Dyeing wastewater treatment method

A technology for printing and dyeing wastewater and treatment methods, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve high operating costs, large investment in reverse osmosis membrane treatment, deep printing and dyeing wastewater Unsatisfactory treatment effect and other problems, to achieve high-quality purification treatment and optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

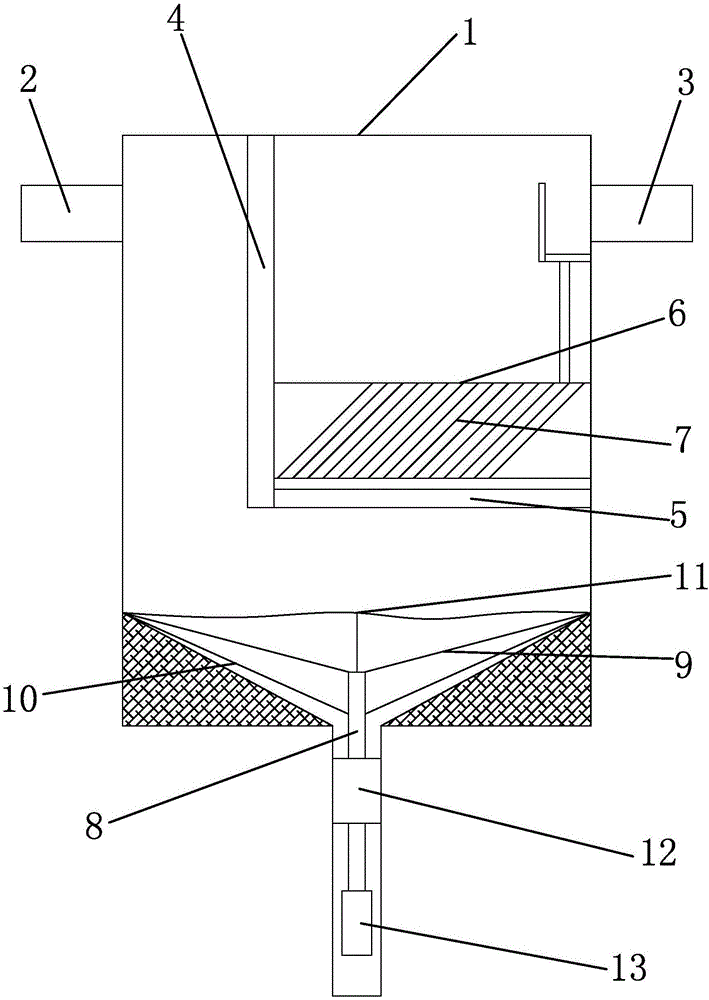

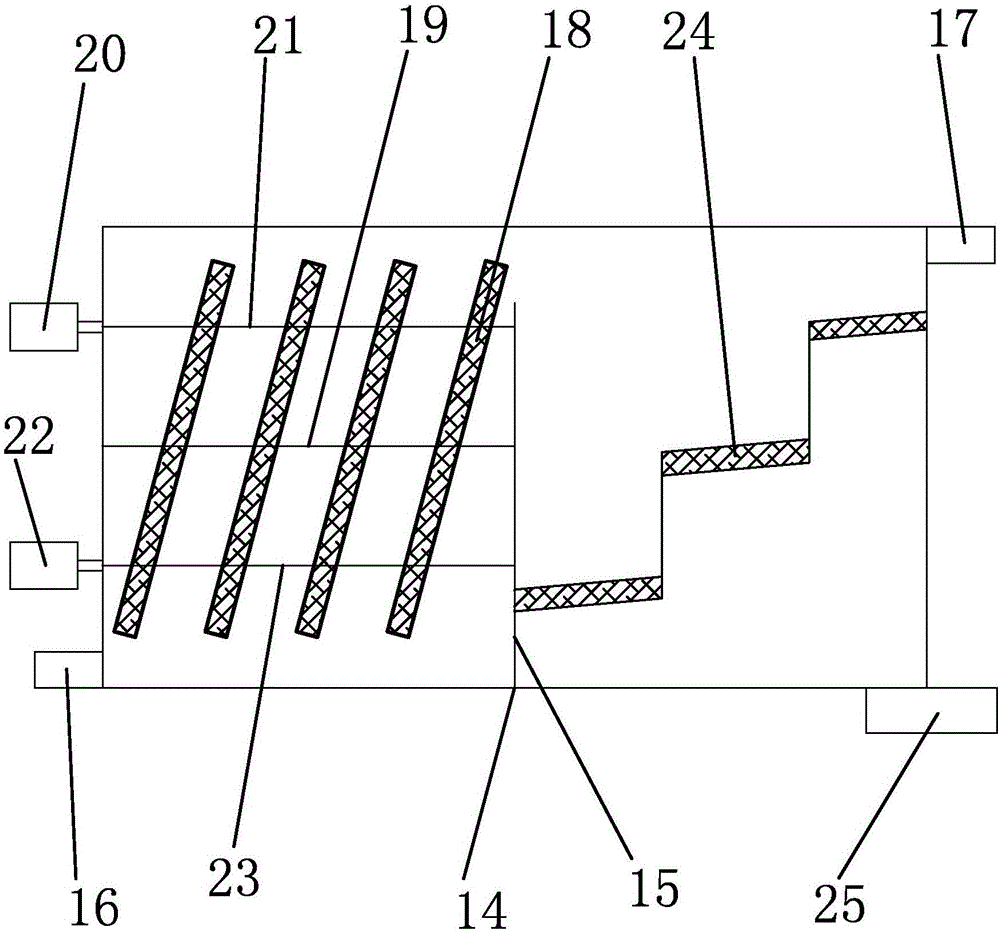

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

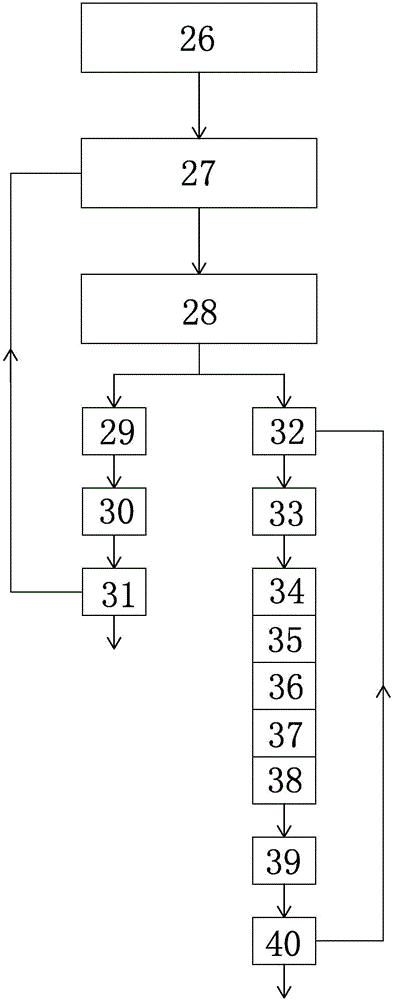

[0035] A method for treating printing and dyeing wastewater, the method comprising the following steps:

[0036] a. Flocculation; put the printing and dyeing wastewater into the flocculation tank for flocculation;

[0037] b. Anaerobic treatment; the water after flocculation is anaerobically treated through an anaerobic hydrolysis acidification device;

[0038] c. Microbial treatment, the water after anaerobic treatment enters the microbial oxidation tank and is treated by microorganisms;

[0039] d. Denitrification and denitrification treatment; the water after treatment in the microbial oxidation tank enters the denitrification and denitrification treatment device for treatment;

[0040] e. Advanced treatment: The wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com