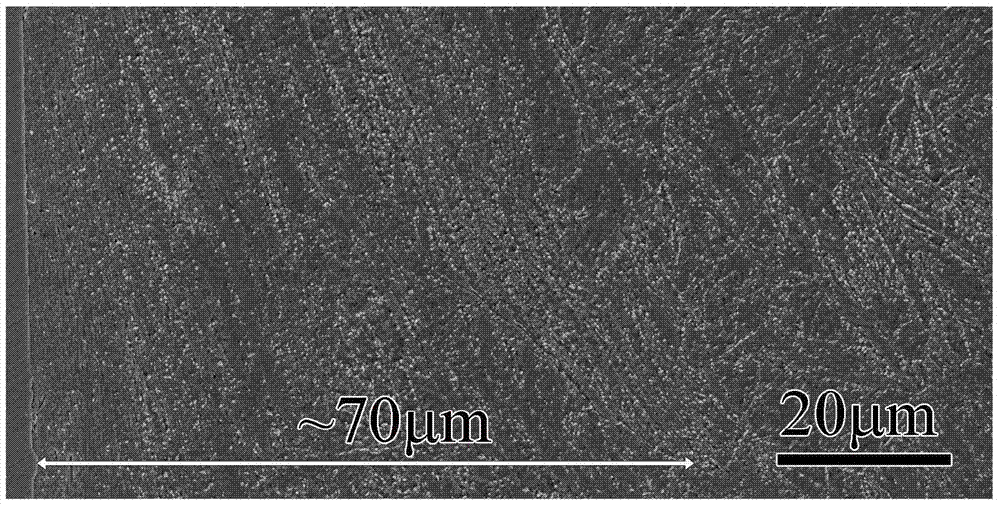

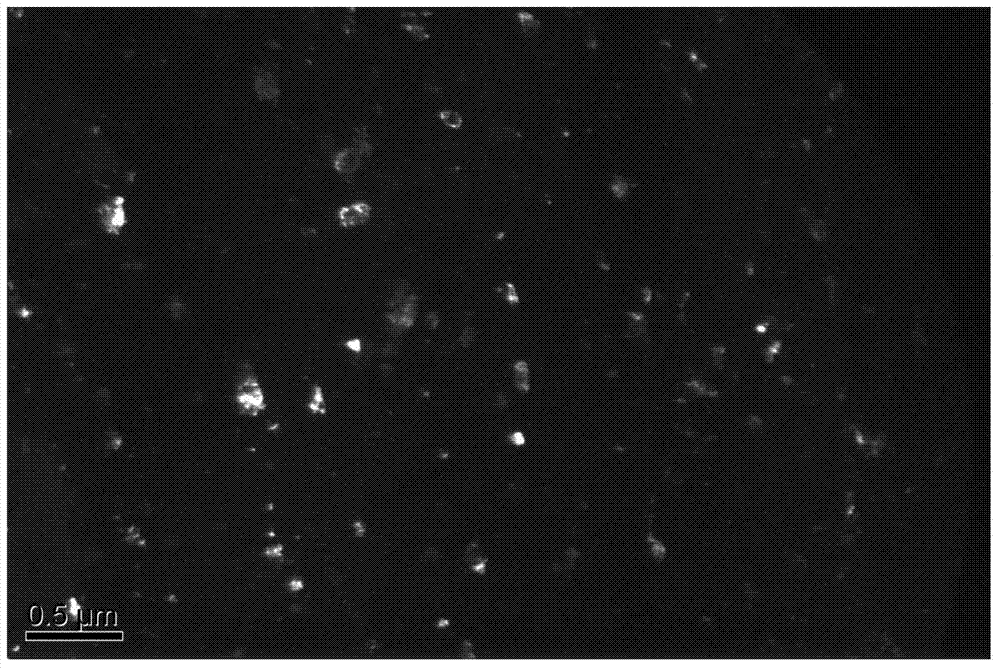

[0030] 9Cr2WVTa low-activation ferrite / martensitic steel is used as the research material to illustrate the influence of the present invention on the lead-bismuth corrosion resistance of low-activation steel, and its composition is shown in Table 1. The heat treatment system of the material before SMGT is: water quenching at 1050°C for 1 hour, air cooling at 750°C for 2 hours; figure 1 It can be seen that the material after heat treatment is composed of tempered martensite and carbide, and the grain size is about 15 μm. The low-activation steel after heat treatment is subjected to surface mechanical rolling treatment, figure 2 is the cross-sectional morphology of the material after SMGT treatment. It can be seen from the figure that its microstructure refinement layer is about 70 μm; image 3 It is a transmission electron microscope dark field image of the surface structure of the material after SMGT treatment, and it can be seen that nanocrystals with a grain size smaller t...

Embodiment 2

[0034] Using the same material as in Example 1, and through the same heat treatment but without pre-oxidation and nano-processing, the sample is placed in the same corrosion environment as in Example 1, and the corrosion results are as follows Figure 6 As can be seen from the figure, an oxide layer with a thickness of about 20 μm has been formed on the surface of the raw material, which is equivalent to the situation in Example 2. It can be seen that the original state coarse-grained material will undergo obvious oxidation in the environment of lead and bismuth, and does not have the performance of corrosion resistance of lead and bismuth.

Embodiment 3

[0036] The same material, heat treatment, and nanonization method as in Example 1 were used, but no pre-oxidation treatment was performed on the material with a nanocrystalline surface. The material with the nanocrystalline surface is placed in the same corrosion environment as in Example 1 for 500h, and its cross-sectional appearance is as follows: Figure 7 shown. It can be seen from the figure that the material has been oxidized in the lead-bismuth environment, and an oxide layer of about 20 μm is formed on the surface of the material. Therefore, pure nanocrystals cannot avoid the corrosion of 9CrWVTa low-activation steel in lead-bismuth alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com