Alloying method for improving liquid lead and bismuth corrosion resistance of high-performance fastener for lead-based reactor

A technology of corrosion performance and fasteners, applied in the direction of nuclear power generation, climate sustainability, reduction of greenhouse gases, etc., can solve the problem of lack of reference and reference, and achieve the effect of improving the corrosion resistance of liquid lead and bismuth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

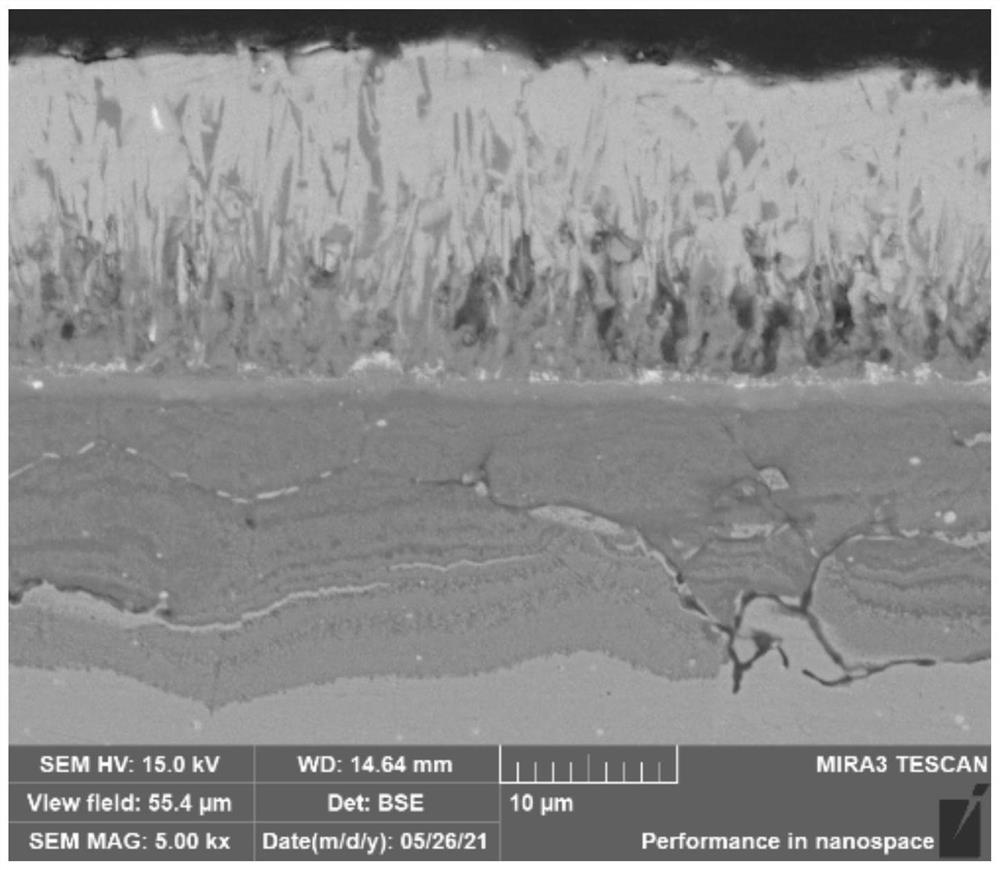

Embodiment 1

[0063] Example 1 (316)

[0064] By weight percentage, the chemical composition of the fastener material is: C: 0.022%; Si: 0.34%; Mn: 1.36%; S: 0.023%; P: 0.03%; Cr: 18.24%; Ni: 12.36%; Mo: 2.53%; N: 0.12%; Fe balance.

[0065] Example 1 is a 316-type austenitic stainless steel, the structure is a single austenite structure, and the Cr and Ni equivalent formulas claimed in the present invention are not applicable to this component.

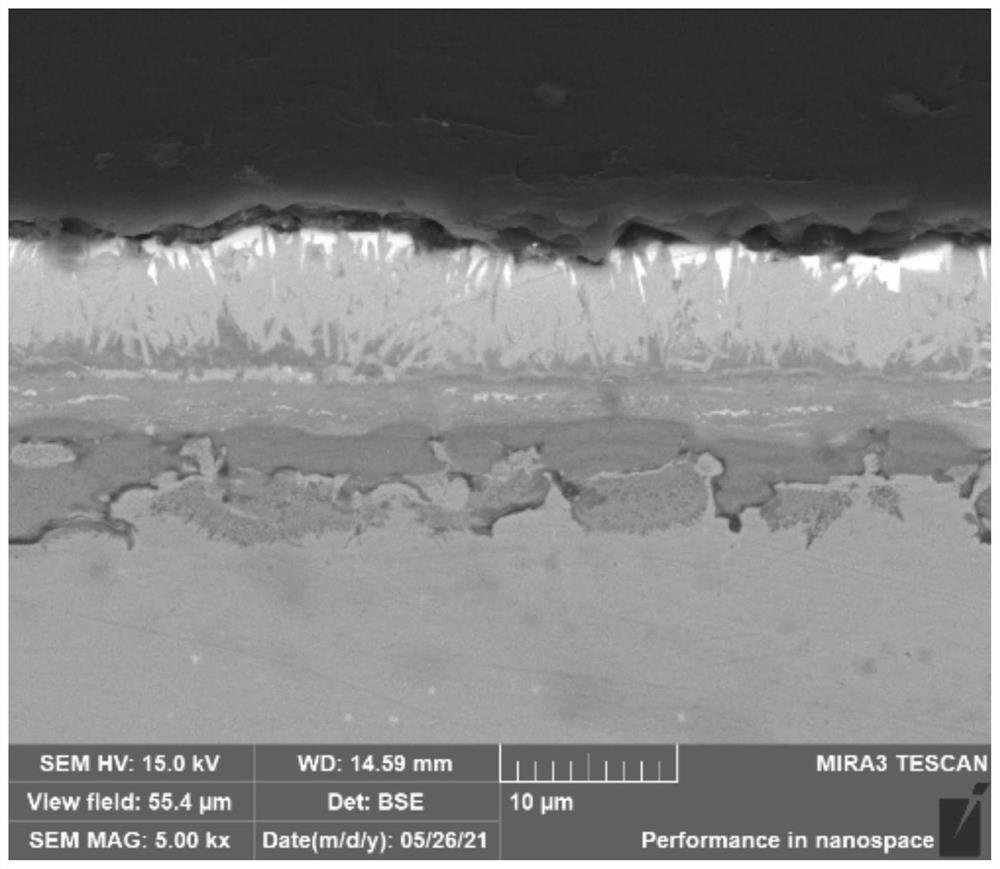

Embodiment 2

[0067] By weight percentage, the chemical composition of the fastener material is: C: 0.055%; Si: 1.57%; Mn: 0.43%; S: 0.0017%; P: 0.009%; Cr: 14.55%; Ni: 9.5%; Mo: 0.05%; Nb: 0.68%; O: 0.002%; N: 0.005%; Fe balance. Among them, the Cr equivalent is 17.30<20, and the Ni equivalent is 11.37≯14.

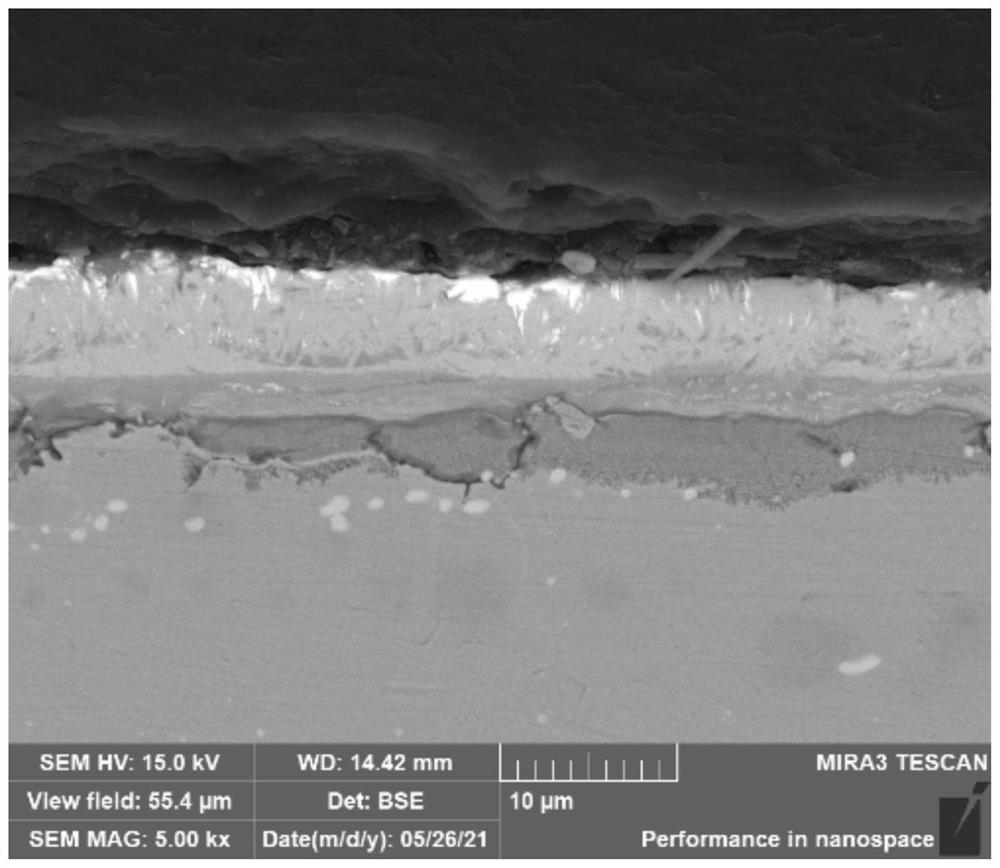

Embodiment 3

[0069] By weight percentage, the chemical composition of the fastener material is: C: 0.052%; Si: 1.51%; Mn: 1.50%; S: 0.0015%; P: 0.009%; Cr: 13.6%; Ni: 12.2%; Mo: 0.05%; Nb: 0.70%; O: 0.002%; N: 0.006%; Fe balance. Among them, the Cr equivalent is 16.2714.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com