Preparation method of nitrogen-doped carbon-coated dual-core shell lithium titanium phosphate or sodium titanium phosphate

A core-shell lithium titanium phosphate, nitrogen-doped carbon technology, applied in the direction of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., can solve the problems of low electronic conductivity, uneven carbon coating, etc., and achieve high yield , Improve the effect of carbon coating, the preparation method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

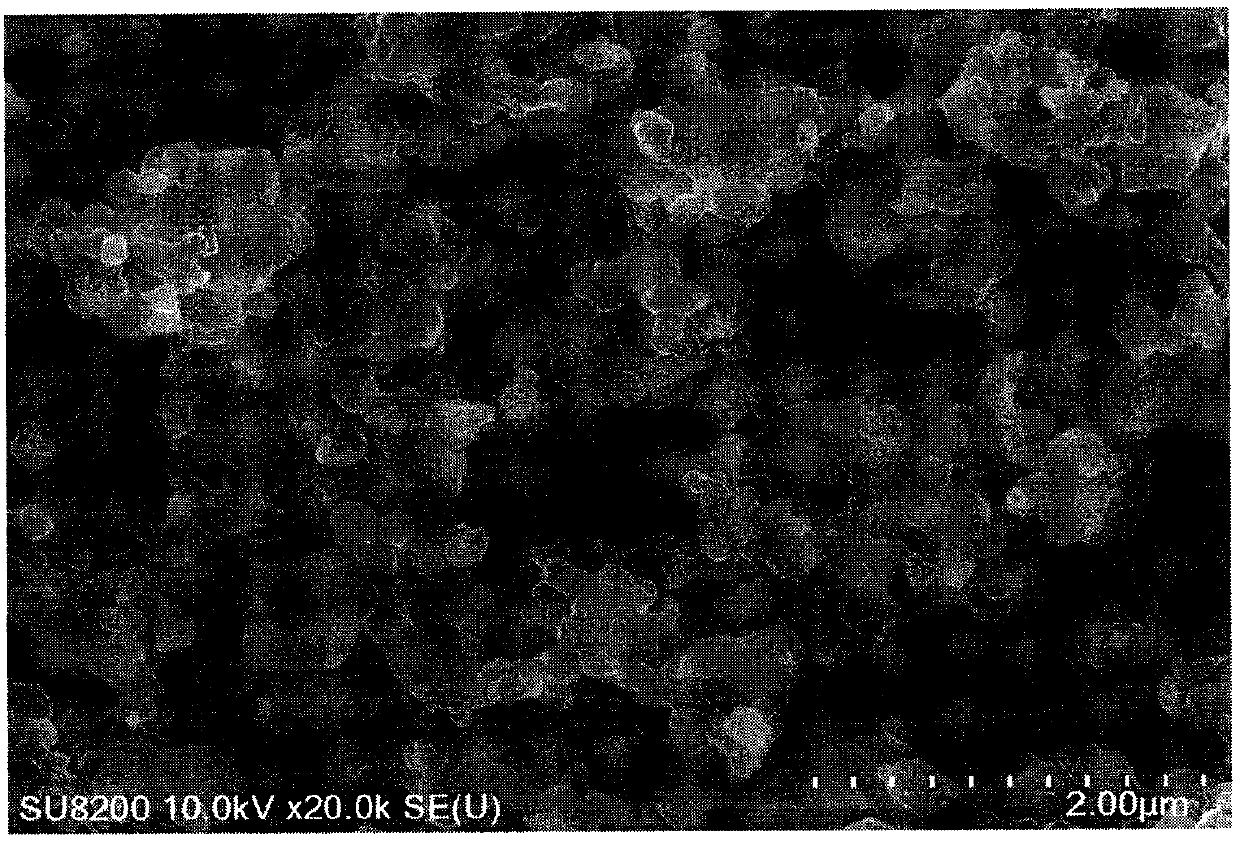

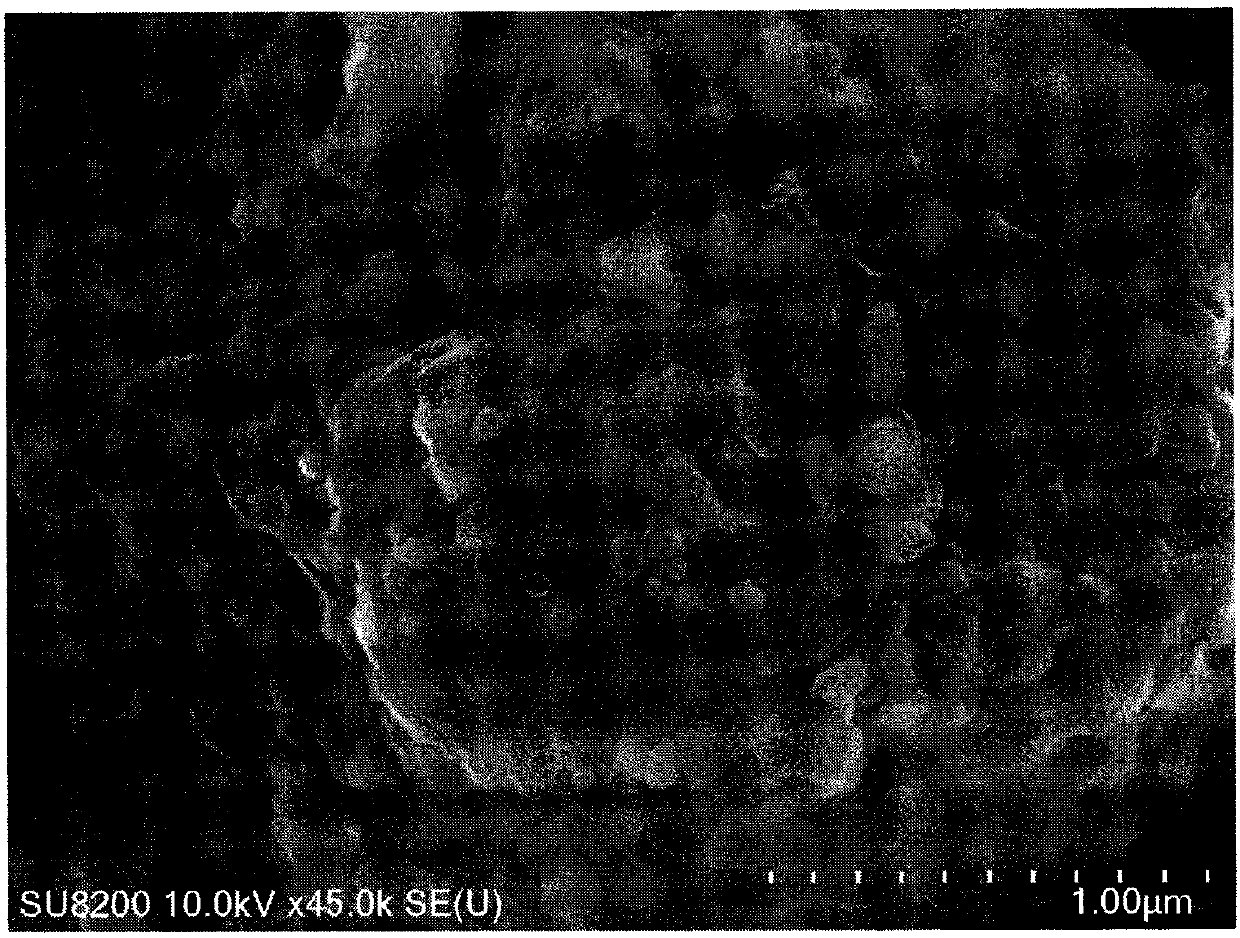

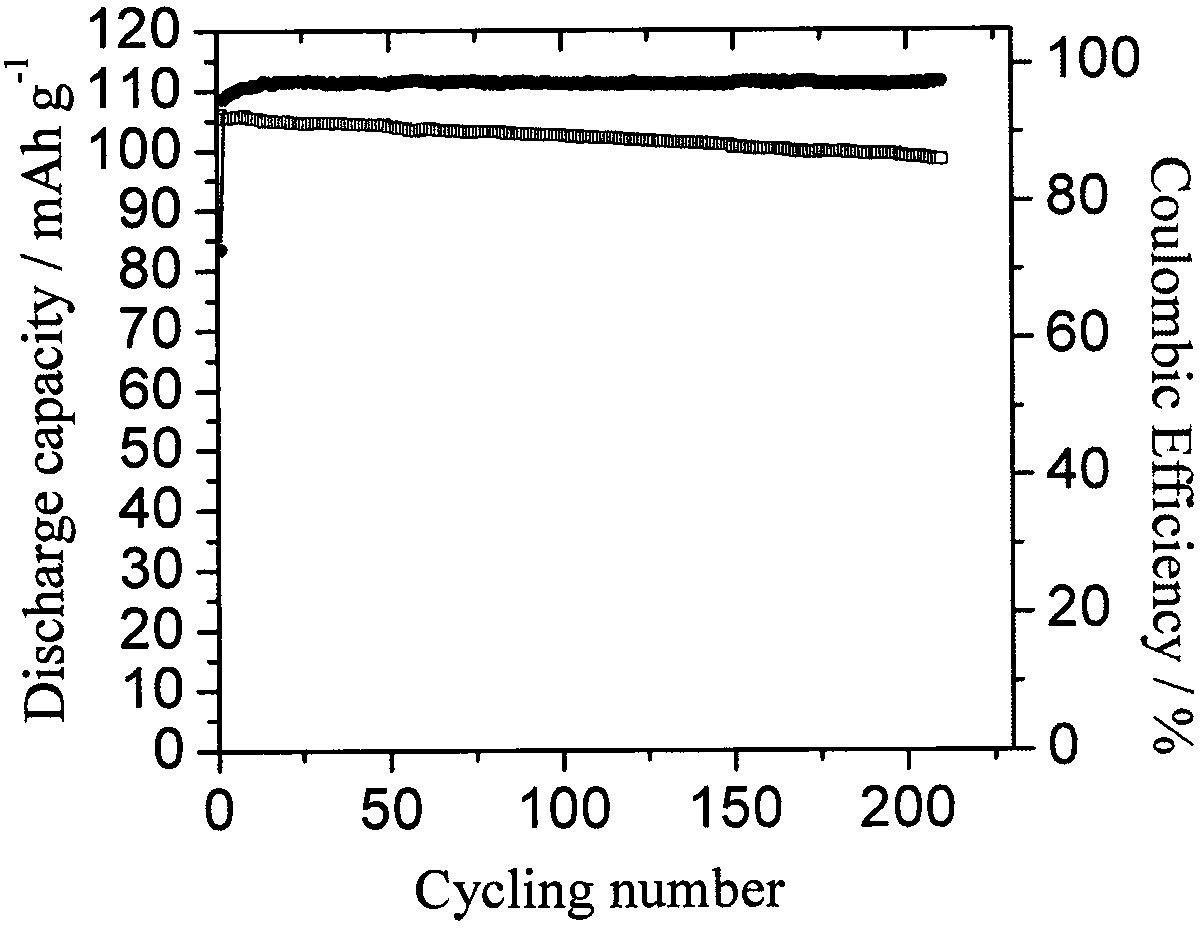

[0024] Mix lithium carbonate, titanium dioxide, and ammonium dihydrogen phosphate to obtain a precursor, make the molar ratio of Li:Ti:P in the precursor 1:2:3, add glucose according to 10% of the total mass of the precursor, and then 30% of the total mass is added with deionized water for ball milling. The mass ratio of balls and mixture is 6:1. After ball milling for 5 hours, the slurry is taken out once and dried by stirring and drying to remove the solvent. The heating temperature is 90 degrees, and then the obtained materials in N 2 Under the gas atmosphere, the temperature was raised to 900°C at a constant temperature of 12 hours at 5°C / min to achieve primary carbon coating and obtain a product with a primary carbon-coated core-shell structure. Then, the product is put into a ball mill jar, the mass ratio of the ball to material is 6:1, it is taken out after ball milling for 2 hours, put into a 1 g / L dopamine buffer solution (100 mL) with a pH value of 8.5, and stirred f...

Embodiment 2

[0027] Mix sodium carbonate, titanium dioxide, and diammonium hydrogen phosphate to obtain a precursor, make the molar ratio of Na:Ti:P in the precursor 1:2:3, add citric acid according to 8% of the total mass of the precursor, and then Add deionized water to 30% of the total mass of the body and carry out ball milling. The mass ratio of the balls to the mixture is 8:1. After ball milling for 6 hours, take out the slurry once, and dry it with stirring and drying to remove the solvent. The heating temperature is 80 degrees, and then the The resulting mixture is at N 2Under the gas atmosphere, the temperature was raised to 800°C at a constant temperature of 8 hours at 5°C / min to achieve primary carbon coating and obtain a product with a primary carbon-coated core-shell structure. Then, the mass ratio of the beads and the mixture is 6: 1, the product is put into a ball mill jar for ball milling for 2h, and the powdery solid taken out is put into a 1.5g / L dopamine buffer solution ...

Embodiment 3

[0030] Lithium carbonate, titanium dioxide, ammonium dihydrogen phosphate are mixed to obtain a precursor, and the molar ratio of Li in the precursor: Ti: P is 1: 2: 3, and Ketjen carbon is added according to 5% of the total mass of the precursor, and then According to 20% of the total mass of the precursor, add deionized water to carry out ball milling, the mass ratio of balls and mixture is 8:1, take out the slurry once after ball milling for 5 hours, remove the solvent by stirring and heating to dry, the heating temperature is 70 degrees, The material obtained by evaporative drying was then subjected to N 2 In an air atmosphere, the temperature was raised at 5°C / min to 700°C for 12 hours at a constant temperature to realize the recombination of primary carbon and lithium titanium phosphate, and obtain a composite of conductive carbon and lithium titanium phosphate. Then, the complex is put into a ball mill jar, the mass ratio of the ball beads to the mixture is 6:1, after b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com