Titanium phosphate lithium material used for cathode of lithium ion battery and preparation method thereof

A lithium ion battery, lithium titanium phosphate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of poor electrochemical performance of materials, low electrical conductivity of materials, serious polarization phenomenon, etc., and it is easy to achieve carbon content. Control, improve conductivity, good reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

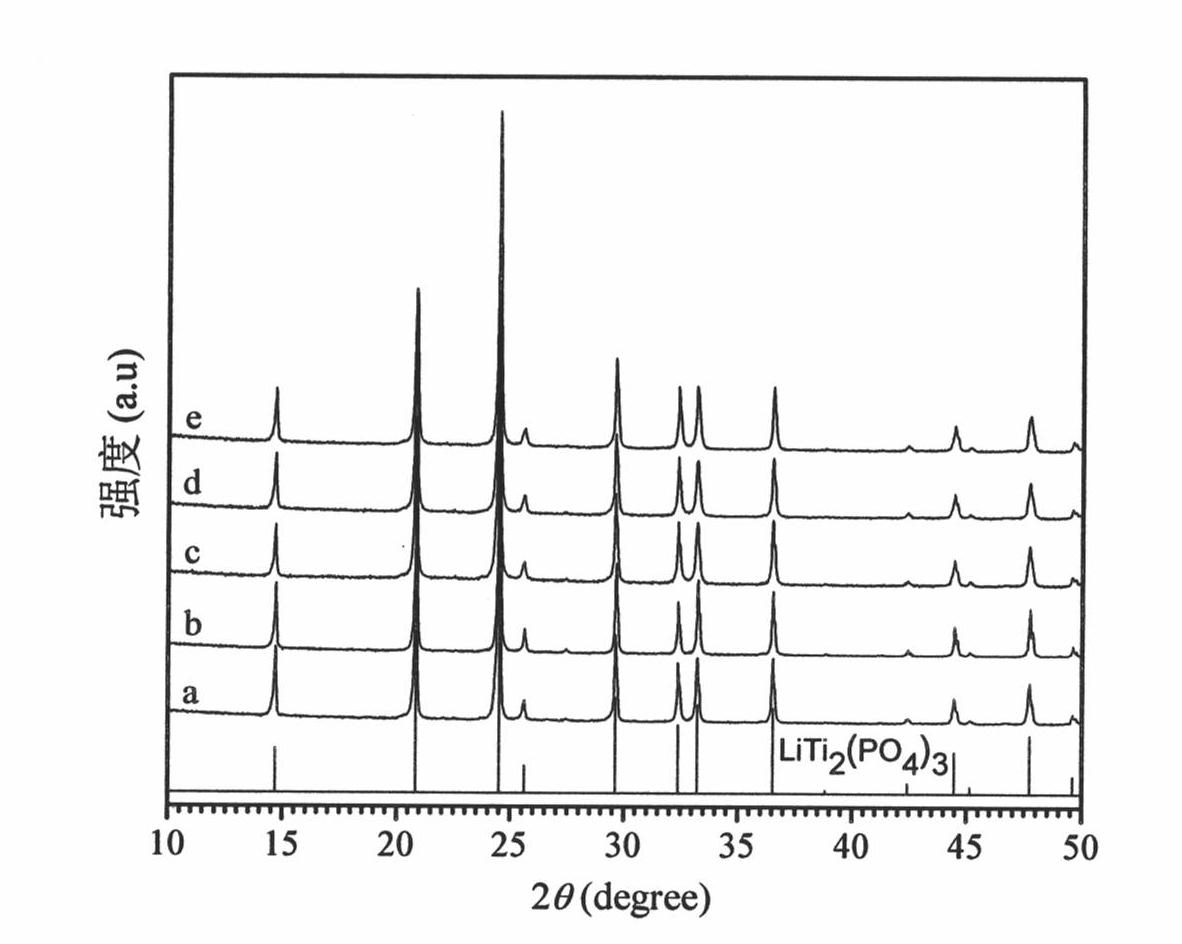

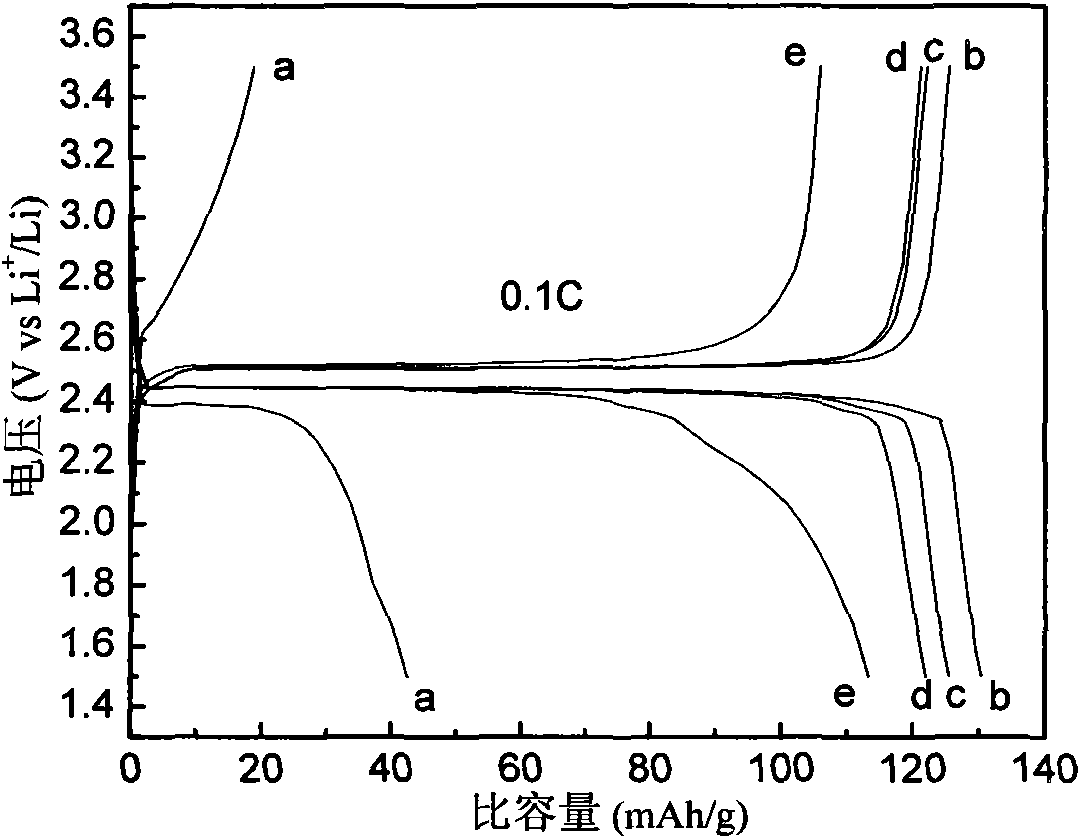

[0026] LiH 2 PO 4 、TiO 2 and NH 4 h 2 PO 4 Weigh the mixed material according to the stoichiometric ratio of Li:Ti:P=1:2:3, use absolute ethanol as the dispersant, mix it according to the mass ratio of ball to material 5:1, and ball mill it on a planetary ball mill at a speed of 300r / min Mix well for 12 hours. After the mixture was stirred and dried at 80°C, the temperature was raised to 950°C in a box furnace at a rate of 5°C / min and roasted at a constant temperature for 12 hours, and then slowly cooled to room temperature in the furnace to obtain white LiTi 2 (PO 4 ) 3 Particles, whose XRD patterns are shown in figure 1Shown in the curve a.

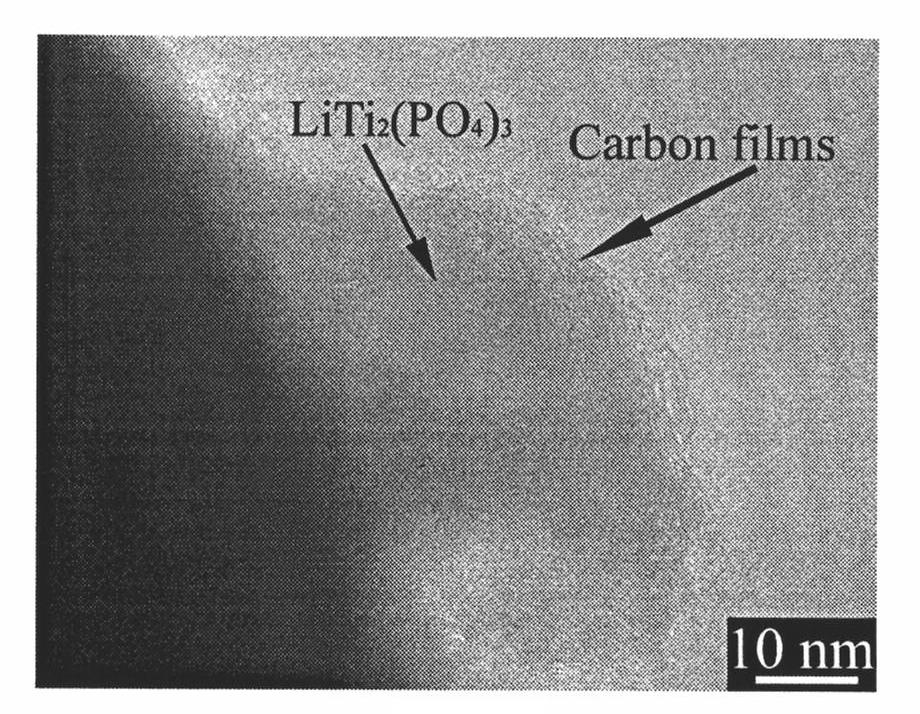

[0027] The synthesized pure LiTi 2 (PO 4 ) 3 Weigh and mix with an appropriate amount of glucose (by mass ratio 1: 0.1), and ball mill at a speed of 300r / min for 12 hours on a planetary ball mill in N 2 Under protection, heat up at 5°C / min to 700°C and roast at constant temperature for 6 hours, then slowly cool to room temp...

Embodiment 2

[0031] Will Li 2 CO 3 、TiO 2 and NH 4 h 2 PO 4 Weigh the mixed material according to the stoichiometric ratio of Li:Ti:P=1:2:3, use absolute ethanol as the dispersant, mix it according to the mass ratio of ball to material 5:1, and ball mill it on a planetary ball mill at a speed of 300r / min Mix well for 12 hours. After the mixture was stirred and dried at 80°C, the temperature was raised to 950°C in a box furnace at a rate of 5°C / min and roasted at a constant temperature for 16 hours, and then slowly cooled to room temperature in the furnace to obtain white LiTi 2 (PO 4 ) 3 particles. The synthesized pure LiTi 2 (PO 4 ) 3 Weigh and mix with an appropriate amount of glucose (by mass ratio 1: 0.1), and ball mill at a speed of 300r / min for 12 hours on a planetary ball mill in N 2 Under protection, heat up at 5°C / min to 700°C and roast at constant temperature for 6 hours, then slowly cool to room temperature in the furnace to obtain LiTi 2 (PO 4 ) 3 / C target produ...

Embodiment 3

[0033] LiOH, TiO 2 and NH 4 h 2 PO 4 Weigh the mixed material according to the stoichiometric ratio of Li:Ti:P=1:2:3, use absolute ethanol as the dispersant, mix it according to the mass ratio of ball to material 5:1, and ball mill it on a planetary ball mill at a speed of 300r / min Mix well for 12 hours. After the mixture was stirred and dried at 80°C, it was heated in a box furnace at a rate of 5°C / min to 1000°C and roasted at a constant temperature for 12 hours, and then slowly cooled to room temperature in the furnace to obtain white LiTi 2 (PO 4 ) 3 particles. The synthesized pure LiTi 2 (PO 4 ) 3 Weigh and mix with an appropriate amount of starch (by mass ratio 1: 0.1), and ball mill at a speed of 300r / min for 12 hours on a planetary ball mill in N 2 Under protection, heat up at 5°C / min to 600°C and roast at a constant temperature for 6 hours, then slowly cool to room temperature in the furnace to obtain LiTi 2 (PO 4 ) 3 / C target product, its XRD pattern see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com