A method for forming pole pieces of aqueous ion batteries based on polytetrafluoroethylene binder

A technology of polytetrafluoroethylene and ion batteries, which is applied in the direction of electrode forming, battery electrodes, batteries, etc., can solve the problem that it is difficult to accurately control the quality and thickness of pole pieces, it is difficult to adopt dry pressing molding process for thick pole pieces, and it is difficult to obtain battery consistency Guarantee and other issues, to achieve significant practical value, good application prospects, and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

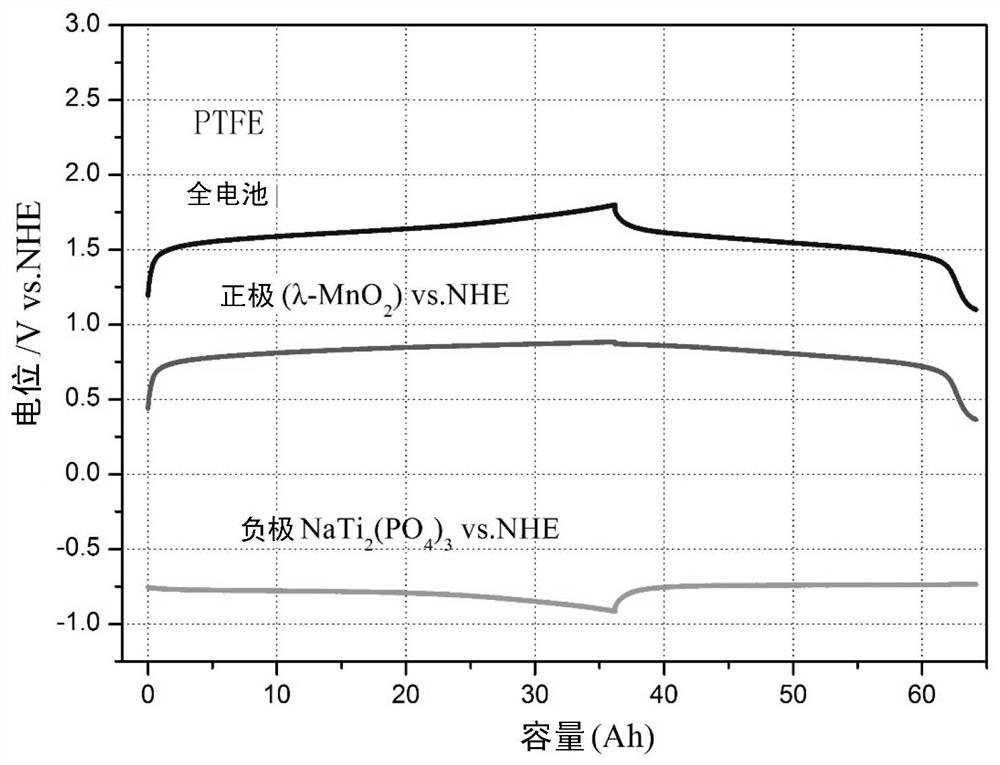

Embodiment 1

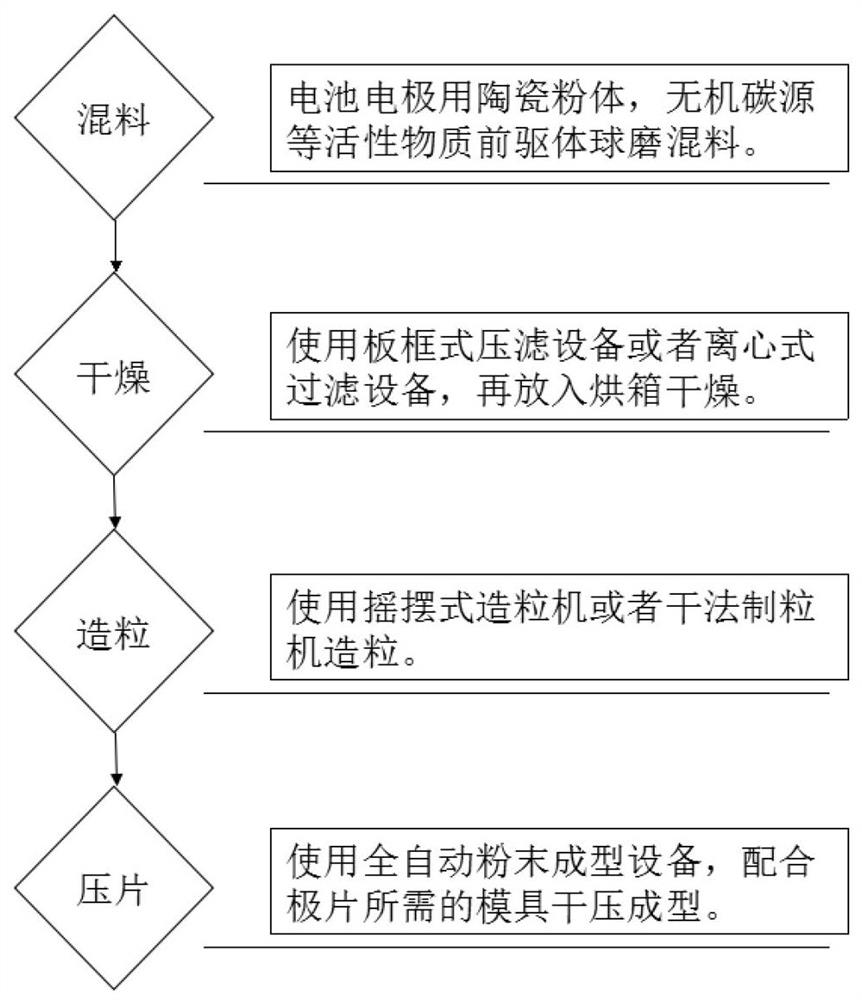

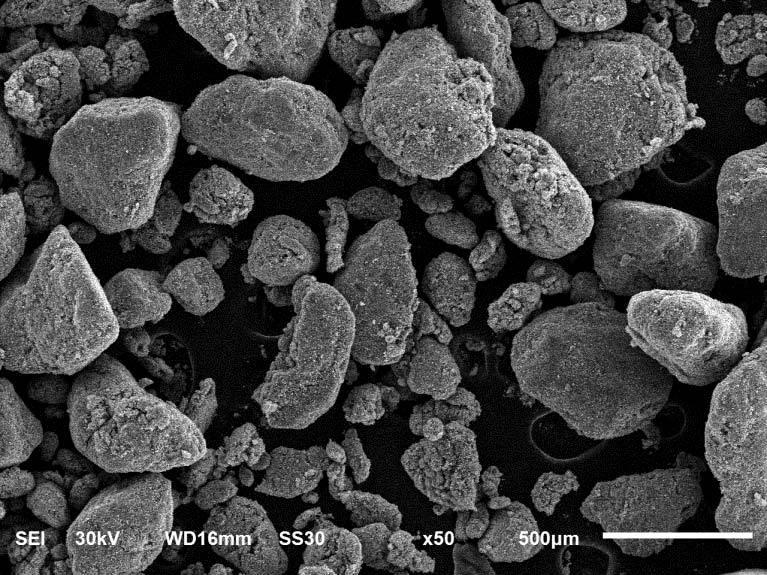

[0045] 60g of positive electrode ceramic powder λ-MnO 2 , Inorganic carbon source 10g carbon black, 15g activated carbon, 10g natural graphite powder as raw material, use deionized water as solvent, control the solid content of powder to be 30wt.%, use zirconia as ball milling beads, material-ball ratio 1: 5. The high speed of the coarse mill is 120 rpm / min for 2 hours to obtain a uniform slurry. Continue to add 5wt.% PTFE binder (different amounts of binder added have different effects on pores, see Table 1), further ball mill at 300 rpm for 5 hours, and pour out the slurry. Filter the obtained slurry with plate-and-frame filter press equipment to obtain a filter cake, and further oven-dry the obtained filter cake, set the temperature at 110°C, and place it for 12 hours to obtain a dry block material, and dry the obtained The material is mechanically granulated, and sieved by vibration with a 3mm mesh to obtain a granular powder with uniform particle size, which is convenien...

Embodiment 2

[0052] 70g of positive electrode ceramic powder LiMn 2 o 4 , Inorganic carbon source 5g carbon black, 5g activated carbon, 10g artificial graphite powder is raw material, uses deionized water as solvent, the solid content of control powder is 30wt.%, uses zirconia as ball milling beads, material-ball ratio 1: 6. Coarse mill high-speed 200 rpm / min ball mill for 4 hours to obtain uniform slurry. Continue to add 10wt.% PTFE binder, further ball mill at 250 rpm for 3 hours, and pour out the slurry. Filter the obtained slurry with plate-and-frame filter press equipment to obtain a filter cake, and further oven-dry the obtained filter cake, set the temperature at 110°C, and place it for 12 hours to obtain a dry block material, and dry the obtained The material is granulated by a swinging granulator, vibrating and sieved with a 1mm mesh to obtain a granular powder with uniform particle size, which is convenient for further electrode sheet forming, and the obtained granular powder i...

Embodiment 3

[0055] 60g negative electrode ceramic powder NaTi 2 (PO4) 3 , 10g of carbon black as an inorganic carbon source, 15g of natural graphite powder as raw materials, using deionized water as a solvent, controlling the solid content of the powder to 60wt.%, using zirconia as ball milling beads, the ratio of material to ball is 1:3, coarse grinding Machine high speed 100 rpm / min ball mill for 5h to obtain uniform slurry. Continue to add 15wt.% PTFE binder, further ball mill at 300 rpm for 2 hours, and pour out the slurry. Filter the obtained slurry with plate-and-frame filter press equipment to obtain a filter cake, and further oven-dry the obtained filter cake, set the temperature at 110°C, and place it for 12 hours to obtain a dry block material, and dry the obtained The material is mechanically granulated, and sieved by vibration with a 2mm mesh to obtain a granular powder with uniform particle size, which is convenient for further electrode sheet forming. The obtained granular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com