Method for preventing internal corrosion of gas turbine by adopting aluminizing process

A gas turbine, internal corrosion technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of unstable operation of gas turbines, unplanned shutdown, unfavorable aluminum coating implementation, etc., to achieve coating The effect of thickness and surface deposition rate satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

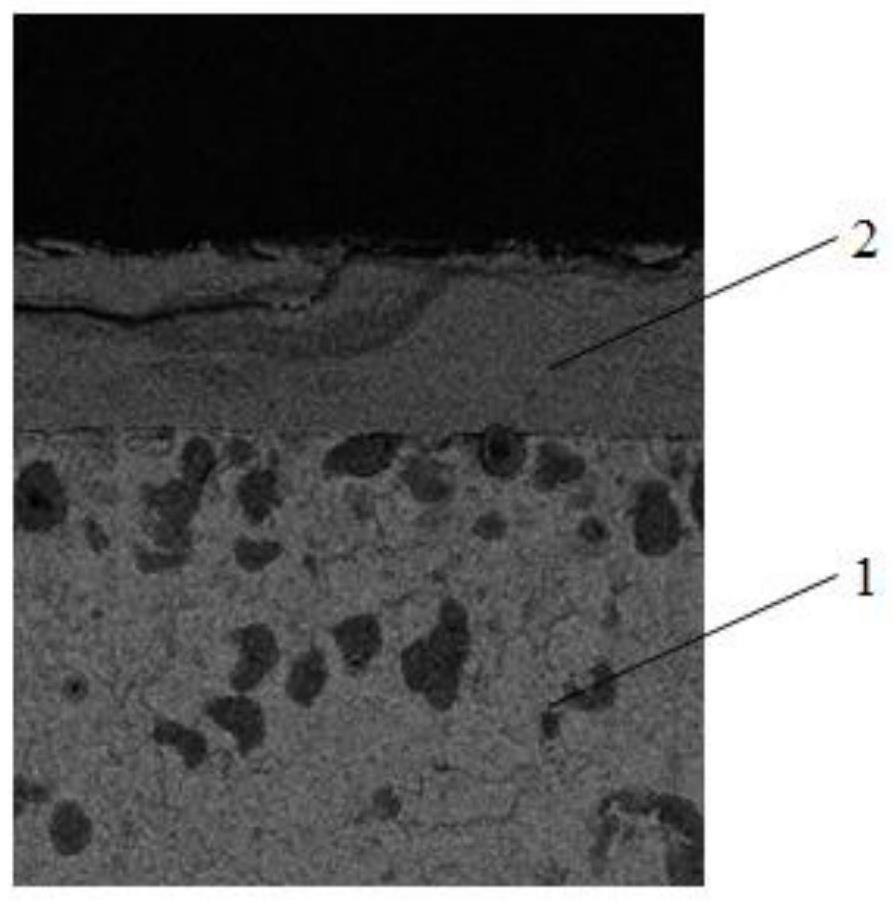

[0029] S1. Workpieces and bars with a diameter of 20mm made of 20CrMo ferritic alloy steel. In terms of mass percentage, 20CrMo ferritic alloy steel includes the following components: C: 0.19%, Si: 0.19%, Mn: 0.43% , Cr: 1.0%, Mo: 0.23%, S: 0.001%, P: 0.005%, Ni: 0.01%, Cu: 0.005%, and the rest is Fe. Place the workpiece in a high-temperature heat treatment furnace with a heat treatment temperature of 350°C, keep it warm for 1 hour, and then cool with the furnace. Then place the workpiece in citric acid with a concentration of 10% for ultrasonic cleaning, the ultrasonic frequency is 20KHz, and the processing time is 15min. Then take the cleaned workpiece out of the cleaning tank and put it directly into the passivation tank to protect its surface.

[0030] S2. Embed the cleaned workpiece and bar in the aluminizing agent respectively. In terms of mass percentage, the aluminizing agent includes the following components: 20% aluminum powder, 0.3% iron powder, 2% ammonium chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com