Electrode material for aptamer sensor, aptamer sensor and preparation method thereof

An aptamer sensor and electrode material technology, which is applied in the direction of material analysis, material analysis, and material electrochemical variables by electromagnetic means, which can solve the problems of low chemical and physical stability, high antibody production cost, and difficult chemical modification. , to achieve the effect of high sensitivity and selectivity, good selectivity, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

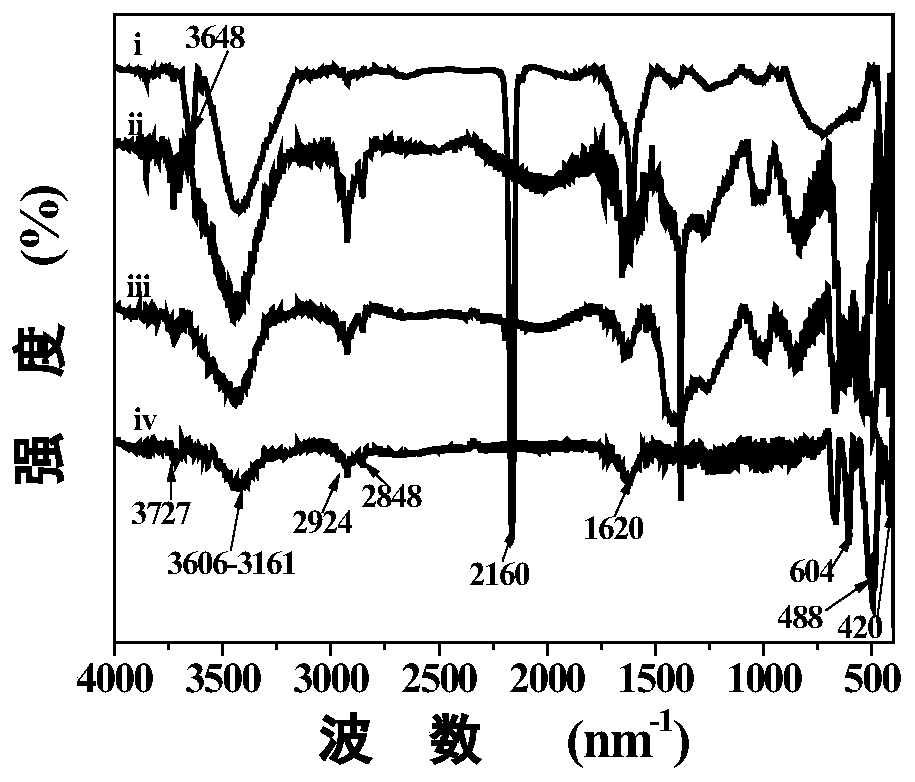

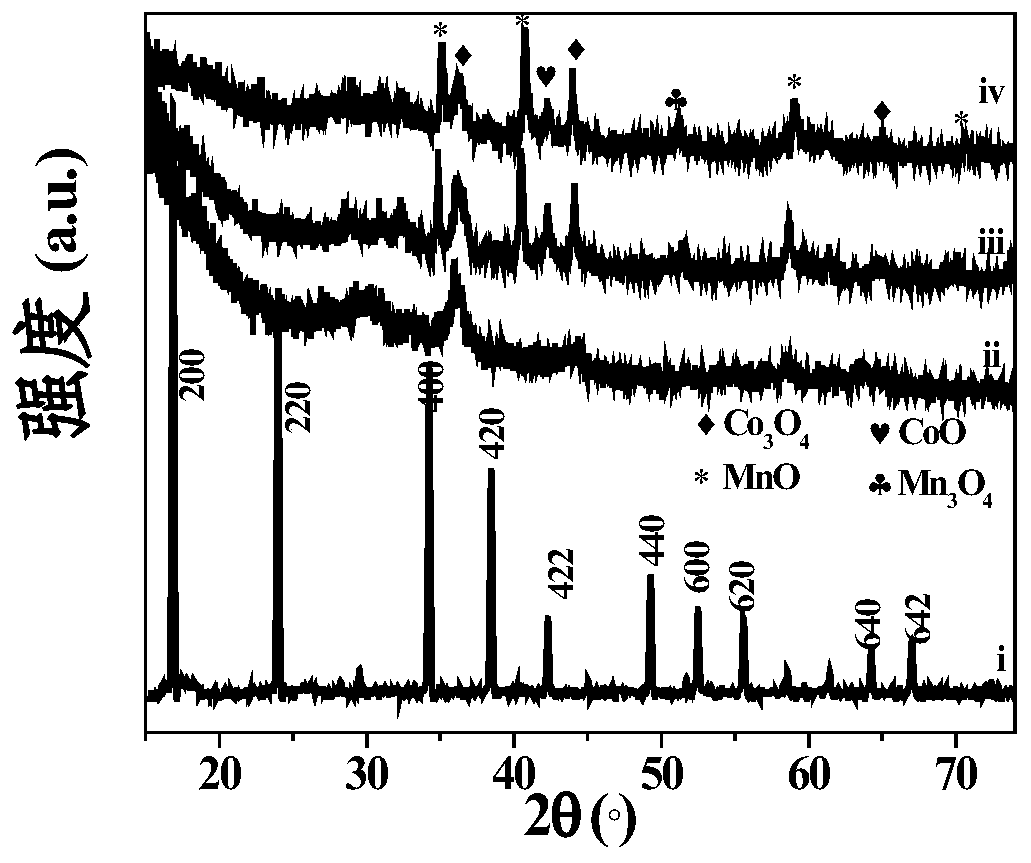

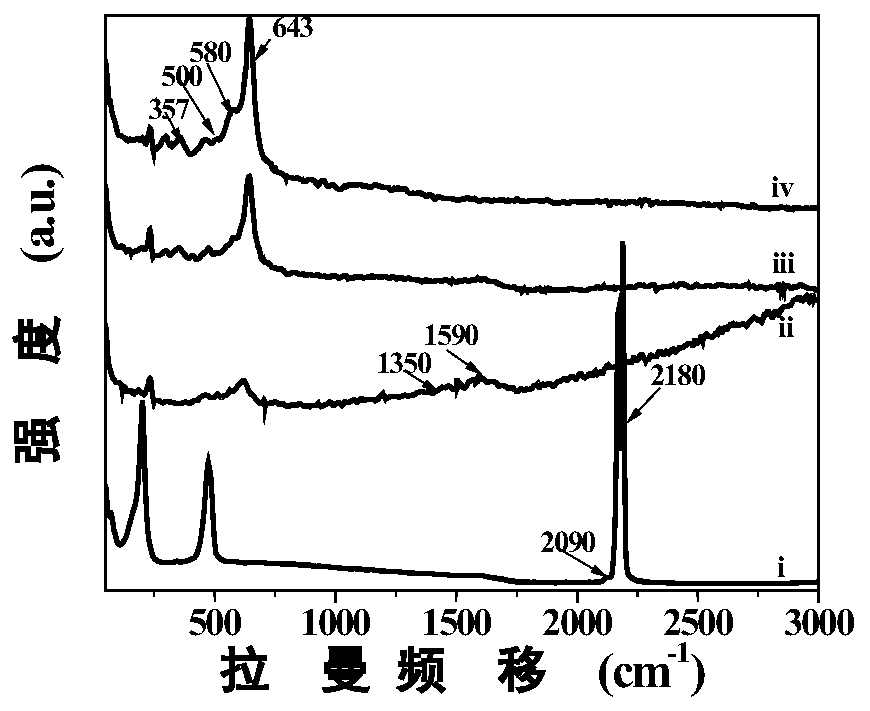

[0065] The electrode material for the aptasensor of this embodiment is prepared by the following steps:

[0066] (1) Manganese cobalt Prussian blue analogue

[0067] Disperse 150 mg of manganese acetate and 150 mg of sodium citrate into 20 mL of ultrapure water under stirring to obtain solution A.

[0068] 133 mg of K 3 [Co(CN) 6 ] was dissolved in 20mL of ultrapure water to obtain solution B.

[0069] Under stirring, solution A was poured into solution B and further stirred for 10 min, then stood at room temperature for 24 h to obtain a yellow precipitate. The precipitate was separated, washed with water and ethanol by centrifugation, and then dried at 70°C for 12 hours to collect the product, which was the manganese cobalt Prussian blue analogue, which was denoted as MnCo PBA.

[0070] (2) Electrode materials for aptamer sensors

[0071] Place the manganese-cobalt Prussian blue analog obtained in step (1) in a tube furnace at 5°C min -1 The heating rate was raised to 5...

Embodiment 2

[0073] The electrode material for the aptamer sensor of this embodiment differs from the preparation steps of the electrode material for the aptamer sensor of Example 1 only in that the calcination temperature in step (2) is different, and the electrode material for the aptasensor of the present embodiment The step (2) of is:

[0074] The manganese-cobalt Prussian blue analogue obtained in step (1) of Example 1 is placed in a tube furnace at 5° C. min -1 The heating rate was increased to 300°C, and the manganese-cobalt Prussian blue analogue was calcined for 2 hours, and then cooled to room temperature to obtain the electrode material for aptasensor, which was designated as Mn-Co-300.

Embodiment 3

[0076] The electrode material for the aptamer sensor of this embodiment differs from the preparation steps of the electrode material for the aptamer sensor of Example 1 only in that the calcination temperature in step (2) is different, and the electrode material for the aptasensor of the present embodiment The step (2) of is:

[0077] The manganese-cobalt Prussian blue analogue obtained in step (1) of Example 1 is placed in a tube furnace at 5° C. min -1 The heating rate was increased to 800°C, and the manganese-cobalt Prussian blue analog was calcined for 2 hours, and then cooled to room temperature to obtain the electrode material for aptasensor, which was designated as Mn-Co-800.

[0078] Two, the specific embodiment of the preparation method of the aptamer sensor of the present invention is as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com