Pretreatment method and system of syngas for synthetic ammonia

A raw material gas and pretreatment technology, which is applied in the field of coal chemical industry, can solve the problems of reduced reaction efficiency, large consumption of useless work, and reduced net value of ammonia in ammonia synthesis equipment, and achieve the goal of increasing product added value, reducing the basis of regeneration energy consumption, and prolonging the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

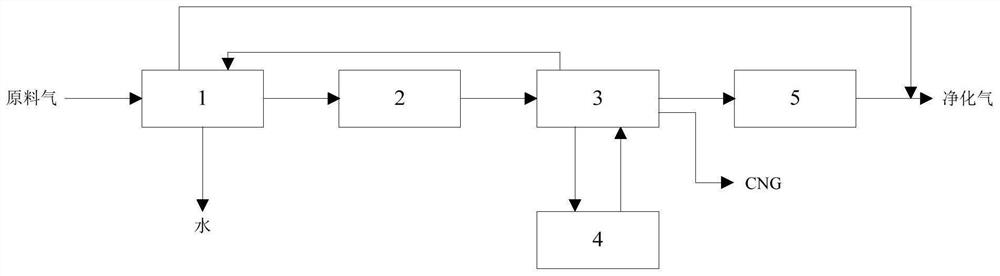

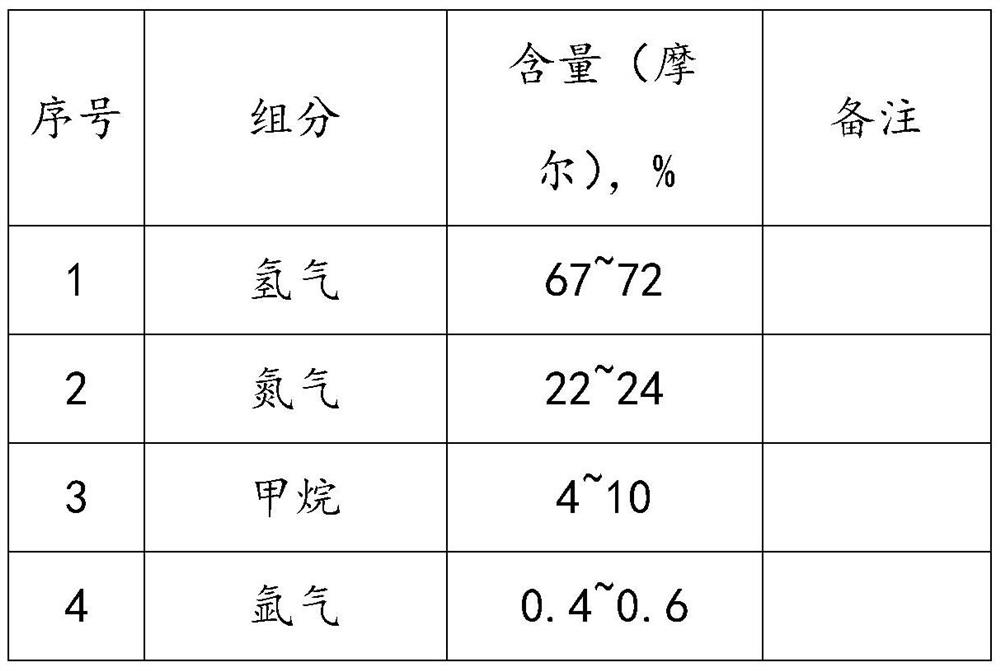

[0082] The raw material gas of an ammonia synthesis section contains 4% to 10% by mole of methane and 0.4% to 0.6% by mole of argon. According to the requirements of the subsequent ammonia synthesis reaction, the methane should be removed to less than 1.5% by mole, and the argon should be used as much as possible. It may be removed, and the main volume percentage of the feed gas in the ammonia synthesis section is as follows:

[0083]

[0084]

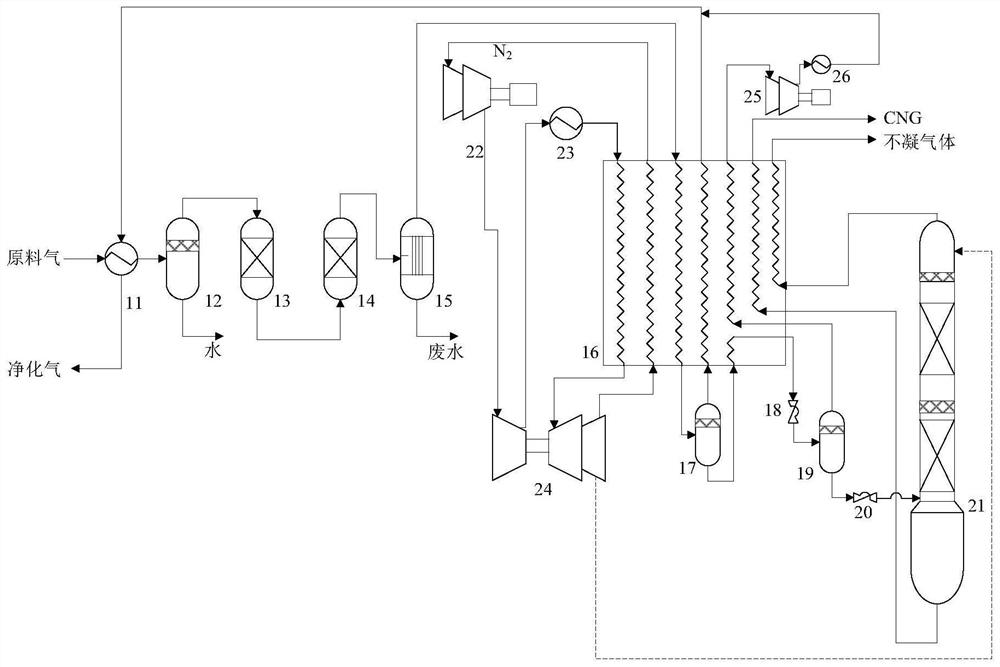

[0085] The raw material gas for ammonia synthesis at room temperature and high pressure from the upstream section enters the first cooler 11, water eliminator 12 and drying tower 13 of the dehydration device 1 in order to cool the raw gas to 10-20°C and remove the moisture in the raw gas to 1ppmv, and then in the demercuration tower 14, the trace amount of mercury in the raw material gas is removed by soaking sulfur-based activated carbon to 0.01μg / Nm 3 . The raw material gas entering the cryogenic separation unit 3 guarantees H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com