Printing and dyeing waste water treating system

A treatment system, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems that it is difficult to ensure that the effluent can meet the national quality requirements, and achieve high quality Purification treatment, optimization effect, and effect of preventing re-diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

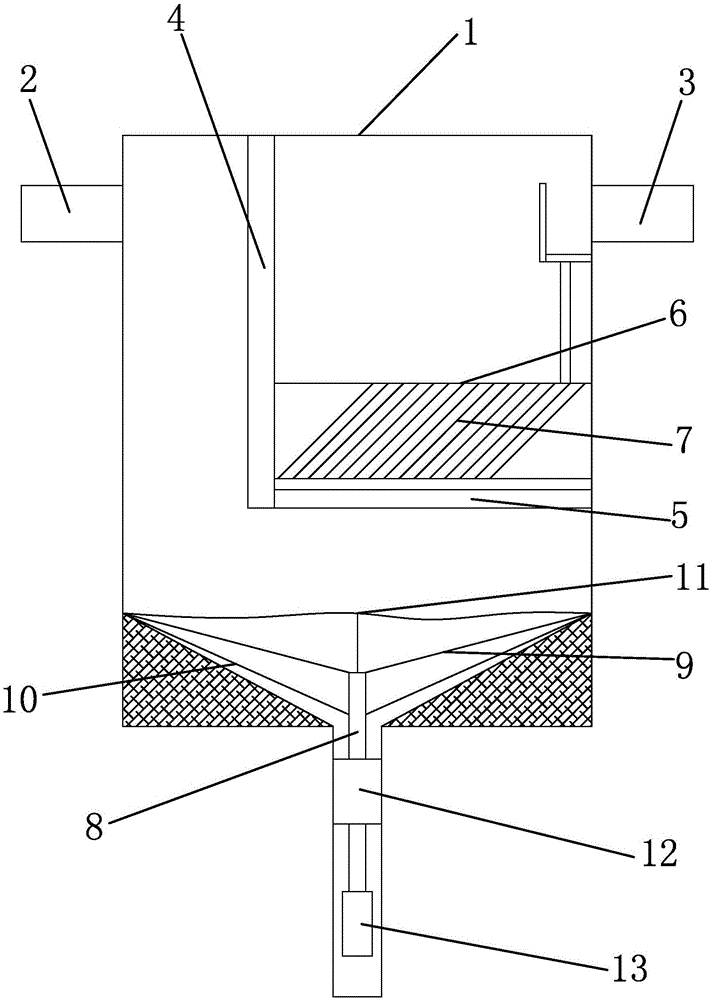

[0031] Printing and dyeing wastewater treatment systems, such as figure 1 As shown, the flocculation tank includes a sedimentation tank 1, an inlet pipe 2 is arranged on the top of one side of the sedimentation tank 1, an outlet pipe 3 is arranged on the top of the other side, a settler is arranged in the sedimentation tank 1, and an inlet pipe is vertically arranged in the sedimentation tank 1. The water partition 4, the lower side of the water inlet partition 4 is fixedly connected with the pool wall of the sedimentation tank 1 through the support beam 5, and the two vertical sides of the water inlet partition 4 are respectively fixedly connected with the pool wall of the sedimentation tank 1 , the water inlet pipe 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com