A method of 3D printing nickel-based superalloy aluminizing coating aluminizing agent and aluminizing

A nickel-based superalloy, 3D printing technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of poor bonding of aluminized coating, uneven thickness of aluminized coating, coating Problems such as poor binding effect, to achieve excellent protection, improve binding performance, and increase the effect of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

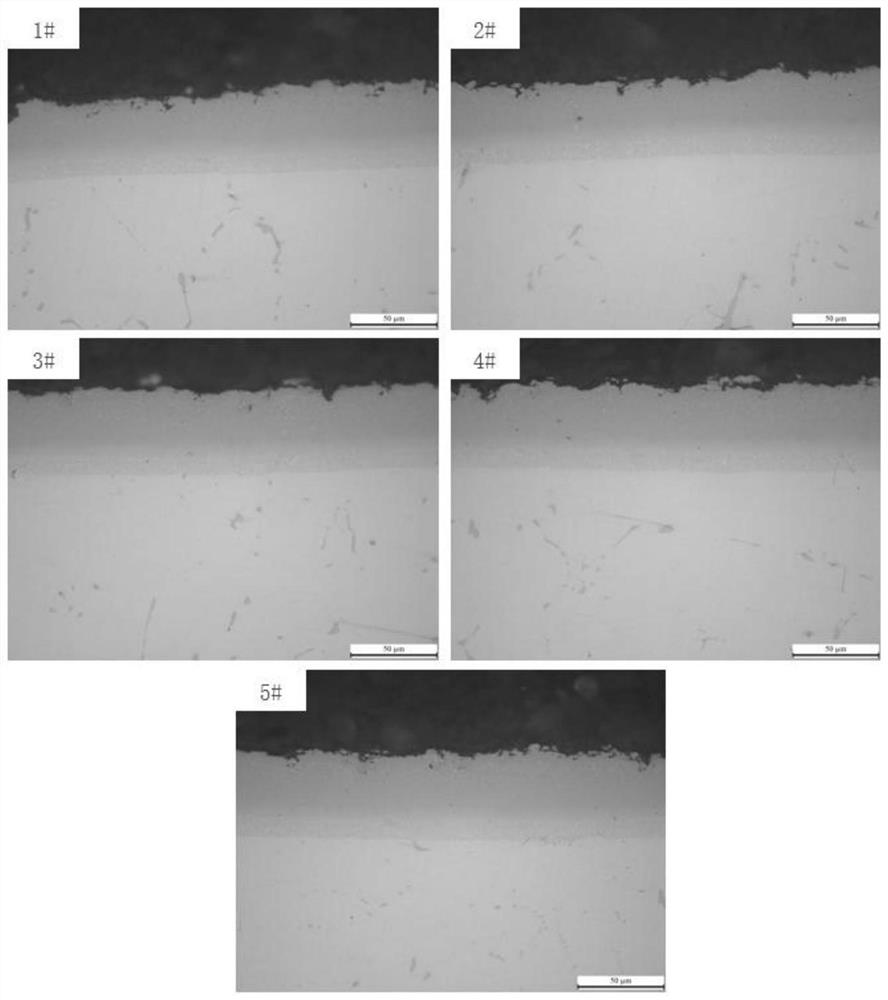

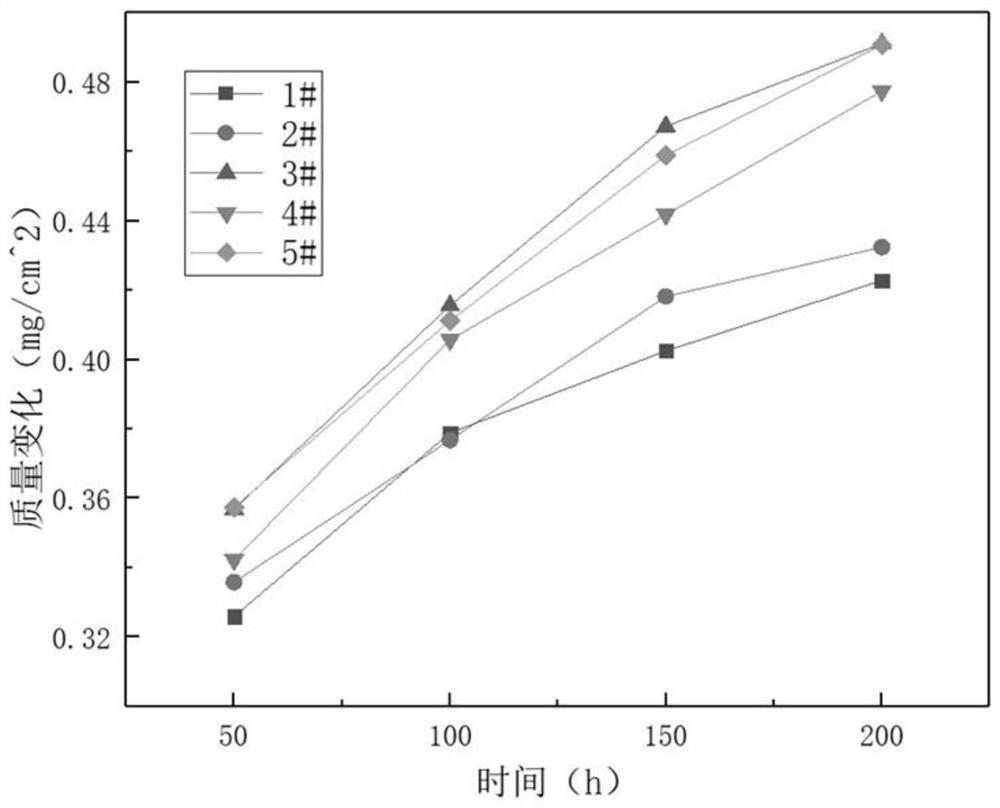

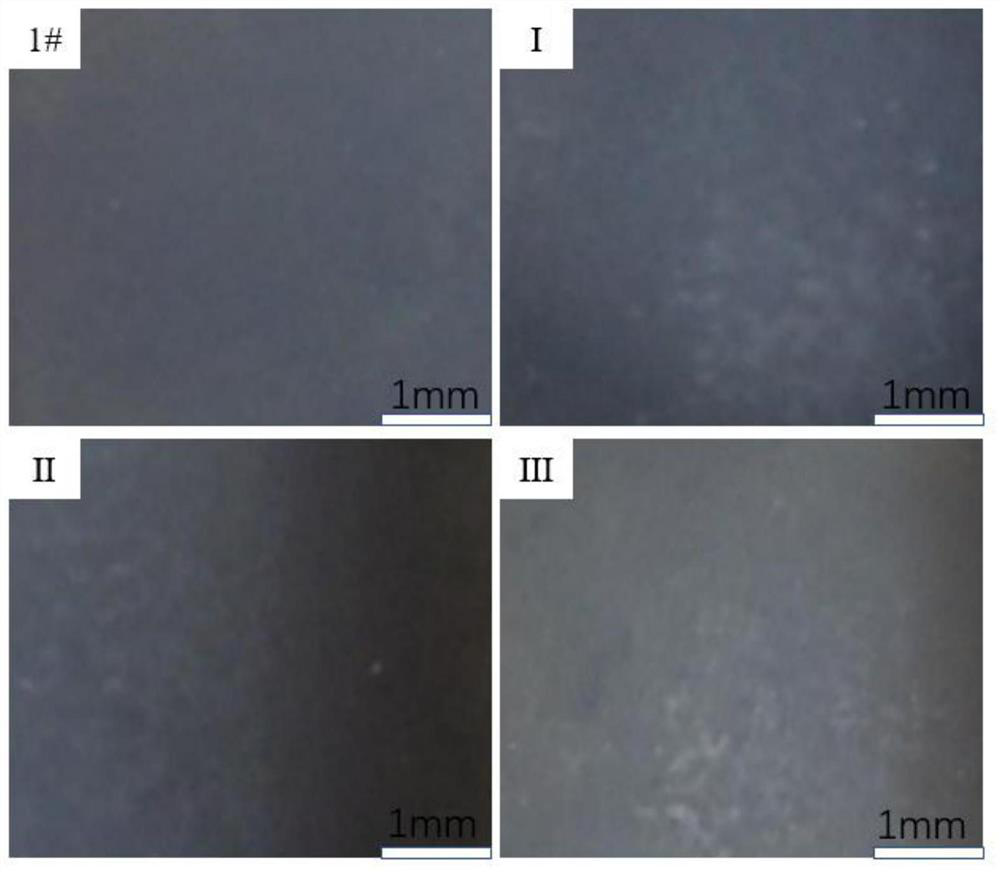

[0025] Aluminum powder, silicon powder, and chromium powder are all obtained by gas atomization powder making, and their powder spherical rates are 93%, 94%, and 93% respectively; the corresponding average particle sizes are 15 μm, 17 μm, and 20 μm. The copper powder is prepared by the rotating electrode powder making method, the spherical rate of the powder is 95%, and the average particle size of the powder is 60 μm. The aviation kerosene that kerosene adopts in the present embodiment.

[0026] The composition of the aluminizing agent is determined as aluminum powder content 83%, silicon powder content 8%, chromium powder content 6%, auxiliary agent content 3.0%, wherein: ammonium chloride content 0.5%, copper powder content 2%, kerosene content 0.5% . First, the powder is vacuum-packed in a sealed tank according to the proportion, leaving one-third of the remaining space in the tank, and placed on a ball mill to mix the powder for 8 hours at room temperature. Then add a p...

Embodiment 2

[0038] Aluminum powder, silicon powder, and chromium powder are all obtained by gas atomization powder making, and their powder spherical ratios are 94.5%, 94%, and 94% respectively; the corresponding average particle sizes are 18 μm, 19 μm, and 22 μm, respectively. The copper powder is prepared by a rotating electrode powder making method, the spherical rate of the powder is 96%, and the average particle size of the powder is 65 μm. The aviation kerosene that kerosene adopts in the present embodiment.

[0039] The composition of the aluminizing agent is 85% of aluminum powder, 6% of silicon powder, 6% of chromium powder, 3.0% of auxiliary agent, among which the content of ammonium chloride is 0.7%, the content of copper powder is 1.8%, and the content of kerosene is 0.5%. First, the powder is vacuum-packed in a sealed tank according to the proportion, leaving one-third of the remaining space in the tank, and placed on a ball mill to mix the powder for 9 hours at room temperat...

Embodiment 3

[0042] Aluminum powder, silicon powder, and chromium powder are all obtained by gas atomization powder making, and their powder spherical ratios are 93%, 95%, and 93.5% respectively; the corresponding average particle sizes are 20μm, 16μm, and 22μm, respectively. The copper powder is prepared by a rotating electrode powder making method, the spherical rate of the powder is 97%, and the average particle size of the powder is 55 μm. The aviation kerosene that kerosene adopts in the present embodiment.

[0043] The composition of the aluminizing agent is determined to be 88% of aluminum powder, 5% of silicon powder, 4% of chromium powder, 3.0% of auxiliary agent, 0.5% of ammonium chloride, 1.8% of copper powder and 0.7% of kerosene. First, the powder is vacuum-packed in a sealed tank according to the proportion, leaving one-third of the remaining space in the tank, and placed on a ball mill to mix the powder for 10 hours at room temperature. Then add a predetermined proportion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com