Method for composite-filtering multiple filter media in aluminum-alloy-melt centrifuge field

A technology of aluminum alloy melt and centrifugal force field, applied in the field of filtration, can solve the problems of high cost and high consumption, and achieve the effect of convenient operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

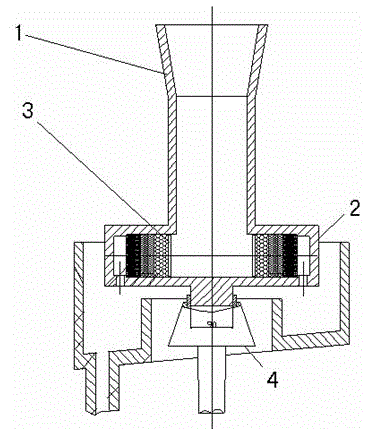

Embodiment 1

[0016] The present invention is realized in this way, and the method steps are: Prefabricated a special cast iron runner with a sprue and 4 outlet channels perpendicular to the sprue, and the sprue is brushed with zinc oxide-water glass coating. The axes of the 4 outlet channels are on a horizontal plane and form an angle of 90°; 4 pieces of porous ceramic filters are placed in each runner outlet channel, and the ceramic filters are stacked in the order of coarse porosity to fine porosity from the inside to the outside In the outlet channel, the innermost layer is a ceramic orifice plate with a hole size of Φ10mm, the second and third layers are foam ceramic filters, the hole size and thickness are 10ppi-20mm, 40ppi-20mm, and the fourth layer is ceramic granular Filter disc, the average size of ceramic particles is Φ2mm and the thickness is 30mm; The high-temperature-resistant ceramic runner is placed tightly in the centrifugal device, and its sprue axis coincides with the rot...

Embodiment 2

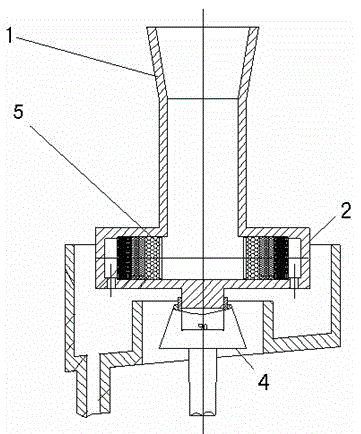

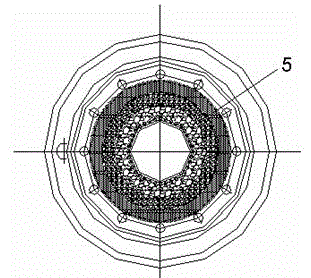

[0018] The present invention is realized in this way, and the method steps are: Prefabricated a special cast iron runner composed of a sprue and an annular outlet channel coaxial with the sprue, and the sprue is brushed with zinc oxide-water glass coating. The ring runner is built with 3 layers of cylindrical porous ceramic filters. The first layer is a columnar ceramic cylinder, the diameter of the ceramic cylinder is Φ8mm, and the column spacing is 7mm; the second and third layers are foam ceramic cylinders with the same hole size The thickness is 10ppi-20mm, 20ppi-20mm, the fourth layer is a granular ceramic filter, the average diameter of ceramic particles is 2mm. When the high temperature resistant metal runner is placed in the centrifugal device, its sprue axis coincides with the rotation axis of the centrifugal device; Preheat the runner to 1000℃ before pouring; Start the centrifugal device, the rotation speed of the centrifugal device is in the range of 500r / min, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com