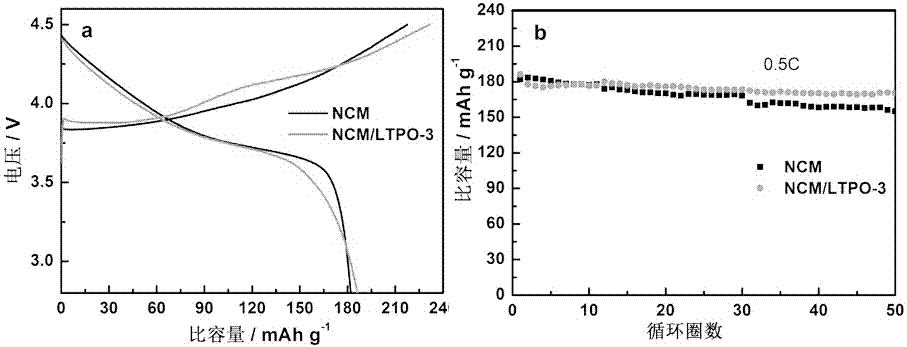

Lithium titanium phosphate-coated LiNi<1/3>Co<1/3>Mn<1/3>O<2> positive electrode material and preparation method therefor

A technology of lithium titanium phosphate and positive electrode materials, applied in the field of electrochemical power sources, to achieve the effect of suppressing side reactions and improving structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Precursor Ni of ternary cathode material obtained by co-precipitation method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , adding Li to the precursor 2 CO 3 , after ball milling with absolute ethanol as the medium for 6 hours, dried, and sintered at 450 °C for 5 hours, then sintered at 900 °C for 12 hours, cooled and sieved to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode material. Preparation of Lithium Titanium Phosphate LiTi 2 (PO 4 ) 3 NCM / LTPO cathode material with coating amount of 0.5 wt. %: Take 1g LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material was sonicated in a mixed solution of 20 mL of absolute ethanol and 20 mL of acetone for 20 minutes, stirred to form a black suspension, and then 0.0088 g of tetrabutyl titanate C was added 16 h 36 o 4 Ti, stirred for 60 minutes. Then 10 mL of deionized water was added dropwise and stirred for 60 min. Finally add 0.0045g of ammonium dihydrogen phosphate NH 4 h 2 PO 4 , 0.0005g lithium hydroxide LiOH·H 2...

Embodiment 2

[0026] Precursor Ni of ternary cathode material obtained by co-precipitation method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , adding Li to the precursor 2 CO 3 , after ball milling with absolute ethanol as the medium for 6 hours, dried, and sintered at 450 °C for 5 hours, then sintered at 900 °C for 12 hours, cooled and sieved to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode material. Preparation of Lithium Titanium Phosphate LiTi 2 (PO 4 ) 3 NCM / LTPO cathode material with coating amount of 1 wt. %: Take 1g LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material was sonicated in a mixed solution of 20 mL of absolute ethanol and 20 mL of acetone for 20 minutes, stirred to form a black suspension, and then 0.0176 g of tetrabutyl titanate C was added 16 h 36 o 4 Ti, stirred for 60 minutes. Then 10 mL of deionized water was added dropwise and stirred for 60 min. Finally add 0.0089g of ammonium dihydrogen phosphate NH 4 h 2 PO 4 , 0.0011g lithium hydroxide LiOH·H 2 O...

Embodiment 3

[0028] Precursor Ni of ternary cathode material obtained by co-precipitation method 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 , adding Li to the precursor 2 CO 3 , after ball milling with absolute ethanol as the medium for 6 hours, dried, and sintered at 450 °C for 5 hours, then sintered at 900 °C for 12 hours, cooled and sieved to obtain LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Ternary cathode material. Preparation of Lithium Titanium Phosphate LiTi 2 (PO 4 ) 3 NCM / LTPO cathode material with coating amount of 2 wt. %: take 1g LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material was sonicated in a mixed solution of 20 mL of absolute ethanol and 20 mL of acetone for 20 minutes, stirred to form a black suspension, and then 0.0352 g of tetrabutyl titanate C was added 16 h 36 o 4 Ti, stirred for 60 minutes. Then 10 mL of deionized water was added dropwise and stirred for 60 min. Finally add 0.0178g of ammonium dihydrogen phosphate NH 4 h 2 PO 4 , 0.0022g lithium hydroxide LiOH·H 2 O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com