Reusable low-temperature aluminizing agent and aluminizing method

An aluminizing agent and aluminizing technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as long-term safe operation of mechanical devices, peeling of oxide skin on the surface of parts, material fracture failure, etc. Achieve the effect of improving high temperature oxidation and corrosion resistance, improving the efficiency of aluminizing process, and low aluminizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

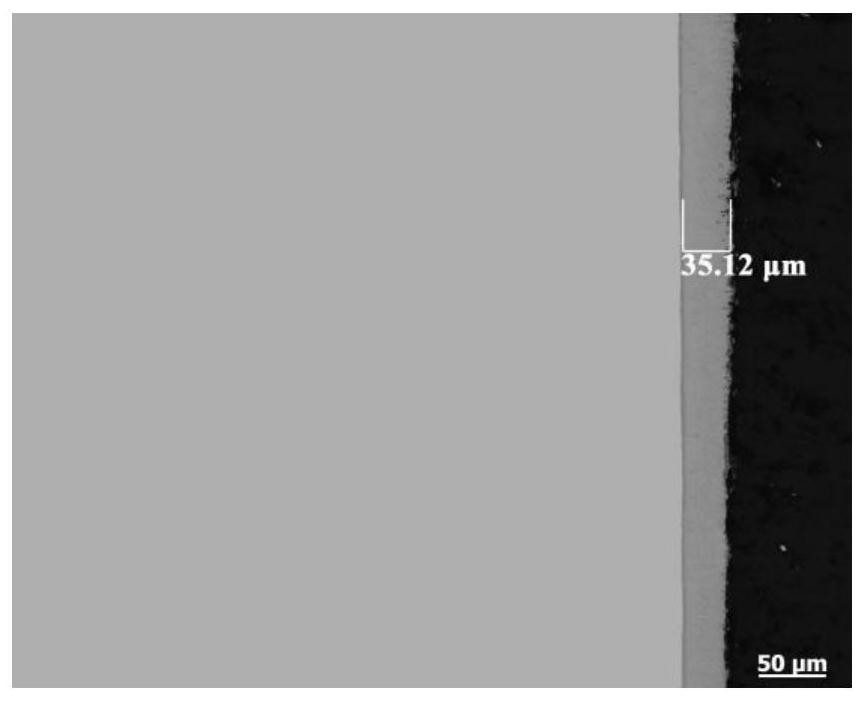

Embodiment 1

[0059] Perform surface aluminizing treatment on GH4169 superalloy parts according to the following steps:

[0060] (1) Preparation of aluminizing agent: fully stir 6 kg of aluminum powder with a particle size of 60 mesh, 0.5 kg of ammonium chloride, 0.5 kg of aluminum trichloride, 1 kg of titanium powder and 92 kg of calcined alumina in a mixer for 30 Minutes, get 100 kg of aluminizing agent.

[0061] (2) Canning: Using the powder embedding method, first lay a layer of aluminizing agent on the bottom of the aluminized tank, with a thickness of about 15-20 mm, then place the parts on the aluminizing agent, and then cover the parts with a layer Aluminizing agent, the thickness is about 15-20mm. Such a layer of aluminizing agent and a layer of parts until the infiltration tank is filled.

[0062] (3) Aluminizing: Put the infiltrating tank into the aluminizing furnace and raise the temperature to 200°C, and vacuumize the furnace to -0.1MPa, then feed nitrogen to raise the pressu...

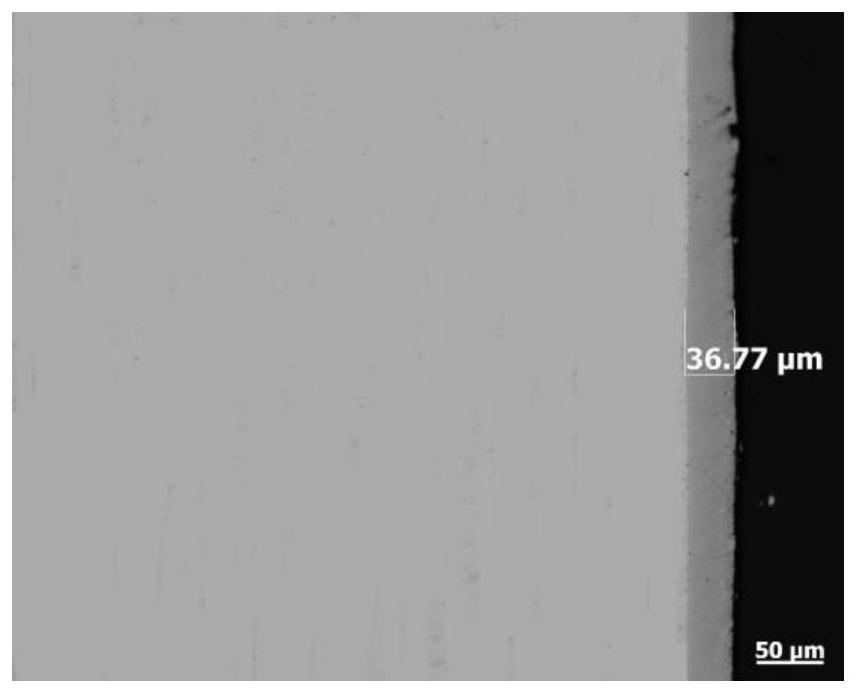

Embodiment 2

[0065] Perform surface aluminizing treatment on GH4169 superalloy parts according to the following steps:

[0066] (1) Preparation of aluminizing agent: fully stir 10kg of aluminum powder with a particle size of 200 mesh, 1.5kg of ammonium chloride, 1.5kg of aluminum trichloride, 2kg of titanium powder and 85kg of calcined alumina in a mixer for 30 Minutes, get 100 kg of aluminizing agent.

[0067] (2) Canning: Using the powder embedding method, first lay a layer of aluminizing agent on the bottom of the aluminized tank, with a thickness of about 15-20 mm, then place the parts on the aluminizing agent, and then cover the parts with a layer Aluminizing agent, the thickness is about 15-20mm. Such a layer of aluminizing agent and a layer of parts until the infiltration tank is filled.

[0068] (3) Aluminizing: Put the infiltrating tank into the aluminizing furnace and raise the temperature to 200°C, and vacuumize the furnace to -0.1MPa, then feed nitrogen to raise the pressure ...

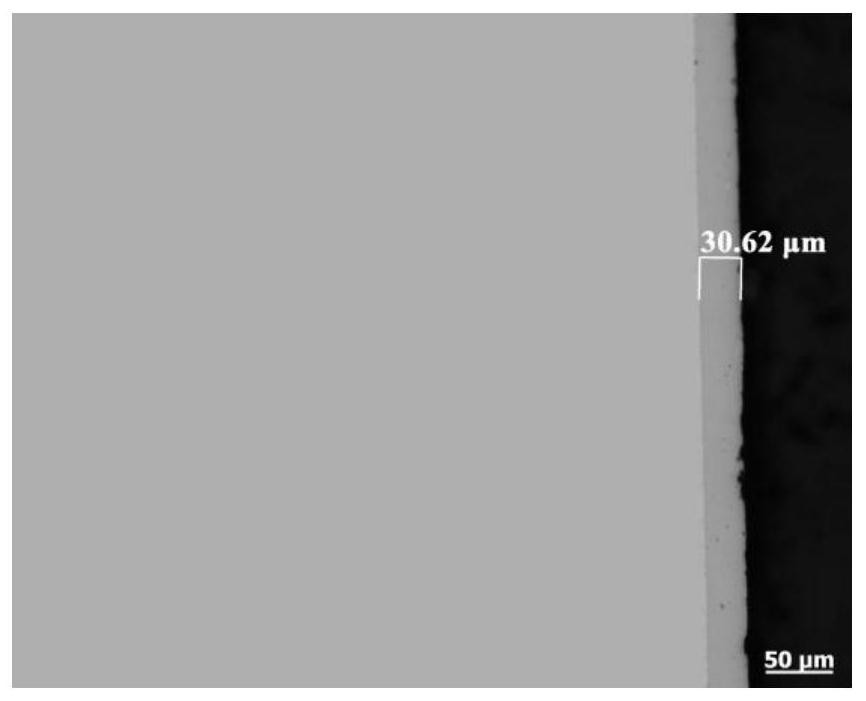

Embodiment 3

[0071] Perform surface aluminizing treatment on GH4169 superalloy parts according to the following steps:

[0072] (1) Preparation of aluminizing agent: 25kg particle size is 100 mesh aluminum-iron powder, 7.5kg ammonium chloride, 7.5kg aluminum trichloride, 6kg titanium powder and 54kg bauxite are fully stirred in the mixer for 30 minutes to obtain 100 kg of aluminizing agent.

[0073] (2) Canning: Using the powder embedding method, first lay a layer of aluminizing agent on the bottom of the aluminized tank, with a thickness of about 15-20 mm, then place the parts on the aluminizing agent, and then cover the parts with a layer Aluminizing agent, the thickness is about 15-20mm. Such a layer of aluminizing agent and a layer of parts until the infiltration tank is filled.

[0074] (3) Aluminizing: Put the infiltrating tank into the aluminizing furnace and raise the temperature to 200°C, and vacuumize the furnace to -0.1MPa, then feed nitrogen to raise the pressure in the furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com