Nanometer lithium aluminium titanium phosphate solid electrolyte material and preparation method therefor

A lithium titanium aluminum phosphate and solid electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the complex preparation process, long time-consuming and low yield of nano-LATP solid electrolyte materials and other problems, to achieve the effect of high yield, short time-consuming, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the preparation method of above-mentioned nanometer LATP solid electrolyte material, the lithium source described in step 1) is lithium nitrate or lithium isopropoxide etc.; The mol ratio of lithium source and aluminum trichloride, titanium tetrachloride and phosphoric acid is (1+x ):x:(2‐x):3, x=0.3~0.5.

[0044] In the preparation method of the above-mentioned nano-LATP solid electrolyte material, the heating temperature in step 1) is 30°C to 70°C. The heating method can be a common method such as a water bath or a constant temperature blast oven.

[0045] In the preparation method of the above-mentioned nano-LATP solid electrolyte material, the drying temperature in step 1) is 100°C-130°C, and the drying time is 4h-6h.

[0046] In the preparation method of the above-mentioned nano-LATP solid electrolyte material, the heat treatment in step 2) refers to keeping the temperature at 300° C. for 2 hours to 4 hours.

[0047] In the preparation method of the above-ment...

Embodiment 1

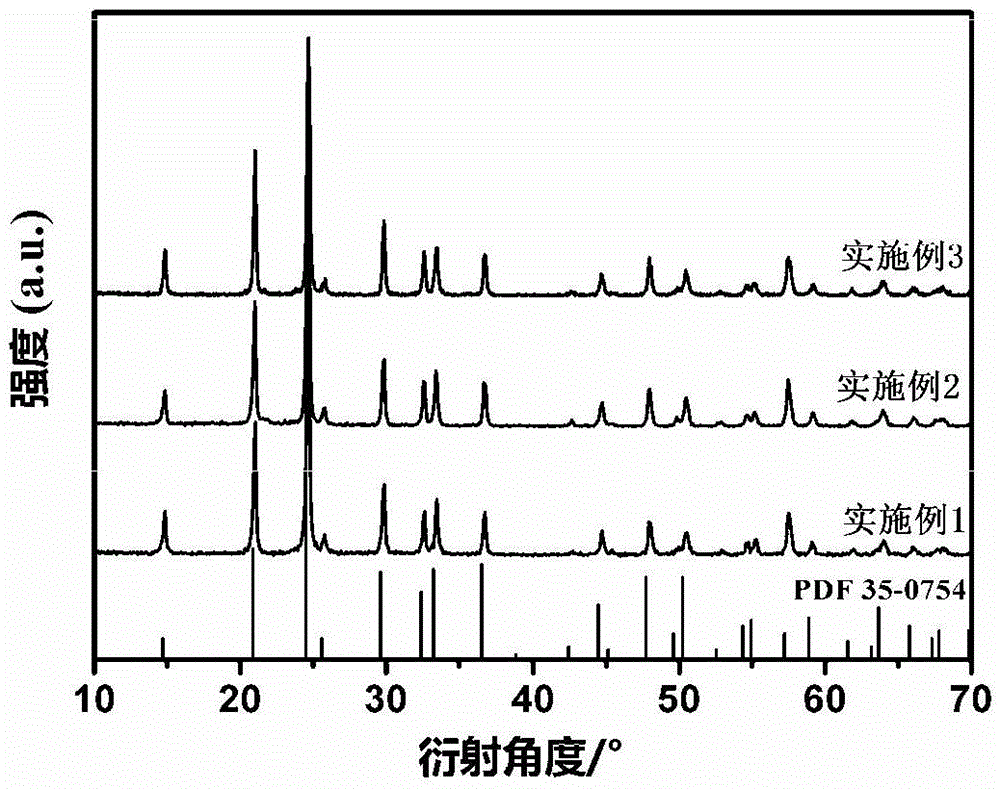

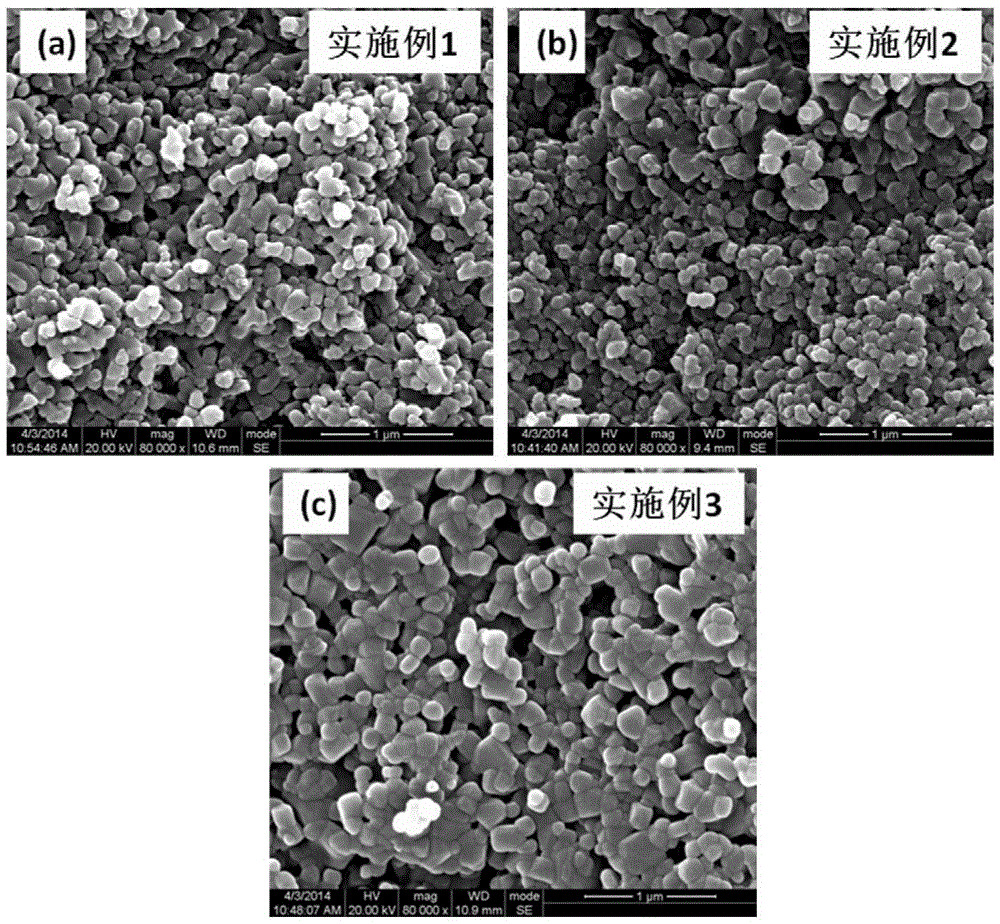

[0051] Embodiment 1 uses the method of the present invention to prepare LATP solid electrolyte material

[0052] According to the stoichiometric ratio in LATP (x=0.4), take 15.17g of titanium tetrachloride and 2.67g of aluminum trichloride and dissolve in absolute ethanol, continue stirring for 30min, then add 4.8g of lithium nitrate or 4.62g of isopropanol Lithium and 14.7g phosphoric acid, continue stirring for 2h. The above solution was heated at 30°C until a viscous gel was formed. The obtained gel was dried in a blast oven at 100°C for 6 h until it was completely dry. After the dried solid is fully ground in a mortar, put it in a muffle furnace and slowly raise the temperature to 300°C at room temperature and keep it warm for 4 hours, then heat it up to 800°C for 2 hours, and the average particle size is about 70 nanometers after the reaction is completed. LATP solid electrolyte material.

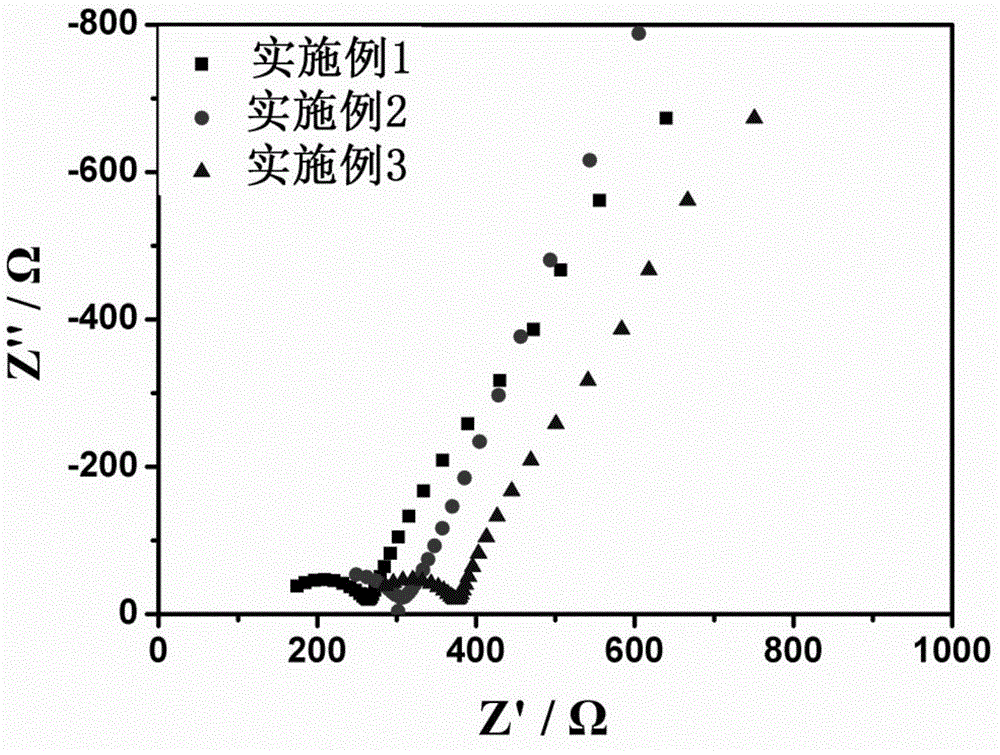

[0053] Put the above-mentioned LATP solid electrolyte material after ball milli...

Embodiment 2

[0054] Example 2 Preparation of LATP solid electrolyte material using the method of the present invention

[0055] According to the stoichiometric ratio in LATP (x=0.4), take 15.17g of titanium tetrachloride and 2.67g of aluminum trichloride and dissolve in absolute ethanol, continue stirring for 30min, then add 4.8g of lithium nitrate or 4.62g of isopropanol Lithium and 14.7g phosphoric acid, continue stirring for 2h. The above solution was heated at 50°C until a viscous gel was formed. The obtained gel was dried in a blast oven at 100°C for 6 h until it was completely dried. After the dried solid is fully ground in a mortar, put it in a muffle furnace and slowly raise the temperature to 300°C at room temperature and keep it warm for 4 hours, then raise the temperature to 800°C and calcinate for 2 hours. After the reaction is completed, the average particle size is about 80 nanometers. LATP solid electrolyte material.

[0056] Put the above-mentioned LATP solid electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com