Method of preparing layered alpha-titanium phosphate

A titanium phosphate and layered technology, which is applied in the field of preparation of layered α-titanium phosphate, can solve the problems of potential safety hazards for operators, high requirements for corrosion resistance of equipment, and low crystallinity of products, and achieve low production costs and high equipment efficiency. The effect of low requirements and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, the preparation of layered α-titanium phosphate

[0016] Slowly add 8.5g of tetrabutyl titanate dropwise into 50mL of deionized water to make it fully hydrolyzed, filter and wash the hydrolyzed precipitate 3 times, then add 9.8g of 85% H 3 PO 4 solution and 10mL deionized water, at this time the H in the mixture 3 PO 4 The concentration of the mixture was 5.5mol / L, and then the mixture was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, placed in an incubator, reacted at 180°C for 16 hours, cooled to room temperature, and centrifuged with deionized water Wash until the pH value is 3.8, and finally dry the product at 50°C to obtain layered α-titanium phosphate.

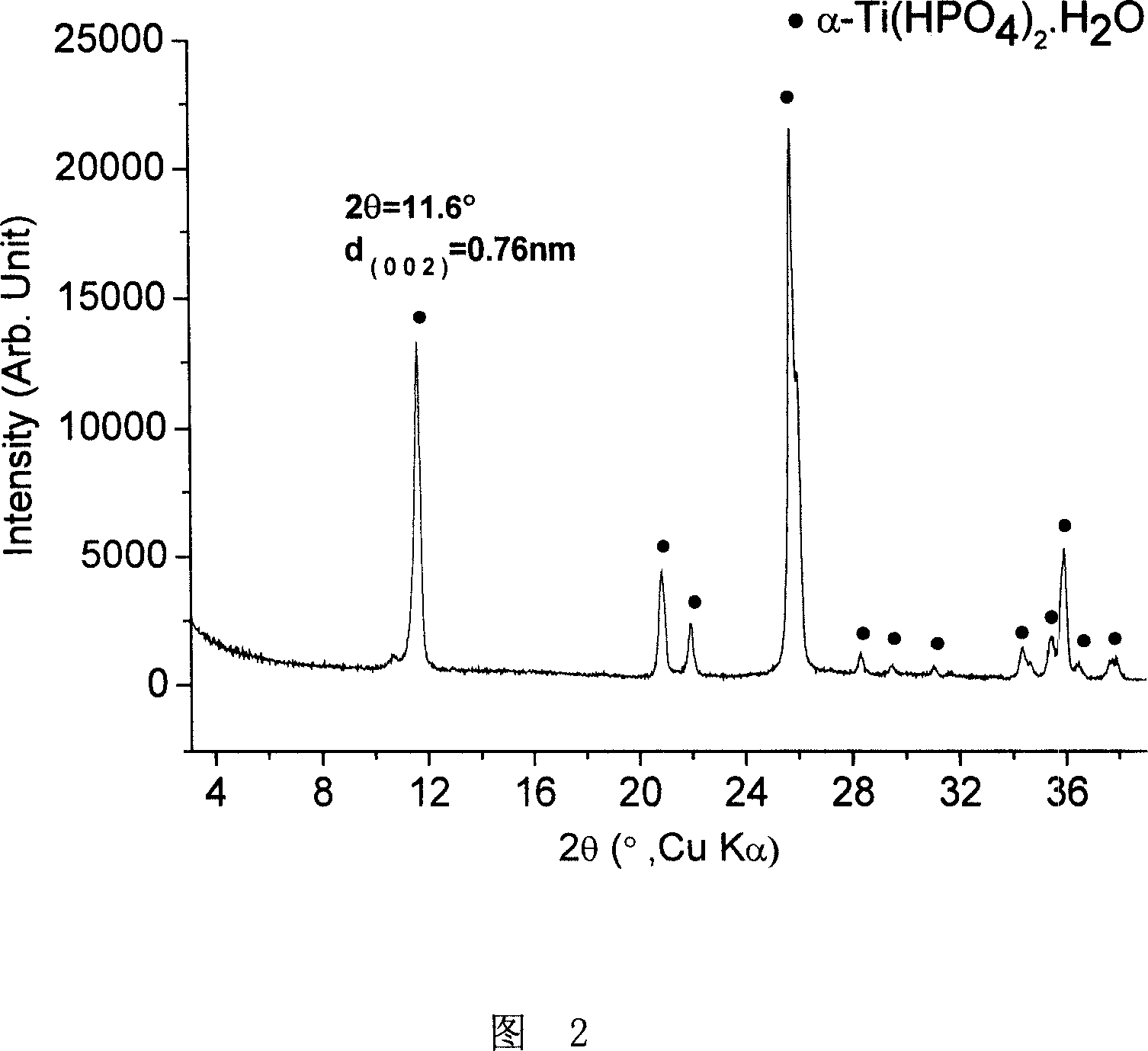

[0017] Sampling, scanning electron microscope (SEM) and X-ray diffraction (XRD) analysis are carried out to the layered α-titanium phosphate prepared by the above-mentioned method, scanning electron microscope observation result is as shown in Figure 1 (figure A is the ...

Embodiment 2

[0018] Embodiment 2, preparation of layered α-titanium phosphate

[0019] Slowly add 7.11 g of tetraisopropyl titanate dropwise into 40 mL of deionized water to make it fully hydrolyzed, filter and wash the hydrolyzed precipitate 5 times, then add 31.16 g of 85% H 3 PO 4 solution and 10mL deionized water, at this time the H in the mixture 3 PO 4 The molar concentration is 10mol / L. Transfer the mixture to a polytetrafluoroethylene-lined stainless steel autoclave, put it in a thermostat, react at 150°C for 24 hours, cool to room temperature, and wash with deionized water until the pH value is 7, and finally the product is dried at 60° C. to obtain layered α-titanium phosphate.

[0020] Sampling was carried out to the layered α-titanium phosphate prepared by the above method for scanning electron microscopy and X-ray diffraction analysis. The test results showed that the above method had obtained a product with good crystallinity, regular and uniform shape, uniform and fine pa...

Embodiment 3

[0021] Embodiment 3, preparation of layered α-titanium phosphate

[0022] Slowly add 5.70 g of ethyl titanate dropwise into 30 mL of deionized water to fully hydrolyze it, filter and wash the hydrolyzed precipitate 4 times, then add 14.3 g of 85% H 3 PO 4 solution and 10mL deionized water, at this time the H in the mixture 3 PO 4 The molar concentration is 7mol / L. Transfer the mixture to a polytetrafluoroethylene-lined stainless steel autoclave, put it in a constant temperature box, react at 200°C for 4 hours, cool to room temperature, and wash with deionized water until the pH value is 6, and finally the product is dried at 70° C. to obtain layered α-titanium phosphate.

[0023] Sampling was carried out to the layered α-titanium phosphate prepared by the above method for scanning electron microscopy and X-ray diffraction analysis. The test results showed that the above method had obtained a product with good crystallinity, regular and uniform shape, uniform and fine partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com