Batch preparation method for low-cost carbon-clad titanium phosphate compound

A carbon-coated phosphoric acid and titanium compound technology, which is applied in the field of titanium phosphate compound ceramic powder and high-temperature solid-phase synthesis reaction method to prepare carbon-coated titanium phosphate compound powder, can solve the problem of difficult large-scale production and complicated production process , many side reactions, etc., to achieve good application prospects, simple synthesis process, and short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

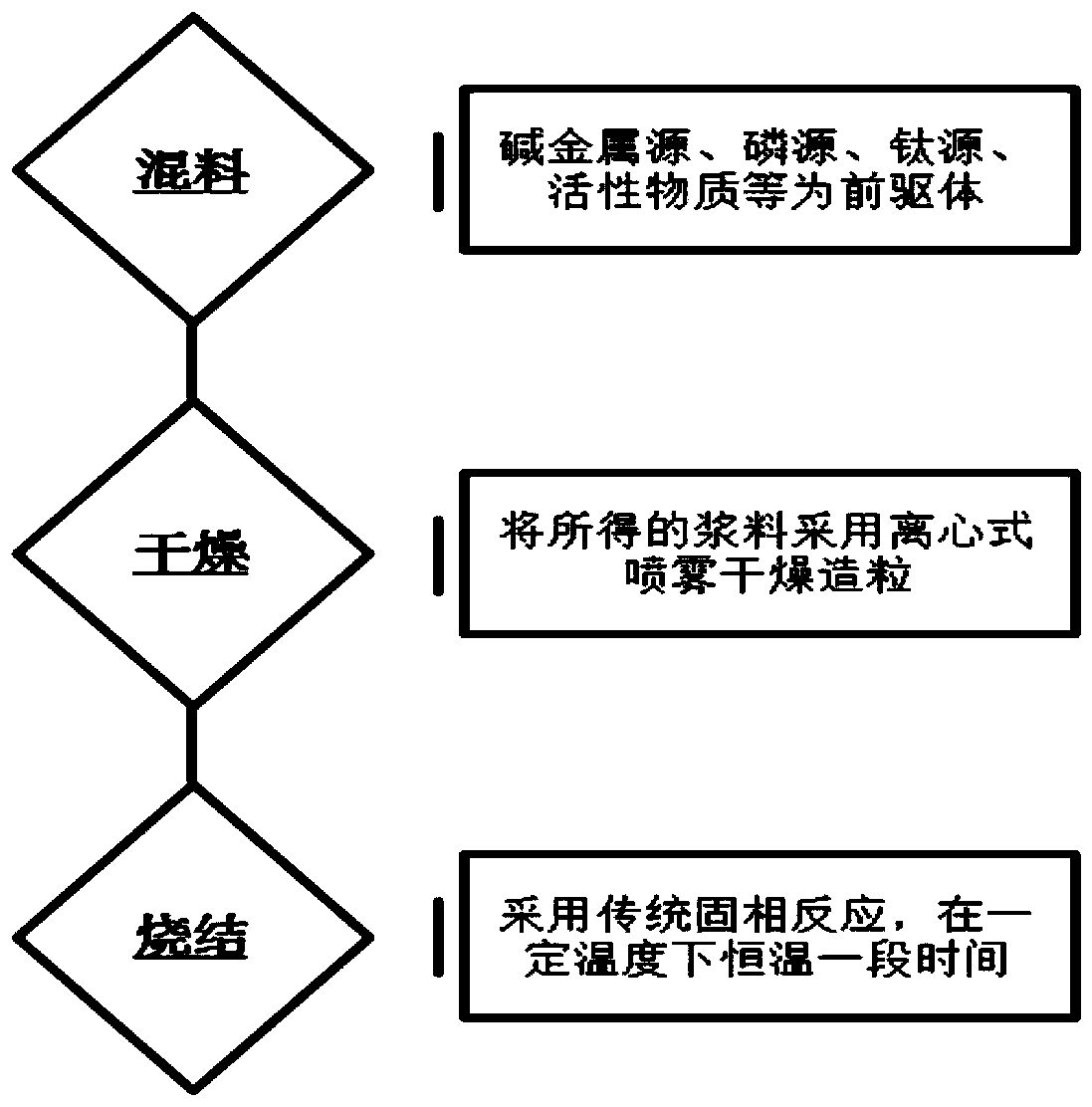

Method used

Image

Examples

Embodiment 1

[0051] Sodium carbonate, ammonium dihydrogen ammonium phosphate, and titanium dioxide powder are used as raw materials, and the content of sodium, titanium, and phosphorus is added to the mixture of ethanol and water (1:10) in a molar ratio of 1:2:3. The raw material powder and ethanol The mass ratio of the mixed liquid with water is 30:70. Polyacrylic acid was selected as the dispersant, and the amount of dispersant added was 1wt.% of the powder, and a uniform slurry was obtained by ball milling at a high speed of 200 rpm for 2 hours. Continue to add the active substance graphite (20wt.%) pretreated by ethanol, further ball mill at 200 r / min for 2 h, and then pour out the slurry. The obtained slurry was spray-dried, the inlet air temperature was set at 220°C, the outlet air temperature was 110°C, and the centrifugal speed was 12000 rpm, and the obtained spherical powder precursor was collected. Put the precursor into an inert gas-filled sintering furnace, and sinter at 750°C...

Embodiment 2

[0053] Lithium carbonate, ammonium dihydrogen phosphate, and titanium dioxide powder are used as raw materials, and the contents of lithium, titanium, and phosphorus are added to the mixed solution of ethanol and water (1:10) in a molar ratio of 1:2:3. The raw material powder and ethanol The mass ratio of the mixed liquid with water is 30:70. Sodium hexametaphosphate was selected as a dispersant, and the amount of dispersant added was 1wt.% of the powder, and a uniform slurry was obtained by ball milling at a high speed of 200 rpm for 2 hours. Continue to add the active substance graphite (20wt.%) pretreated by ethanol, further ball mill at 200 r / min for 2 h, and then pour out the slurry. The obtained slurry was spray-dried, the inlet air temperature was set at 220°C, the outlet air temperature was 110°C, and the centrifugal speed was 15,000 rpm, and the obtained spherical powder precursor was collected. Put the precursor into an inert gas-filled sintering furnace, and sinter...

Embodiment 3

[0055] Sodium carbonate, ammonium dihydrogen phosphate, and titanium dioxide powder are used as raw materials, and the content of potassium, titanium, and phosphorus is added to the mixed solution of ethanol and water (1:10) in a molar ratio of 1:2:3. The raw material powder and ethanol The mass ratio of the mixed solution with water is 20:80. Castor oil was selected as the dispersant, and the amount of dispersant added was 1wt.% of the powder, and a uniform slurry was obtained by ball milling at a high speed of 200 rpm for 2 hours. Continue to add the active substance graphite (20wt.%) pretreated by ethanol, further ball mill at 200 r / min for 2 h, and then pour out the slurry. The obtained slurry was spray-dried, the inlet air temperature was set at 220°C, the outlet air temperature was 110°C, and the centrifugal speed was 17,000 rpm, and the obtained spherical powder precursor was collected. Put the precursor into an inert gas-filled sintering furnace, and sinter at 750°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com