Dustproof coating for inner wall of shell of dust collector

A technology for dust-proof coatings and vacuum cleaners, which is applied in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., and can solve problems that affect the use of vacuum cleaners, easy accumulation of dust, and poor dust-proof performance of vacuum cleaner shells. Achieve good protection, strong weather resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Provide below the preparation method of vacuum cleaner shell inner wall dust-proof coating of the present invention, it may further comprise the steps:

[0031] 1) Add the resin, water-based polyurethane emulsion, polytetrafluoroethylene emulsion and silicone oil into the mixer, mix and stir evenly, raise the temperature to 70-110°C, and continue stirring for 20-60min;

[0032] 2) Cool down to room temperature, add nano zinc oxide powder, nano magnesium oxide powder, filler and coupling agent in sequence, and stir for 1-3h;

[0033] 3) Add deionized water and dispersant in turn, adjust the rotation speed to 1200-1500rpm, and stir at high speed for 40-80min;

[0034] 4) Add dustproof agent A, dustproof agent B and titanium phosphate powder in sequence, and stir for 1-3 hours;

[0035] 5) Add a curing agent and continue to stir for 30-90 minutes to obtain a dust-proof coating for the inner wall of the vacuum cleaner shell.

[0036] When in use, the inner wall of the vac...

Embodiment 1

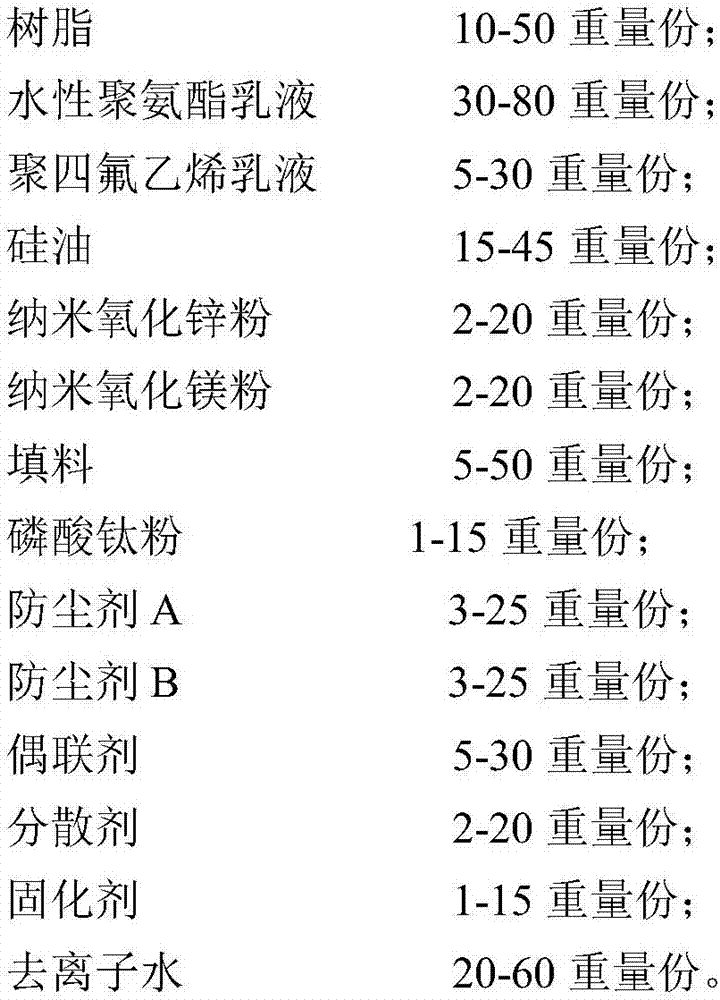

[0039] The dust-proof coating for the inner wall of the vacuum cleaner housing includes the following raw materials in parts by weight:

[0040]

[0041]

[0042] Wherein, the resin is a mixture of one or more of epoxy resin, fluorocarbon resin and ABS resin. The silicone oil is a mixture of one or more of polyether modified silicone oil, epoxy modified silicone oil and dimethyl silicone oil. The filler is one or a mixture of nano-silicon carbide and nano-boron carbide. The dustproof agent A is one of polyethylene glycol methacrylic acid copolymer, polyether ester amide, polyether ester acetamide, polyethylene oxide, palmitate quaternary ammonium salt, and ethoxylated lauramide or a mixture of several. The dustproof agent B is a mixture of one or more of sodium perfluorooctanoate, potassium perfluorooctane sulfonate, and fatty alcohol polyetheramide. The coupling agent is a silane coupling agent. The dispersant is one or more of stearamide, microcrystalline paraffin,...

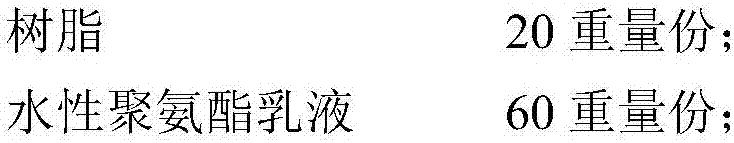

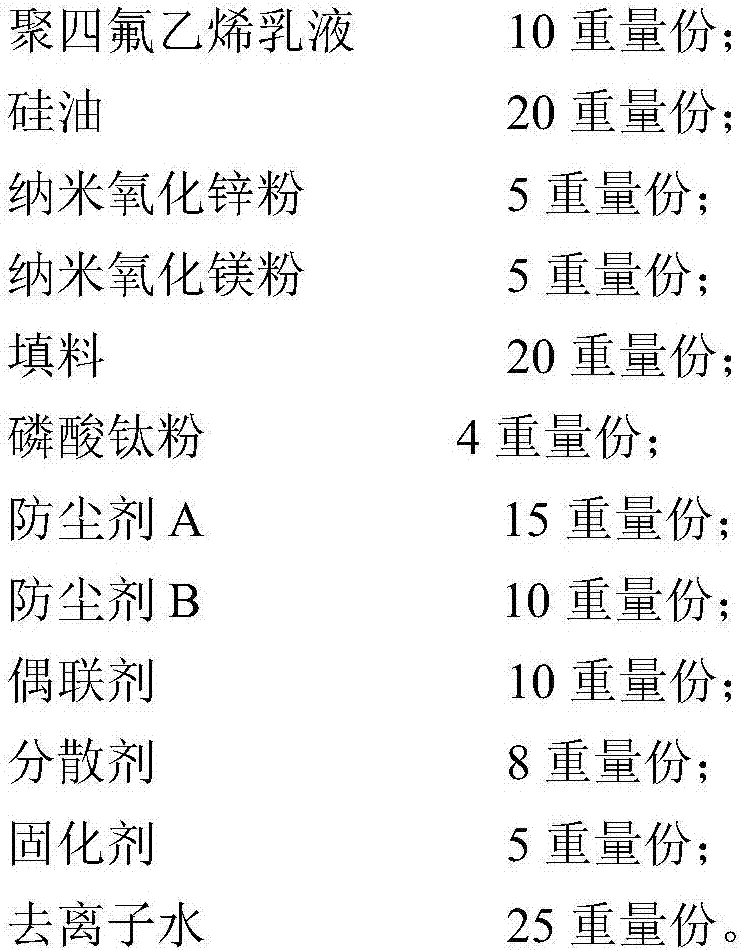

Embodiment 2

[0044] The dust-proof coating for the inner wall of the vacuum cleaner housing includes the following raw materials in parts by weight:

[0045]

[0046] Wherein, the resin is a mixture of one or more of epoxy resin, fluorocarbon resin and ABS resin. The silicone oil is a mixture of one or more of polyether modified silicone oil, epoxy modified silicone oil and dimethyl silicone oil. The filler is one or a mixture of nano-silicon carbide and nano-boron carbide. The dustproof agent A is one of polyethylene glycol methacrylic acid copolymer, polyether ester amide, polyether ester acetamide, polyethylene oxide, palmitate quaternary ammonium salt, and ethoxylated lauramide or a mixture of several. The dustproof agent B is a mixture of one or more of sodium perfluorooctanoate, potassium perfluorooctane sulfonate, and fatty alcohol polyetheramide. The coupling agent is a silane coupling agent. The dispersant is one or more of stearamide, microcrystalline paraffin, calcium ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com