Starch grafted coal gangue coated nano zero-valent iron composite material and preparation method thereof

A technology of nano-zero-valent iron and starch grafting, which is applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as cumbersome steps, high cost, and environmental health threats, and achieve treatment Simple method, anti-oxidation, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

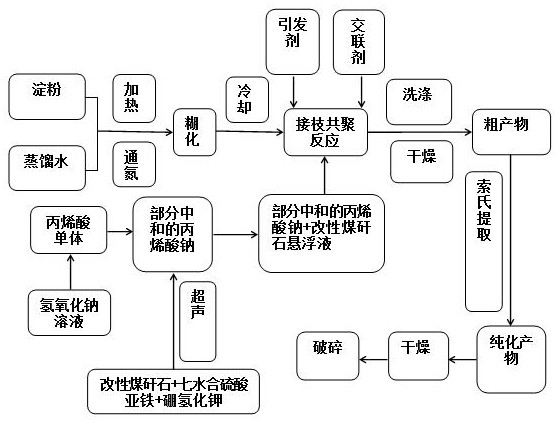

[0045] A preparation method of starch-grafted coal gangue-coated nano-zero-valent iron composite material, comprising the following steps:

[0046] S1. Prepare starch into 5-10 wt% starch aqueous solution, and gelatinize in a 90°C water bath for 30-60min to obtain starch gelatinization liquid, wherein the concentration of the starch aqueous solution is preferably 5-8 wt%;

[0047] S2. After mixing the dispersant and surfactant, the suspension obtained by ultrasonic dispersion is added to the starch gelatinized liquid prepared in step S1 whose temperature has dropped to 40°C and stirred, and an inert gas is introduced to keep the whole reaction process under control. in an inert atmosphere;

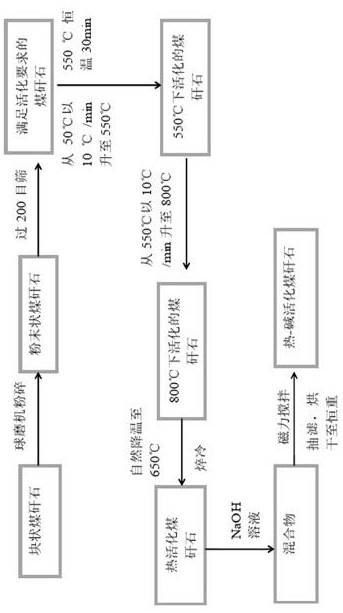

[0048] S3. Add the modified coal gangue to the mixed solution composed of ferrous sulfate heptahydrate and potassium borohydride under the protection of nitrogen, and vigorously stir to obtain the mixed solution a;

[0049] S4. Slowly add the sodium hydroxide solution into the beaker cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com