Multistage crystallization and precipitation treatment method and system for wastewater desalination

A technology of crystallization precipitation and treatment method, applied in the direction of flocculation/sedimentation water/sewage treatment, water/sewage treatment, neutralization water/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

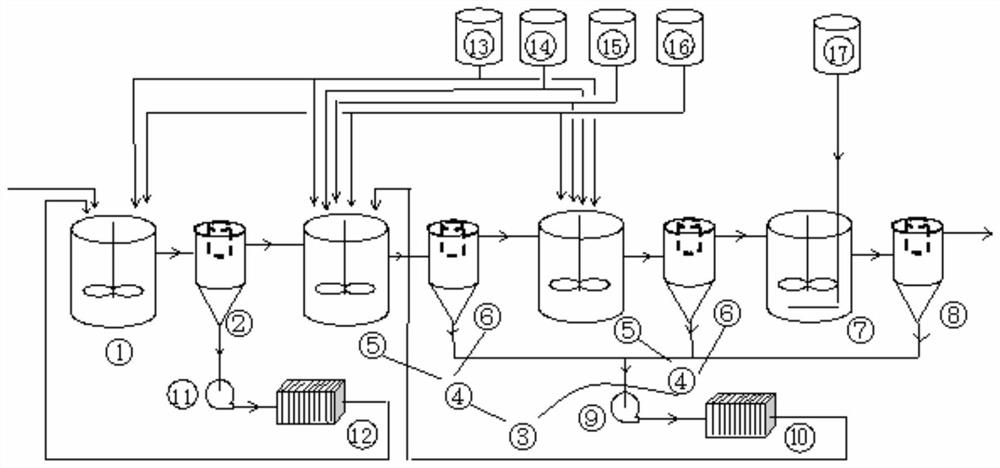

Method used

Image

Examples

Embodiment 1

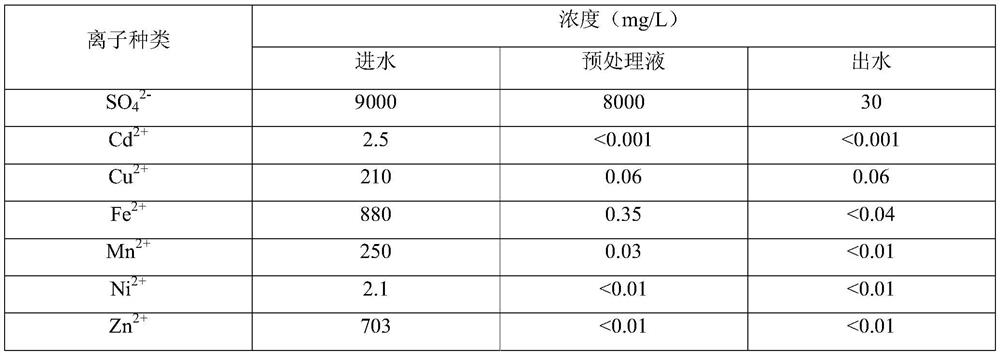

[0112] When the saline wastewater contains a large amount of heavy metal ions, the wastewater containing thousands of ppm salt is input into the heavy metal reaction tank, and the calcium agent is added from the calcium agent storage tank: Ca(OH) 2 , carry out the pre-precipitation reaction, the reaction stays for 40 minutes, and the pH is controlled at 9.0, so that the heavy metal ions in the wastewater can react to form precipitates. At the same time, other ions in wastewater such as SO 4 2+ and CO 3 2+ It will also partially react with calcium ions in calcium preparations to form precipitates. A pH meter is used to continuously detect the pH value of the reaction solution to control the addition of calcium agent, and to make other ions in the wastewater such as SO 4 2+ and CO 3 2+ It remains in the wastewater in a dissolved state. In order to improve the precipitation effect of the sediment, add flocculant: aluminum sulfate from the flocculant storage tank, add 100m...

Embodiment 2

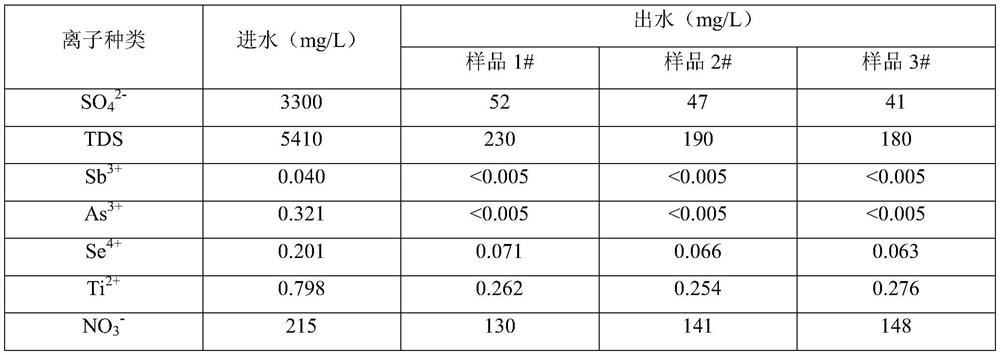

[0126] When the salty wastewater does not contain heavy metal ions, the wastewater containing thousands of ppm of salt is directly input into the crystal reaction unit. In the crystal reaction part, two crystal reaction units are arranged, and each crystal reaction unit is provided with a crystal reaction tank and a crystal precipitation tank sequentially along the water inlet direction of the saline wastewater. Enter the first crystal reaction part, in the crystal reaction tank of the crystal reaction unit, add calcium agent: CaO from the calcium agent storage tank, add auxiliary agent: magnesium sulfate from the auxiliary agent storage tank, and add aluminum agent from the aluminum agent storage tank : Ferric aluminate, carry out precipitation reaction, the reaction stays for 60 minutes, the pH is controlled at 12, and calcium aluminum crystals are precipitated, and the soluble ions in the wastewater are combined with calcium aluminum through in situ ion exchange, molecular e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com