Preparation method of titanium phosphate/germanium-aluminum-lithium solid electrolyte

A technology of solid electrolyte and titanium phosphate, applied in the direction of solid electrolyte, non-aqueous electrolyte, chemical instruments and methods, etc., can solve the problems of unfavorable industrial production, materials are easy to contain impurities, high heat treatment temperature, etc., and achieve convenient industrial production, ion conductivity The effect of high efficiency and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

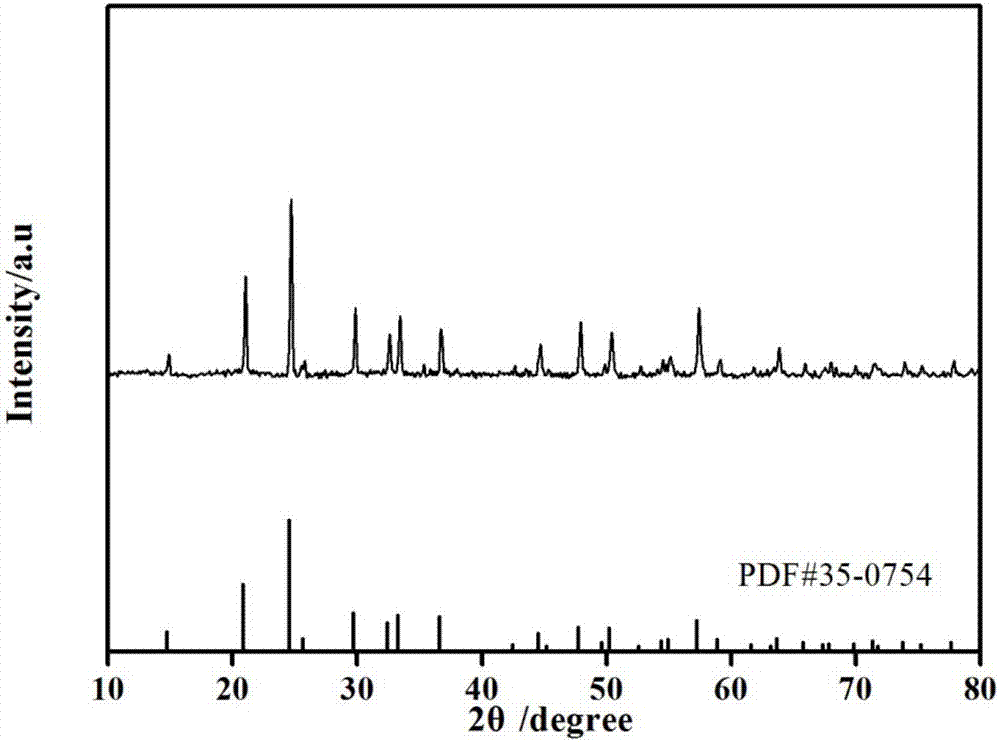

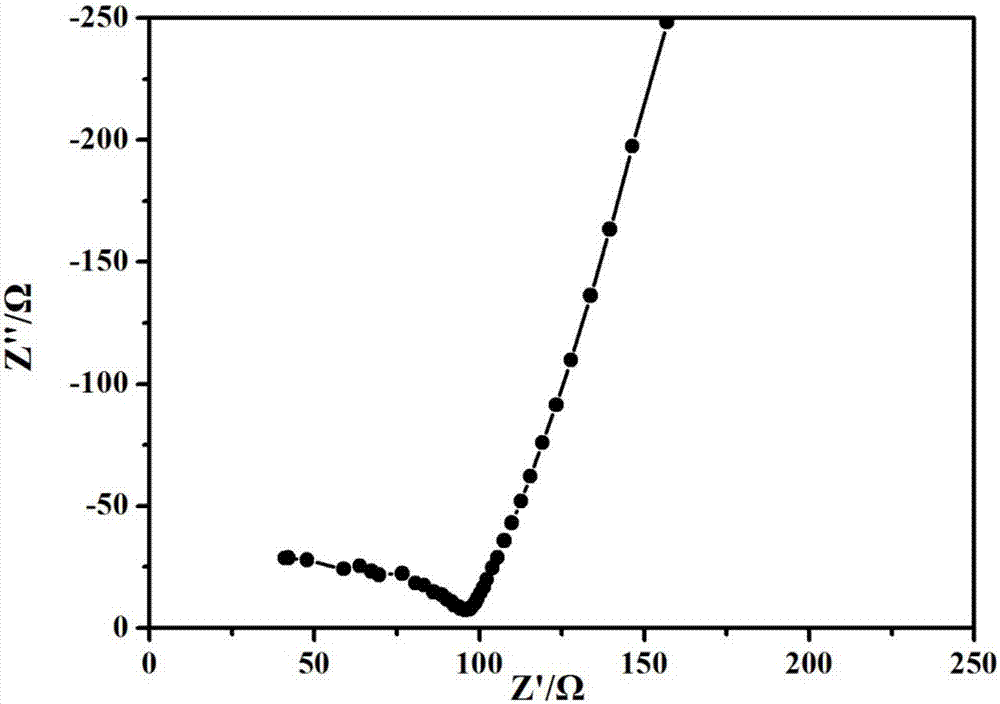

[0033] A kind of Li 1+x al x m 2-x (PO 4 ) 3 The preparation method of the solid electrolyte adopts the molten salt assisted solid phase method, and utilizes the molten salt to become a molten state to provide a liquid environment, which is conducive to the full mixing of the precursors and obtaining Li 1+x al x m 2-x (PO 4 ) 3 x=0-0.7, M=Ti, Ge type solid electrolyte material.

[0034] Specific preparation process:

[0035] Lithium nitrate (LiNO 3 ), aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), ammonium dihydrogen phosphate (NH 4 h 2 PO4 ) and molten salt urea (CH 4 N 2 O) Prepare according to the mole fraction ratio of 1.3:0.15:1.7:3:3.

[0036] Put the above materials in a corundum crucible and mix them evenly. Put the powder mixture into a muffle furnace, keep the temperature at 150°C for 3h, then raise the temperature to 700°C for 4h. The obtained powder was put into a high-energy ball mill jar, and ball milled at 150r / min for 2h. The powder ...

Embodiment 2

[0038] A kind of Li 1+x Al x m 2-x (PO 4 ) 3 The preparation method of the solid electrolyte adopts the molten salt assisted solid phase method, and utilizes the molten salt to become a molten state to provide a liquid environment, which is conducive to the full mixing of the precursors and obtaining Li 1+x Al x m 2-x (PO 4 ) 3 x=0-0.7, M=Ti, Ge type solid electrolyte material.

[0039] Specific preparation process:

[0040] Lithium nitrate (LiNO 3 ), aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and molten salt urea (CH 4 N 2 O) Prepare according to the mole fraction ratio of 1.3:0.15:1.7:3:6, and other process parameters are the same as in Example 1.

Embodiment 3

[0042] A kind of Li 1+x Al x m 2-x (PO 4 ) 3 The preparation method of the solid electrolyte adopts the molten salt assisted solid phase method, and utilizes the molten salt to become a molten state to provide a liquid environment, which is conducive to the full mixing of the precursors and obtaining Li 1+x al x m 2-x (PO 4 ) 3 x=0-0.7, M=Ti, Ge type solid electrolyte material.

[0043] Specific preparation process:

[0044] Lithium nitrate (LiNO 3 ), aluminum oxide (Al 2 o 3 ), titanium dioxide (TiO 2 ), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and molten salt urea (CH 4 N 2 O) Prepare according to the mole fraction ratio of 1.3:0.15:1.7:3:9, and other process parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com