Anti-crease finishing liquid and anti-crease finishing method for real silk shell fabric

A technology of anti-wrinkle finishing and raw materials, which is applied in fiber treatment, textiles, papermaking, animal fibers, etc. It can solve the problems of poor anti-wrinkle performance and affect the hand feel of fabrics, achieve excellent appearance smoothness and comfort, improve anti-wrinkle performance, and good breathable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The fabric selected in this embodiment is a silk quilt cover fabric, and the cloth kind is: bleached cloth of 22D / 2*22D / 3110*48 threads / inch.

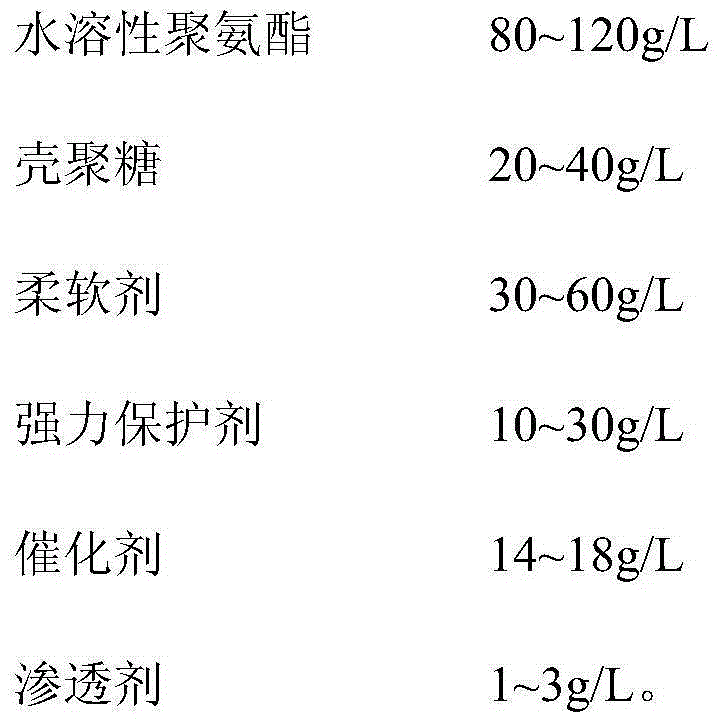

[0032] The formula of anti-wrinkle finishing liquid is:

[0033] The dosage of water-soluble polyurethane Nano-PU is 80g / L; the dosage of chitosan is 40g / L; the dosage of strong protective agent FINETEXPES is 30g / L; the dosage of softener TEXILONESP is 60g / L; the dosage of penetrating agent 230N is 2g / L; the dosage of catalyst MgCl 2 The dosage is 10g / L, and the catalyst sodium hypophosphite is 7g / L.

[0034] Adopt above-mentioned anti-wrinkle finishing agent in the present embodiment to carry out anti-wrinkle treatment to above-mentioned real silk fabric, concrete process is as follows:

[0035] The silk fabric is dipped and rolled twice in the anti-wrinkle finishing solution, and the excess rolling rate is 80%;

[0036] Pre-bake at 120°C for 2 minutes;

[0037] Then bake at 160°C for 4 minutes;

[0038] Cool the baked fabr...

Embodiment 2

[0042] The selected real silk fabric in this embodiment is: 22D / 2*22D / 4110*46 woven fabric.

[0043] The amount of water-soluble polyurethane Nano-PU in the anti-wrinkle finishing solution is 120g / L; the amount of chitosan is 20g / L; the amount of strong protective agent FINETEXPES is 10g / L; the amount of softener TEXILONESP is 30g / L; 2 The dosage is 17g / L.

[0044] The anti-wrinkle finishing solution disclosed above in this embodiment is used to finish the silk fabric, and the specific process is as follows:

[0045] The silk fabric is dipped and rolled twice in the anti-wrinkle finishing solution, and the excess rolling rate is 70%;

[0046] Pre-bake at 80°C for 4 minutes;

[0047] Then bake at 180°C for 3 minutes.

[0048] Cool the baked fabric, put it into an industrial washing machine containing 3g / L penetrant 230N aqueous solution, bath ratio 1:20, wash at 40°C for 10 minutes, dehydrate and dry at 50°C-60°C Dry it under the sun, and rehydrate the dried fabric for 30 m...

Embodiment 3

[0052] The fabric selected in this embodiment is a real silk quilt cover fabric, and the cloth kind is: 22D / 2*22D / 3110*48 bleached cloth.

[0053] The formula of anti-wrinkle finishing liquid is:

[0054]The dosage of water-soluble polyurethane PU-new is 100g / L; the dosage of chitosan is 30g / L; the dosage of strong protective agent FINETEXPES is 20g / L; the dosage of softener Hi-Soft40 is 40g / L; the dosage of penetrant 230N is 3g / L; the dosage of catalyst MgCl 2 The dosage is 16g / L.

[0055] Adopt above-mentioned anti-wrinkle finishing agent in the present embodiment to carry out anti-wrinkle treatment to above-mentioned real silk fabric, concrete process is as follows:

[0056] The silk fabric is dipped and rolled twice in the anti-wrinkle finishing solution, and the excess rolling rate is 75%;

[0057] Pre-bake at 100°C for 3 minutes;

[0058] Then bake at 150°C for 4 minutes;

[0059] Cool the baked fabric, put it into 230N aqueous solution containing 3g / L penetrating ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com