Preparation method of carbon-coated mesoporous lithium titanium phosphate

A technology of carbon-coated mesoporous lithium titanium phosphate and phytic acid, which is applied to electrical components, battery electrodes, circuits, etc., can solve problems such as carbon-coated mesoporous lithium titanium phosphate, and achieve improved electrochemical performance and large Effect of specific surface area and short synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

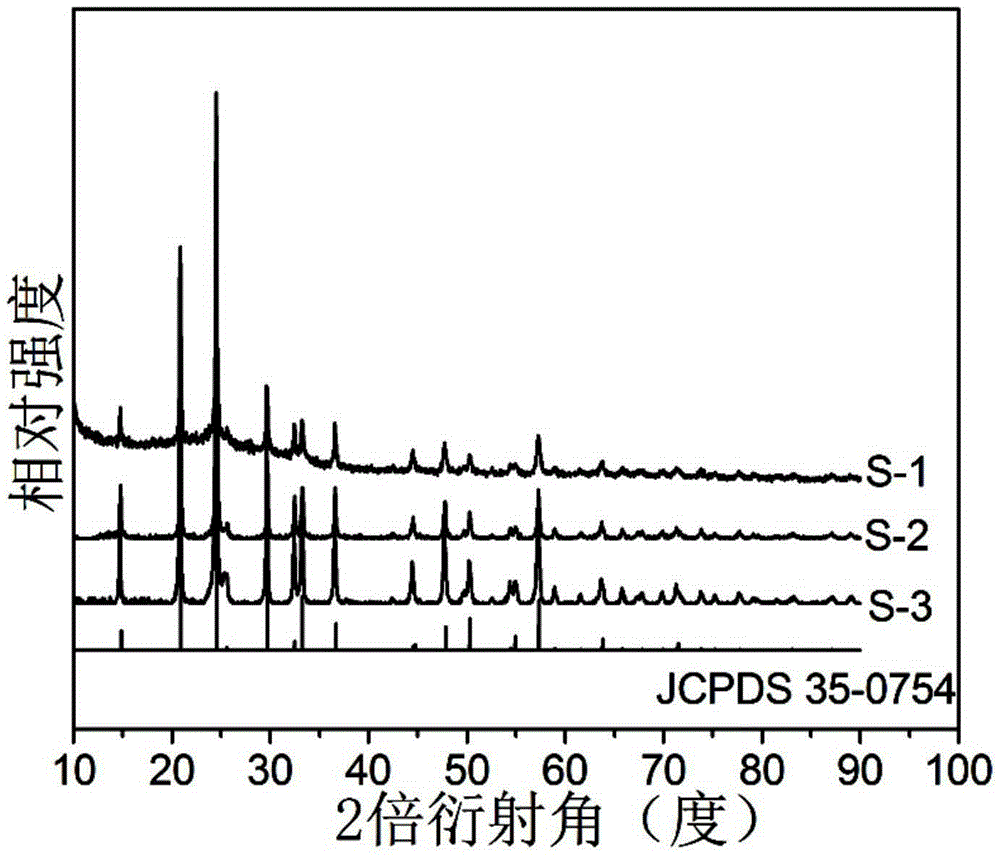

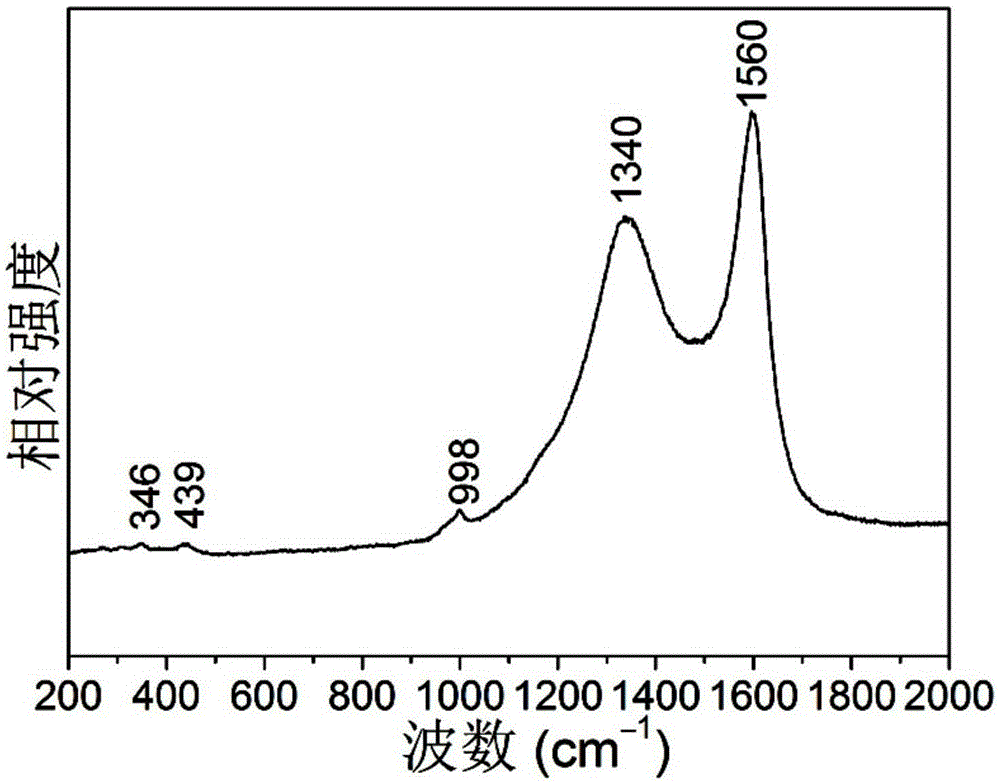

Embodiment 1

[0041] A method for preparing carbon-coated mesoporous lithium titanium phosphate, the steps are as follows:

[0042] Add 2.1 mL of tetrabutyl titanate to 50 mL of the mixed solution of n-butanol / absolute ethanol with a volume ratio of 1:1, stir to dissolve, and obtain mixed solution A;

[0043] Add 1.48mL of 50wt% phytic acid and 0.15g of lithium hydroxide to 10mL of distilled water, stir to dissolve, and obtain mixed solution B;

[0044] Under the condition of stirring at 100 rpm, the mixed liquid B was added dropwise to the mixed liquid A, and the stirring was continued for 1 hour to obtain the mixed liquid C;

[0045] The mixed solution C is suction filtered, and the obtained solid is placed in a 40°C blast drying oven and dried for 10 hours to obtain solid powder D;

[0046] Transfer the solid powder D to a ceramic crucible, place the crucible in a tube furnace, and heat up from room temperature to 750℃ in a nitrogen atmosphere, keep it for 2h, and the heating rate is 5℃min -1 , Na...

Embodiment 2

[0048] A method for preparing carbon-coated mesoporous lithium titanium phosphate, the steps are as follows:

[0049] Add 2 mL of tetraisopropyl titanate to 60 mL of a 4:1 volume ratio of isobutanol / absolute ethanol mixed solution, stir to dissolve, and obtain a mixture A;

[0050] Add 1.48mL of 50wt% phytic acid and 0.22g of lithium acetate to 10mL of distilled water, stir to dissolve, and obtain mixed solution B;

[0051] Under the condition of stirring at 400 rpm, drop the mixed solution B into the mixed solution A, and continue to stir for 2 hours to obtain the mixed solution C;

[0052] The mixed solution C is suction filtered, and the obtained solid is placed in a blast drying oven at 80°C and dried for 6 hours to obtain solid powder D;

[0053] Transfer the solid powder D to a ceramic crucible, place the crucible in a tube furnace, and heat up from room temperature to 750°C in an argon atmosphere, hold for 3 hours, and increase the temperature at a rate of 5°C min -1 , Natural co...

Embodiment 3

[0055] A method for preparing carbon-coated mesoporous lithium titanium phosphate, the steps are as follows:

[0056] Add 2 mL of tetraisopropyl titanate to 60 mL of a mixture of isobutanol / absolute ethanol with a volume ratio of 3:1, stir to dissolve, and obtain a mixture A;

[0057] Add 1.48mL of 50wt% phytic acid and 0.78g of lithium sulfate monohydrate to 10mL of distilled water, stir to dissolve them, and obtain mixed solution B;

[0058] Under the condition of stirring at 300 rpm, drop the mixed liquid B into the mixed liquid A and continue to stir for 2 hours to obtain the mixed liquid C;

[0059] The mixed solution C is suction filtered, and the obtained solid is placed in a 60°C blast drying oven and dried for 6 hours to obtain solid powder D;

[0060] Transfer the solid powder D to a ceramic crucible, place the crucible in a tube furnace, and heat up from room temperature to 750°C in an argon atmosphere, keep it for 4 hours, and heat up at a rate of 5°C min -1 , Natural coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com