Synthetic method of mesopore metallic oxide, mixed metallic oxide and metallic phosphate serial microballons using mesopore carbon microballons as form

A metal phosphate, mixed metal technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of difficult to achieve morphology control, poor controllability, limitations, etc. The effect of application prospect, large room for modulation, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

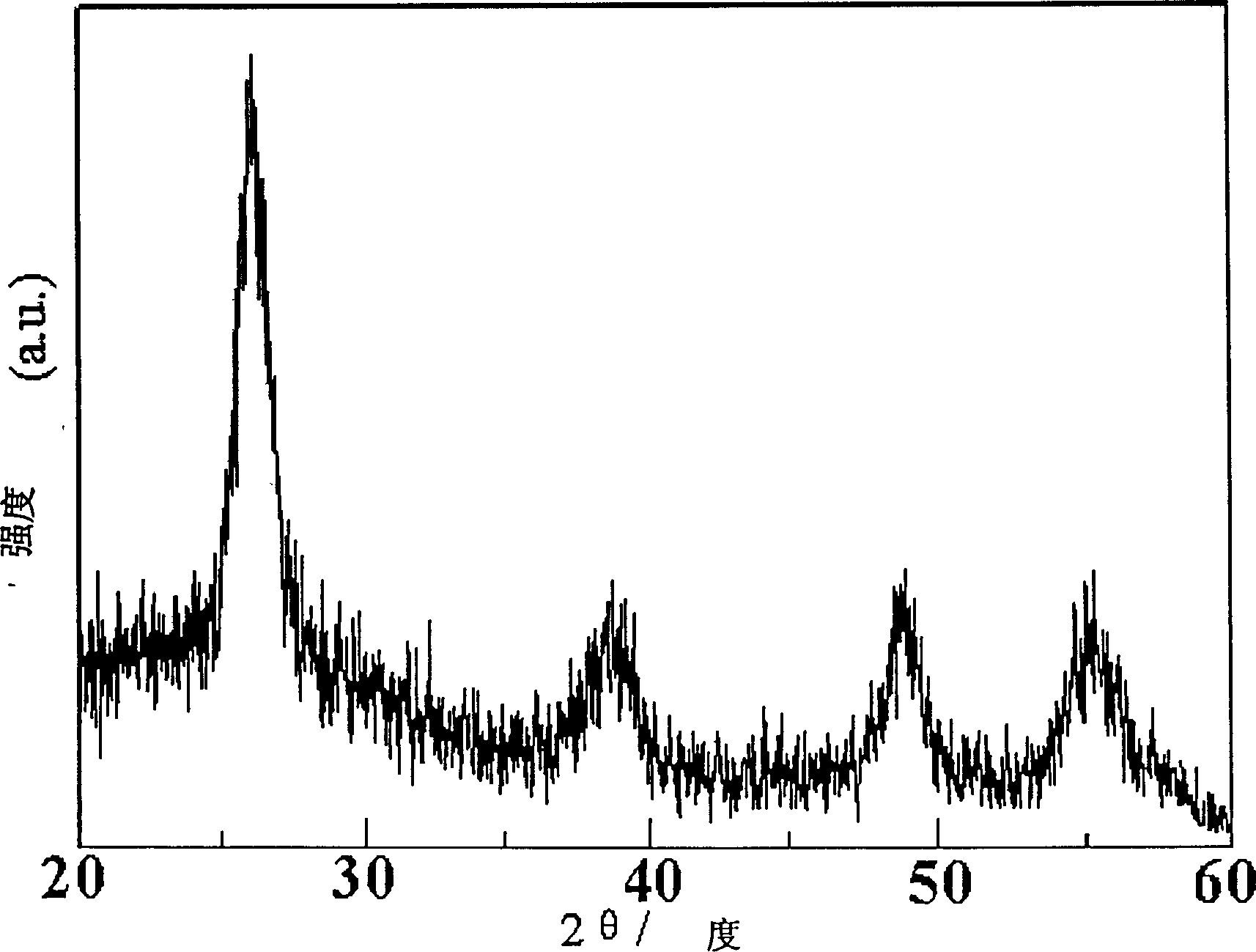

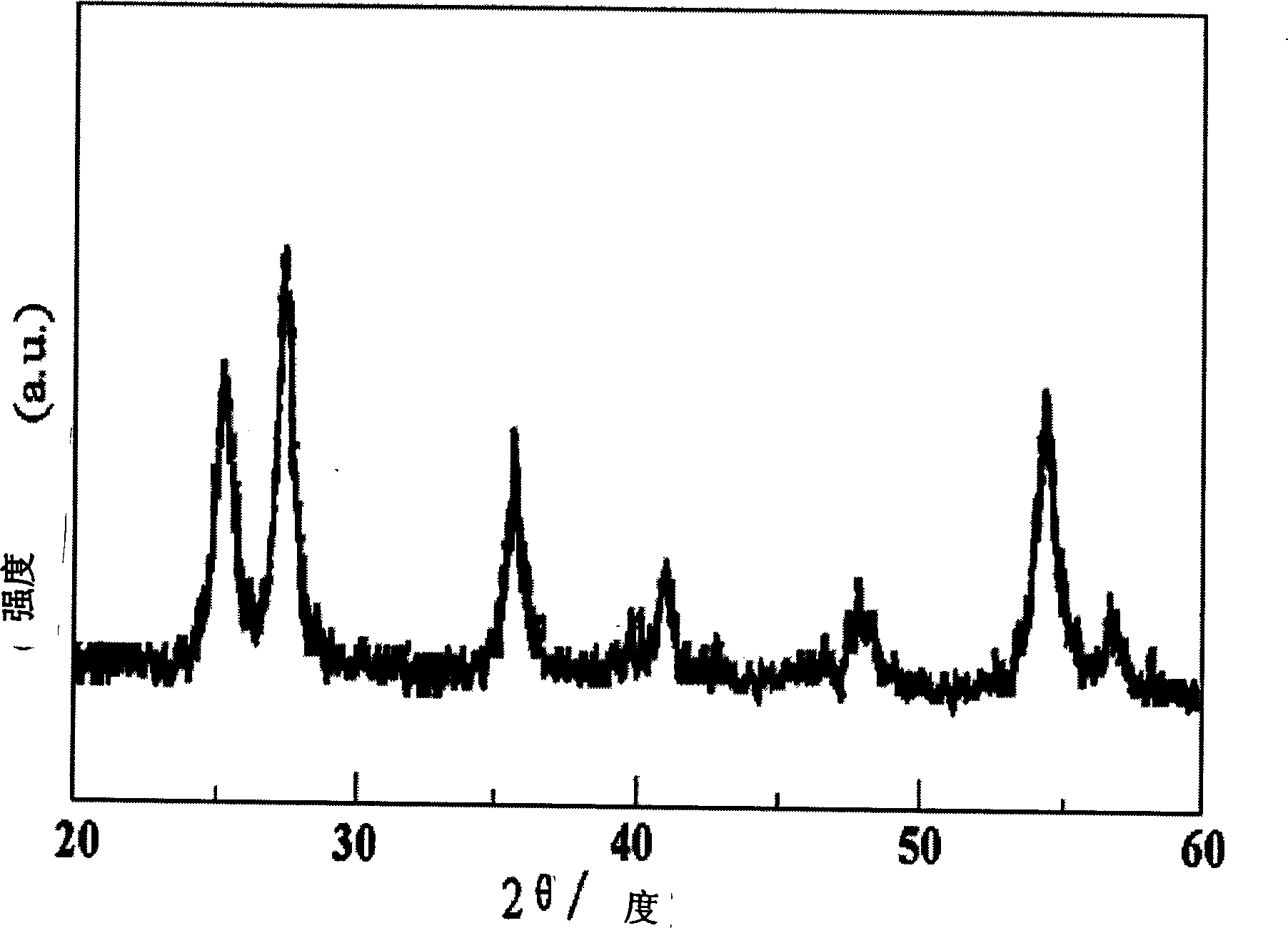

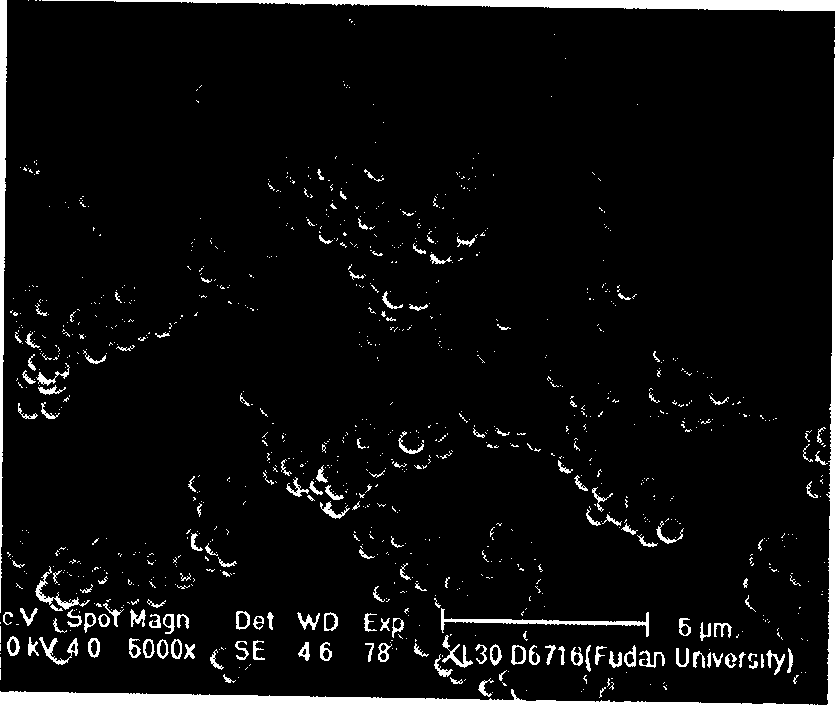

[0030] A dilute sulfuric acid solution of sucrose with a concentration of 1 wt% was added to the mesoporous silica microspheres. Stir at room temperature for 24 h, dry after centrifugation. Carbonize at 900°C for 5 hours in a nitrogen atmosphere to obtain carbon-silicon composite microspheres, which are soaked in 40 wt% hydrofluoric acid, washed sequentially with a large amount of water and isopropanol, and dried at 100°C. Mesoporous carbon microspheres were obtained.

example 2

[0032] Treat according to the method of Example 1, the concentration of the added sucrose dilute sulfuric acid solution is 50wt%, and obtain mesoporous carbon microspheres.

example 3

[0034] According to the method of Example 1, the carbonization temperature is 200° C. and the time is 8 hours, and the morphology of the obtained mesoporous carbon microspheres changes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com