Wet fly ash gelled material and preparation method thereof

A technology for wet discharge of fly ash and cementitious materials, applied in the field of wet discharge of fly ash cementitious materials and its preparation, can solve the problem that wet discharge of fly ash has not been utilized as a resource and has not yet formed an industrialized wet discharge of fly coal Insufficient utilization of ash products and wet-discharged fly ash, etc., to achieve the effects of improving governance efficiency, low price, saving resources and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

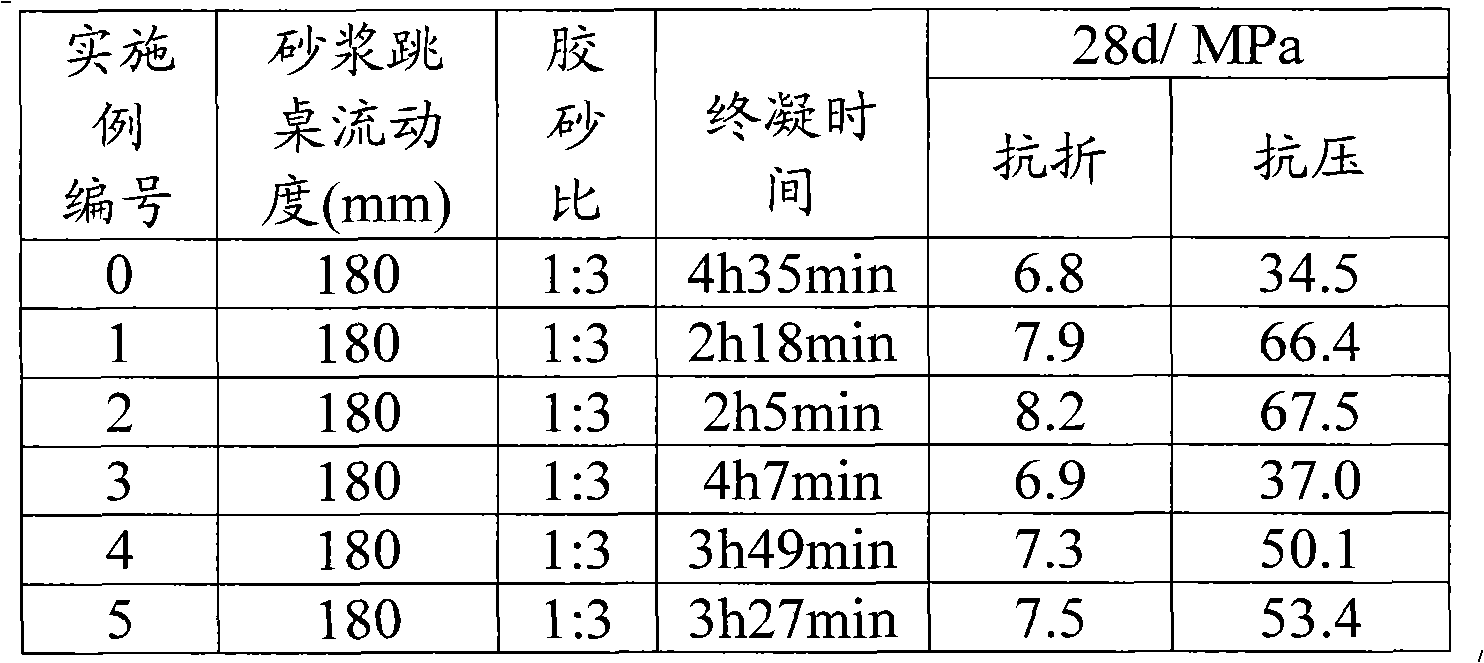

Examples

Embodiment 1

[0036] In the present embodiment, each raw material mass percentage is as follows:

[0037] 45% dry fly ash; 47% active mineral material; 8% chemical curing agent;

[0038] Described active mineral material is made of the raw material of following mass percentage:

[0039] 60% blast furnace slag; 10% cement clinker; 20% metakaolin; 10% gypsum;

[0040] Described chemical curing agent is made from the raw material of following mass percentage:

[0041] Aluminum sulfate 3%; potassium carbonate 5%; sodium silicate 14%; sodium carbonate 40%; sodium sulfate 5%; lignosulfonate water reducer 30%, naphthalenesulfonate water reducer 3%.

Embodiment 2

[0043] In the present embodiment, each raw material mass percentage is as follows:

[0044] 49.5% dry fly ash; 49% active mineral material; 1.5% chemical curing agent;

[0045] Described active mineral material is made of the raw material of following mass percentage:

[0046] 10% blast furnace slag; 50% cement clinker; 30% metakaolin; 10% gypsum;

[0047] Described chemical curing agent is made from the raw material of following mass percentage:

[0048] 10% aluminum sulfate; 20% potassium carbonate; 10% sodium silicate; 15% sodium carbonate; 15% sodium sulfate; 7% lignosulfonate water reducer; 23% naphthalene sulfonate water reducer.

Embodiment 3

[0050] In the present embodiment, each raw material mass percentage is as follows:

[0051] 66% dry fly ash; 28% active mineral materials; 6% chemical curing agent;

[0052] Described active mineral material is made of the raw material of following mass percentage:

[0053] 30% blast furnace slag; 30% cement clinker; 35% metakaolin; 5% gypsum.

[0054]Described chemical curing agent is made from the raw material of following mass percentage:

[0055] Aluminum sulfate 3%; potassium carbonate 30%; sodium silicate 5%; sodium carbonate 5%; sodium sulfate 30%; lignosulfonate water reducer 5%, naphthalenesulfonate water reducer 22%. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com